Patents

Literature

75results about How to "Adjustable friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

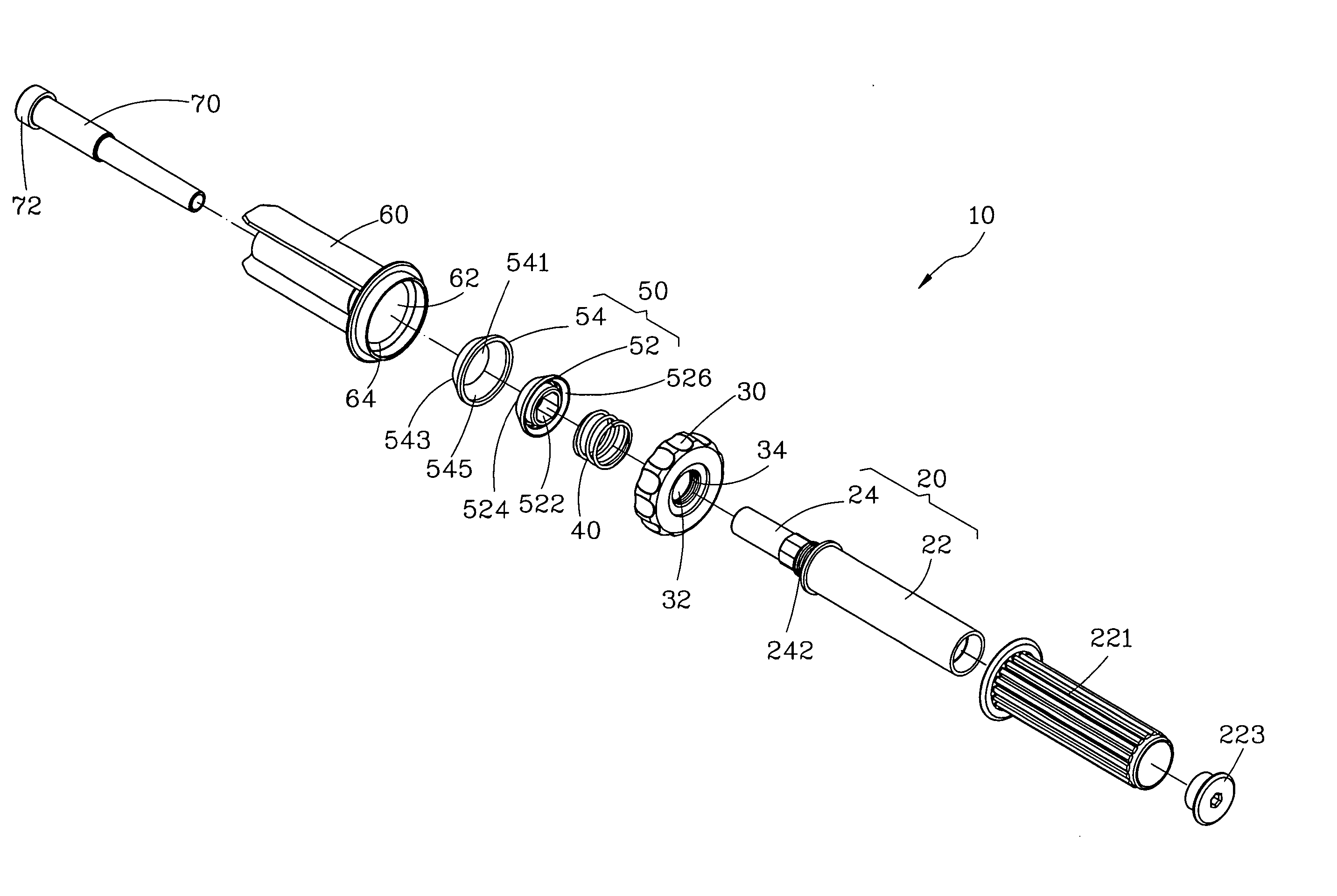

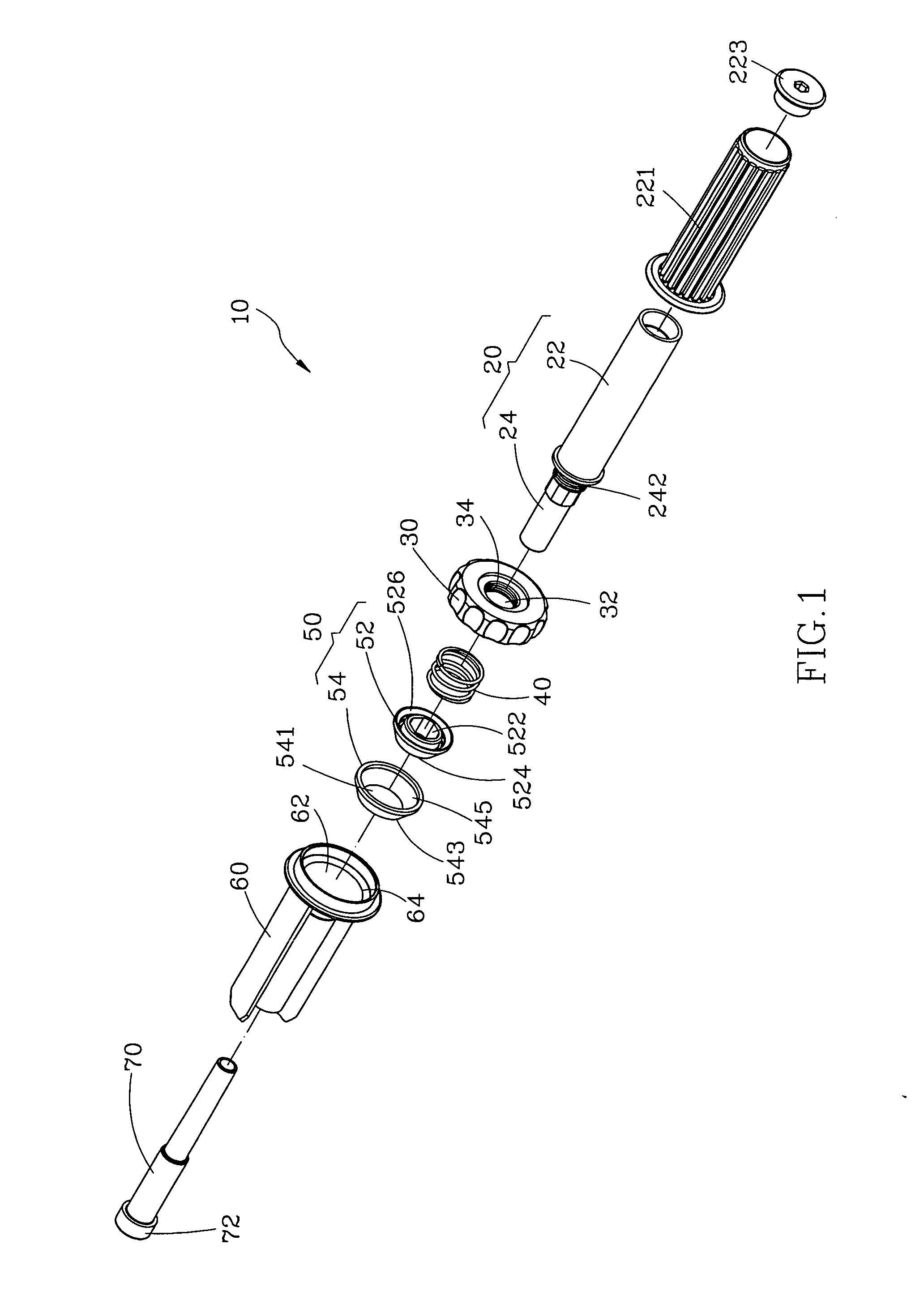

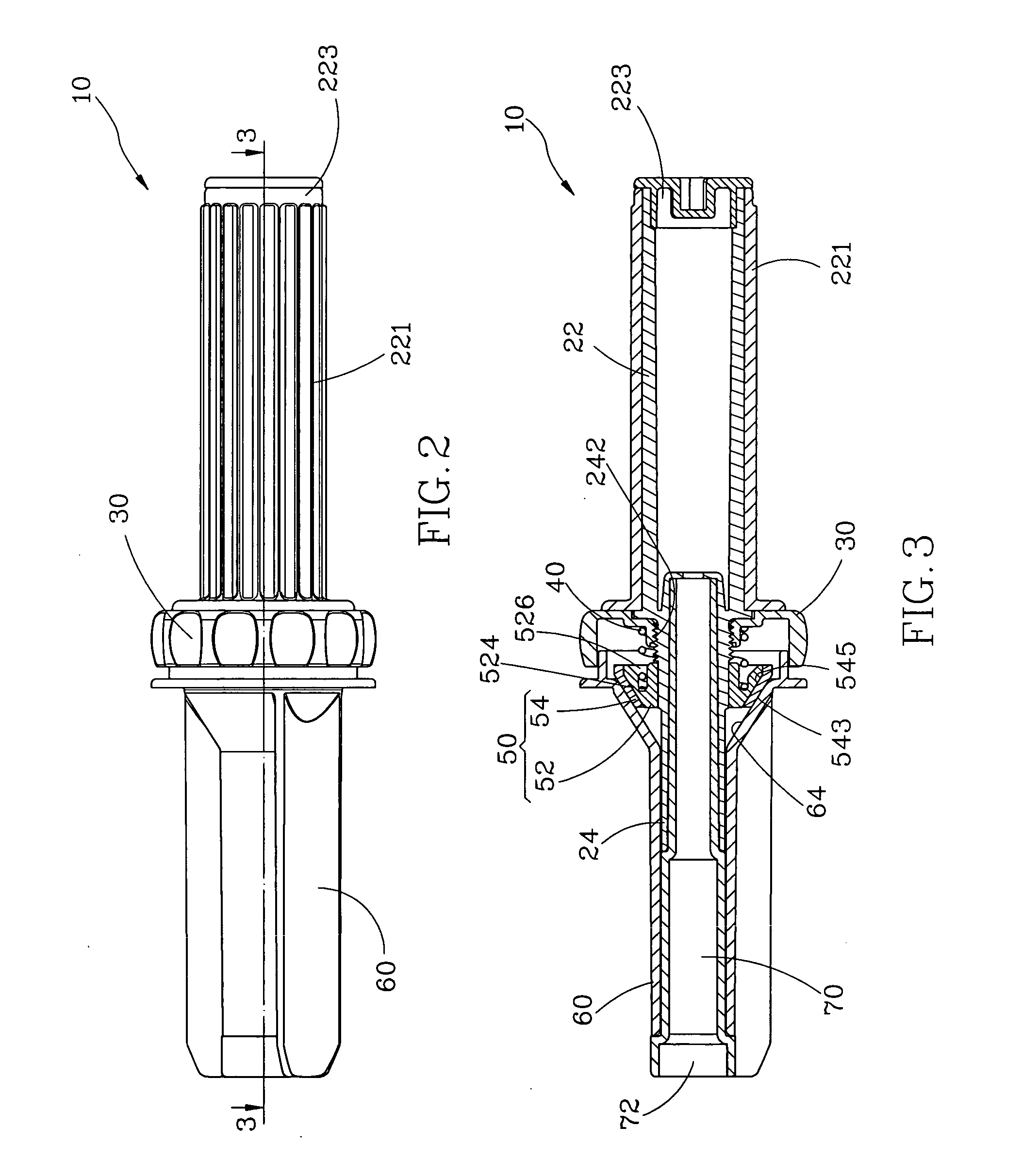

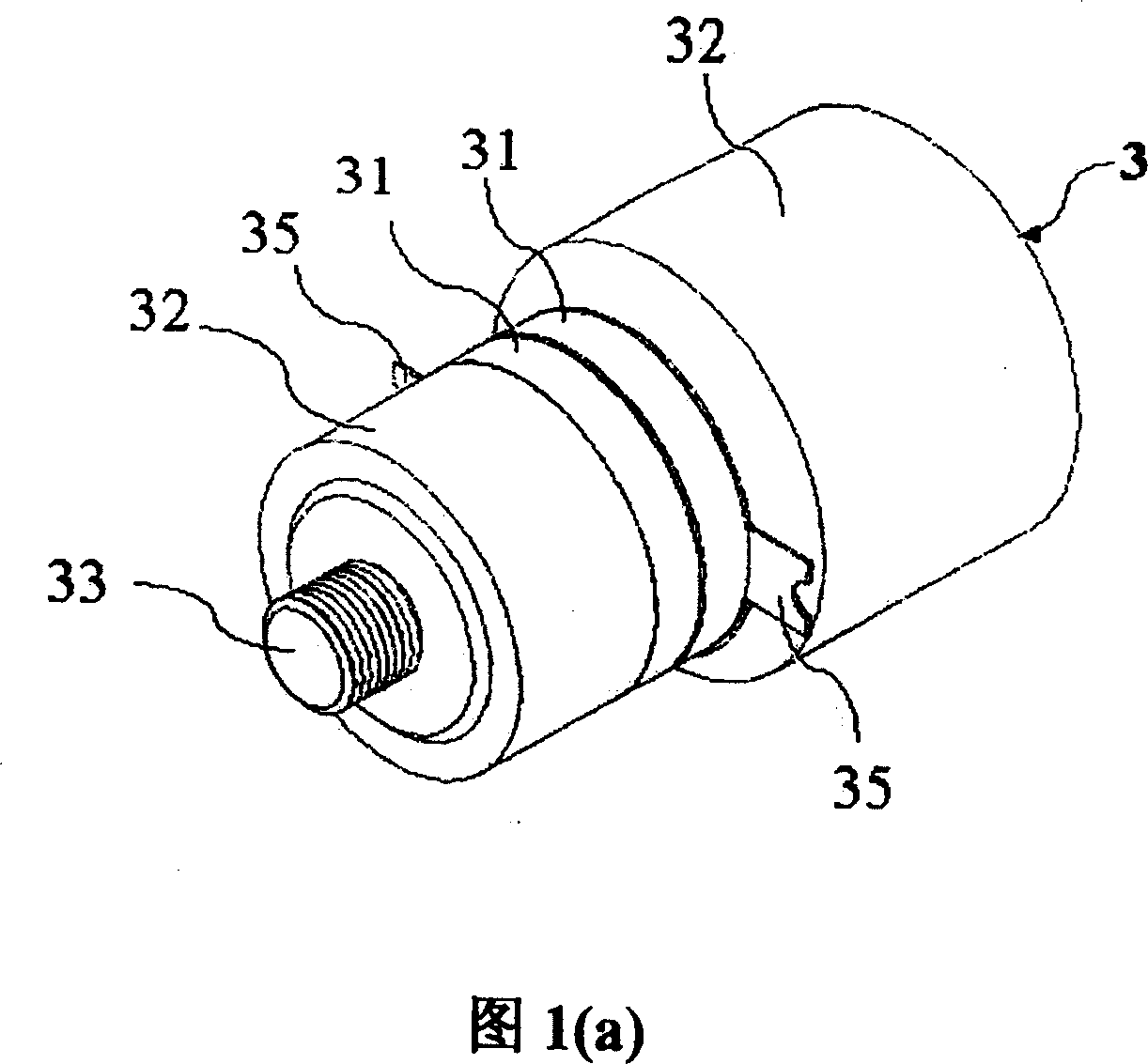

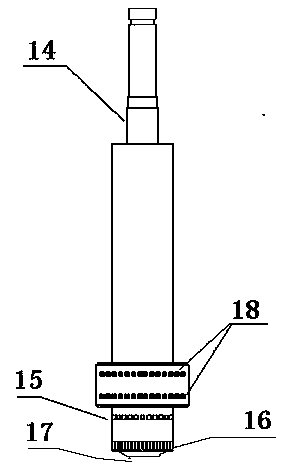

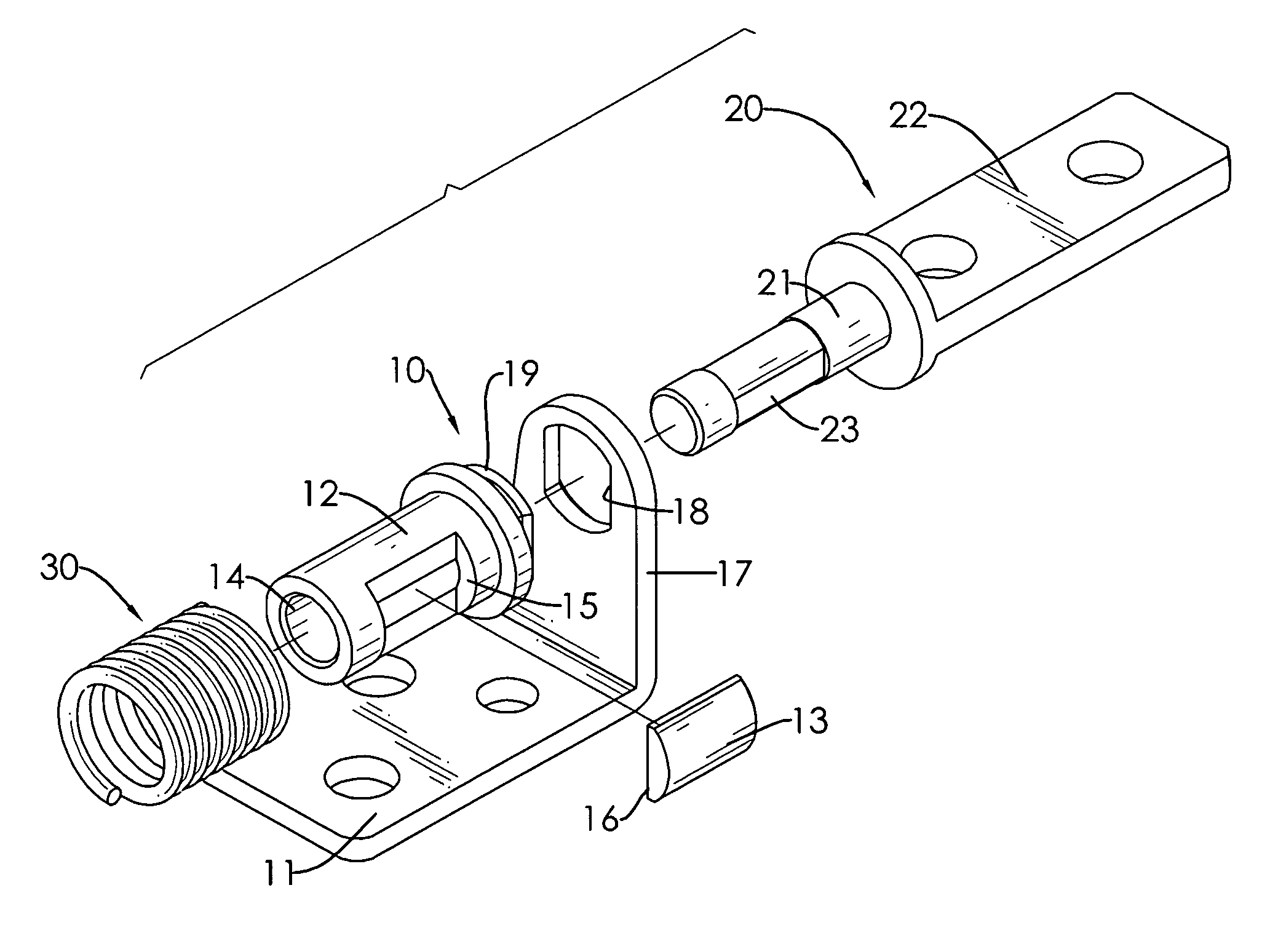

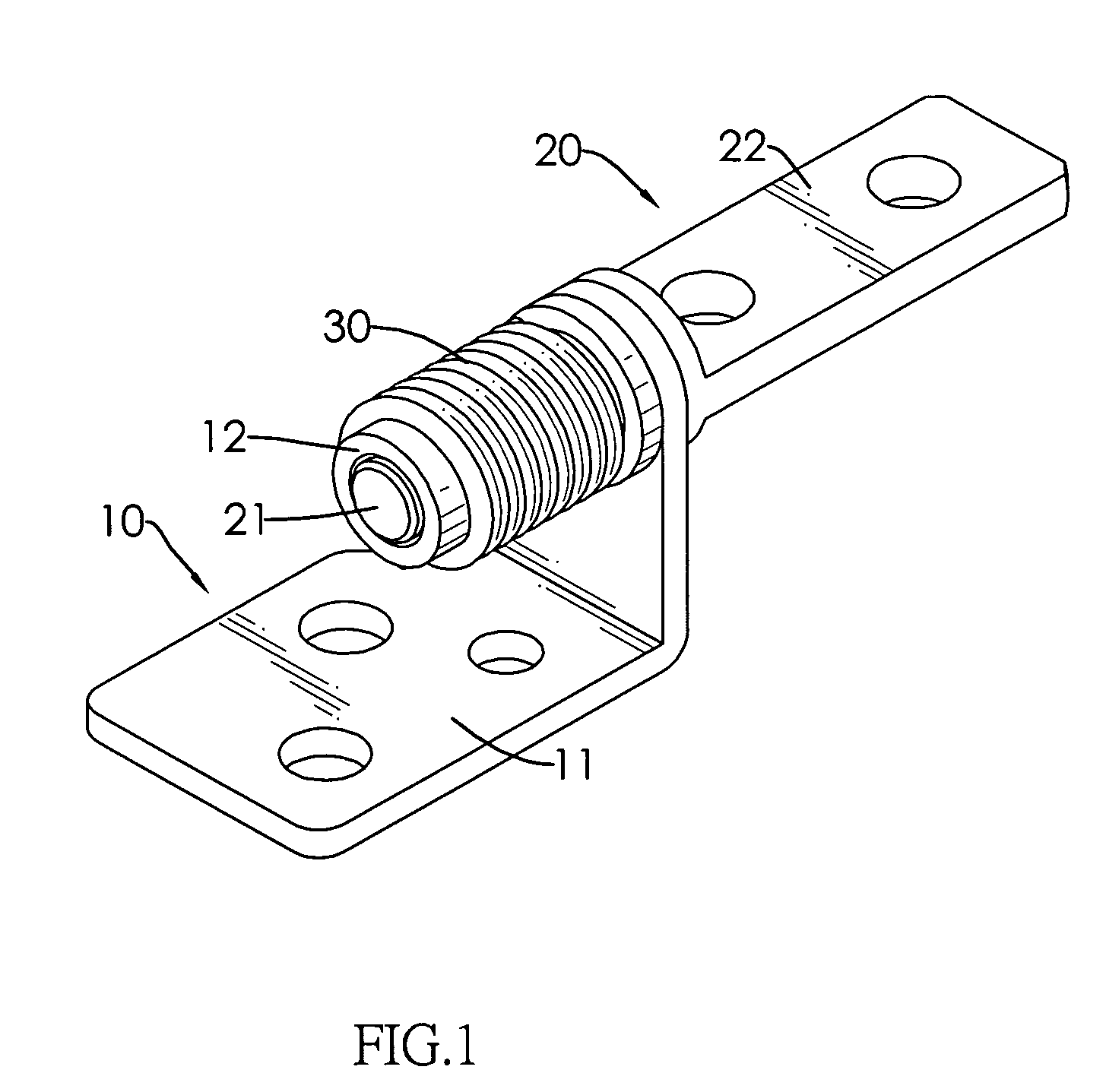

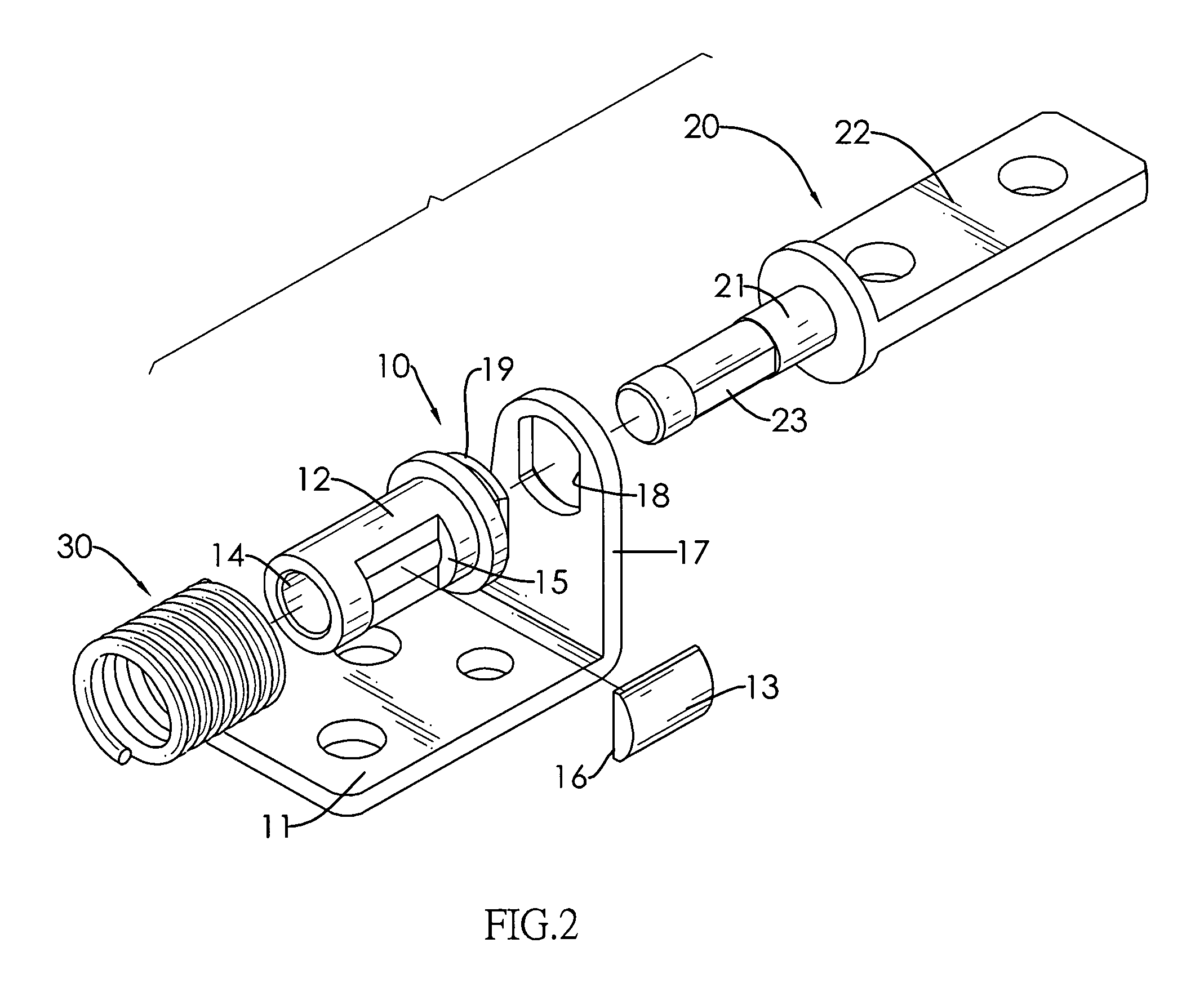

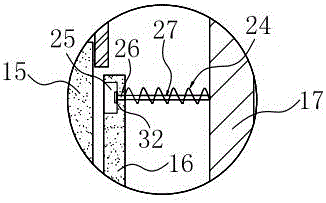

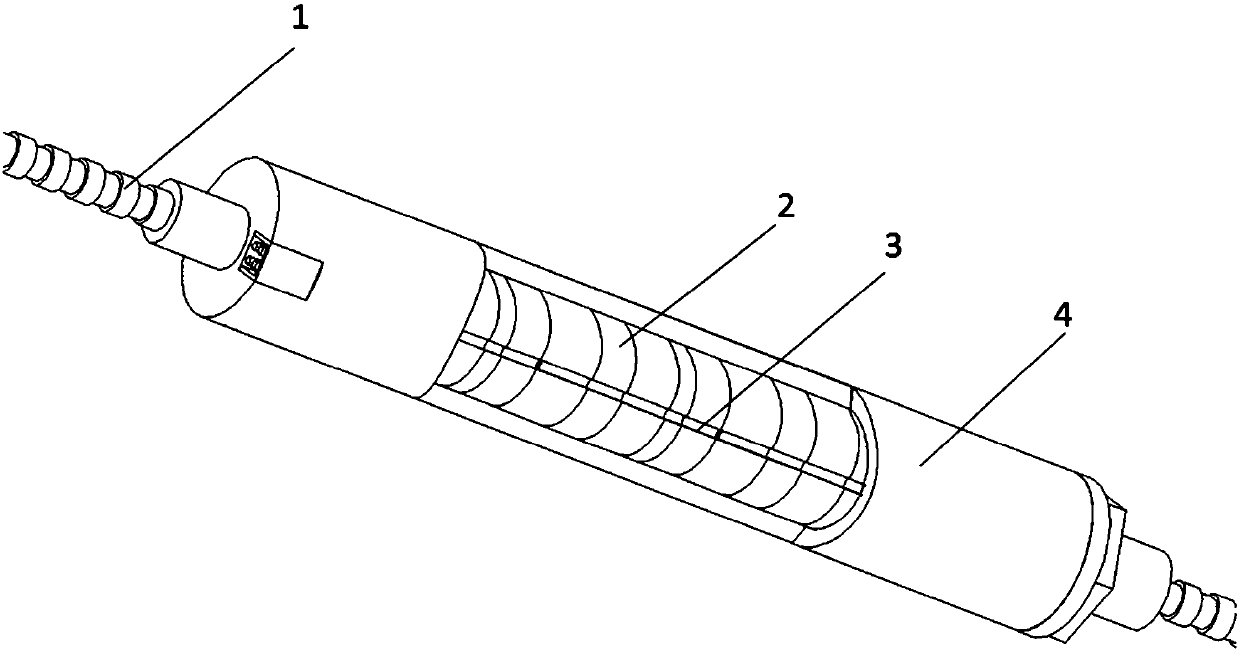

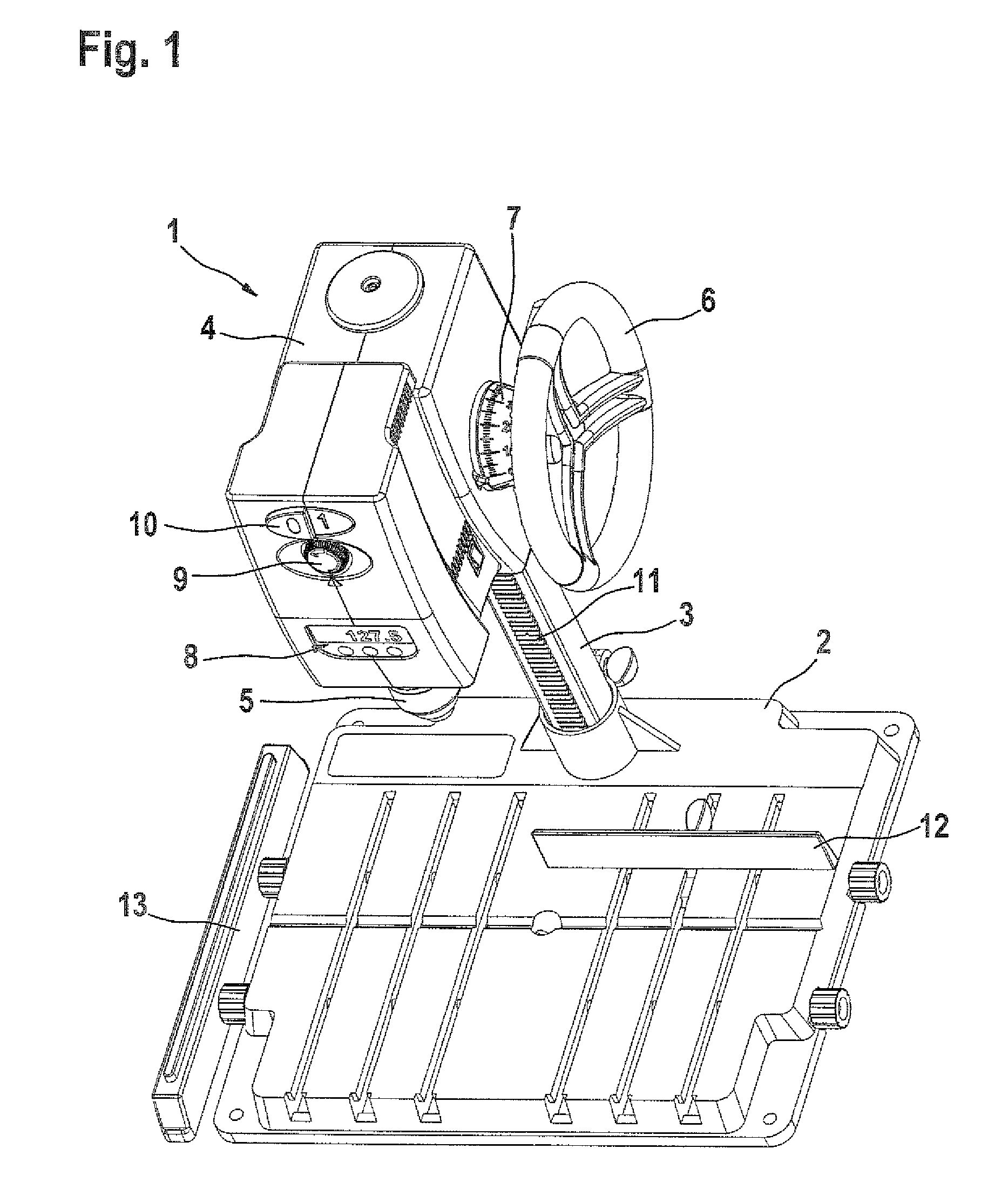

Stretch film dispenser

A stretch film dispenser includes a core member having a handle and a threaded section. A roller is provided on the core member for rotation. A brake device is provided on the core member to press the roller. An adjusting device has a threaded hole to be screwed onto the core member, and an elastic member between the brake device and the adjusting device having ends urging on the brake device and the adjusting device respectively. The adjusting device is rotated to move toward or away from the brake device to compress the elastic member with various degrees, and the elastic member may urges the brake device to press the roller for providing various frictions to the roller.

