Alkali-resistant polyimide fiber

A polyimide fiber, alkali-resistant technology, applied in the direction of fiber chemical characteristics, single-component synthetic polymer rayon, textiles and papermaking, etc., can solve problems such as weak performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

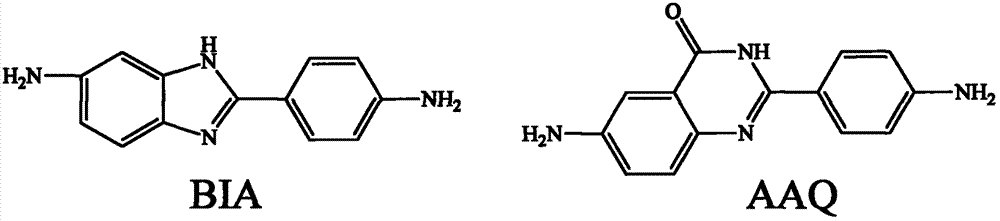

[0028] A: Using pyromellitic dianhydride and 4,4'-diaminodiphenyl ether and 2-(4-aminophenyl)-5-aminobenzimidazole to synthesize polyamic acid (PAA) with a solid content of 10wt% Solution, the molar content of 2-(4-aminophenyl)-5-aminobenzimidazole in diamine is 5%. After filtering and vacuuming to remove air bubbles, the wet spinning process is used to spin and obtain alkali-resistant polyimide fiber;

