Electric brake motor

A technology of electric braking and motor, which is applied in the direction of electrical components, electric components, and control of mechanical energy, etc. It can solve the problems of large-scale braking parts, restrictions on the immediate braking of the motor shaft 2a, and large volume of motor equipment, so as to save power consumption , The effect of simple design structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

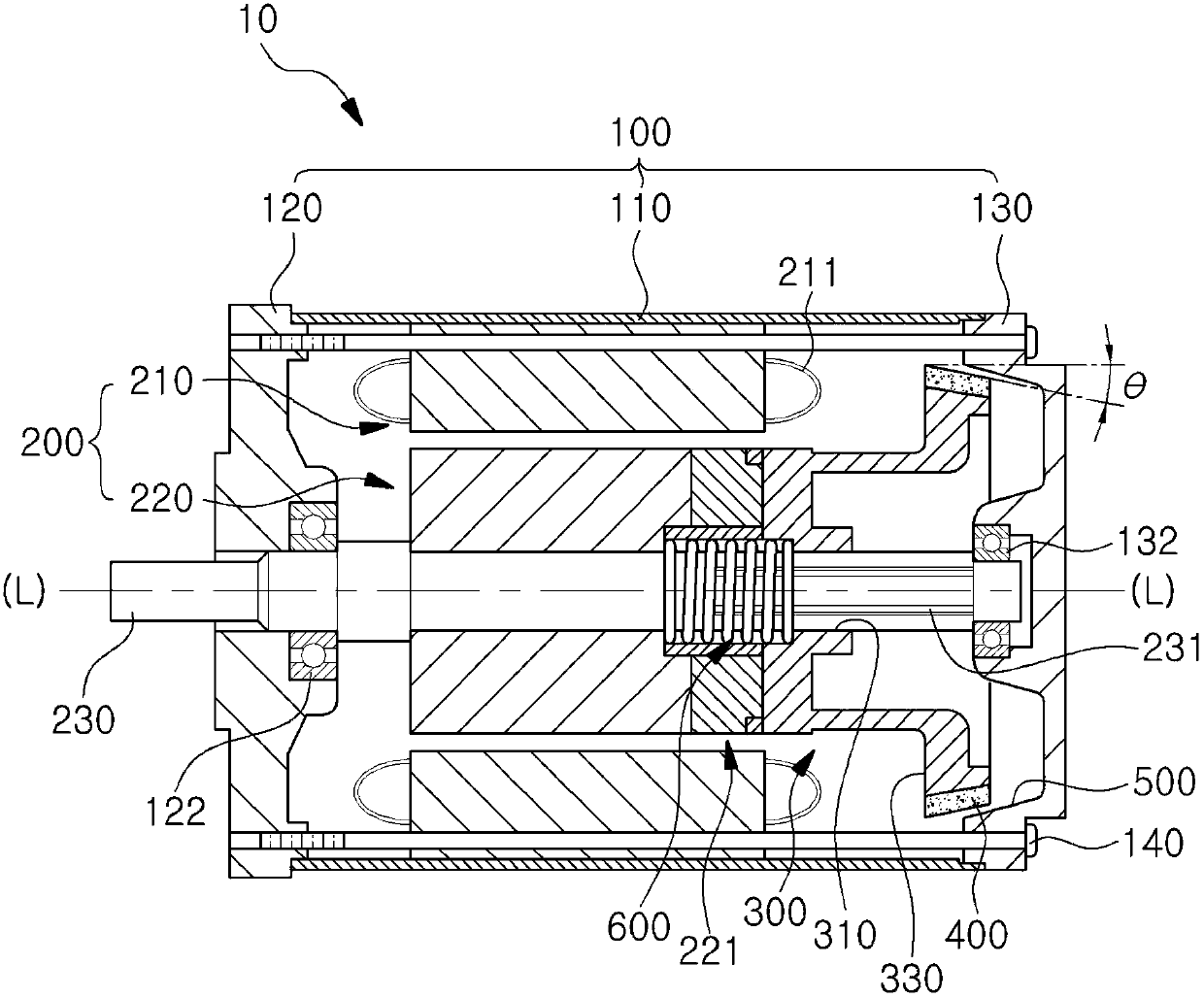

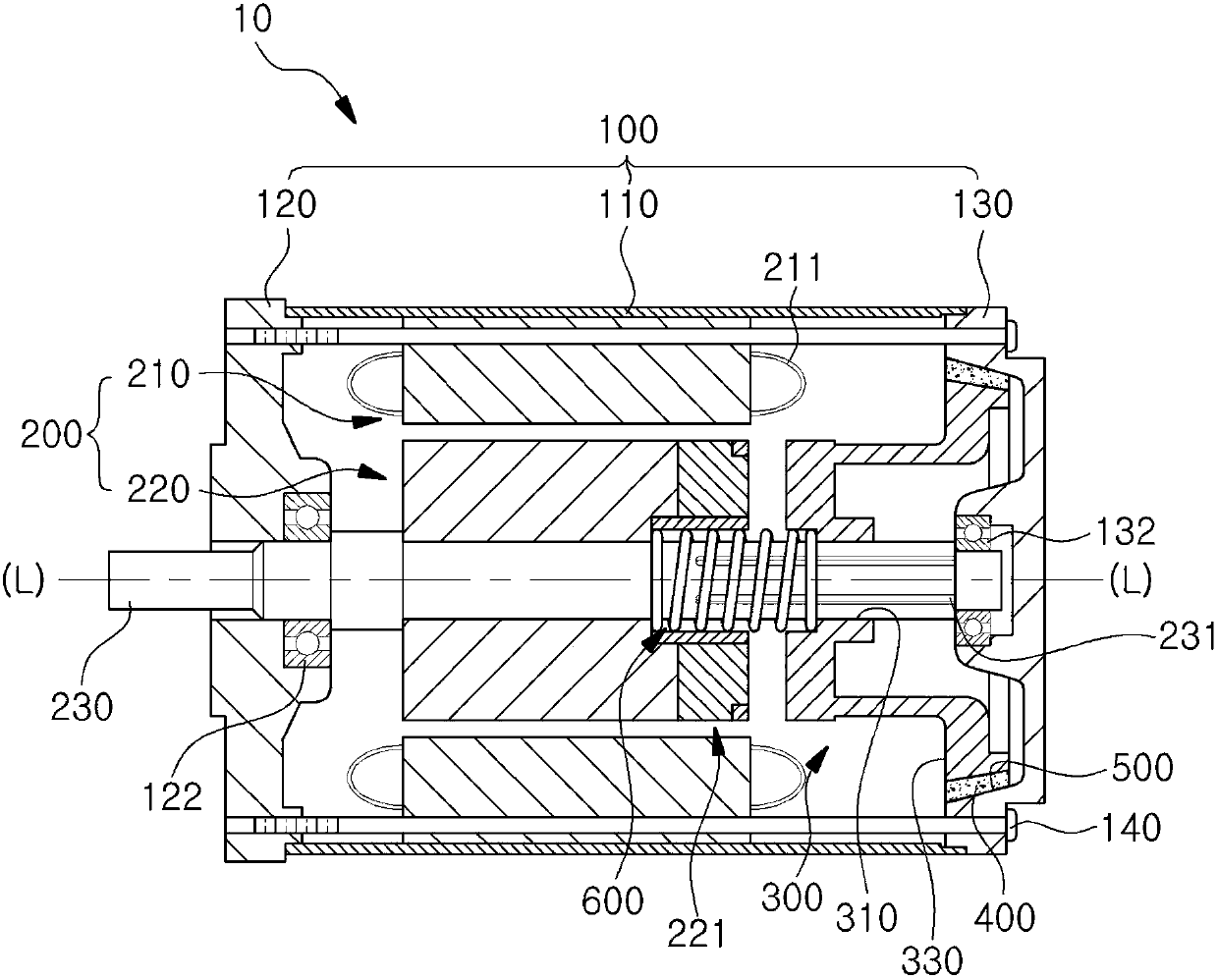

[0031] The objectives, features and advantages of the present invention described above will be described in detail as follows. Hereinafter, the preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings of the present invention.