Owner:HUANG HARRISON

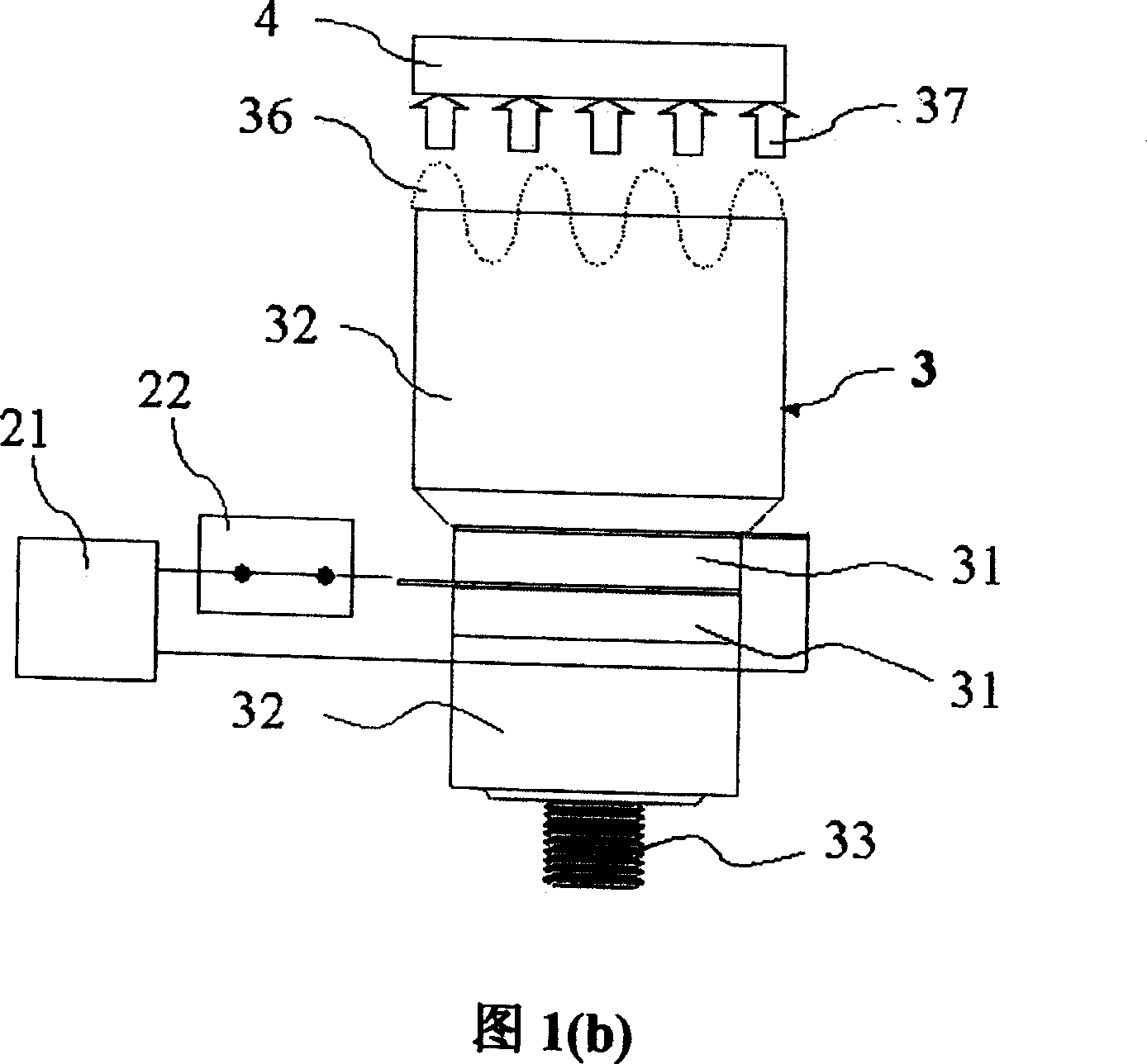

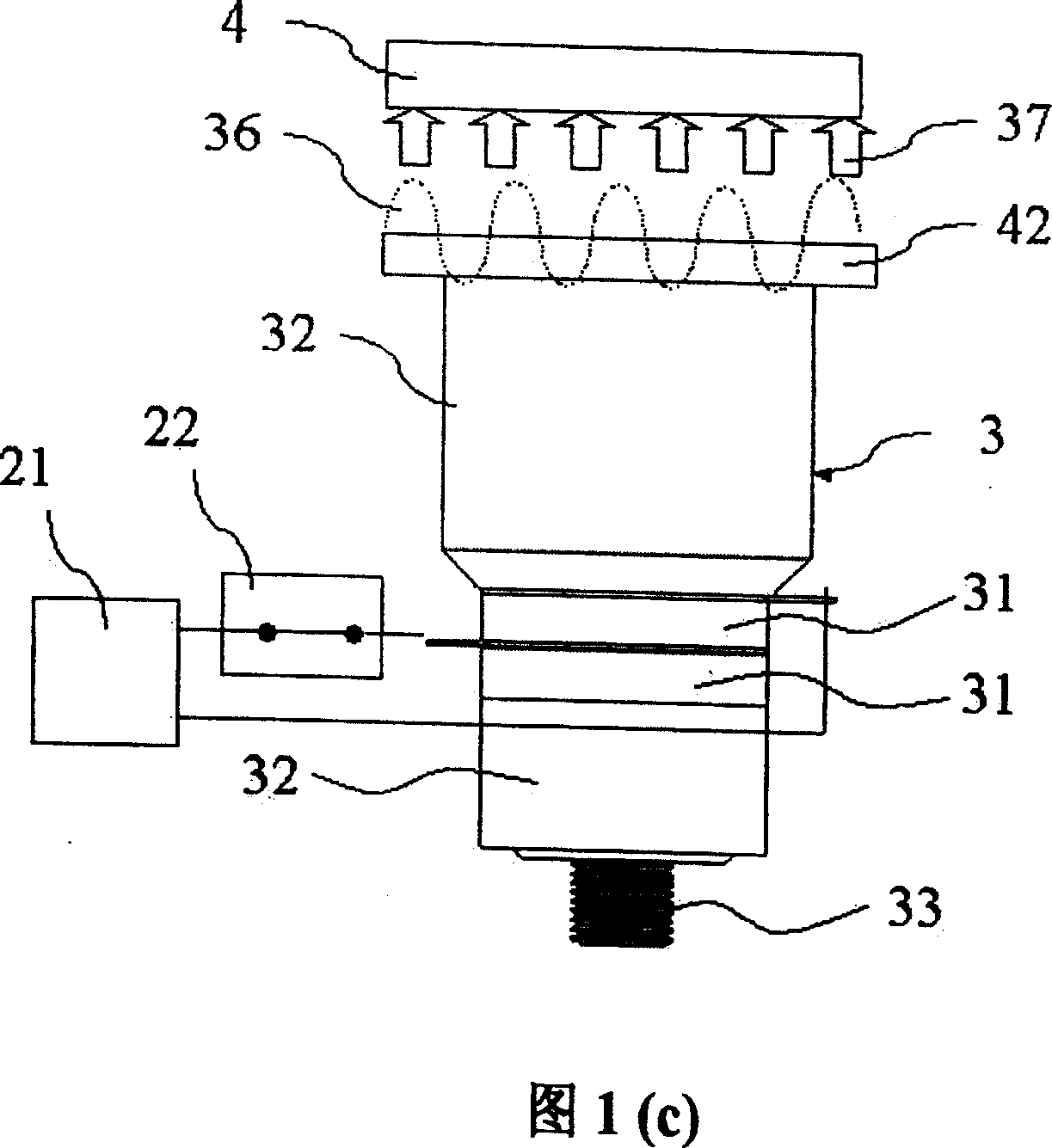

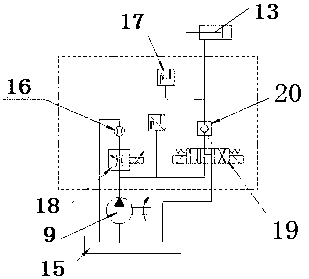

Modularized ultrasonic clutch and brake apparatus

The modular ultrasonic clutch and brake mechanism consists of control and power source module, driving element, driven element, support assembly, pre-stress regulator, fixing seat and pedestal. Both the driving element and the driven element have piezoelectric component and contact tightly, so that the load end will rotate synchronously with the motor shaft in use as clutch and will produce braking effect in use as brake. When alternate power source is applied onto the piezoelectric components, the counter-piezoelectric effect of the piezoelectric components will make the combining surface of the mechanism produce mechanism vibration and separation, and this makes the load end stop rotating in use as clutch and the load end produce no braking effect in use as brake.

