Novel oil gas condensation cooling device on top of fractional distillation tower

A technology for condensing coolers and fractionating towers, which is applied in the chemical industry, cold exchange equipment, and petroleum fields. It can solve the problems of complex anti-corrosion process, short anti-corrosion time, and medium leakage, so as to reduce metal consumables, improve corrosion resistance, and reduce industrial use costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

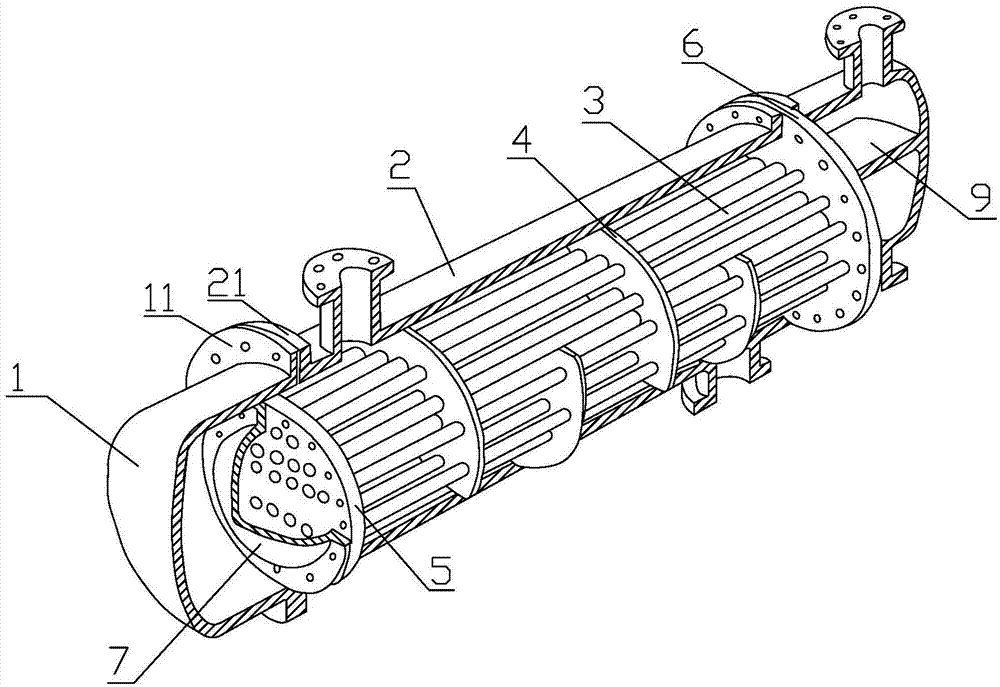

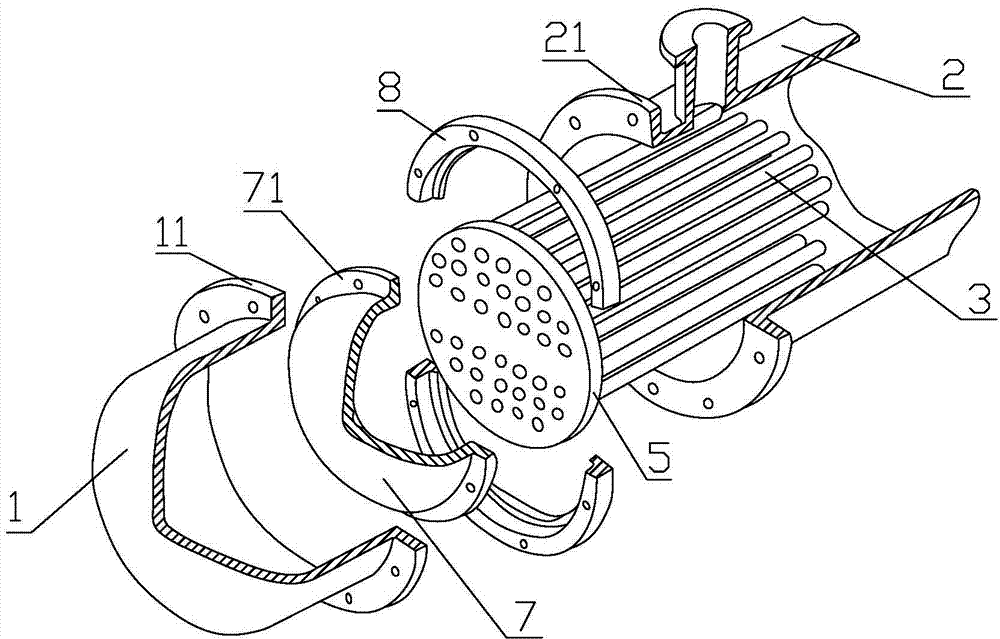

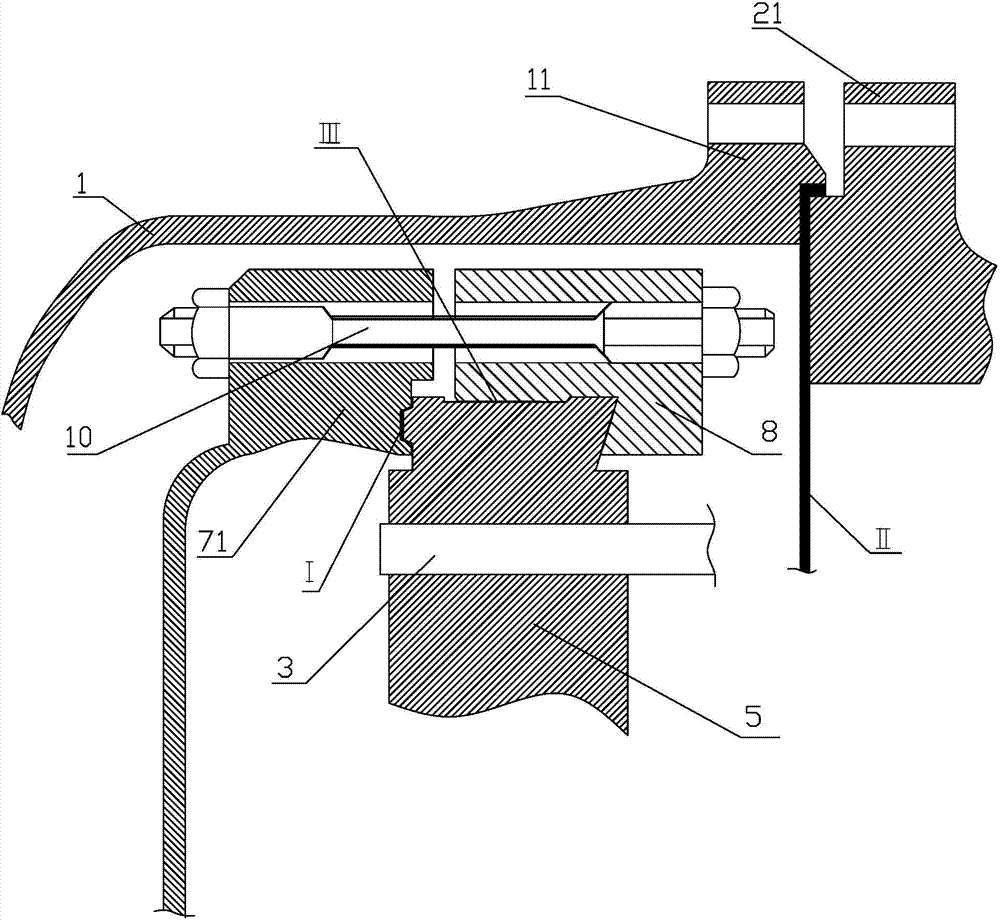

[0023] In order to facilitate description and understanding of the technical content of the present invention, the present invention will be further described below in conjunction with the accompanying drawings.

[0024] like figure 2 and image 3 The new oil-gas condensing cooler at the top of the fractionating column is shown in the figure 1 The structure of the floating head part is improved on the basis of the above. The structure of the floating head end of this new oil-gas condensing cooler at the top of the fractionation tower is improved, and the cover plate part of the floating head 7 is improved from a spherical crown shape to a groove shape, which can also be said to make the cover plate part look like a washbasin, that is, The recessed depth of the cover plate has been increased. This trimming enables the medium in the tube side to have sufficient baffle space when the direction of the medium is reversed at the floating head, so that the medium in the tube side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com