Cable-driving rope replacing mechanism

A cable-driven and rope-feeding technology, which is applied in the field of the rope-changing mechanism of the cable-driven wire rope of the astronomical telescope, to avoid damage and improve safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with drawings and embodiments.

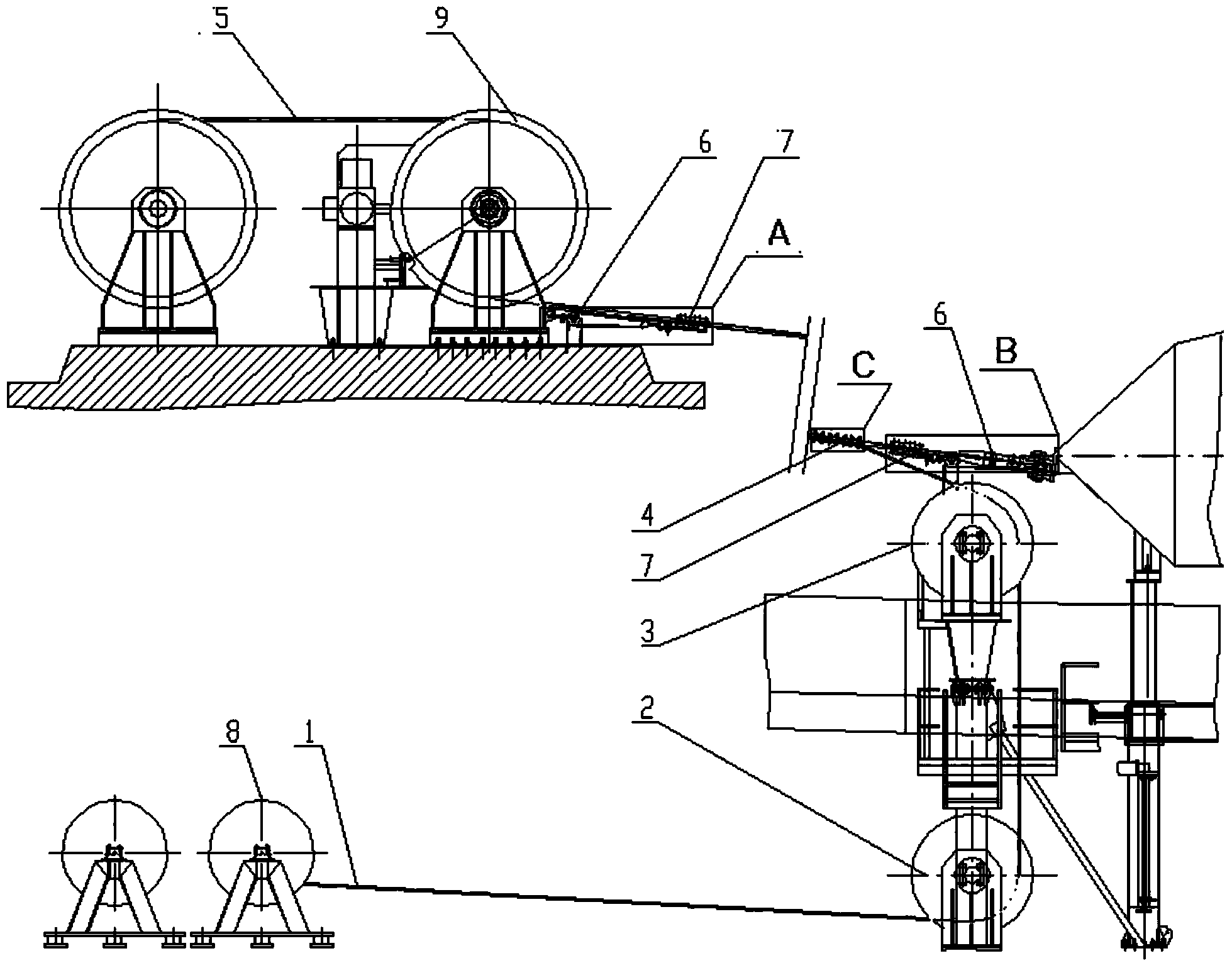

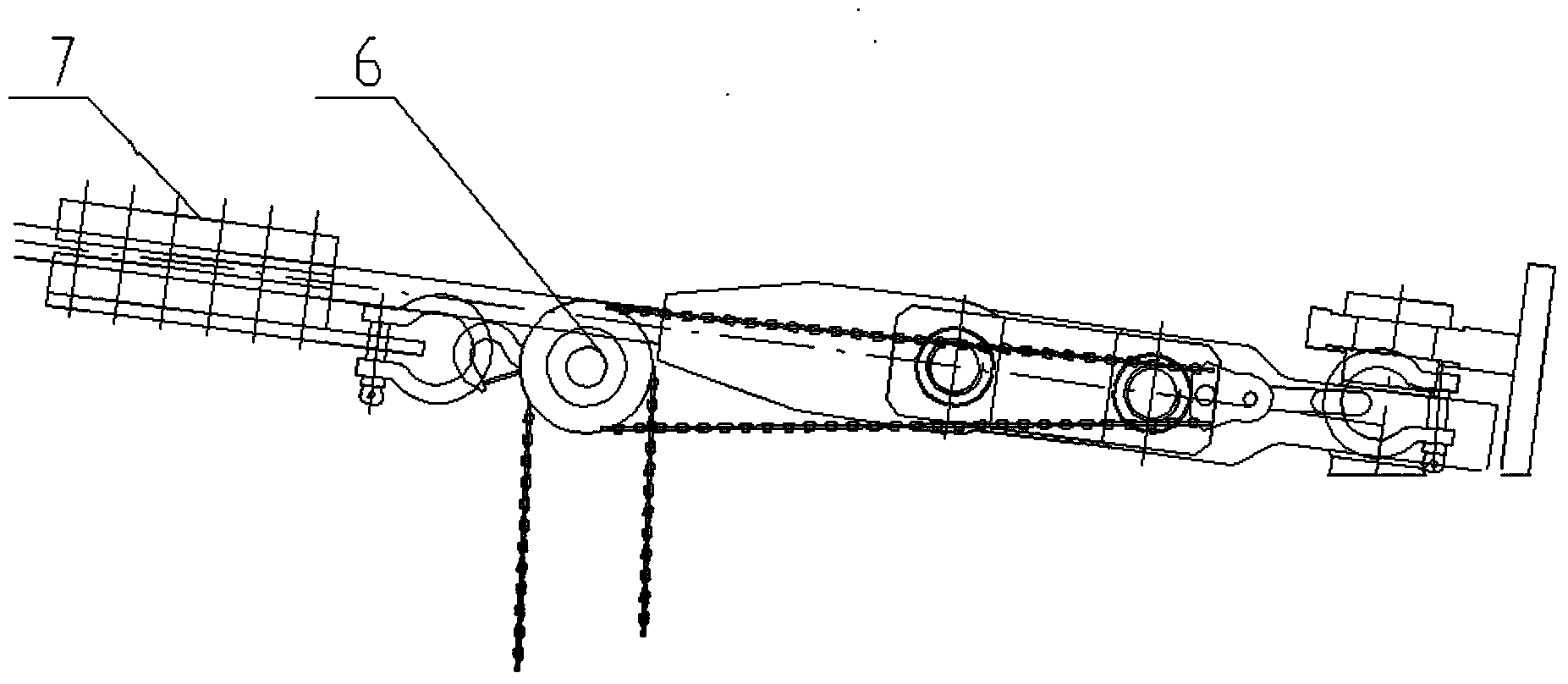

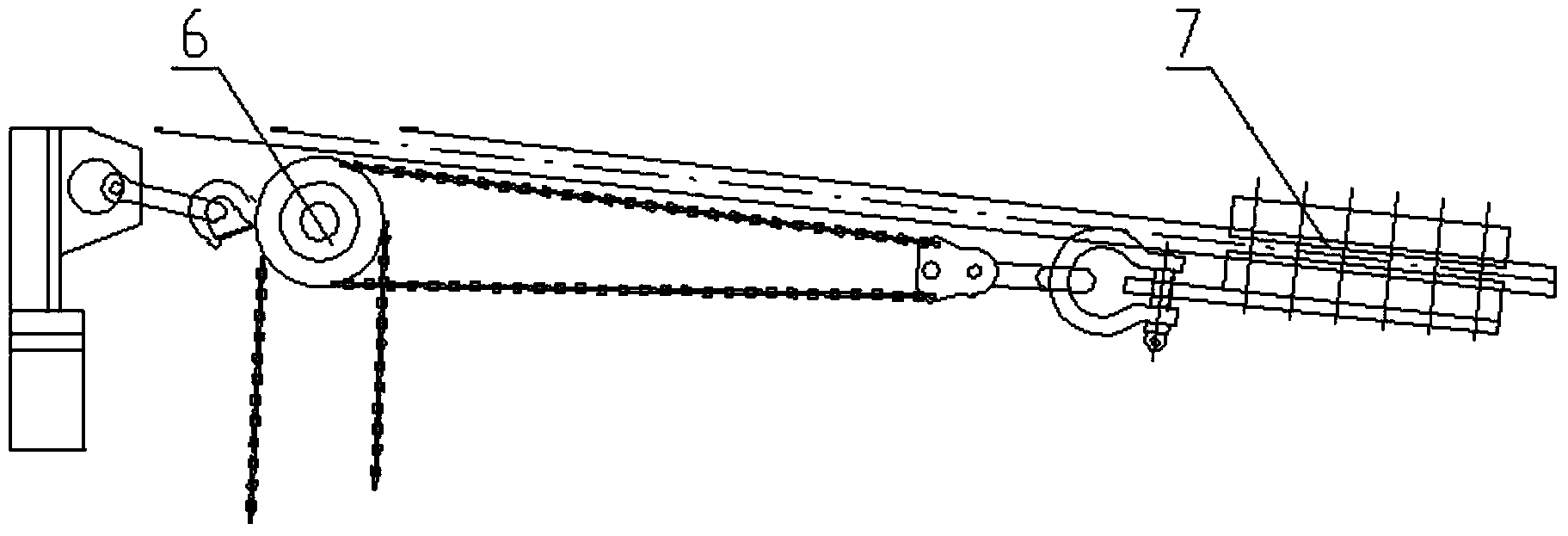

[0027] The embodiment is the signal receiving device of the telescope used in the field of astronomy—the cable changing mechanism of the cable driving the wire rope of the feed cabin. The mechanism is mainly composed of Φ26×50m process steel wire rope Ⅰ1, ground guide pulley 2, maintenance guide pulley 3, U-shaped clip 4, Φ26×650m process steel wire rope Ⅱ5, 10t chain hoist 6, rope splint 7, rope changing mechanism hoist 8, and Cooperate with the hoist 9 of the cable driving mechanism, the hoist 8 of the rope changing mechanism is arranged on the ground below the port entry platform of the cable driving part, the ground guide pulley 2 is arranged in front of the hoist 8 of the rope changing mechanism, and the maintenance guide pulley 3 is arranged on the port entry platform of the cable driving part One end of the process steel wire rope I1 bypasses the maintenance guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com