Owner:张国财

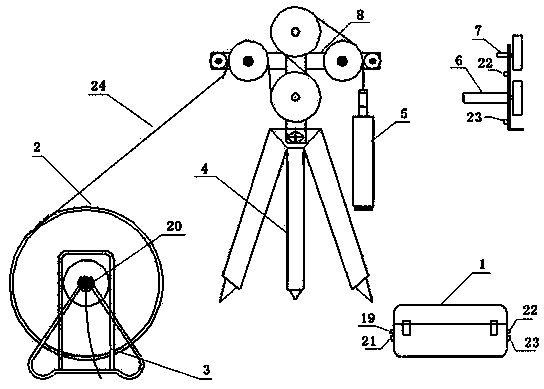

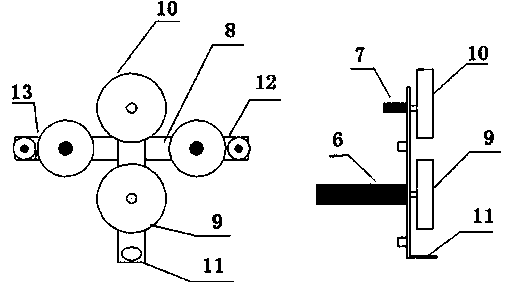

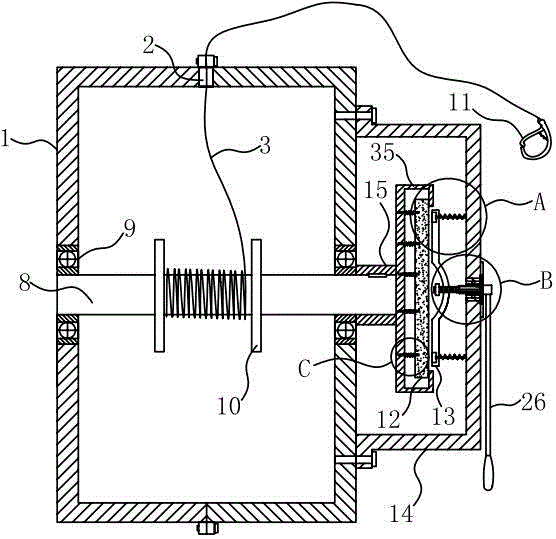

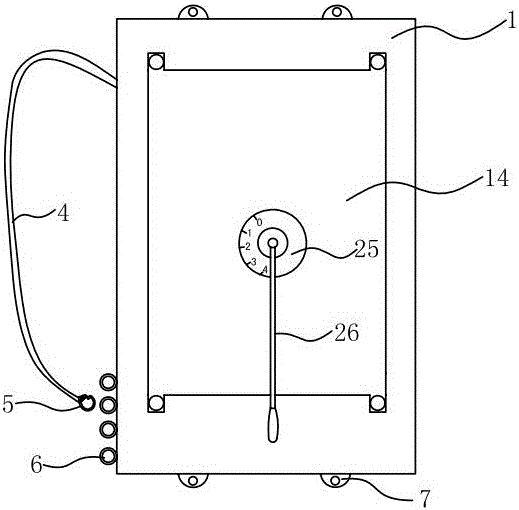

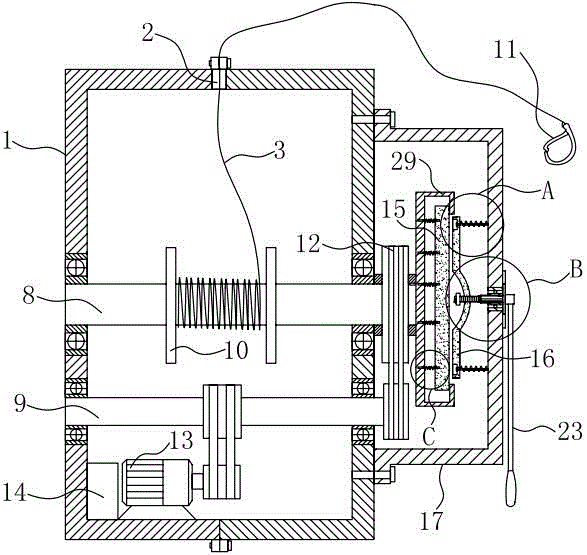

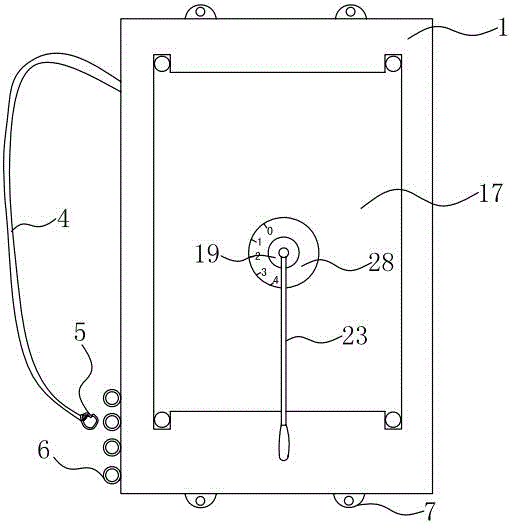

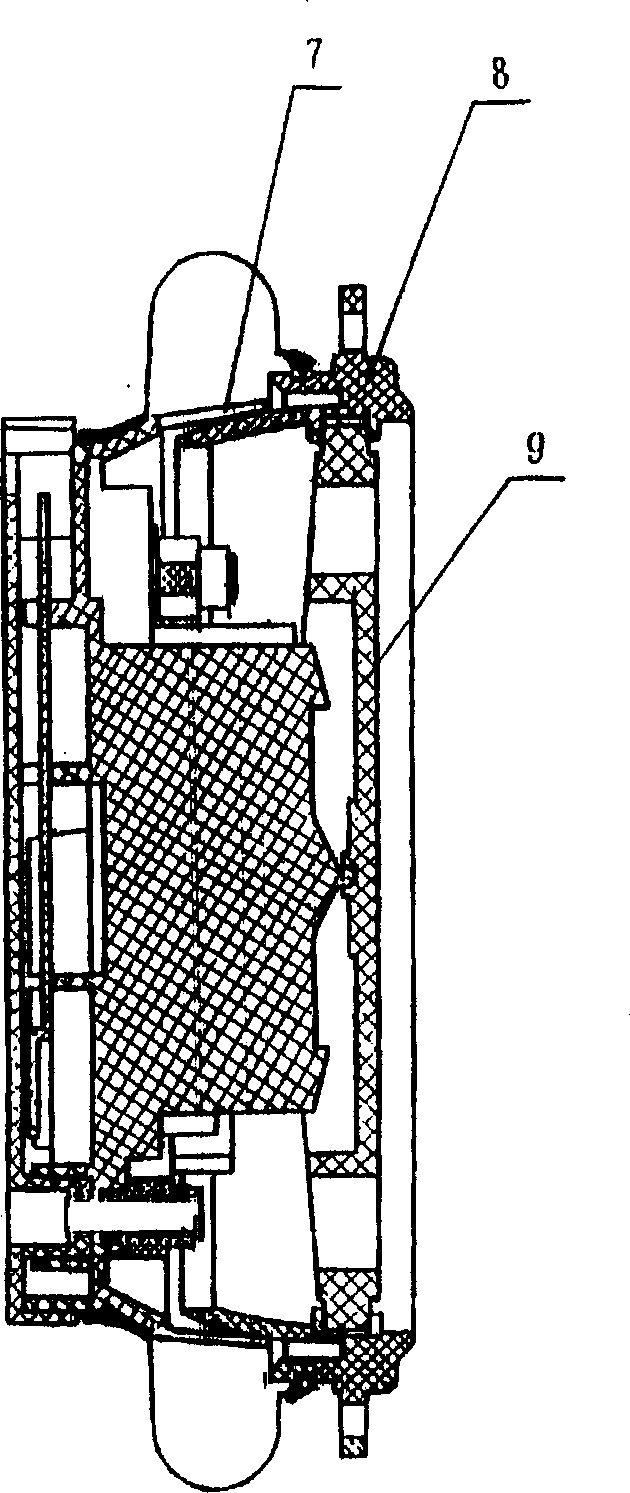

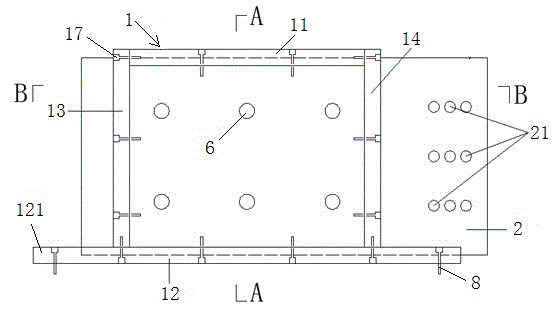

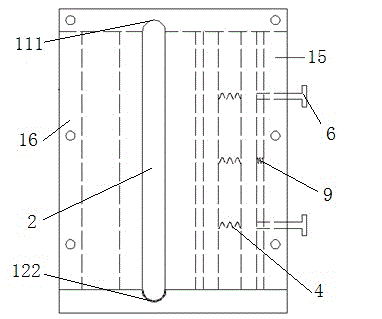

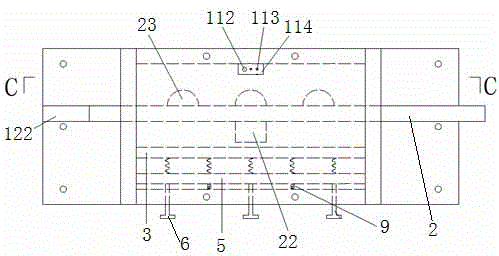

Intelligent drilling television imaging instrument

InactiveCN103628861ASolve foggingSolve the disadvantages of being easily scratched by the well wallConstructionsGlass coverEngineering

The invention relates to an intelligent drilling television imaging instrument, which mainly consists of a main controller, an underground probe, an underground cable, a windlass, a hub, a stepper motor, a depth counter and a tripod. The main controller is used for collecting and storing the information such as image splicing, video, depth and azimuth angle; the underground cable is used for supplying power to the probe and transmitting a control order, video, angle and the like; the underground probe is used for shooting a picture and video and recording the underground azimuth angle and transmitting the information to an industrial control computer through the cable; the depth counter is used for recording the underground depth of the underground probe; the stepper motor is used for controlling the probe to ascend and descend at a constant speed. An open-type lens is directly arranged in the water, and no glass cover is arranged in front of the lens, so that a shot image of a well wall is clearer, and the color retention is more authentic; a combined-type light source is adopted, so that the well wall and the underground situation can be directly observed; by adopting the unique stepper motor and the depth counting hub device, the probe can be lowered and lifted at a constant speed, and the images are completely spliced; by introducing electronic rock core library software, an electronic rock core file is established.

Owner:YUEYANG AOCHENG TECH

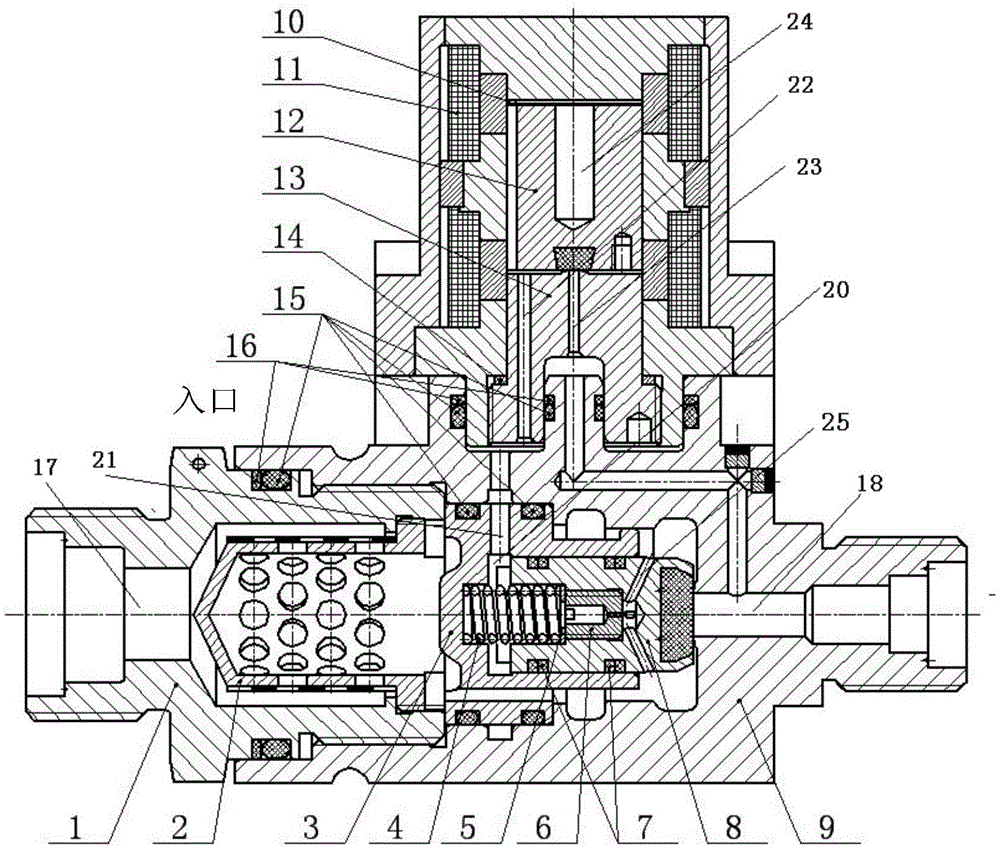

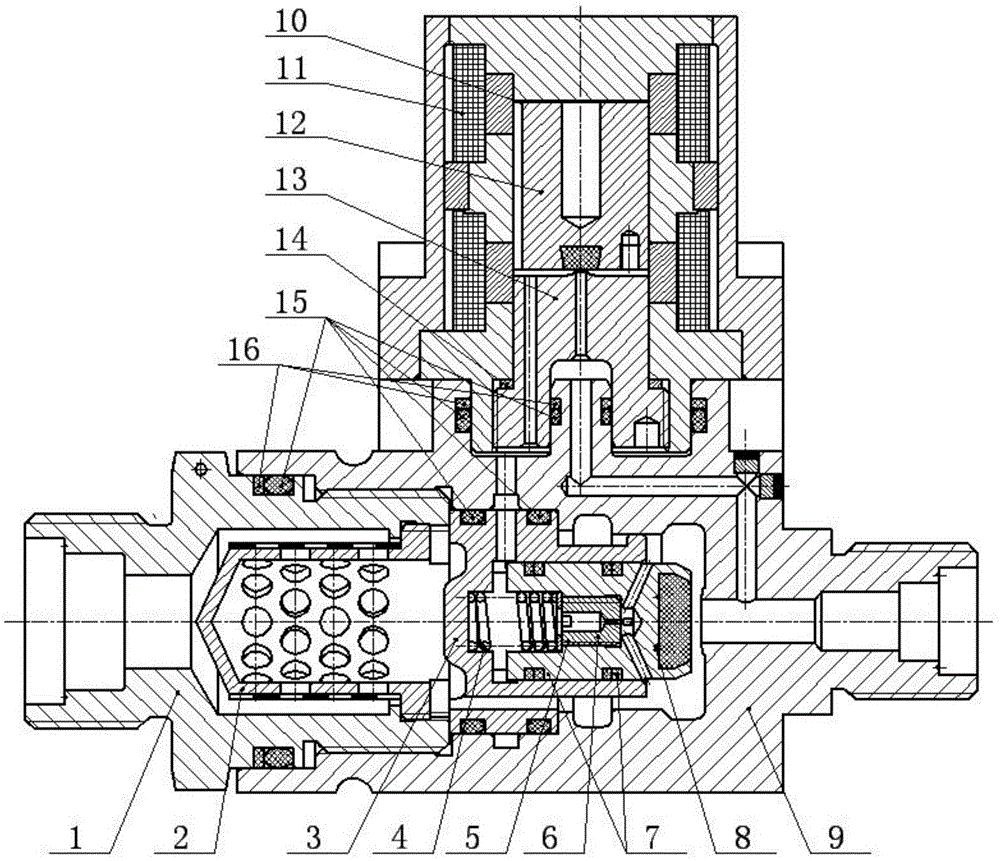

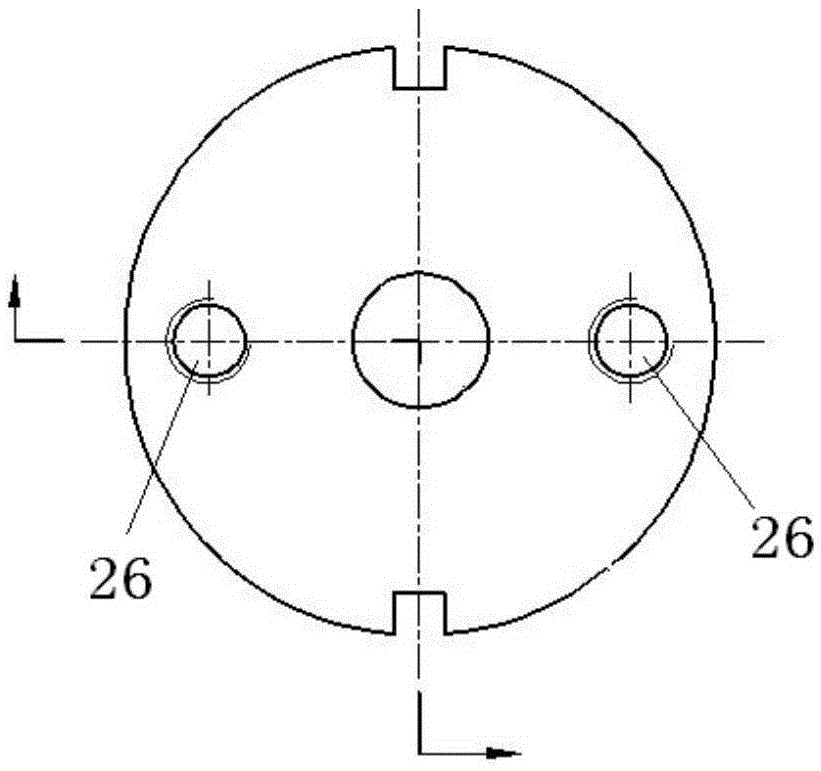

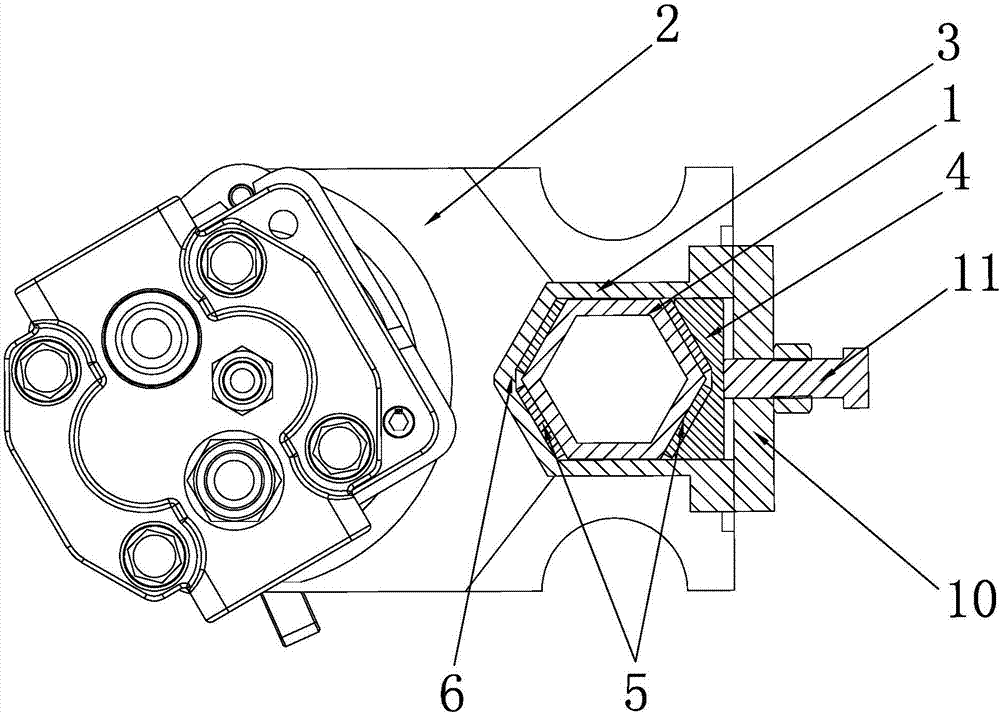

Built-in pilot operated solenoid valve

ActiveCN105570470ASimple structureSmall sizeOperating means/releasing devices for valvesEqualizing valvesCurrent limitingSolenoid valve

The invention discloses a built-in pilot operated solenoid valve with a self-locking function. The built-in pilot operated solenoid valve mainly consists of a primary valve body, a filter neck, a filter, a valve bush, a cylindrical spring, a spring force regulating pad, a current-limiting pin, current blocking rings, a primary valve element, a secondary valve coil assembly, a magnetism isolating pad, a secondary valve element and a secondary valve seat, wherein a secondary valve adopts a coil and permanent magnet combined drive source, has a bistable-state passive self-holding function, and power can be provided for state shifting by two coils. By virtue of matching between mounting force of the current-limiting pin and mounting force of the cylindrical spring, reliable action of a primary valve is realized. Under a small-flow working condition, a medium can flow to the downstream through a channel between the current-limiting pin and the secondary valve. A reverse sealing structure made of a metal-hard plastic can give consideration to gastight requirements of high-pressure and low-pressure working conditions. The product can be used gas and liquid-path switch valves with large-flow multi-action needs, and is especially suitable for a high-pressure medium. By virtue of interface adaptive improvement, the built-in pilot operated solenoid valve further can be used as a control valve of an attitude and orbit control liquid rocket engine.

Owner:XIAN AEROSPACE PROPULSION INST

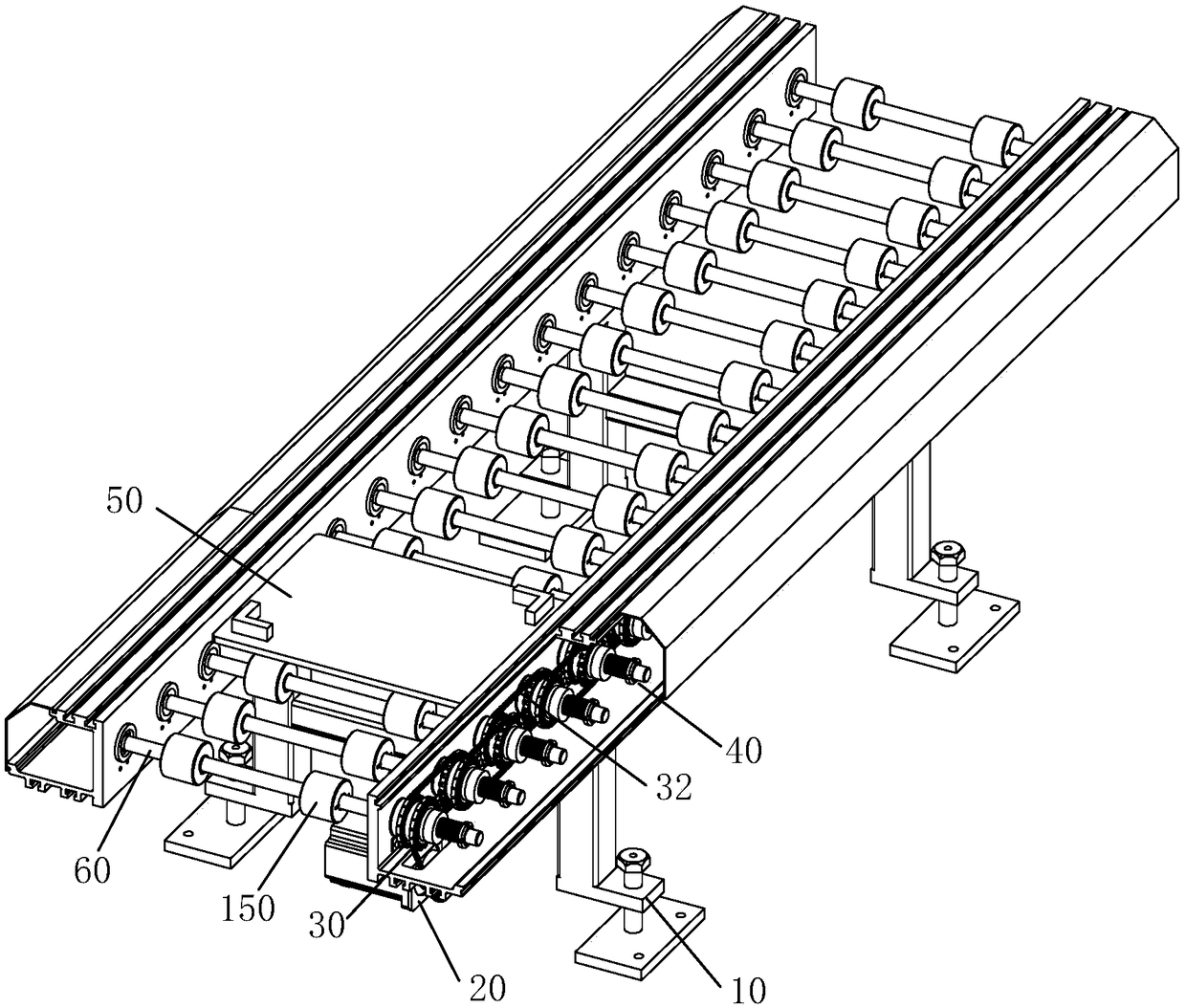

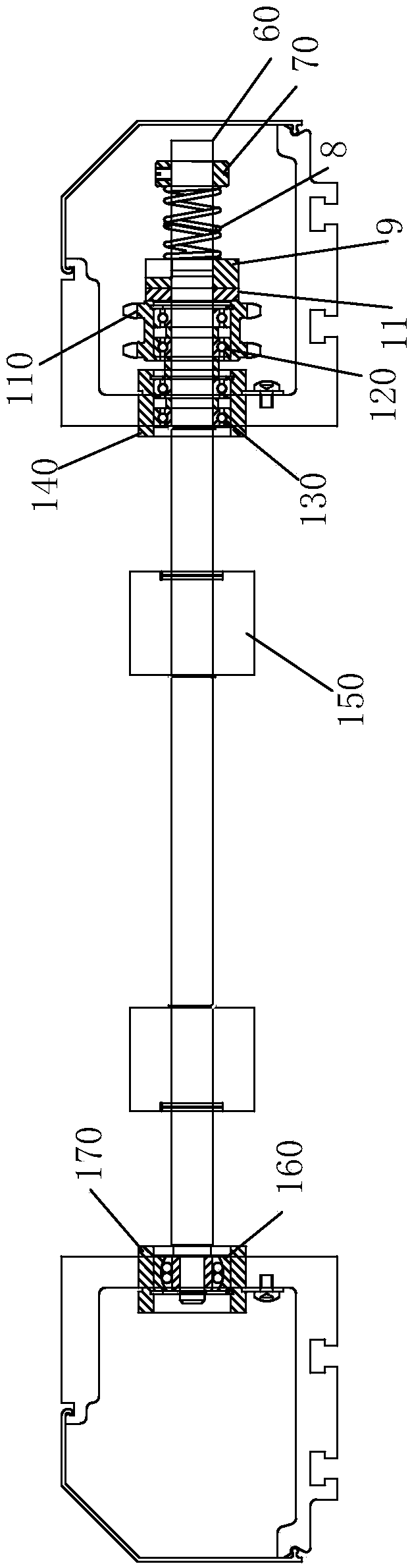

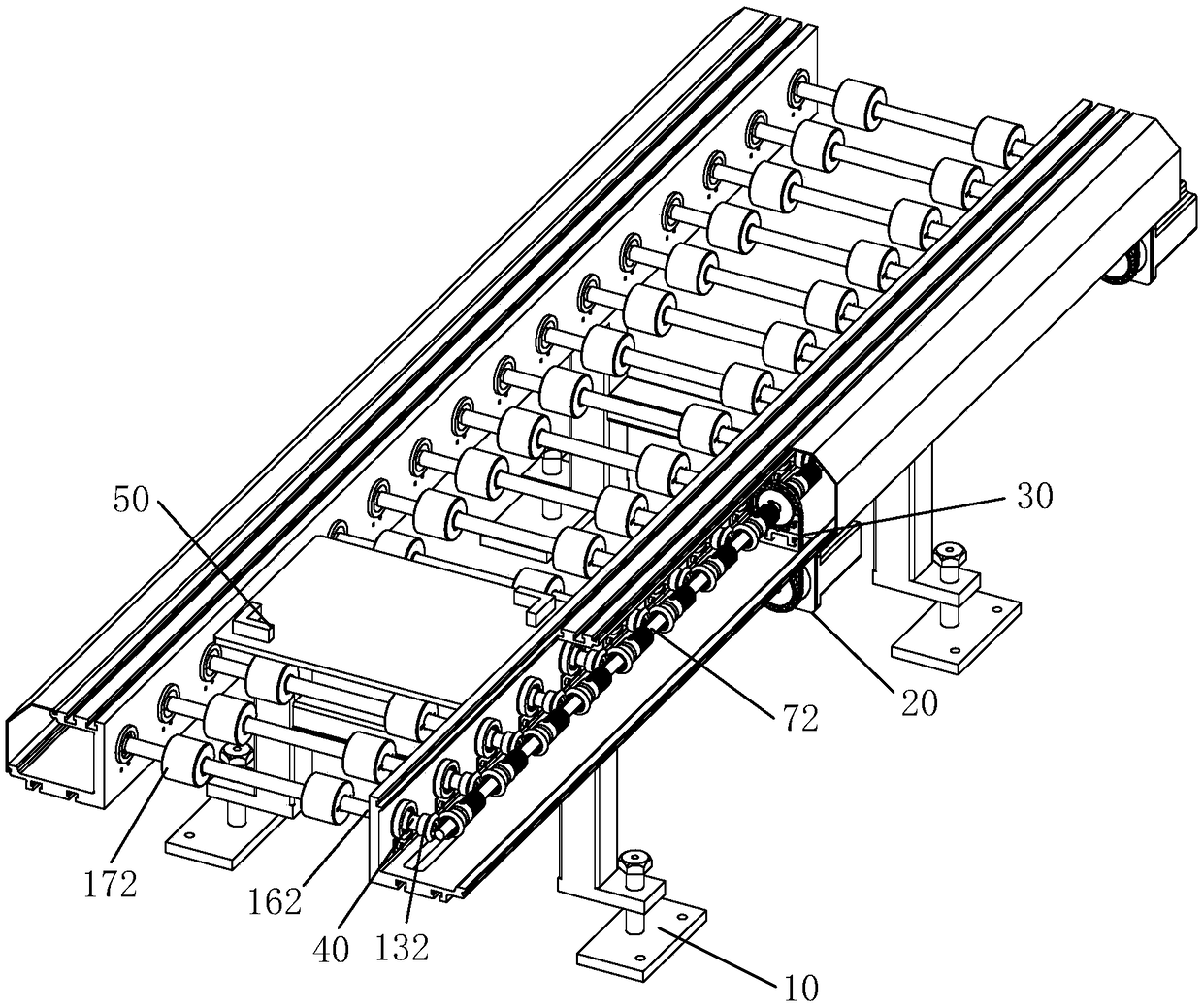

Automatic tool conveying assembly line

The invention discloses an automatic tool conveying assembly line. The automatic tool conveying assembly line comprises assembly line supports. A motor power assembly, a shaft driving assembly and a plurality of transmission shaft assemblies which are arranged side by side are mounted on the assembly line supports. Each transmission shaft assembly comprises a transmission shaft. The shaft drivingassembly comprises a power transmission piece, a shaft connecting piece and a transmission friction assembly. The transmission friction assembly is connected with the power transmission piece and theshaft connecting piece through frictional transmission. The frictional transmission force of the transmission friction assembly is smaller than or equal to the maximum power load of the motor power assembly. When the frictional force exceeds the maximum frictional force of the transmission friction assembly under the condition that a tool is blocked or gets stuck, power transmitted through friction is cut off, the power transmission piece still rotates, and the load of the motor is not changed, so that the motor is prevented from being burnt down; and meanwhile, the cut-off power stops the transmission shaft from rotating, and thus, abrasion of the tool is avoided. Thus, abnormal abrasion between transmission wheels and the tool is prevented, and the operating stability of the assembly line is improved.

Owner:WEIFANG LOKOMO PRECISION IND

Hinge and an electronic device with the same

InactiveUS8082627B2Less preciseness in sizeReduce manufacturing costWing fastenersSubstation equipmentManufacturing cost reductionEngineering

A hinge is mounted in an electronic device with a cover and a base. The hinge has a first pivoting assembly, a second pivoting assembly and a resilient unit. The first pivoting assembly has a resilient plug. The resilient plug is mounted between the second pivoting assembly and the resilient unit to provide friction and to keep the second pivoting assembly from departing from the first pivoting assembly. The friction is adjusted by changing the resilience of the resilient plug or the resilient unit, or by changing the thickness of the resilient plug. Therefore, preciseness of the size of other component is less required to reduce the manufacturing cost.

Owner:SHIN ZU SHING

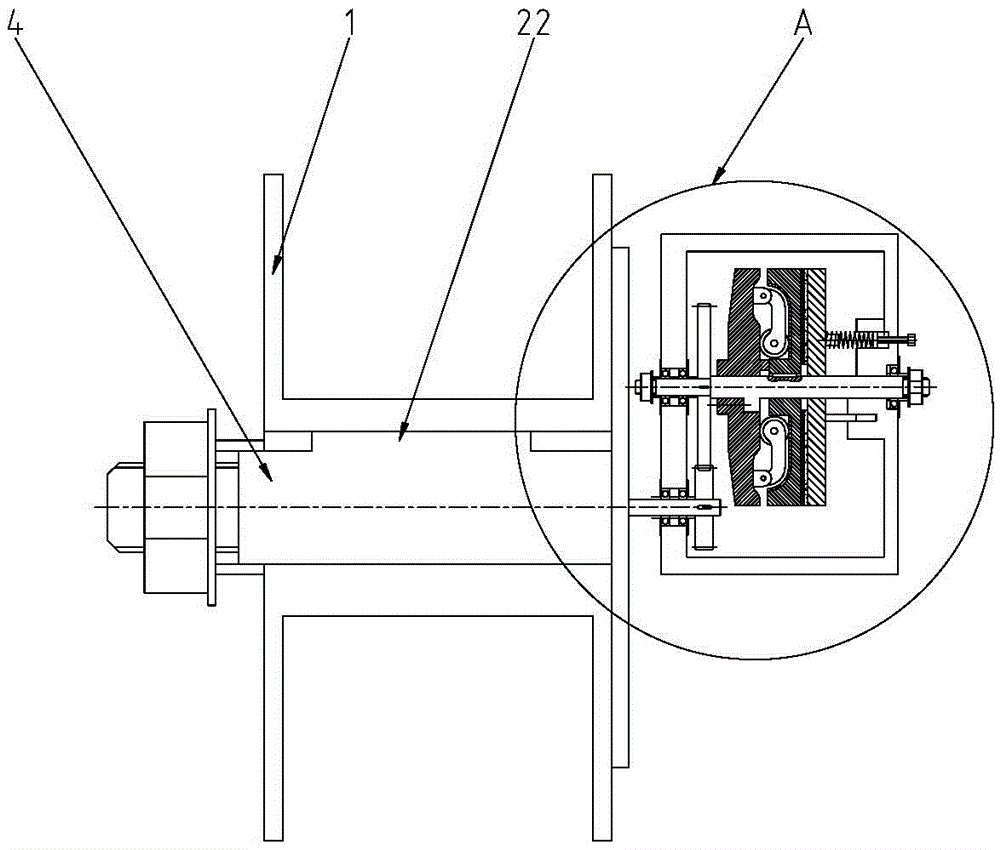

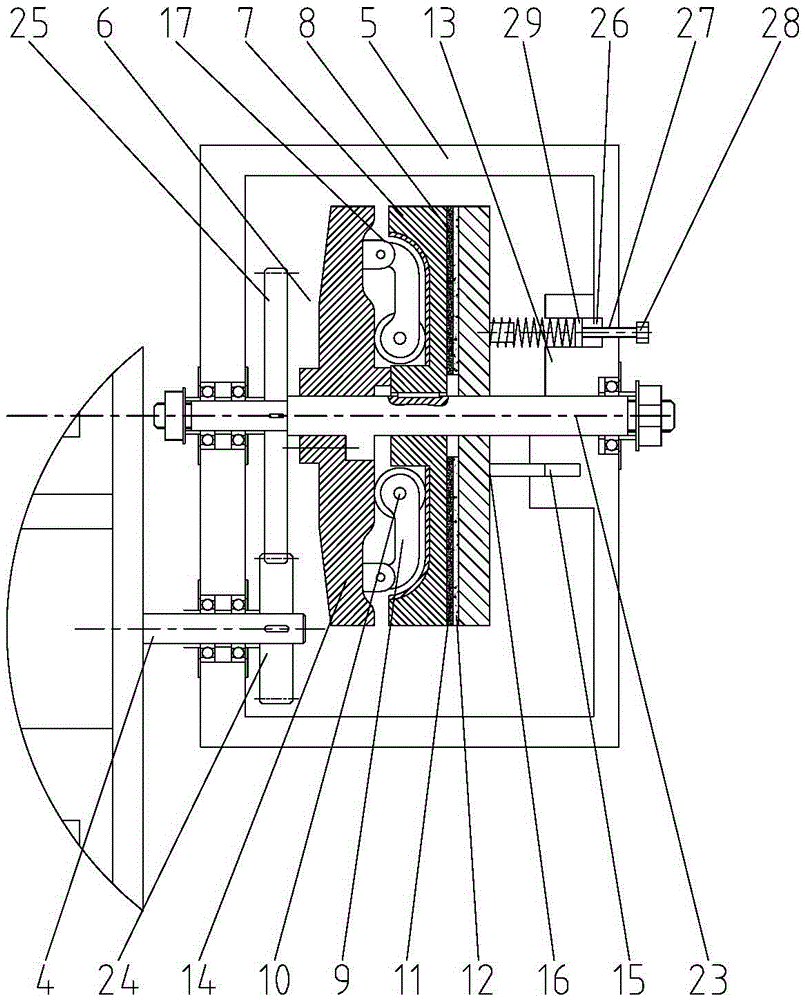

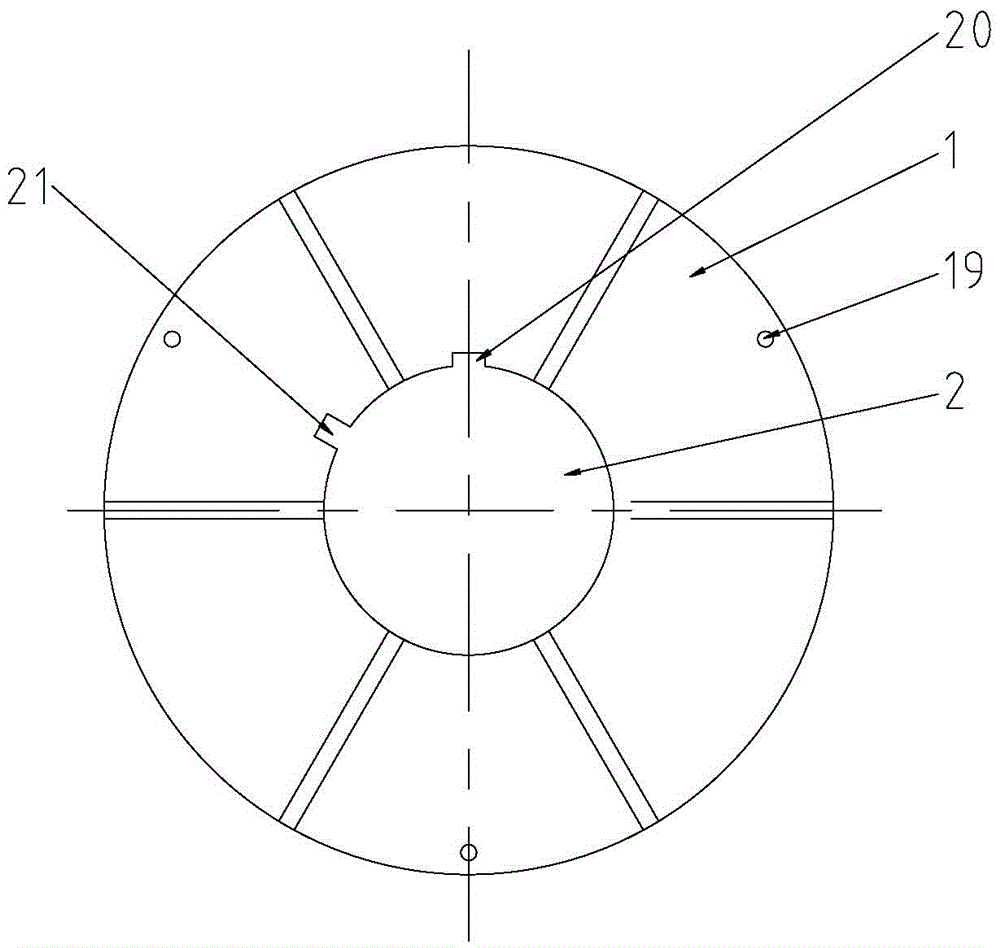

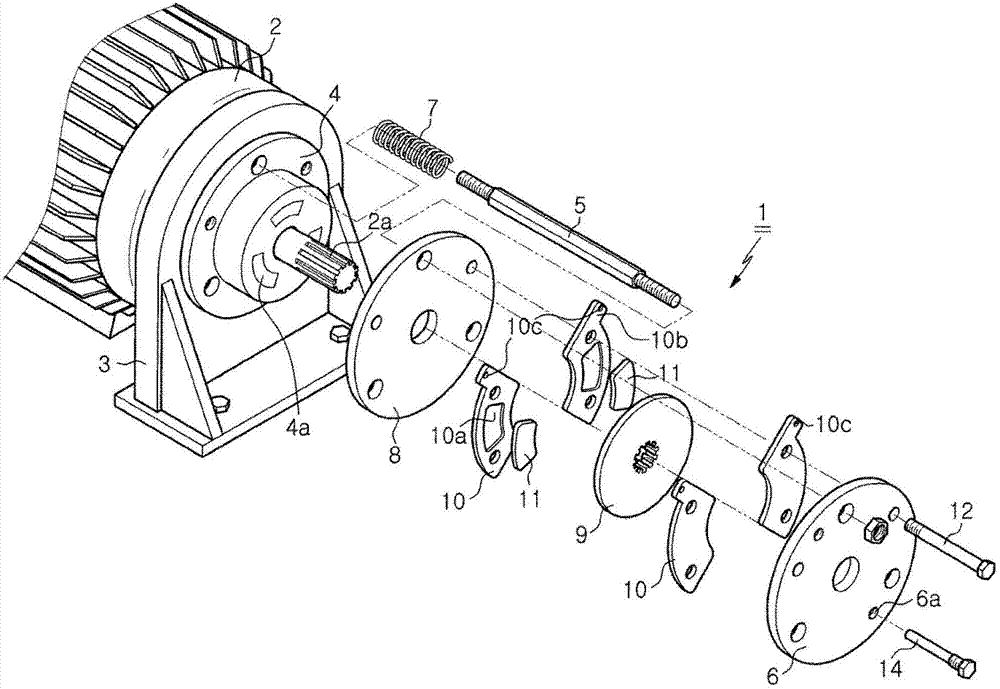

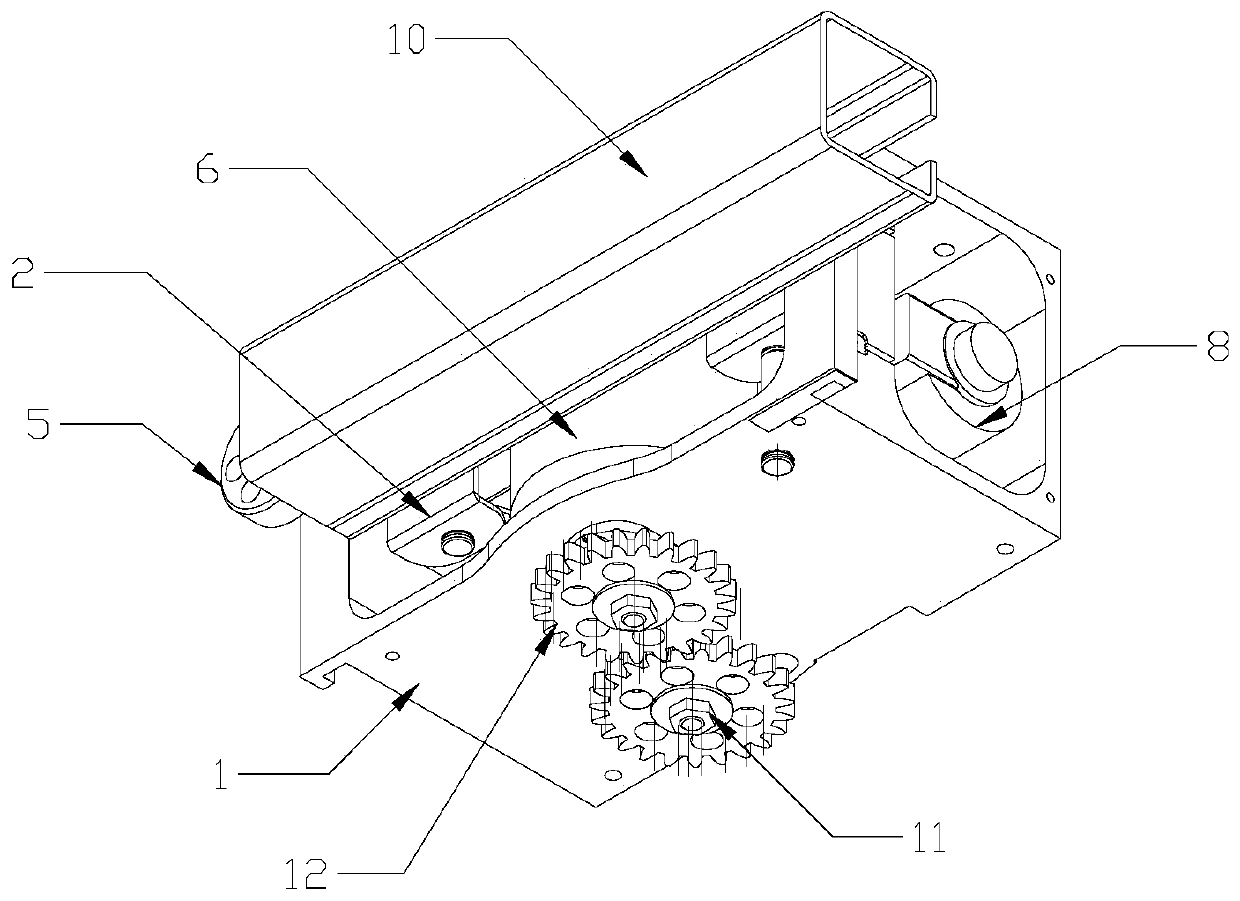

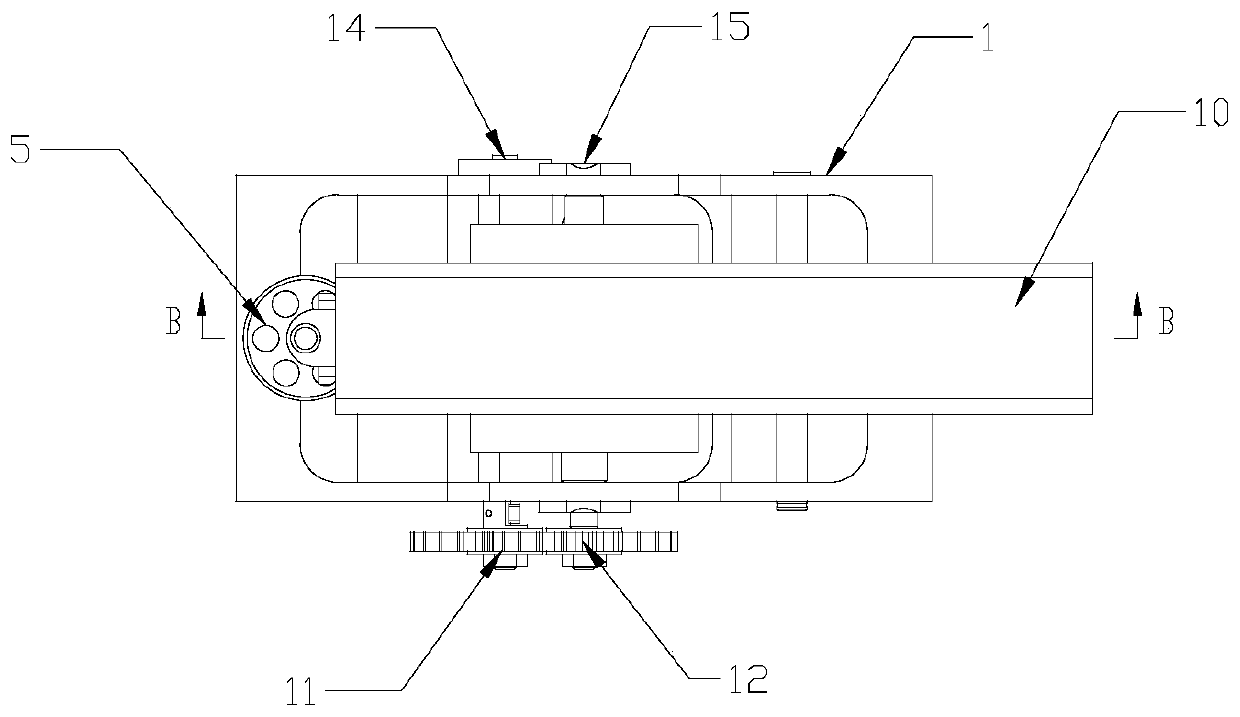

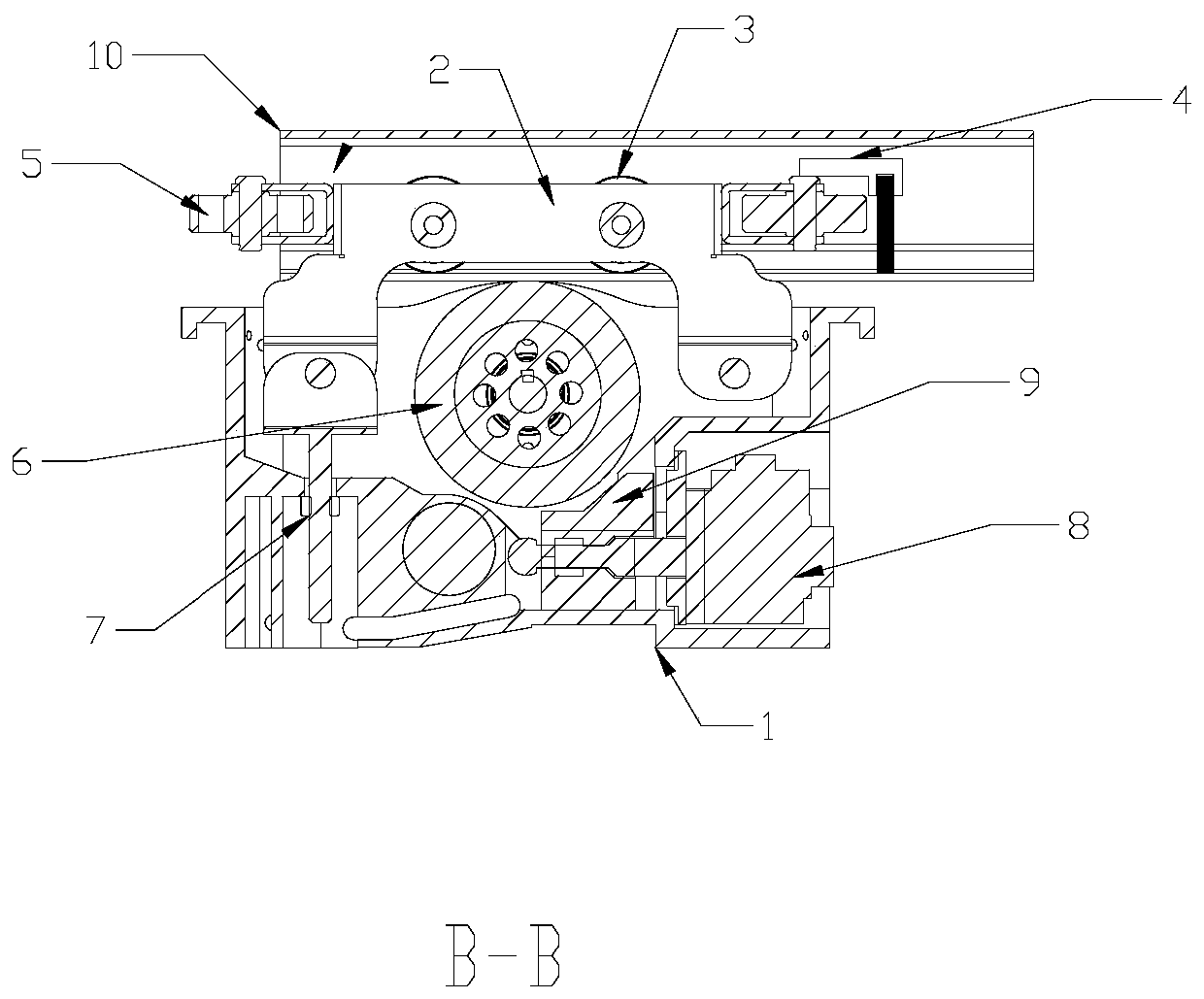

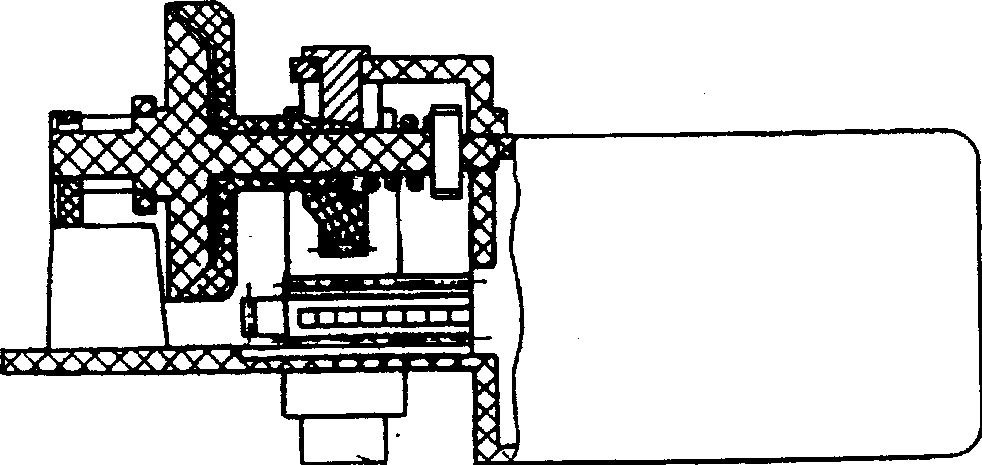

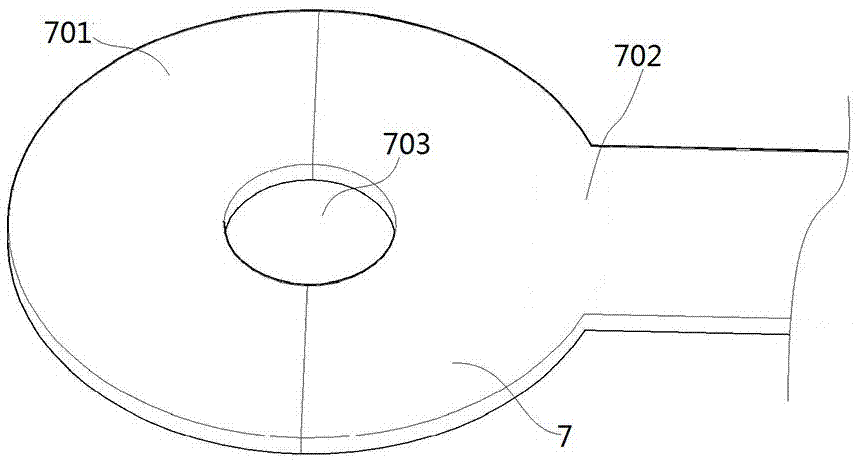

Adjustable self-adaptive wire spool system

InactiveCN105819271AIncrease frictionOvercome external forcesFilament handlingGear transmissionSelf adaptive

An adjustable self-adaptive wire spool system comprises a wire spool body. The wire spool body is provided with a center through hole. The peripheral wall of the wire spool body is provided with a wire winding groove. A winding shaft is arranged in the center through hole in a sleeved mode. A self-adaptive friction mechanism is mounted on the winding shaft and comprises a shell. A rotary shaft is arranged in the shell. A gear transmission mechanism is arranged between the rotary shaft and the winding shaft. The shell is further internally provided with a rotary arm disk, a friction disk I and a friction disk II. Rotary arm mechanisms are annularly and evenly distributed on the side face of the side, facing the friction disk I, of the rotary arm disk. Each rotary arm mechanism comprises a rotary arm located in the radial direction of the rotary arm disk, and one end of each rotary arm is in hinged connection with the rotary arm disk. Friction surfaces matched with each other are arranged between the friction disk I and the friction disk II. A spring and a sliding guide mechanism are arranged between the friction disk II and the shell. The shell is provided with a groove used for mounting of the spring. The bottom of the groove is provided with an adjusting mechanism used for adjusting pre-pressure exerted on the friction disk II by the spring.

Owner:CHONGQING CITY SOUTH FLAME RETARDANT WIRE & CABLE CO LTD

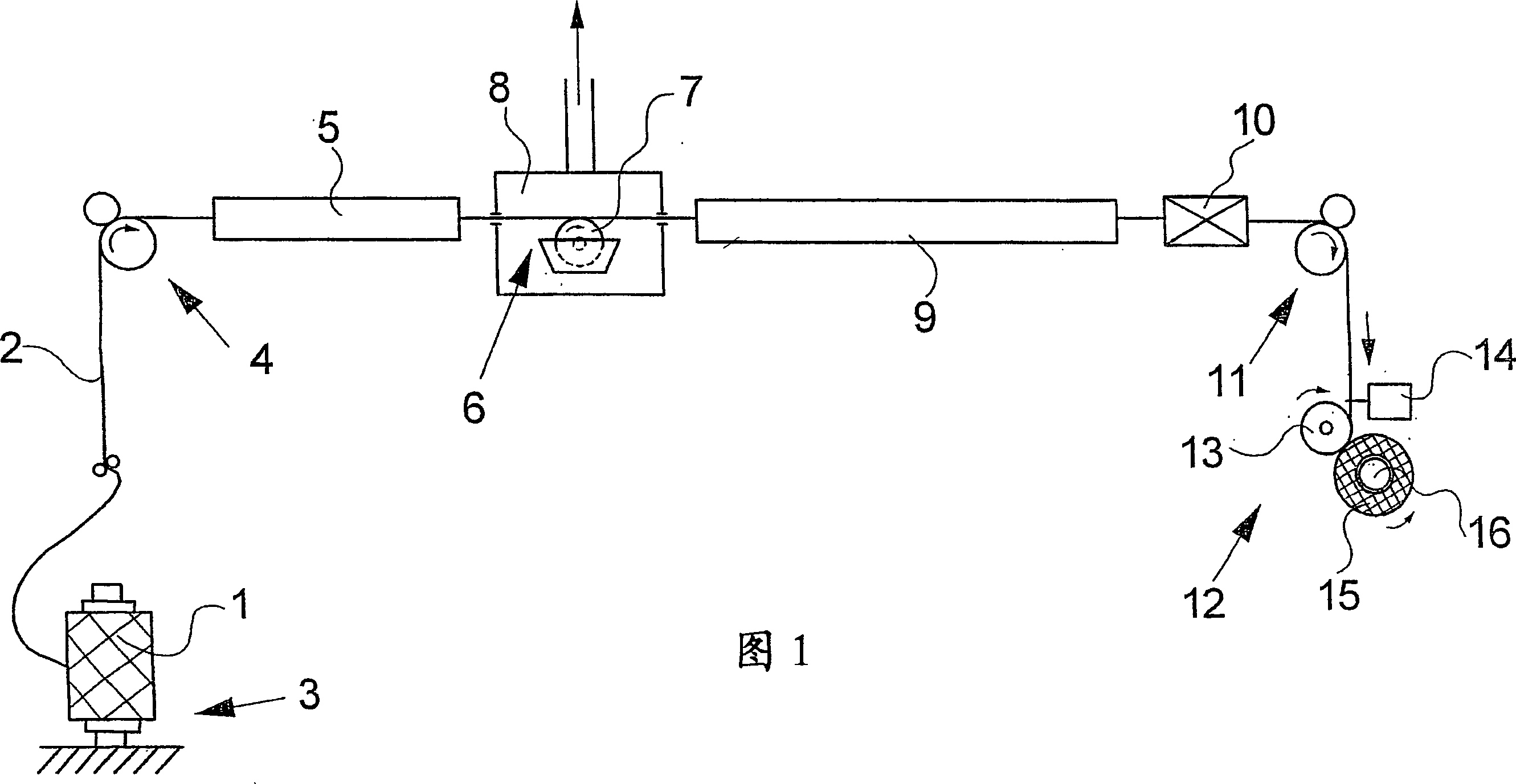

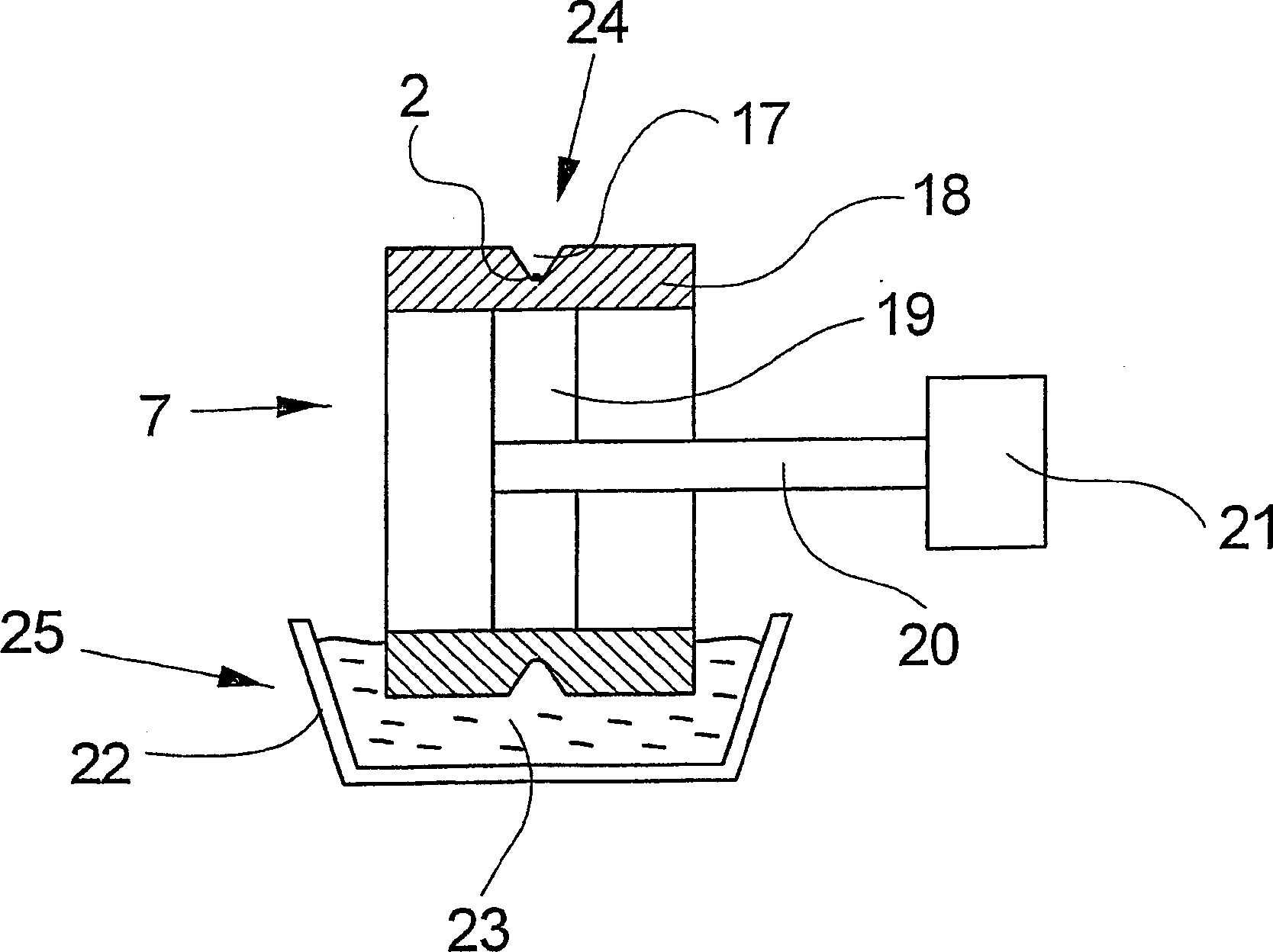

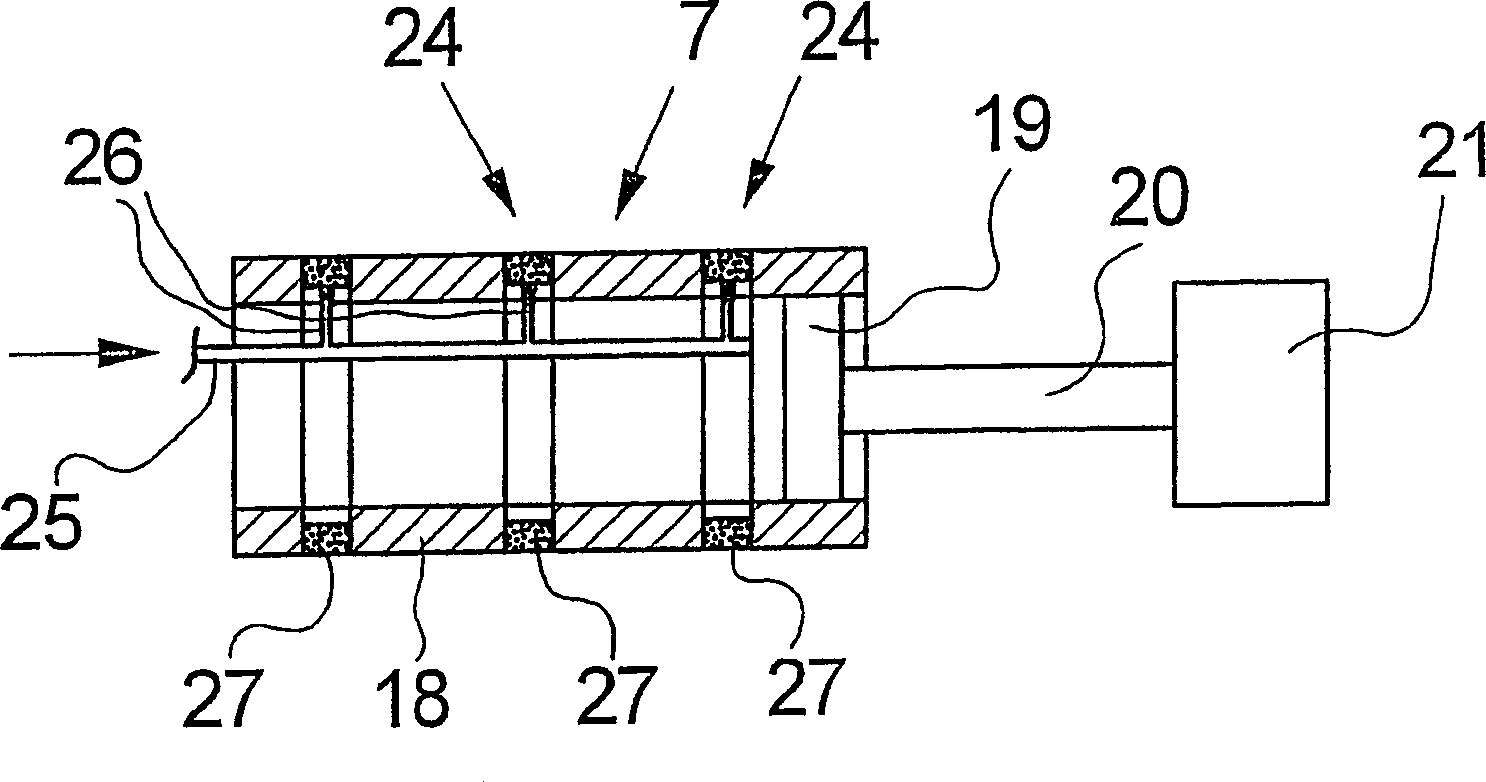

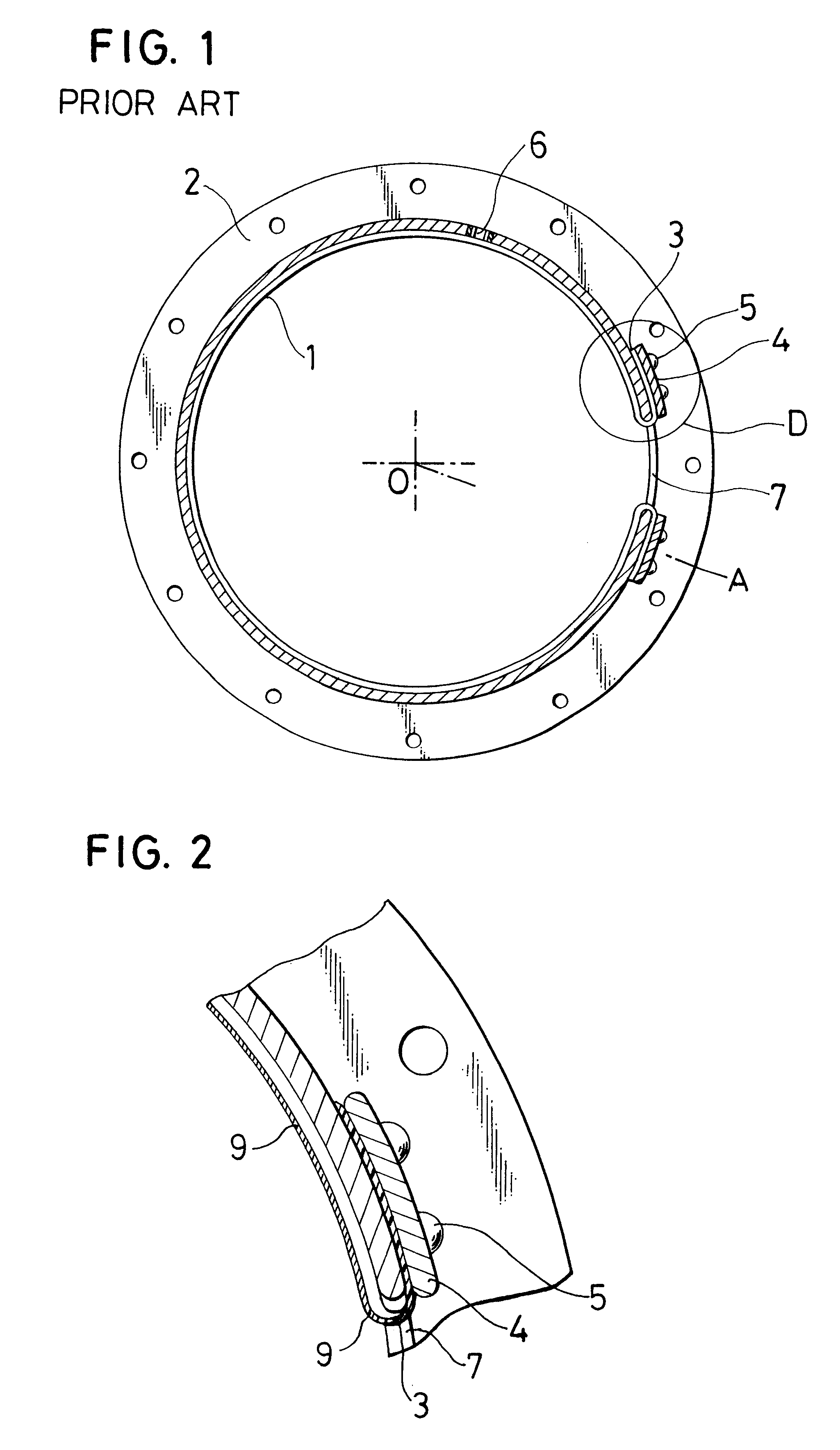

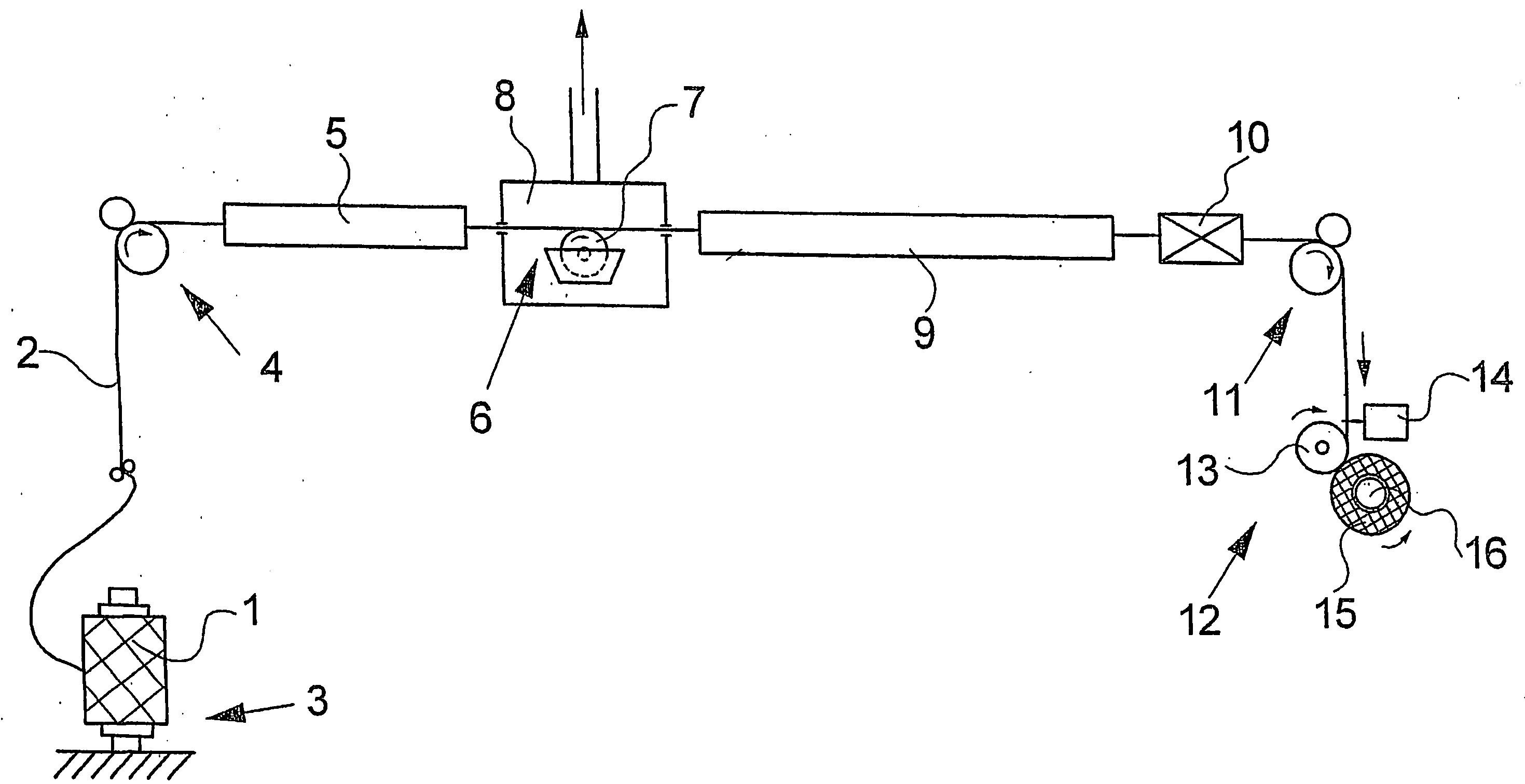

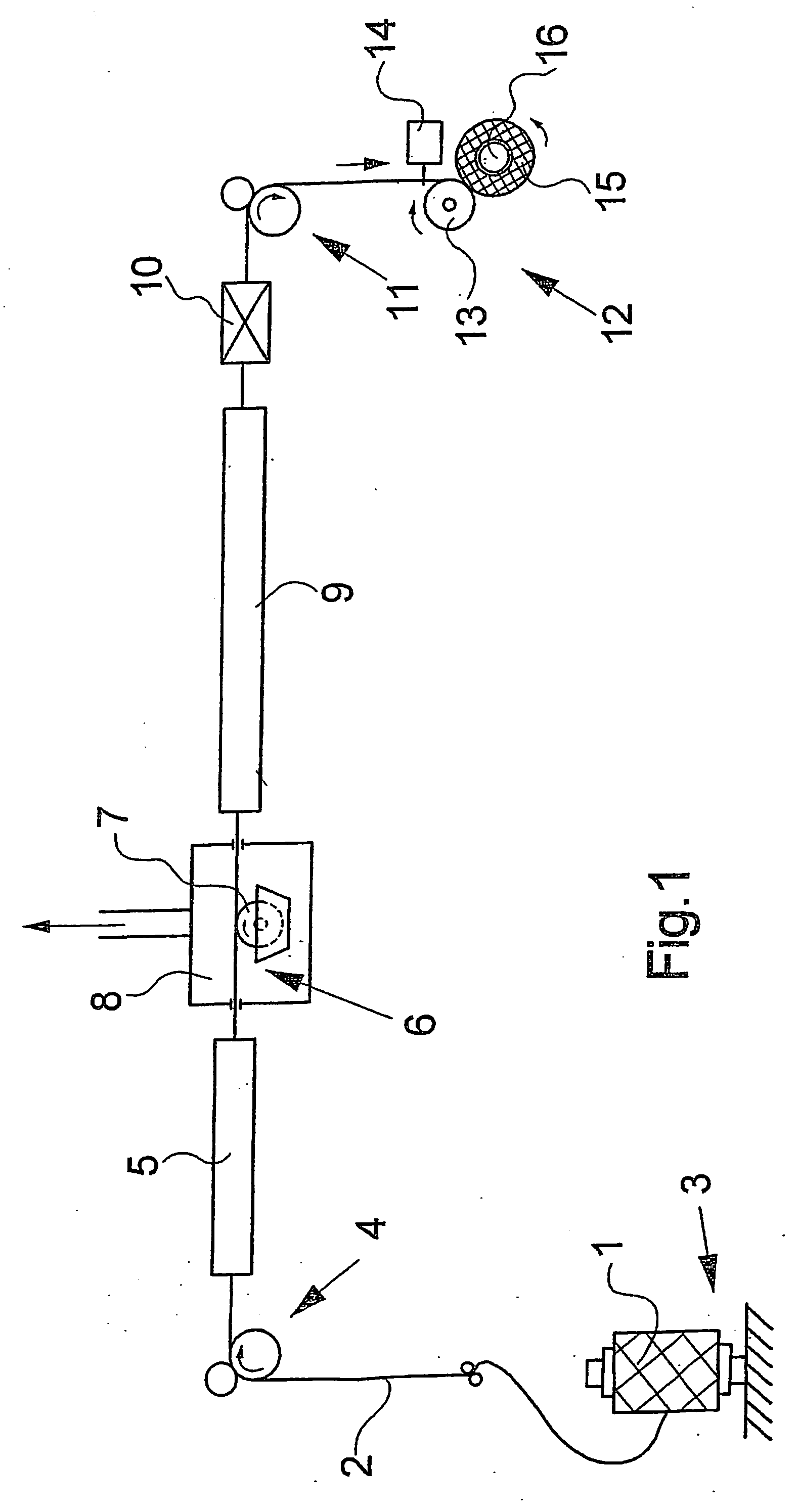

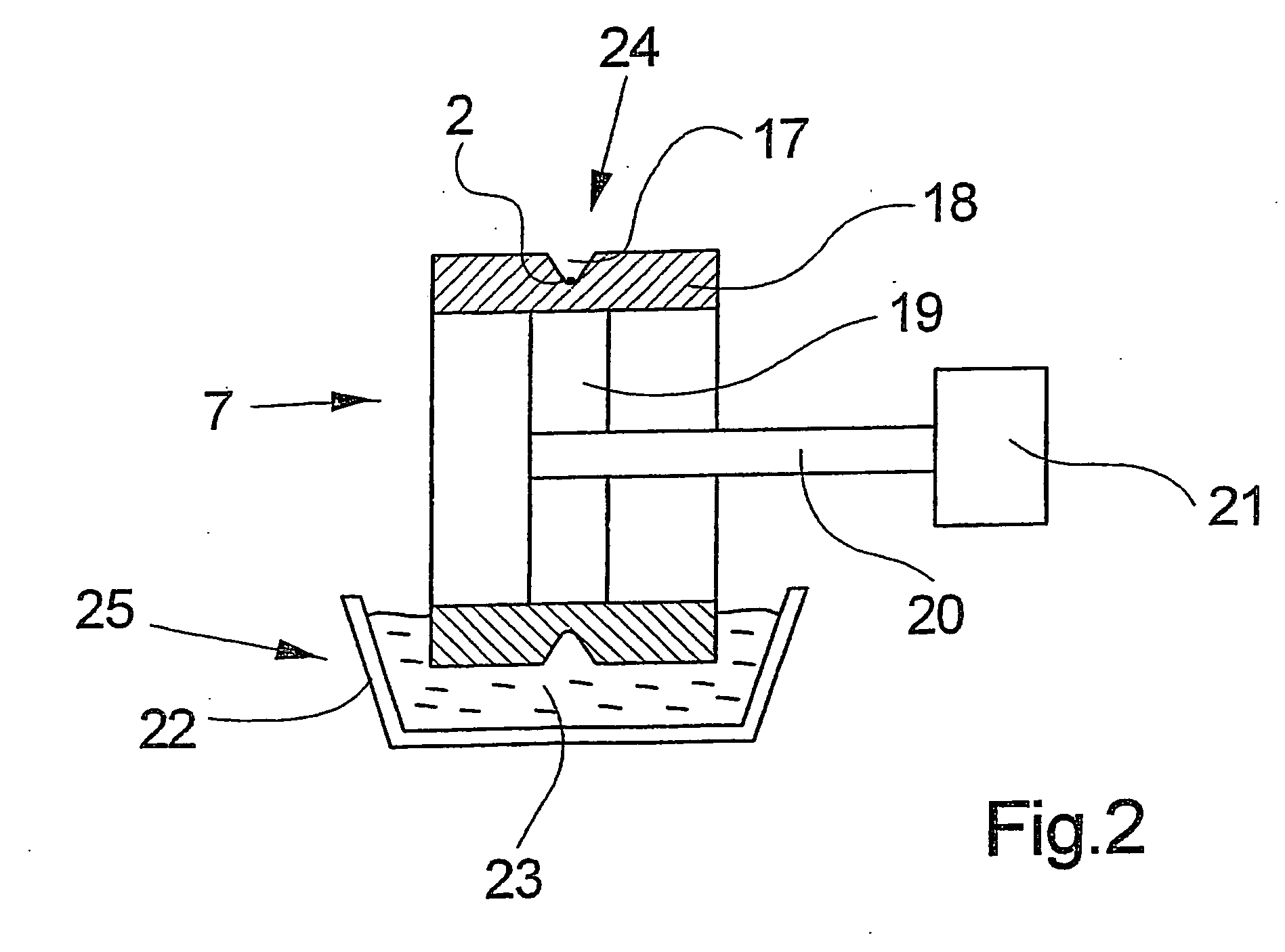

Yarn false twist texturing apparatus

InactiveCN1650055AContinuous uniform quantitativeAdjust to any degree of drynessLiquid/gas/vapor yarns/filaments treatmentCooling fluidWetting

A texturing apparatus for draw texturing a synthetic yarn. To this end, the texturing machine comprises a first feed system, a heating device, a cooling device, a texturing unit, a second feed system, and a takeup device for winding the textured yarn. Between the heating device and the cooling device, a wetting device is provided for wetting the heated yarn with a cooling fluid for purposes of precooling. The wetting device consists of a rotatable cooling cylinder which includes on its circumference a yarn track that contains a cooling fluid. The yarn can be wetted by contacting the yarn track. At the point of contact, the yarn friction is advantageously dependent on the relative speed between the yarn and the yarn track on the circumference of the cooling cylinder.

