Environmentally-friendly runway snow melting and deicing agent

An environmentally friendly, deicing agent technology, applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of eutrophication of soil and water sources, and achieve long-lasting effects, high deicing efficiency and ability, and environmentally friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

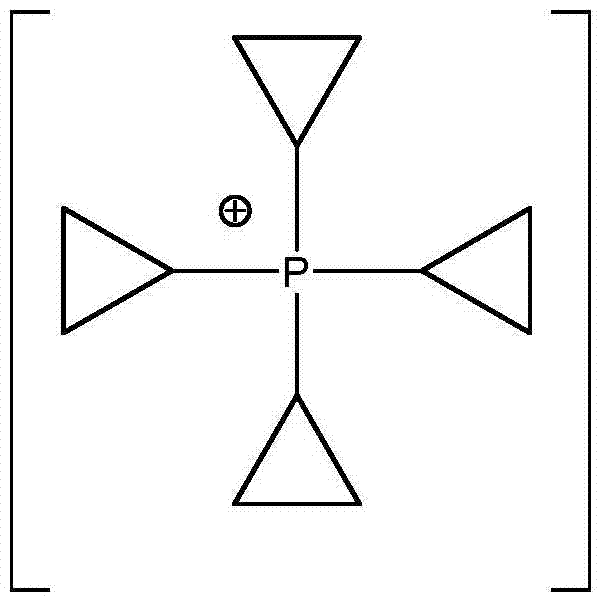

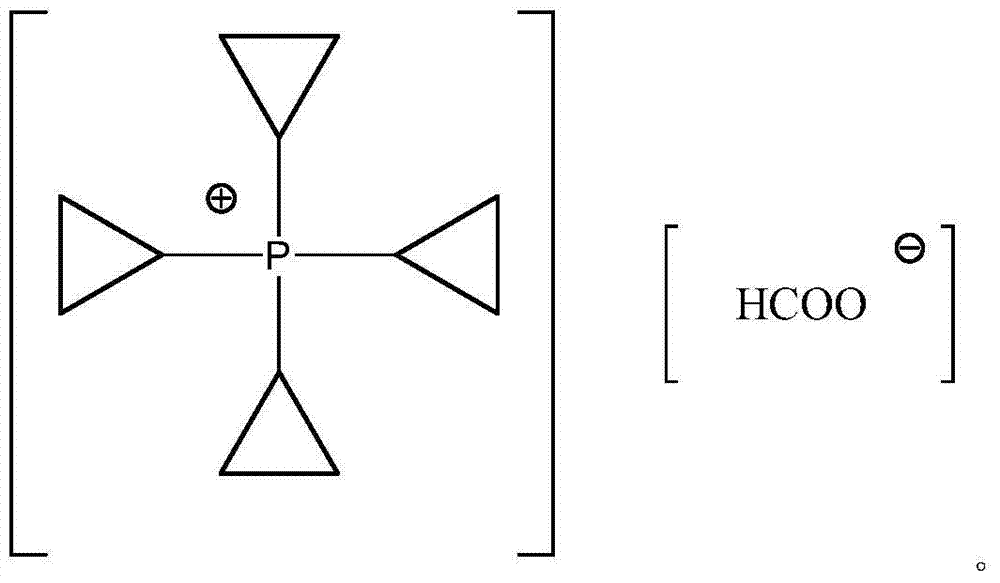

[0027] The formula is: 90 parts by weight of ionic liquid and 10 parts by weight of sodium gluconate are mixed into a snow-melting and deicing agent, wherein the structure of the ionic liquid is:

[0028]

[0029] Take two 150ml ceramic crucibles with the same diameter and height, add 100ml of deionized water, and then place them in a low-temperature constant temperature refrigerator at -10°C ± 1°C to freeze until frozen. Pipette 25ml of the snow-melting and deicing agent of Example 1. Snow-melting de-icing agent and traditional sodium chloride solution (reference solution). Put it into a 50ml beaker, and also place it in a low-temperature constant temperature refrigerator at -10°C ± 1°C for 12 hours before use. Take out the ceramic crucible with ice cubes from the above-mentioned refrigerator, wipe the water on its surface quickly with a cloth, weigh, and the mass is accurate to 0.1g. Pour the snow-melting and deicing agent containing Example 1 into the crucible quickly,...

Embodiment 2

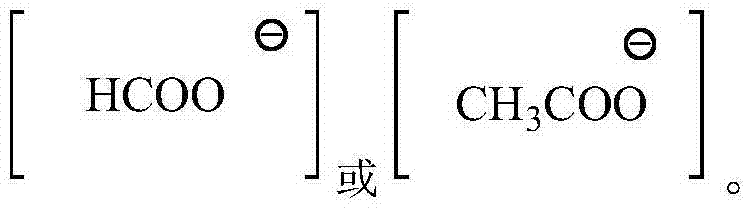

[0031] The formula is: 95 parts by weight of ionic liquid and 5 parts by weight of sodium carbonate are mixed into a snow-melting and deicing agent, wherein the structure of the ionic liquid is:

[0032]

[0033] Take two 150ml ceramic crucibles with the same diameter and height, add 100ml of deionized water, and then place them in a low-temperature constant temperature refrigerator at -10°C ± 1°C to freeze until frozen. Pipette 25ml of the snow-melting and deicing agent of embodiment 2. Snow-melting de-icing agent and traditional sodium chloride solution (reference solution). Put it into a 50ml beaker, and also place it in a low-temperature constant temperature refrigerator at -10°C ± 1°C for 12 hours before use. Take out the ceramic crucible with ice cubes from the above-mentioned refrigerator, wipe the water on its surface quickly with a cloth, weigh, and the mass is accurate to 0.1g. Quickly pour the ionic liquid deicing agent of the present invention into the crucibl...

Embodiment 3~5

[0035] Take a 150ml ceramic crucible with the same diameter and height, add 100ml deionized water, and place it at -10 ℃ ±1 ℃ Freeze in a low temperature freezer until frozen. Then the crucible that has been frozen is at different temperatures, add the snow melting and deicing agent of 50g embodiment 1 or embodiment 2 to do snow melting and deicing experiment, the results are as follows:

[0036]

[0037] It can be seen from the above experimental results that the deicing efficiency of the ionic liquid snow melting and deicing agent is much higher than that of the traditional sodium chloride solution, especially when the temperature is lower.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap