Electromagnetic pilot operated valve with internal waterproof structure

A technology of electromagnetic pilot valve and pilot valve, which is applied in the direction of valve shell structure, valve details, valve device, etc., can solve the problems of no waterproof, inconvenient maintenance of electromagnetic pilot valve, jamming, etc., and achieve the effect of fewer processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

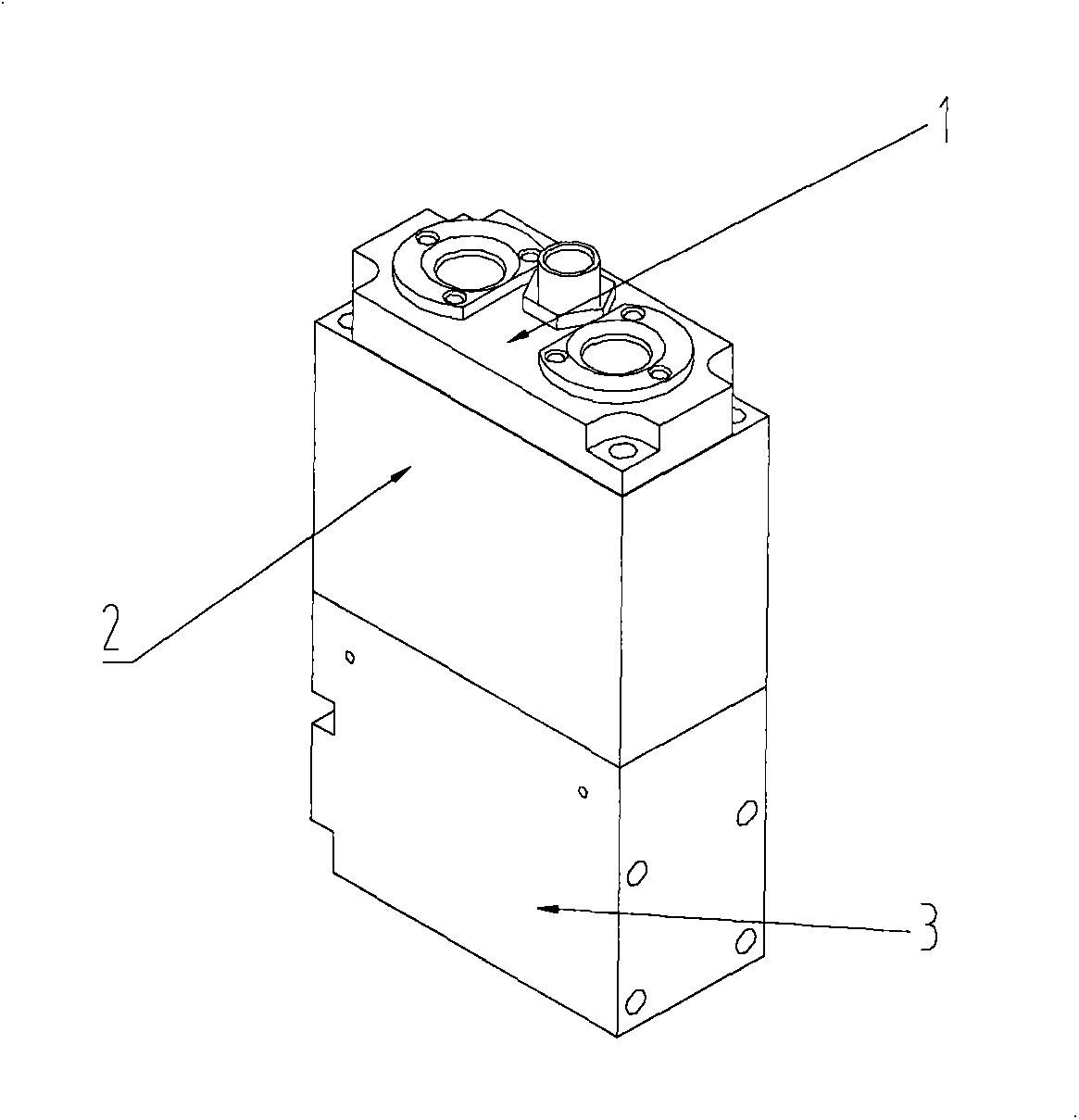

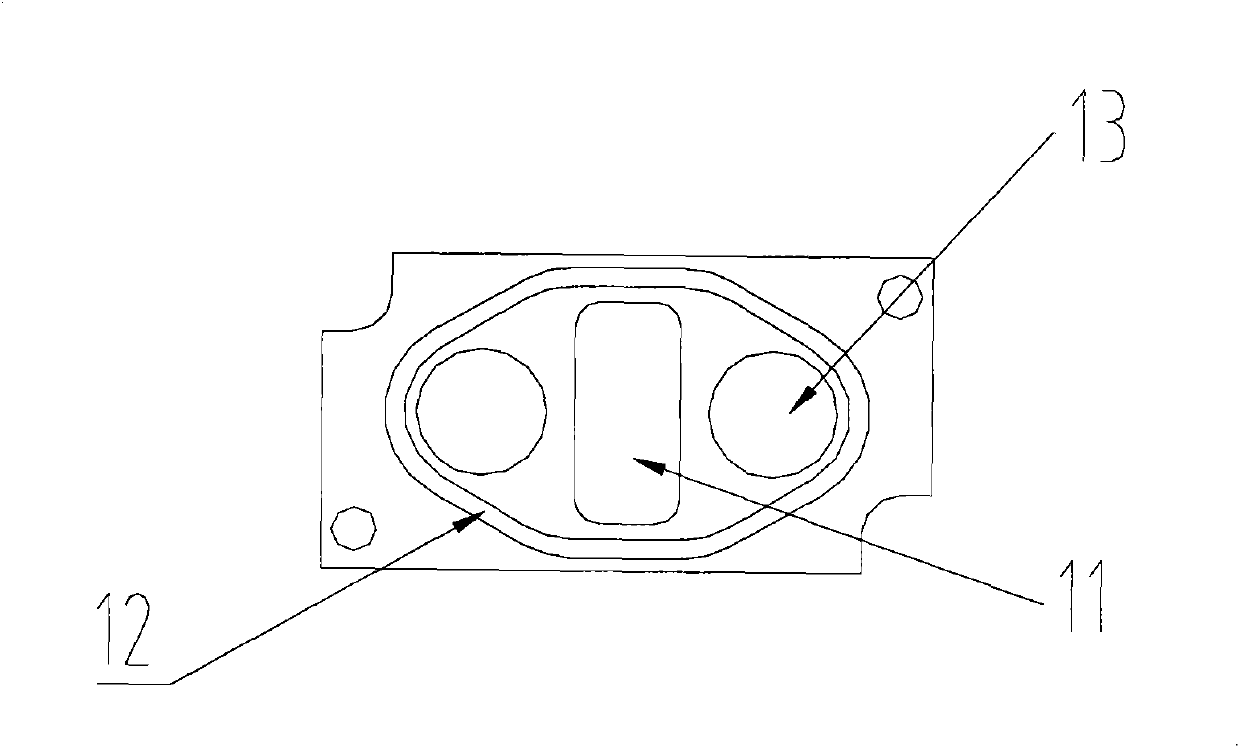

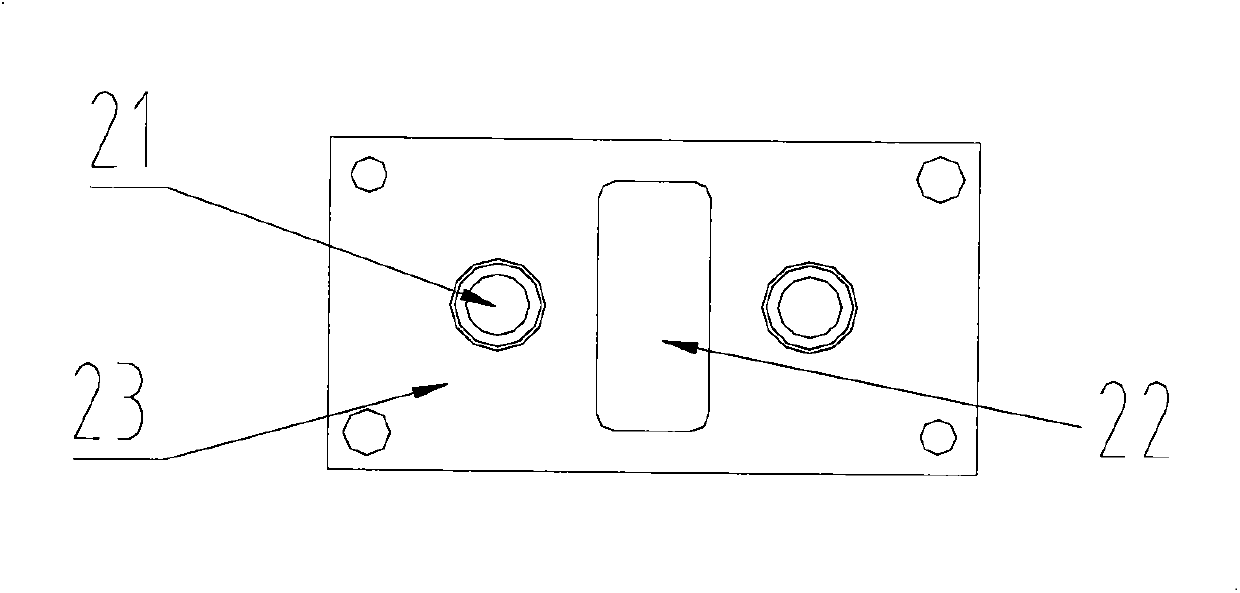

[0021] The electromagnetic pilot valve of the present invention will be described in detail below in conjunction with the accompanying drawings. The electromagnetic pilot valve according to the present invention is as attached figure 1 As shown, it includes the pilot valve body, the pilot valve body includes the end cover, the electromagnet and the copper valve body, the end cover and the copper valve body are fixedly connected at the opposite ends of the electromagnet, and the two valve stems run through the shell of the electromagnet. One end is protected by the end cover, and the other end extends into the copper valve body. During use, the valve stem is driven up and down by controlling the electromagnet to complete the normal function of the electromagnetic pilot valve.

[0022] As we all know, the environment in coal mines is relatively harsh. Coal dust and water vapor can easily infiltrate from the joints between the end cover, the pilot valve body and the electromagnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com