Owner:SAURER GMBH & CO KG

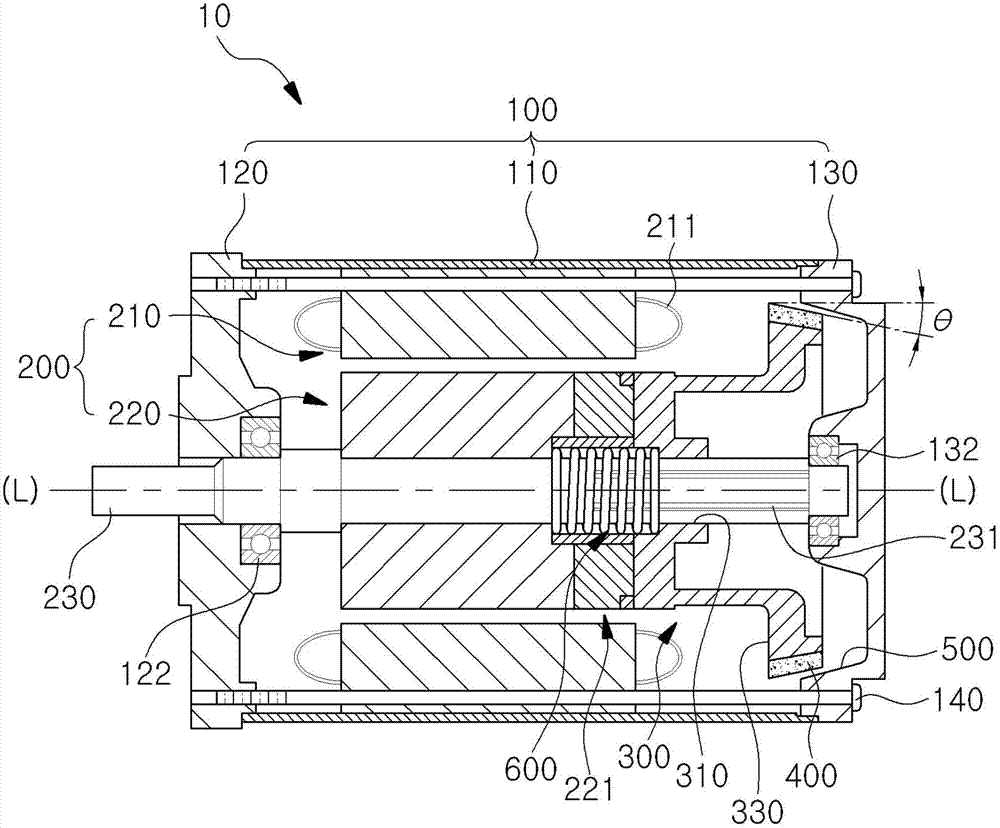

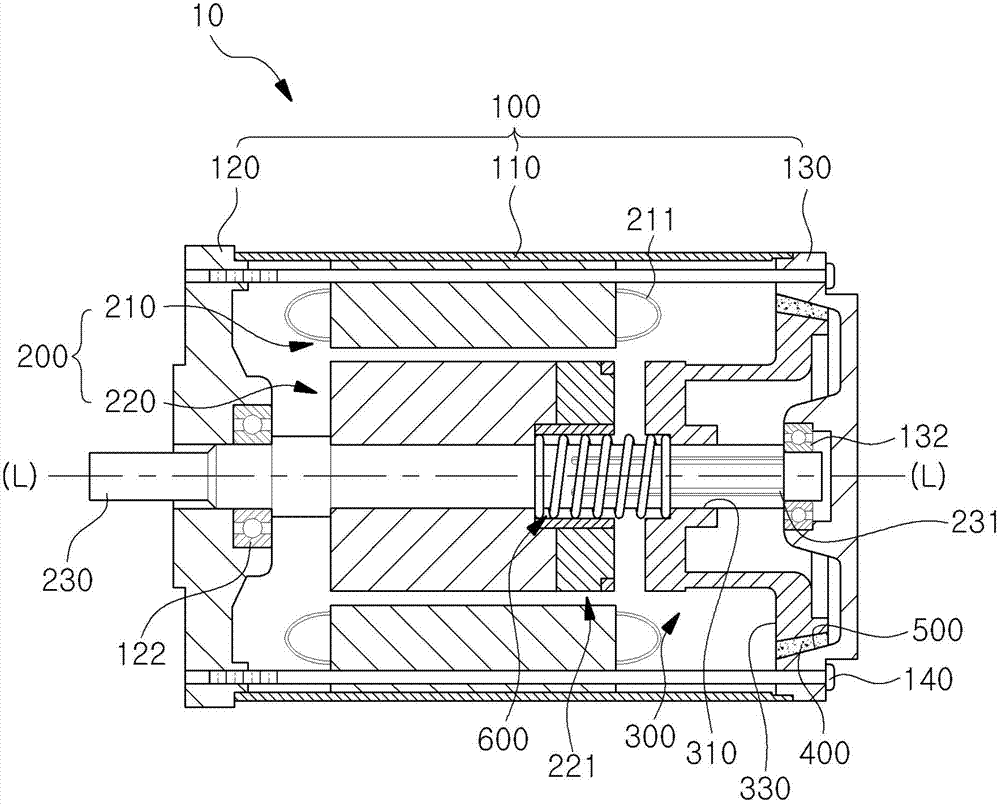

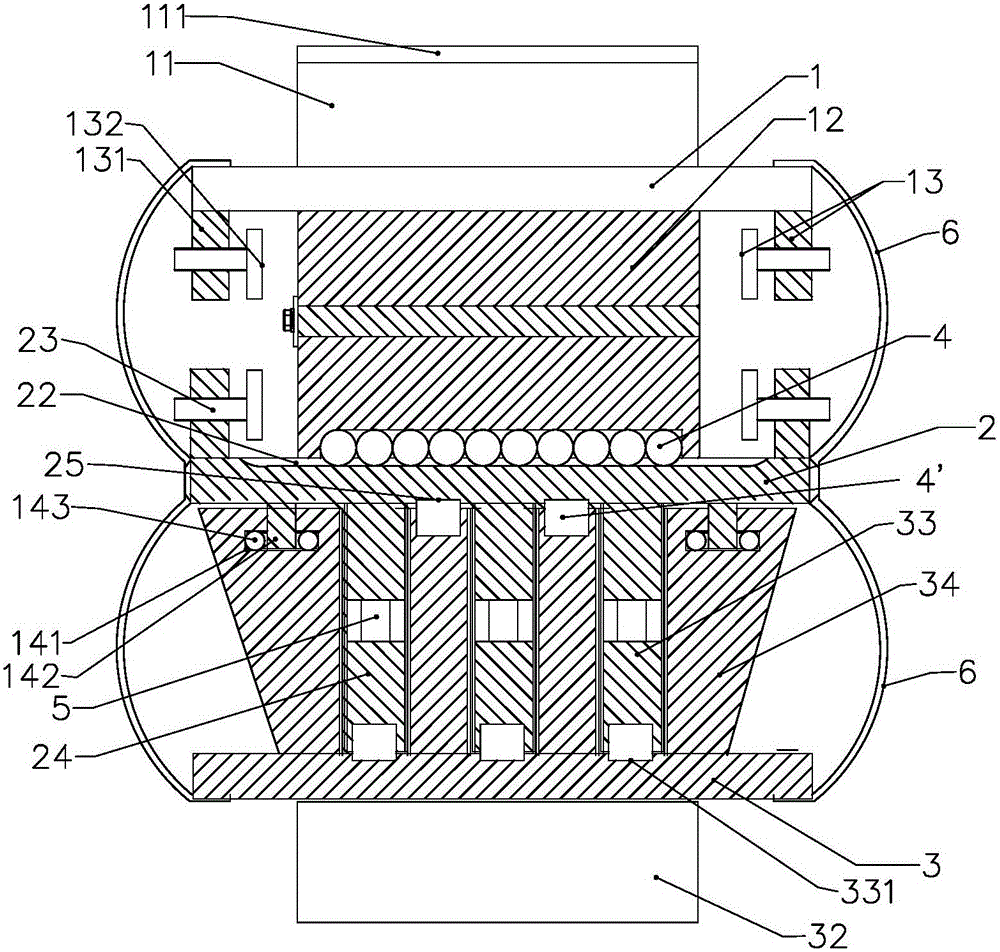

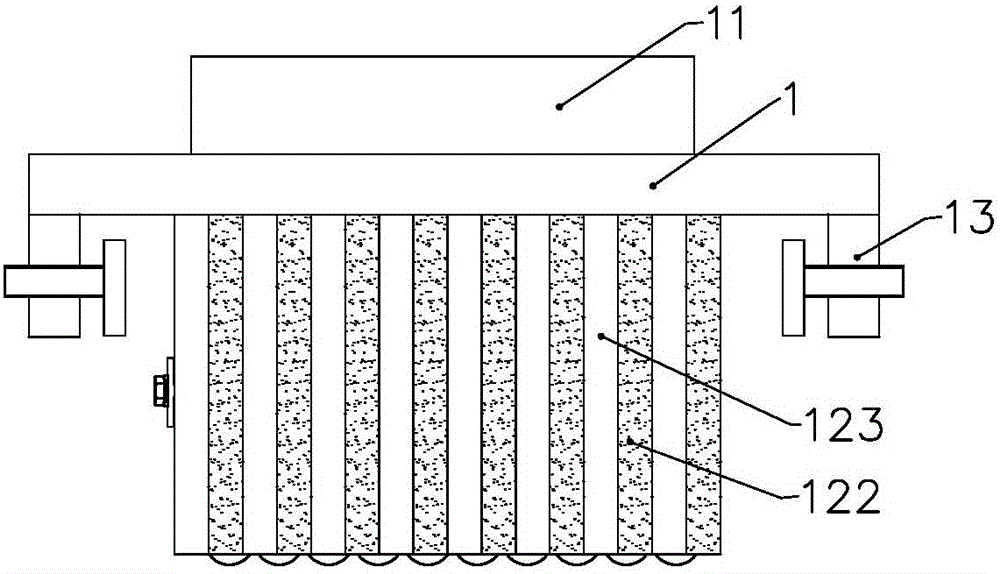

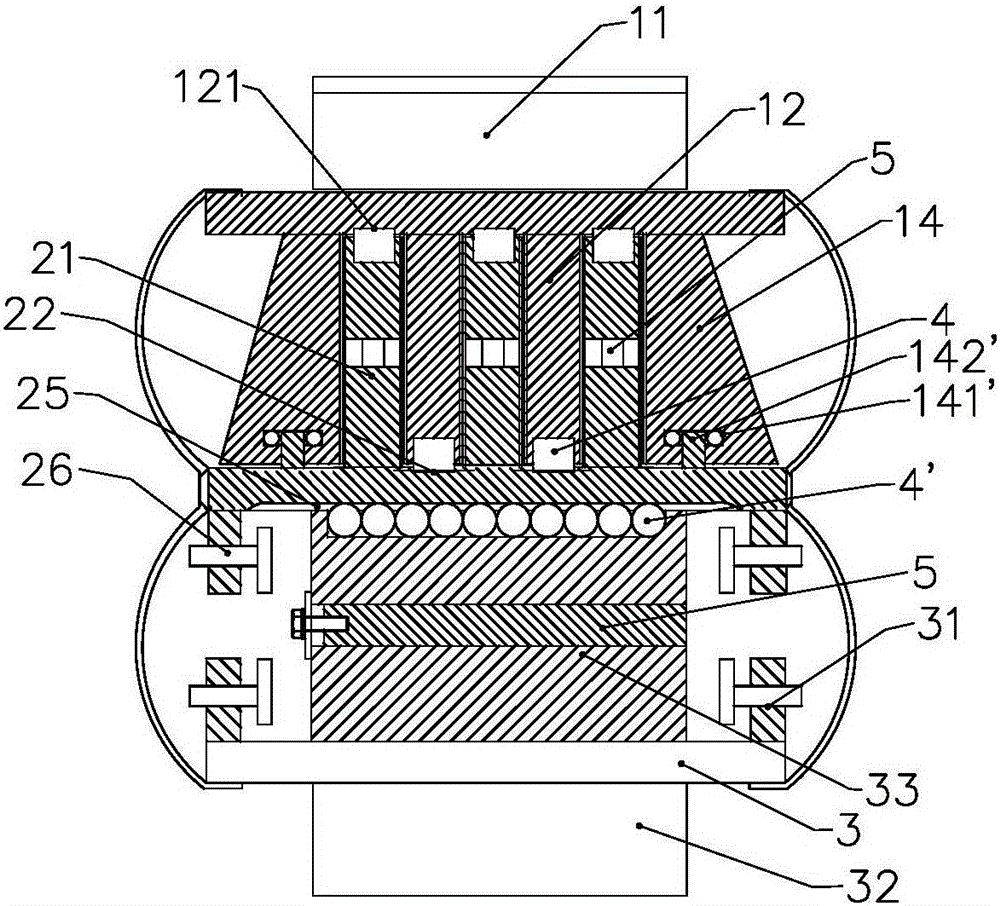

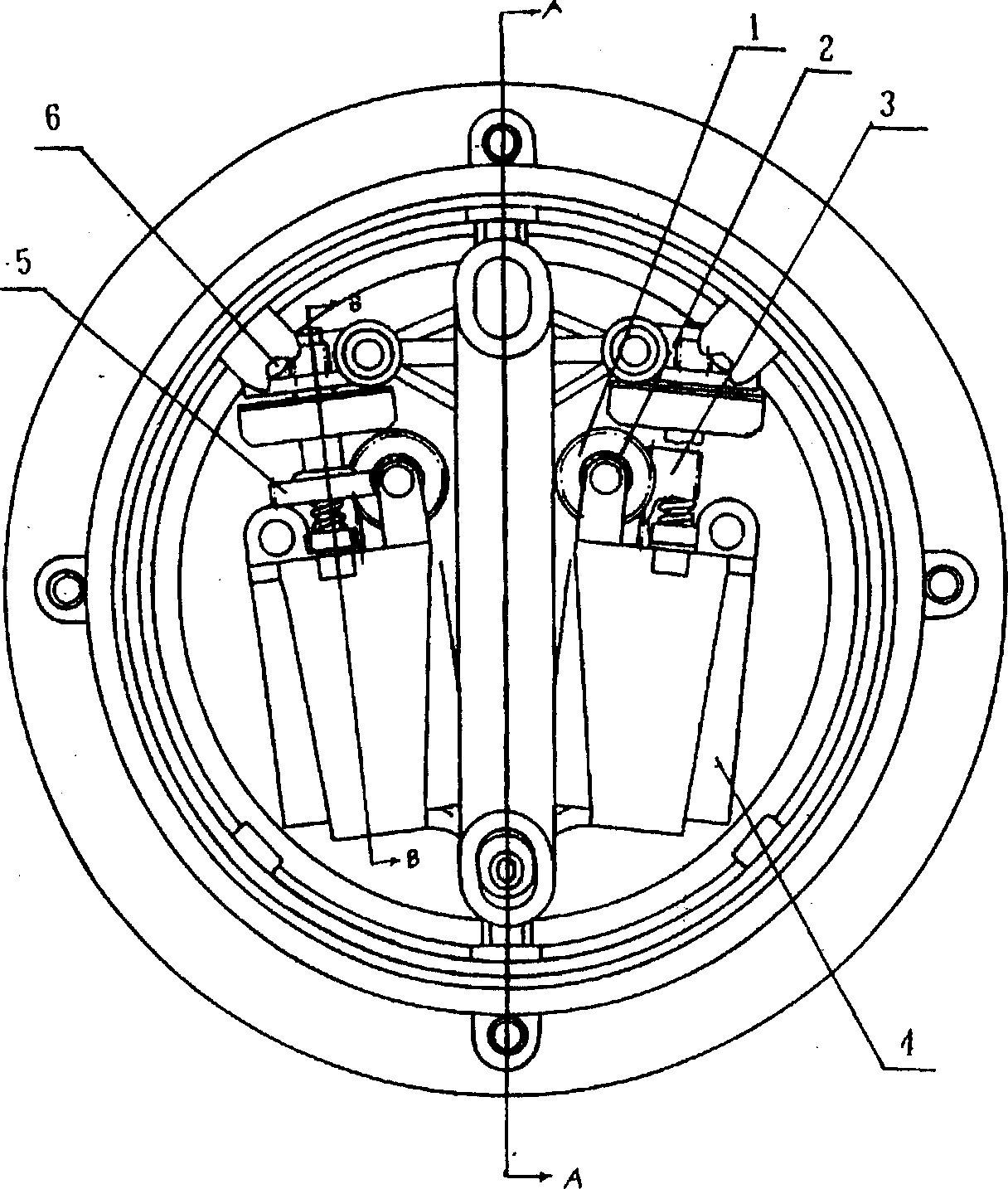

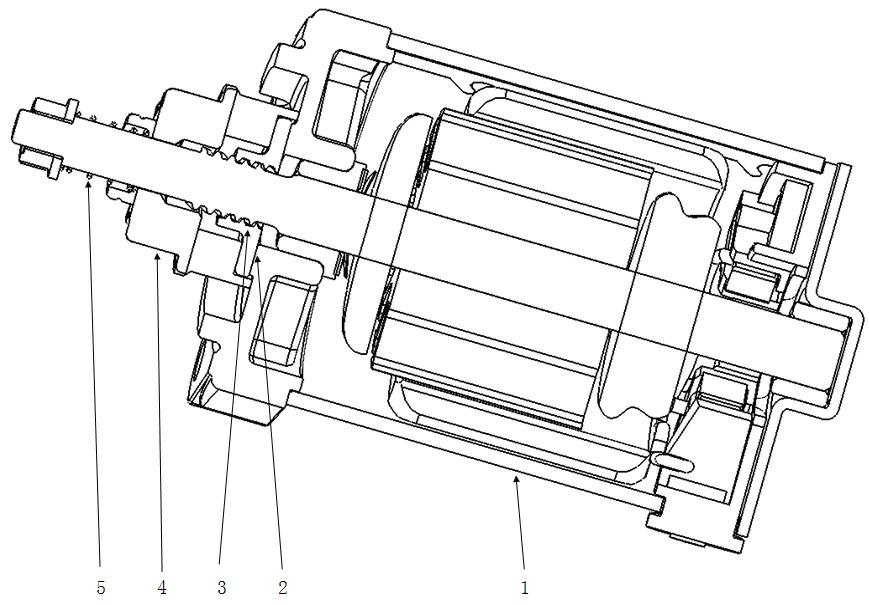

Electric break motor

ActiveCN103715823AMaximum braking torqueMiniaturizationAxially engaging brakesMechanical energy handlingEngineeringMotor shaft

The invention discloses an electric break motor. The motor comprises a case, a front cover and a rear cover; a stator inside the case, and a rotation driving unit of a rotor, wherein the rotation driving unit is in the middle of the stator, rotates through power supplied by a driving power source and is formed by connection in the middle penetrating the motor; a cylindrical clutch unit sliding vertically along extension of a motor shaft, made from magnetic material, moving along a rotor direction and pulled by a magnetic field formed on the rotor when power is supplied by the power source; a friction liner that reduces gradually toward the rear in terms of external diameter and is arranged, in an inclined manner, on the circumference of the other outer side of the clutch unit; a disc unit that gradually reduces in internal diameter toward the rear, is disposed, in an inclined manner, on the inner circumference of the rear cover to be opposite to the friction liner, and contacts the friction liner along with sliding of the clutch unit to generate friction; and a pressing spring between the rotor and the clutch unit on the motor shaft and applies pressure to the clutch unit toward the rear cover in an elastic manner.

