Waterproof connection belt and its manufacturing method, building and construction method

A manufacturing method and a technology for connecting belts, which are applied in the construction, building structure, processing of building materials, etc., can solve the problems that the waterproof structure cannot reach the design state, the construction quality of the waterproof structure is difficult to control, and the waterproof structure is complicated. The quality of waterproofing works is reduced, the waterproofing quality is controllable, and the waterproofing effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] This embodiment provides a waterproof connecting belt, which is arranged at the deformation joint of the building to play a waterproof role. The waterproof connecting belt includes a base layer of waterproof elastic material, the base layer includes two side wings for overlapping the installation surfaces on both sides of the deformation seam, and a bending structure connected between the two side wings for buffering the deformation amount of the deformation seam. There is an adhesive layer on the back which can be used for sticking and fixing the wings on both sides to the installation surfaces on both sides of the deformation joint. When in use, the bending structure is arranged in the gap between the installation surfaces on both sides of the deformation joint.

[0077] The waterproof connecting belt of this embodiment is made of waterproof elastic material, and the bending structure on the base layer itself has an expansion and contraction allowance. When the deforma...

Embodiment 2

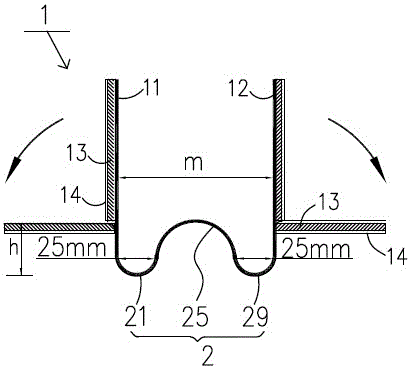

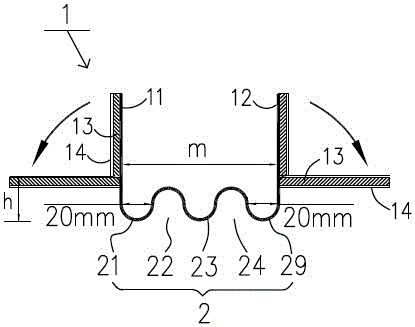

[0080] like Figure 1 to Figure 3 Shown is the second embodiment of the waterproof connecting belt of the present invention, which includes a waterproof elastic material base layer 1, and the base layer 1 includes two side wings 11, 12 overlapped on the installation surfaces on both sides of the deformation seam and connected between the two side wings for use. In the bending structure 2 for buffering the deformation of the seam, an adhesive layer 13 and an isolation layer 14 are arranged on the backsides of the two side wings in order from top to bottom.

[0081] The area of the adhesive layer 13 is equivalent to the area of the corresponding side wings, and can be used for bonding the side wings to the installation surfaces on both sides of the deformation seam. The area of the isolation layer 14 covers at least the adhesive layer 13, so that the isolation layer 14 can fully play the role of protecting the adhesiveness of the adhesive layer 13, and is also convenient f...

Embodiment 3

[0089] This embodiment provides a manufacturing method of a waterproof connecting tape, such as Figure 1 to Figure 3 As shown, the method includes:

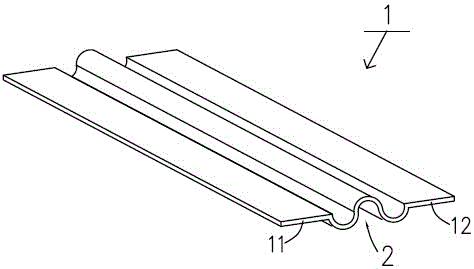

[0090] S1. Make a waterproof elastic material base layer 1 with a bending structure 2 and two side wings 11, 12 (see image 3 ), the length direction of the bending structure 2 extends in the longitudinal direction, and can be stretched or compressed in the transverse direction to buffer the deformation amount of the building deformation joint;

[0091] S2. The backsides of the two wings 11 and 12 are respectively covered with adhesive material to form the adhesive layer 13 .

[0092] In the above step S1, any one of the following steps can be used to fabricate the waterproof elastic material base layer with the bending structure and the two side wings.

[0093] S11. First prepare a waterproof elastic material substrate with a larger size, cut it into several base blocks with a size smaller than the base layer, and then form a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com