Warm air blower core assembly having variable power

A technology for heaters and components, applied in air heaters, lighting and heating equipment, fluid heaters, etc., can solve problems such as unfavorable energy saving, low assembly efficiency, and large power span, so as to increase the power adjustment range and improve production efficiency. , the effect of small power span

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following examples are further explanations and supplements to the present invention, and do not constitute any limitation to the present invention.

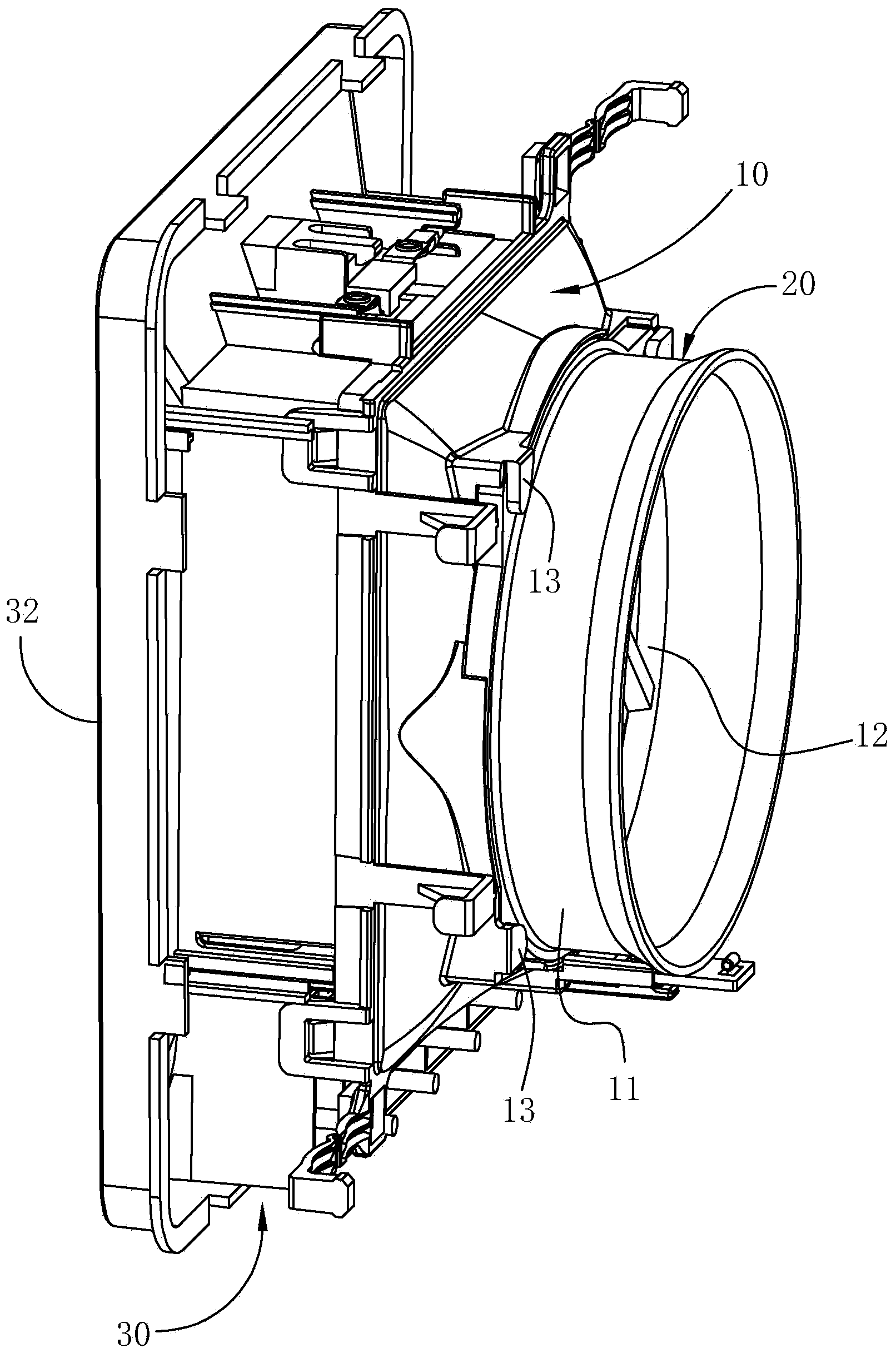

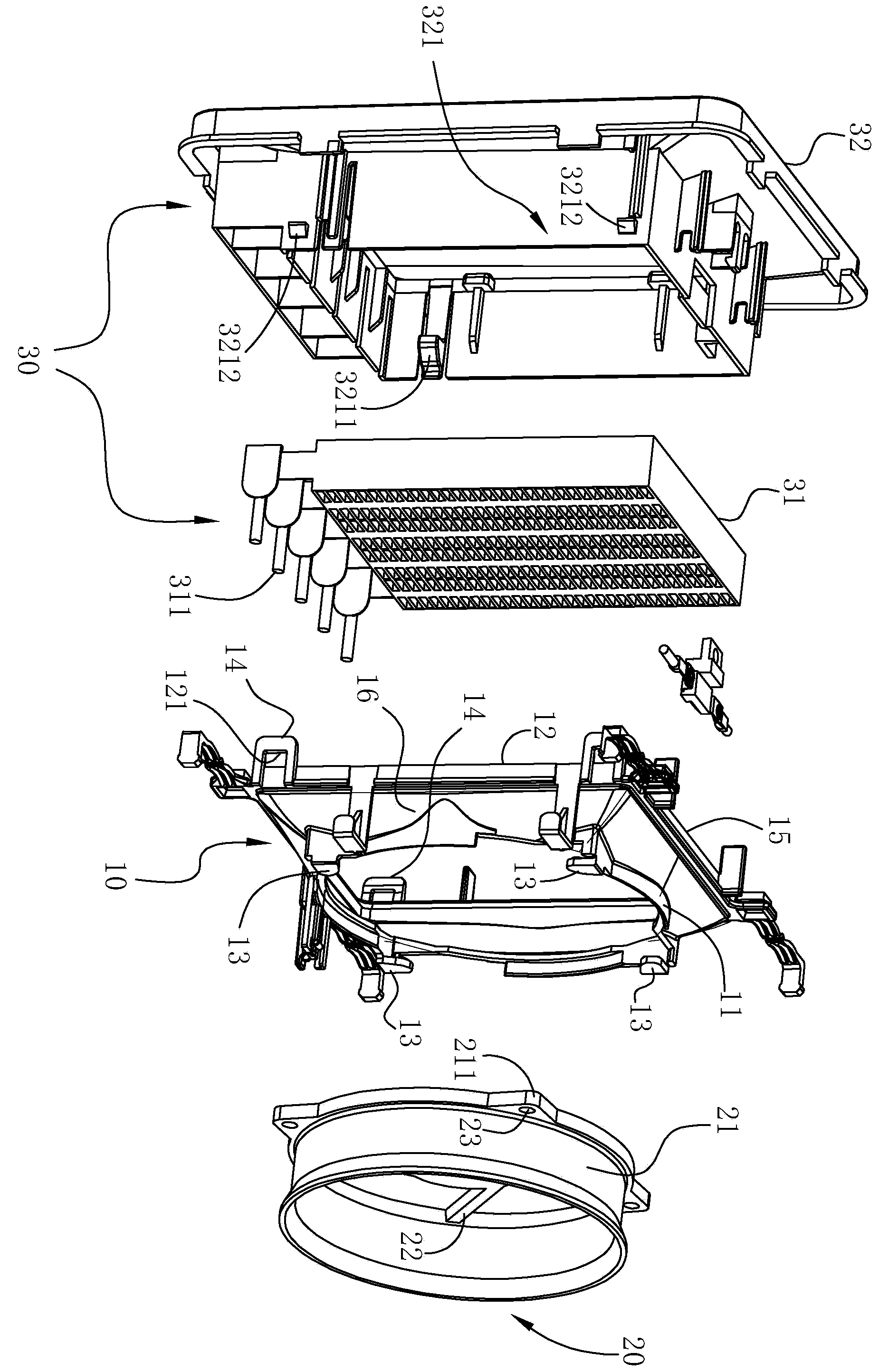

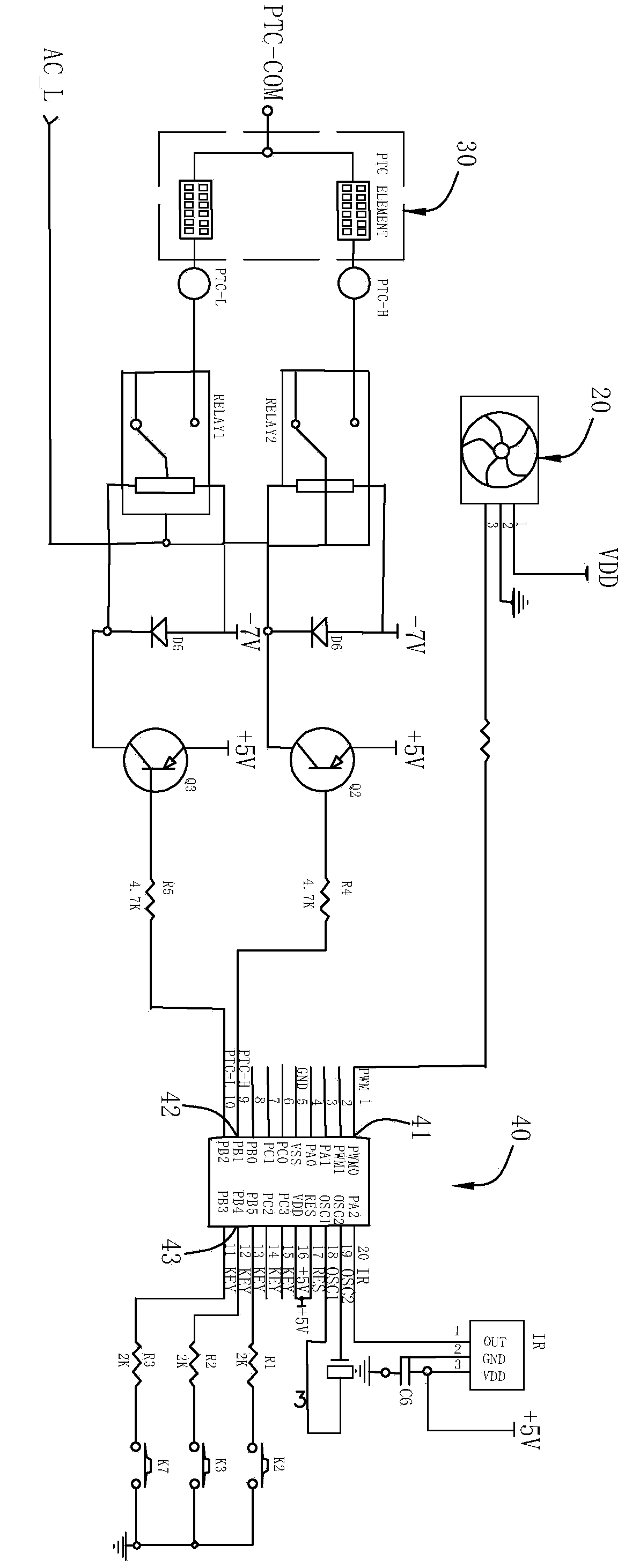

[0021] like figure 1 , figure 2 As shown, the variable power heater core assembly of the present invention includes an air duct shell 10, a fan 20, a PTC heating component 30, a microprocessor 40 and a motor (not shown in the figure). The air duct casing 10, the fan 20, the PTC heating component 30, the microprocessor 40 and the motor are integrated into one body.

[0022] like figure 1 , the core assembly of the heater is to integrate the air duct shell 10, the fan 20, and the PTC heating component 30 through buckles and fasteners, wherein the fan 10 and the air duct shell 20 are buckled and fastened. , the air duct shell 10 and the PTC heating component 30 are fastened and tightly connected.

[0023] like figure 2 , the air duct shell 10 is a rectangular frame-type shell, which is composed of a frame 15 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com