Roadheader Hob Bearing Assembly with Composite Sensor

A composite sensor and bearing assembly technology, applied in bearing assembly, bearing components, mechanical bearing testing, etc., can solve problems such as embedded application limitations and large vibration of hob bearings, achieving simple structure, no damage to integrity, and good rigidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

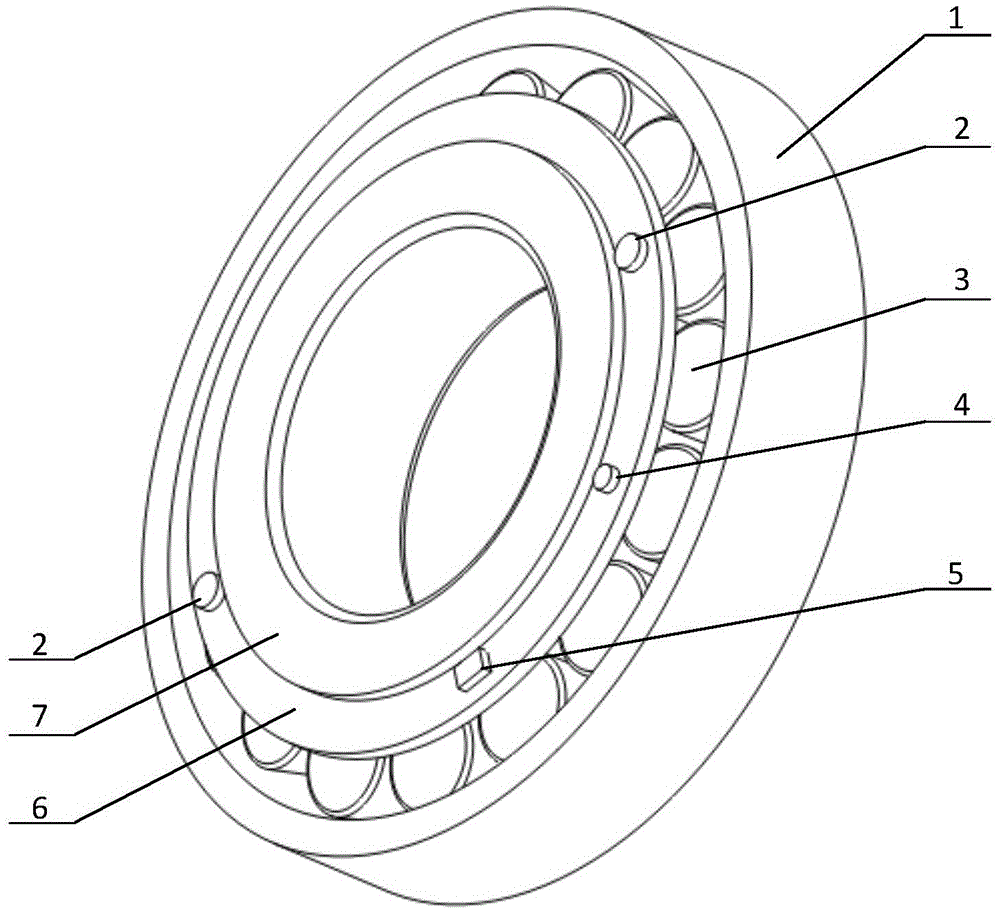

[0010] The specific implementation of the present invention will be described in detail in conjunction with the accompanying drawings and technical solutions. In the construction of the roadheader, it mainly depends on the hob installed on the cutter head of the roadheader to ditch, roll, crush and cut rocks, soil layers and sand and gravel. The hob is composed of a cutter body, a cutter ring, a bearing, a cutter shaft and a seal. When the roadheader is working, the bearing as the load-bearing part and key part of the hob bears huge radial and axial loads. Due to the unstable cutting force during the rock breaking process, the tool generates a lot of vibration, which may cause the hob bearing to run unsteadily in the rolling rock breaking process, and the bearing will quickly dissipate under the action of strong external force and its own non-stop operation. Therefore, it is necessary to use a vibration sensor to detect the vibration signal of the bearing. Since the hob beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com