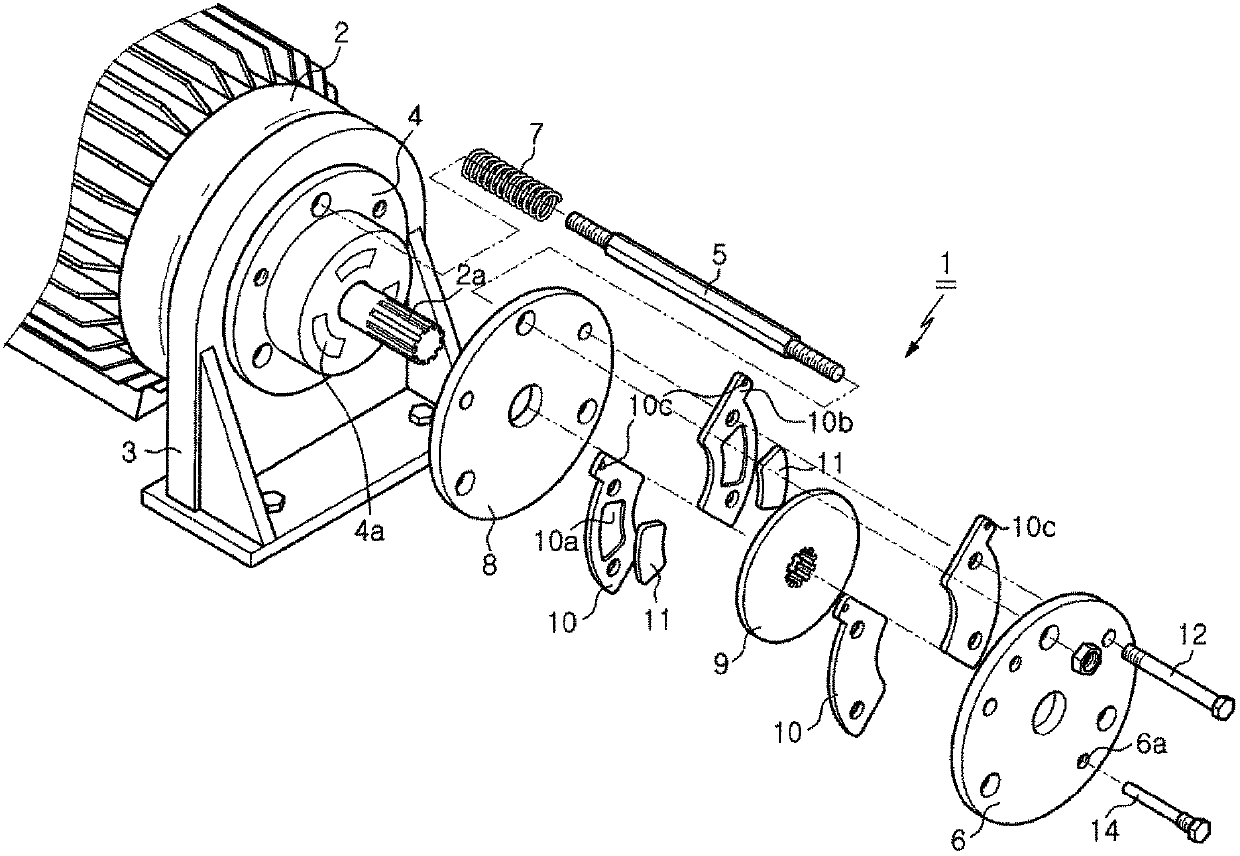

[0032] In the electric brake motor 10 of the preferred embodiment of the present invention, in order to stop the rotation of the motor shaft 230 when the driving power supply is cut off, the direction in which the friction force is generated and the direction in which the motor shaft 230 rotates are opposed to each other. Relatively weak, instant braking can also be achieved. Such as Figure 2 to Figure 5 As shown, it includes a cover part 100, a rotation driving part 200, a clutch part 300, a friction lining 400, a disc part 500, a pressure spring 600 and a magnetic field biasing part 221.

[0033] Here, the cover part 100 is a cover structure formed on the outside of the electric brake motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com