Full vacuum horizontal lng submersible pump pool

A submersible pump pool, full vacuum technology, applied in the direction of non-variable capacity pumps, pumps, pump components, etc., can solve the problem of not achieving economic benefits, affecting the operating cost of LNG vehicle filling stations, and the filling efficiency of submersible pumps. problems, to achieve the effect of improving the filling efficiency rate, excellent cold insulation performance, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

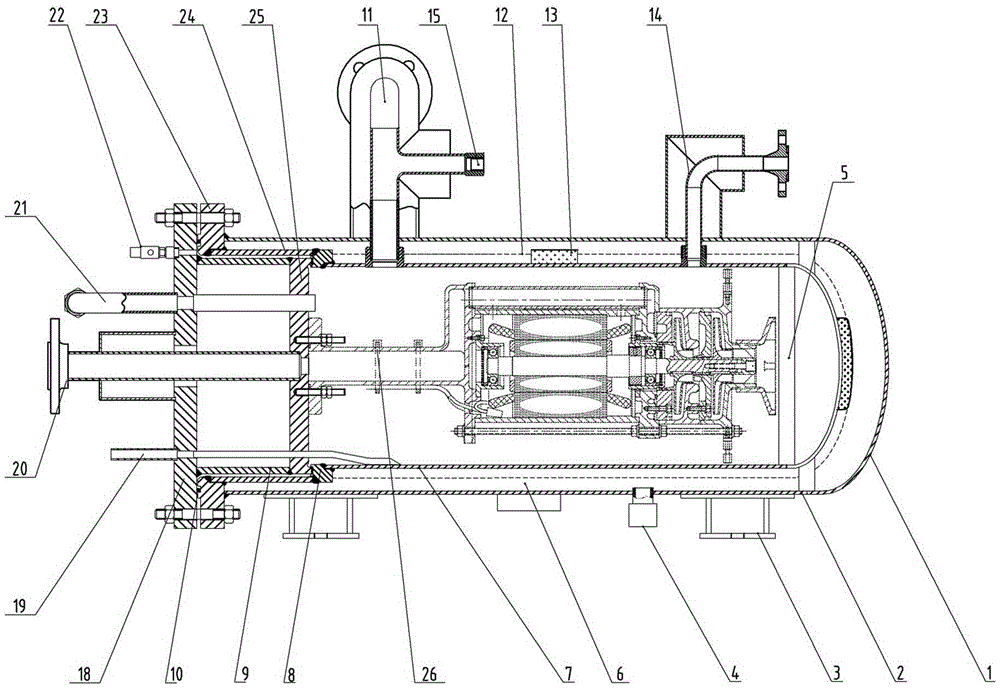

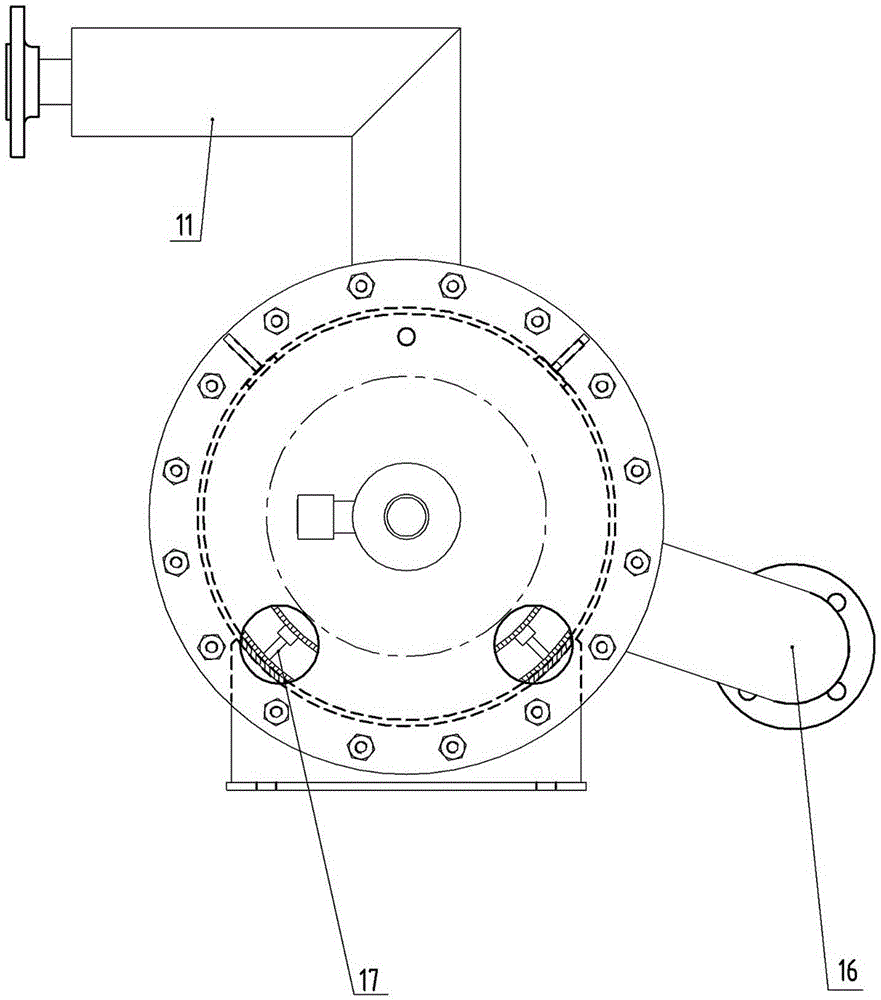

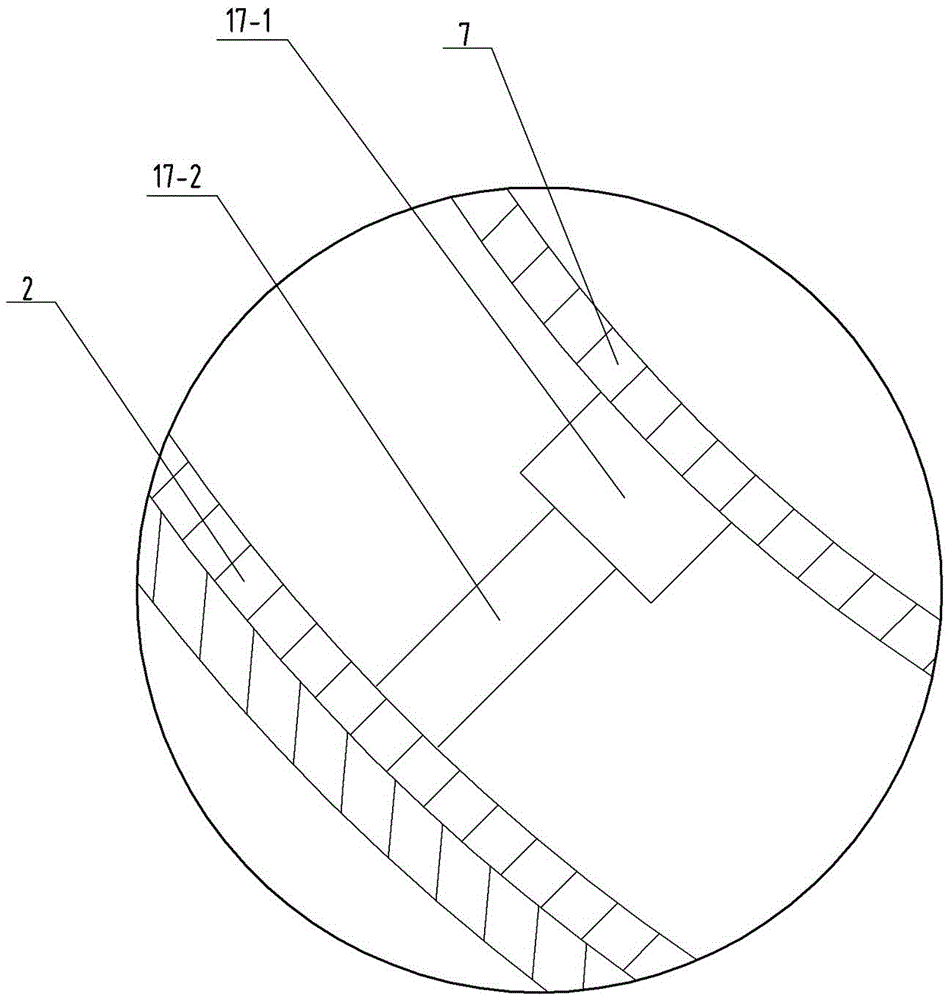

[0028] Example: see figure 1 , figure 2 and image 3 , a full vacuum horizontal LNG submersible pump pool, comprising a pump pool body 6, a submersible pump and a support 3, the support 3 is arranged at the lower part of the pump pool body 6, and the pump pool body 6 is composed of an inner cylinder 7 and an outer cylinder 2, the inner cylinder is composed of an inner head and a cylindrical body, the outer body is composed of an outer head 1 and a cylindrical body, and the connection between the head and the body is provided with Backing plate 5, a vacuum sandwich structure is formed between the inner and outer cylinders 7 and 2, and a vacuum joint 4 is fixedly connected to the outer wall of the outer cylinder 2, and the vacuum joint 4 is connected to the inner and outer cylinders. The sandwich structure between the cylinders 7 and 2 is connected, the submersible pump 26 is installed in the pump pool body 6, and the axes of the two are coincident, the pump pool body is plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com