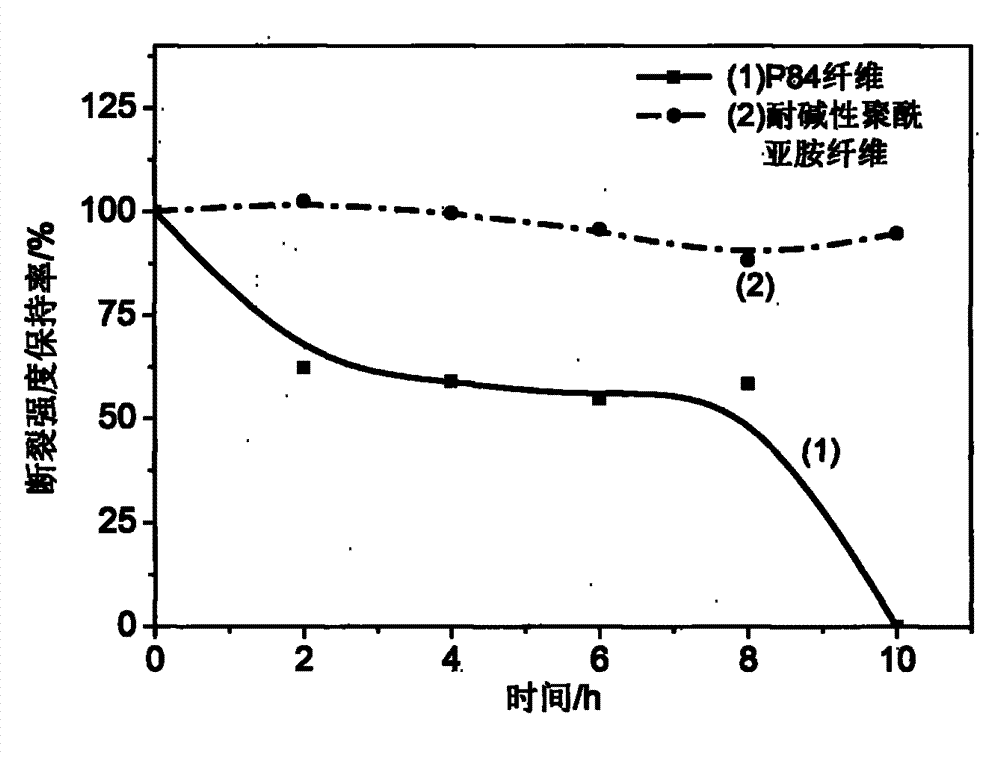

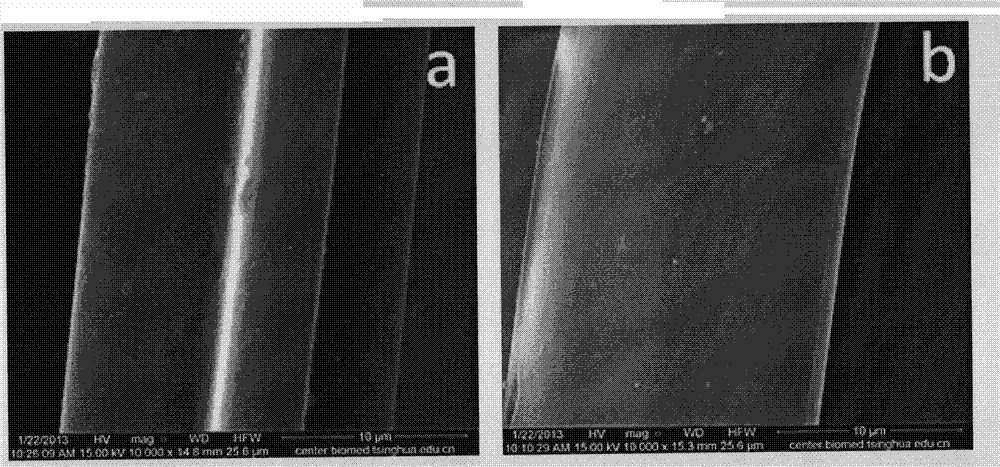

[0029] B: The obtained alkali-resistant polyimide fiber and the commercialized P84 fiber were soaked in a 5wt% NaOH solution at room temperature for 10 hours, and then the two fibers were cleaned, dried, and the mechanical properties of the fibers were tested. The obtained The breaking strength retention rate of the fiber is as figure 2 shown. The surface SEM photos of alkali-resistant polyimide fiber and P84 fiber etched in 5wt% NaOH solution for 10 hours are as follows: image 3 shown.

[0030] C: The obtained alkali-resistant polyimide fiber and the commercialized P84 ...

Embodiment 2

[0035] A: Use pyromellitic dianhydride, 4,4'-diaminodiphenyl ether and 2-(4-aminophenyl)-6-amino-4(3H)-quinazolinone to synthesize a solid content of 15wt % polyamic acid (PAA) solution, the molar content of 2-(4-aminophenyl)-6-amino-4(3H)-quinazolinone in diamine is 10%, filter and vacuumize to remove bubbles Finally, the wet spinning process is used to spin and obtain alkali-resistant polyimide fibers;

[0036] B: The obtained alkali-resistant polyimide fiber and the commercialized P84 fiber were soaked in a 5wt% NaOH solution at room temperature for 10 hours, and then the two fibers were cleaned, dried, and the mechanical properties of the fibers were tested. The obtained Fiber breaking strength retention.

[0037] C: The obtained alkali-resistant polyimide fiber and the commercialized P84 fiber add 20wt% H at room temperature 2 SO 4 After soaking in the solution for 120 hours, the two kinds of fibers were washed, dried, and the mechanical properties of the fibers were t...

Embodiment 3

[0042] A: Using 3,3',4,4'-diphenylmethyl ether tetra-acid dianhydride (ODPA) and 4,4'-diaminodiphenyl ether and 2-(4-aminophenyl)-5-aminobenzene And imidazole and 2-(4-aminophenyl)-6-amino-4(3H)-quinazolone synthetic solid content is the polyamic acid (PAA) solution of 20wt%, 2-(4-aminophenyl )-5-aminobenzimidazole and 2-(4-aminophenyl)-6-amino-4(3H)-quinazolinone have a molar content of 8% in diamine respectively, filter and vacuum to remove bubbles Finally, the dry spinning process is used to spin and obtain alkali-resistant polyimide fibers;

[0043] B: The obtained alkali-resistant polyimide fiber and the commercialized P84 fiber were soaked in a 5wt% NaOH solution at room temperature for 10 hours, and then the two fibers were cleaned, dried, and the mechanical properties of the fibers were tested. The obtained Fiber breaking strength retention.

[0044] C: The obtained alkali-resistant polyimide fiber and the commercialized P84 fiber add 20wt% H at room temperature 2 S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com