Ship multi-core tube feeding optimization method

An optimization method and core tube technology, applied in the optimization field of ship multi-core tube blanking, can solve the problems of waste of multi-core tubes and low utilization rate of raw materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The technical scheme of the present invention is: perform mathematical abstraction on the problem of multi-core tube blanking, convert the actual production problem into a mathematical problem, establish a mathematical model, and use the first adaptive descending algorithm and genetic algorithm to solve the mathematical model, by realizing the above Two algorithms calculate the total demand of raw materials, and give the cutting mode corresponding to each raw material in detail.

[0078] The present invention is divided into the following steps:

[0079] The first step is to establish a mathematical model;

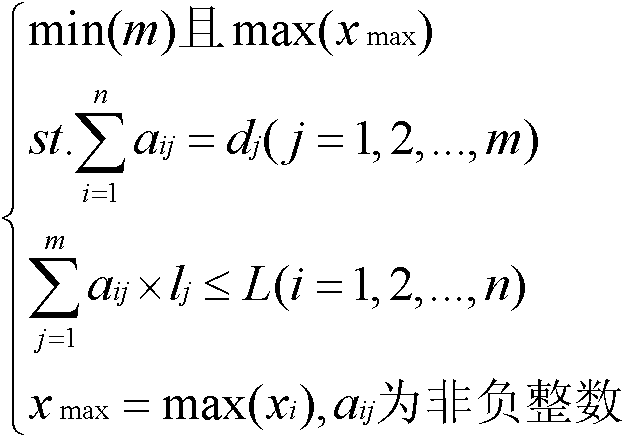

[0080] For the first adaptive descending algorithm, the mathematical model is:

[0081]

[0082] Among them, L is the length of the raw material, n is the quantity of the required specification (n>0)l i and d i Length and quantity (1≤l i ≤n, 0≤d i ≤L), m is the root teaching that requires raw materials a ij is the cutting quantity of each raw material (1≤...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com