X-ray casting automatic inspection device

An automatic detection device, X-ray technology, applied in measuring devices, material analysis using wave/particle radiation, comprehensive factory control, etc., can solve the problems of heavy workload, low work efficiency, and affecting the detection time of castings, etc., to achieve Increased service life, reduced failure points, simple, high-speed and reliable CANopen bus control wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

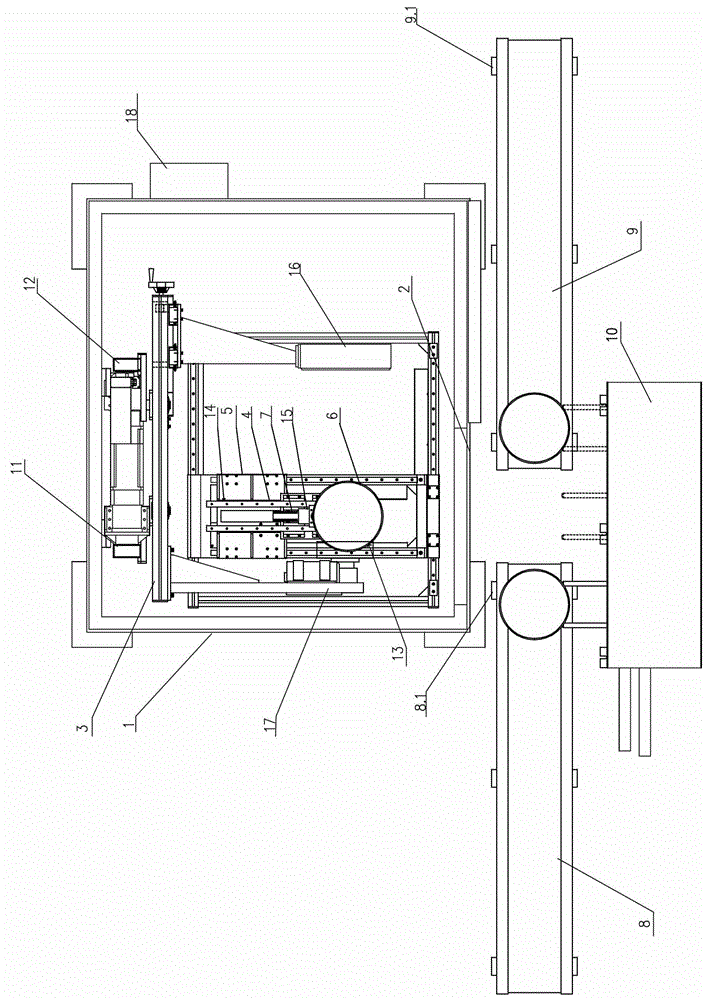

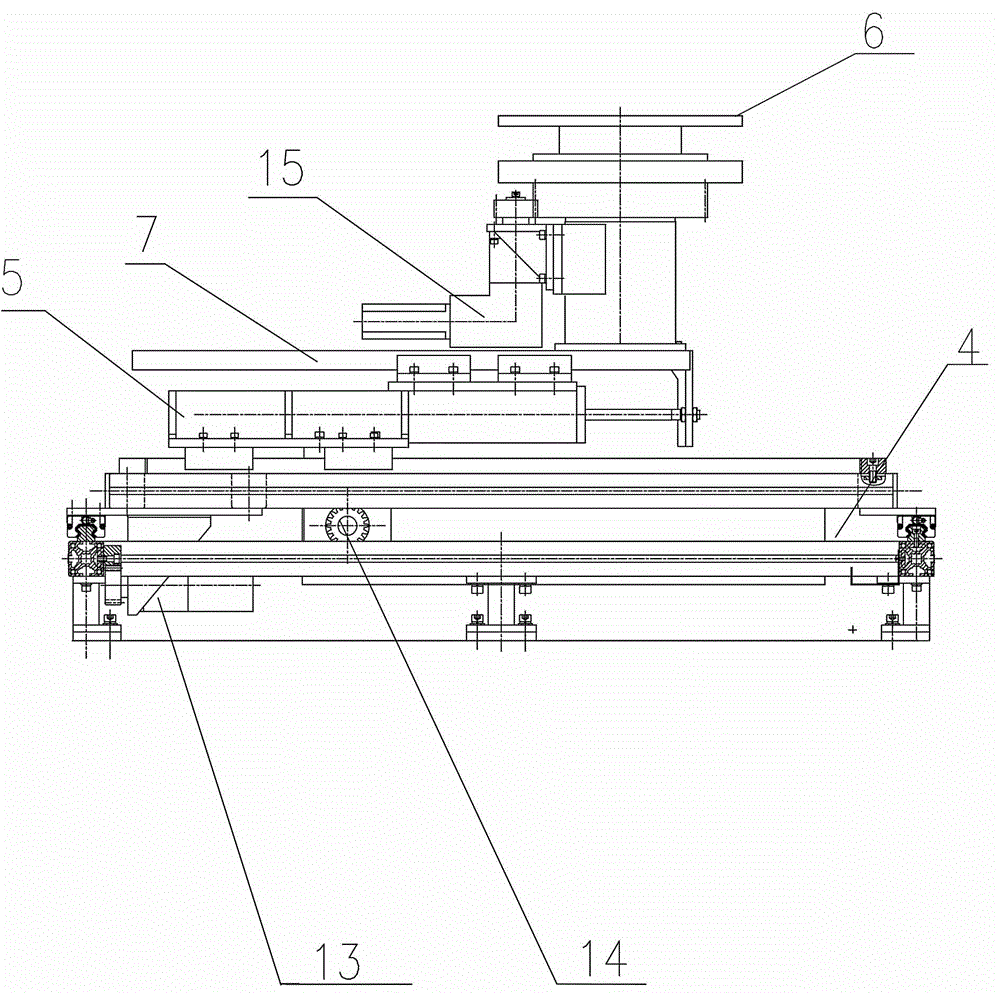

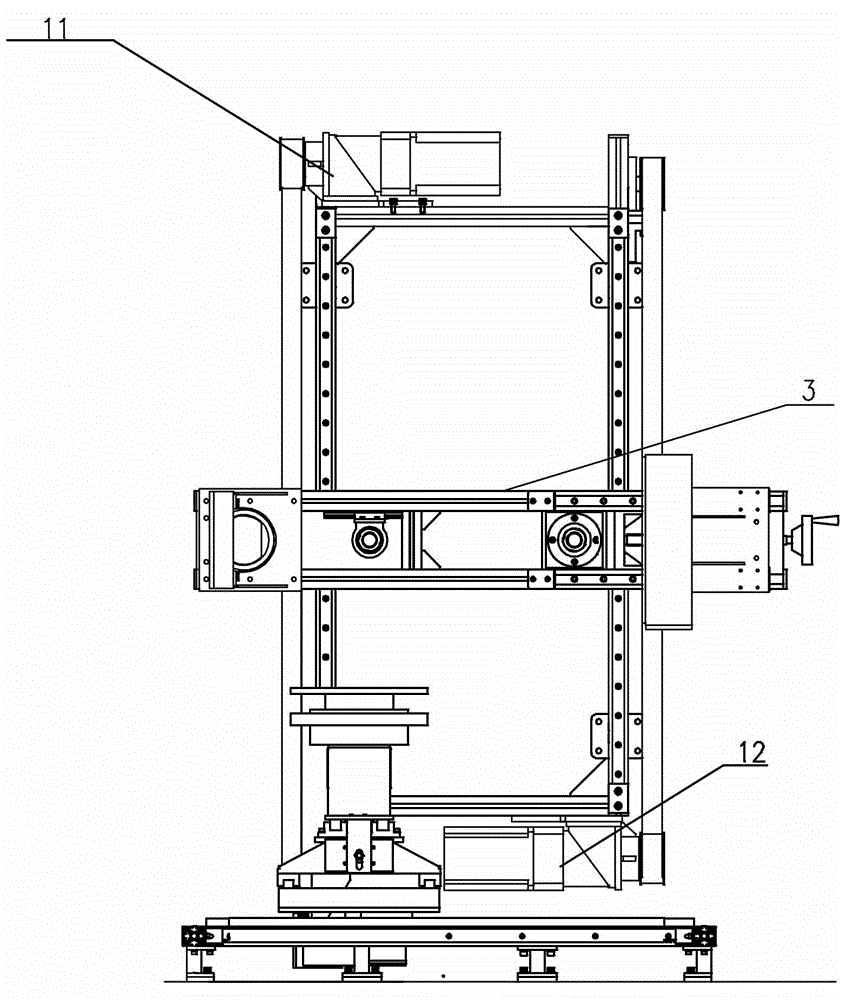

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0013] A kind of X-ray casting automatic detection device, such as figure 1 , figure 2 , image 3 As shown, the use of X-rays for automatic assembly line inspection of castings is especially suitable for enterprises with a large output and low output due to slow inspection speed. Its specific structure is: a π-arm mechanism 3 is installed directly opposite the protective lead door 2 on the protective lead room 1, and a 1# π-arm lifting servo motor 11 is installed on the upper left corner of the π-arm mechanism 3. The lower right corner of the mechanism 3 is equipped with a 2# π-arm deflection servo motor 12, a ray tube device 16 and a flat panel device 17 are respectively provided at both ends of the arm of the π-arm mechanism 3, and a The left and right mechanism 4 of the workbench is provided with a 3# workbench left and right servo motor 13 near the bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com