Data cable reel device for test

A data cable and testing technology, which is applied in the field of data cable reeling device for testing, can solve the problems of wiring, wiring difficulty, etc., and achieve the effects of simple structure, easy processing, and convenient wiring and wiring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

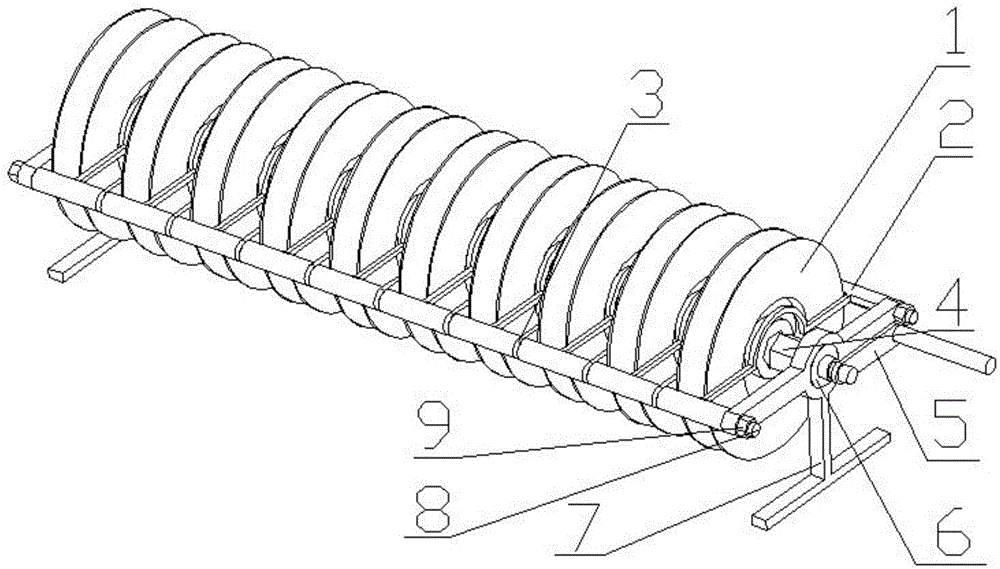

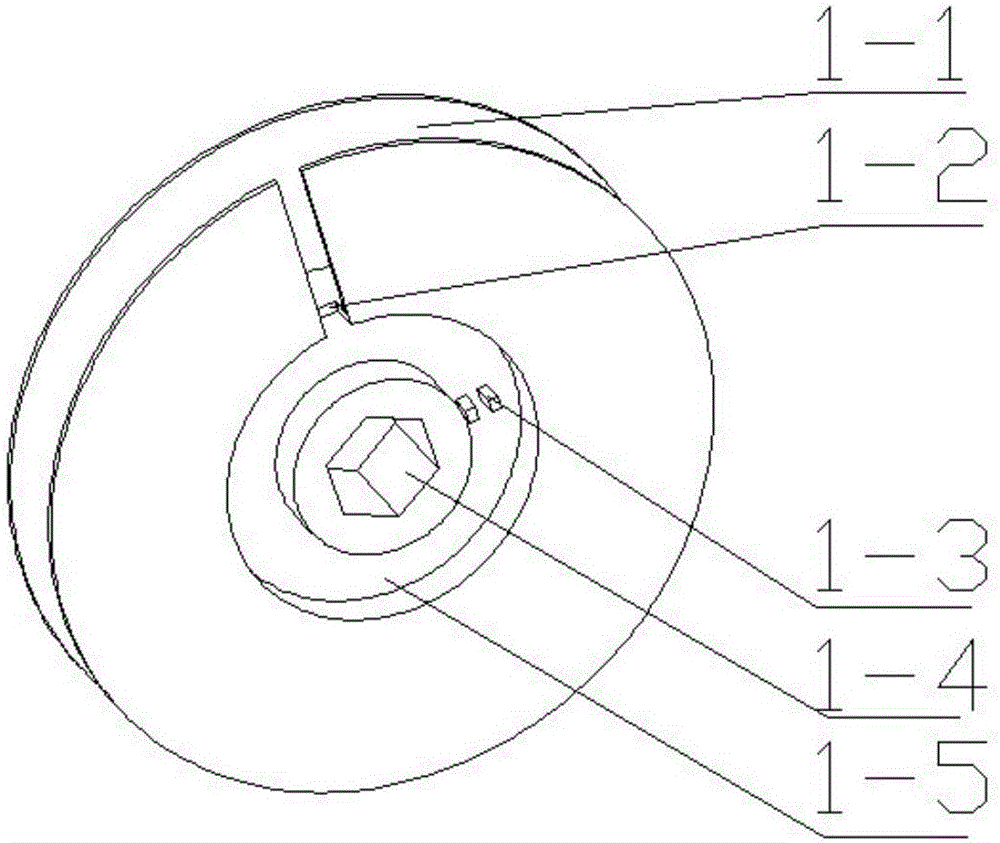

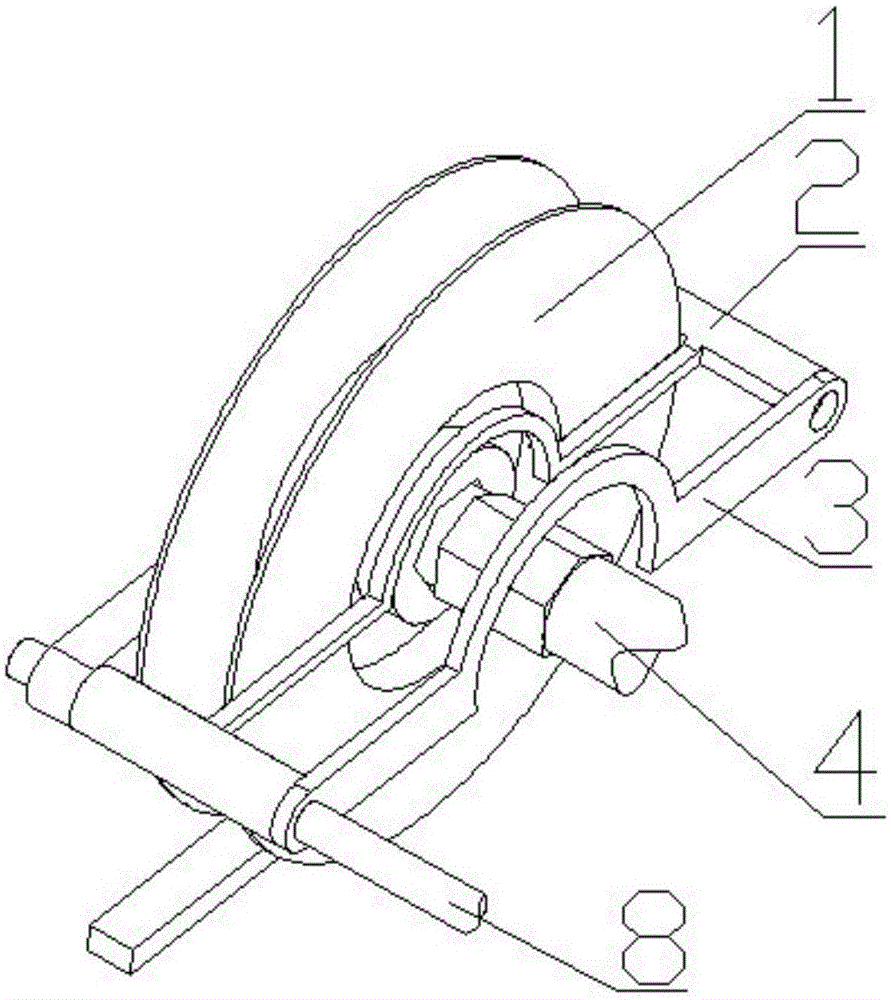

[0010] Specific implementation mode 1. Combination Figure 1 to Figure 3 Describe this embodiment, a data cable reel device for testing, including: a plurality of reels 1, a plurality of positioning buckles 2, a plurality of partitions 3, a drive shaft 4, a handle 5, a bearing 6, a main bracket 7, Parts such as sub-bracket 8 and mounting nut 9. The plurality of wire reels 1 are respectively installed on the corresponding shaft sections on the drive shaft 4 through the installation ports 1-4, each wire reel 1 has an outer wire reel 1-1 and an inner wire reel 1-5, and the inner wire reel 1-5 has an outer wire reel 1-5. There are buckles 1-3, which are used to fix the data cables on the inner cable tray 1-5. During use, most of the data cables are wound on the outer cable tray 1-1, and the data cables about 50-100cm pass through the threading port 1- 2 Wrap around the inner cable reel 1-5, and fix it to the inner cable reel through buckles 1-3. The partition plate 3 is used to ...

specific Embodiment approach 2

[0012] Embodiment 2. This embodiment is the method for installing and using the test data cable reeling device described in Embodiment 1. The specific process is:

[0013] 1. Reel about 50-100cm of the end of the data cable connected to the data acquisition device on the inner reel, and reel the rest on the outer reel.

[0014] 2. Put each wire reel on the circular shaft section, pull out a data cable of appropriate length from the outer wire reel according to the test needs, take out the data wire from the inner wire reel, and connect it to the data acquisition terminal;

[0015] 3. After the test is completed, reel each data line and the section connected to the data acquisition end to the inner reel, place each reel on the hexagonal shaft section, turn the handle, and retract the data line;

[0016] 4. During the measurement process, refer to 2 and 3 for the coils that need to be adjusted in length until the final test is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com