Owner:李德昌

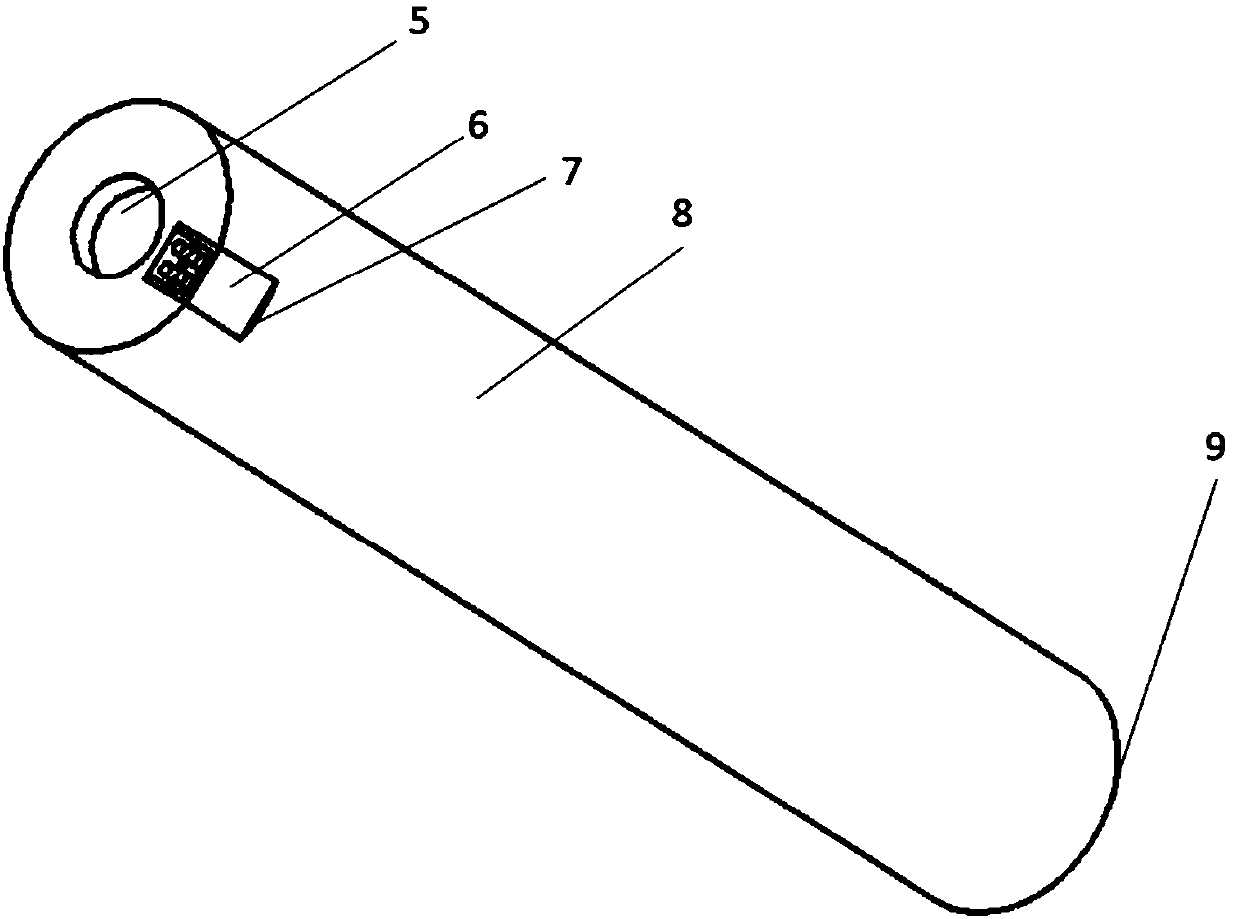

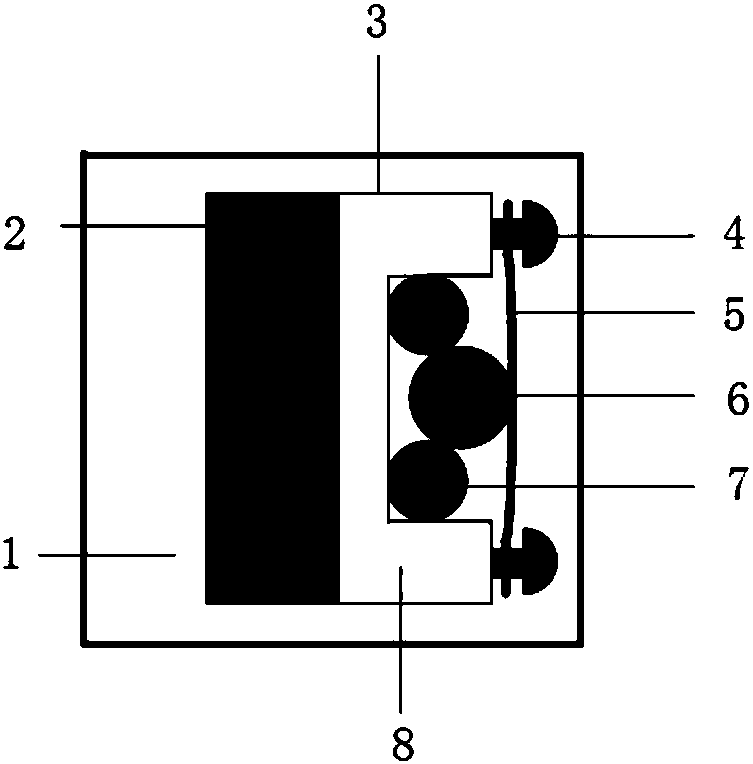

Portable backpack descent control device

ActiveCN105664385AAdjustable frictionPrevent looseningBuilding rescueControl engineeringFriction force

The invention discloses a portable backpack descent control device.The portable backpack descent control device comprises a shell, a friction plate and a descent control rope, wherein the shell is provided with a descent control rope outlet and double shoulder straps.A rotating shaft used for installing the friction plate and winding the descent control rope is arranged in the shell.The friction plate comprises a main friction plate and an auxiliary friction plate which is arranged opposite to the main friction plate and used for reducing the descending speed of the descent control device.A friction box is connected to the shell, the main friction plate is arranged in a cavity of the friction box and fixedly connected with the rotating shaft, and a control device used for adjusting the friction force of the auxiliary friction plate and the main friction plate is connected to the friction box in a sliding mode.The portable backpack descent control device is simple in structure, convenient to operate, safe, reliable and capable of saving time and labor.

Owner:张文革

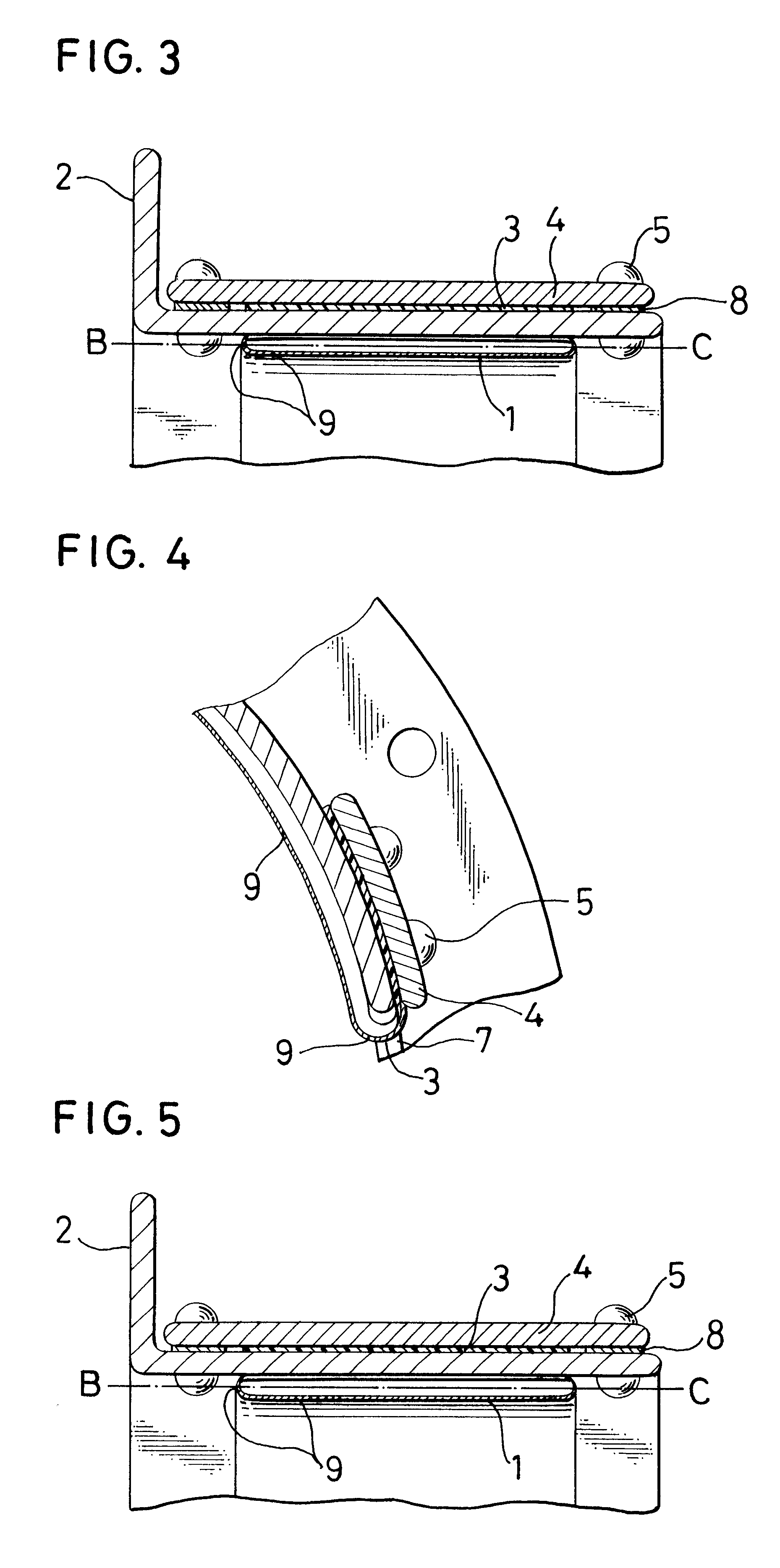

Tube-pressed brake

InactiveUS6374961B1Prevent leakageAdjustable frictionBraking membersDrum brakesEngineeringMechanical engineering

Owner:NSK WARNER

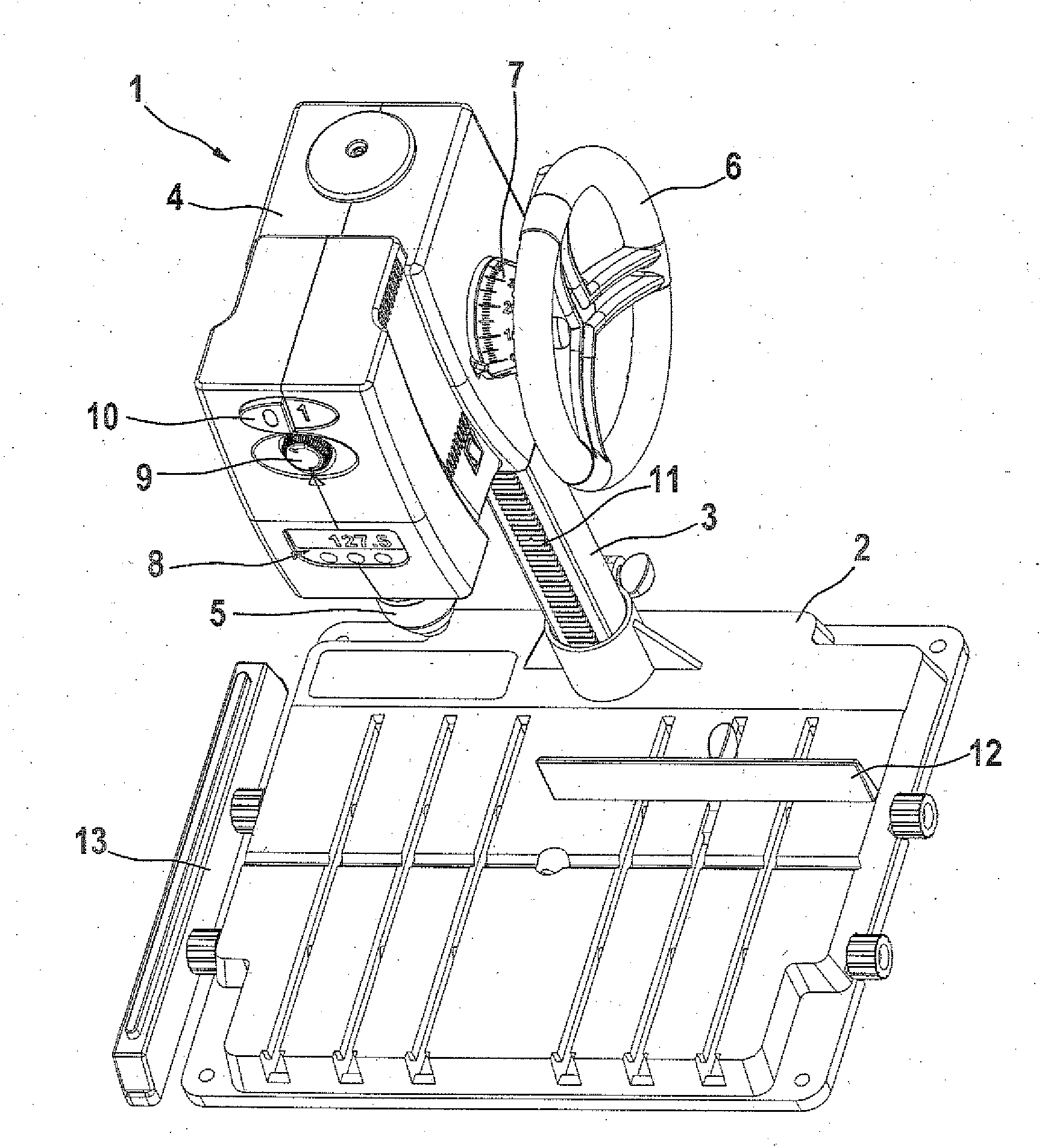

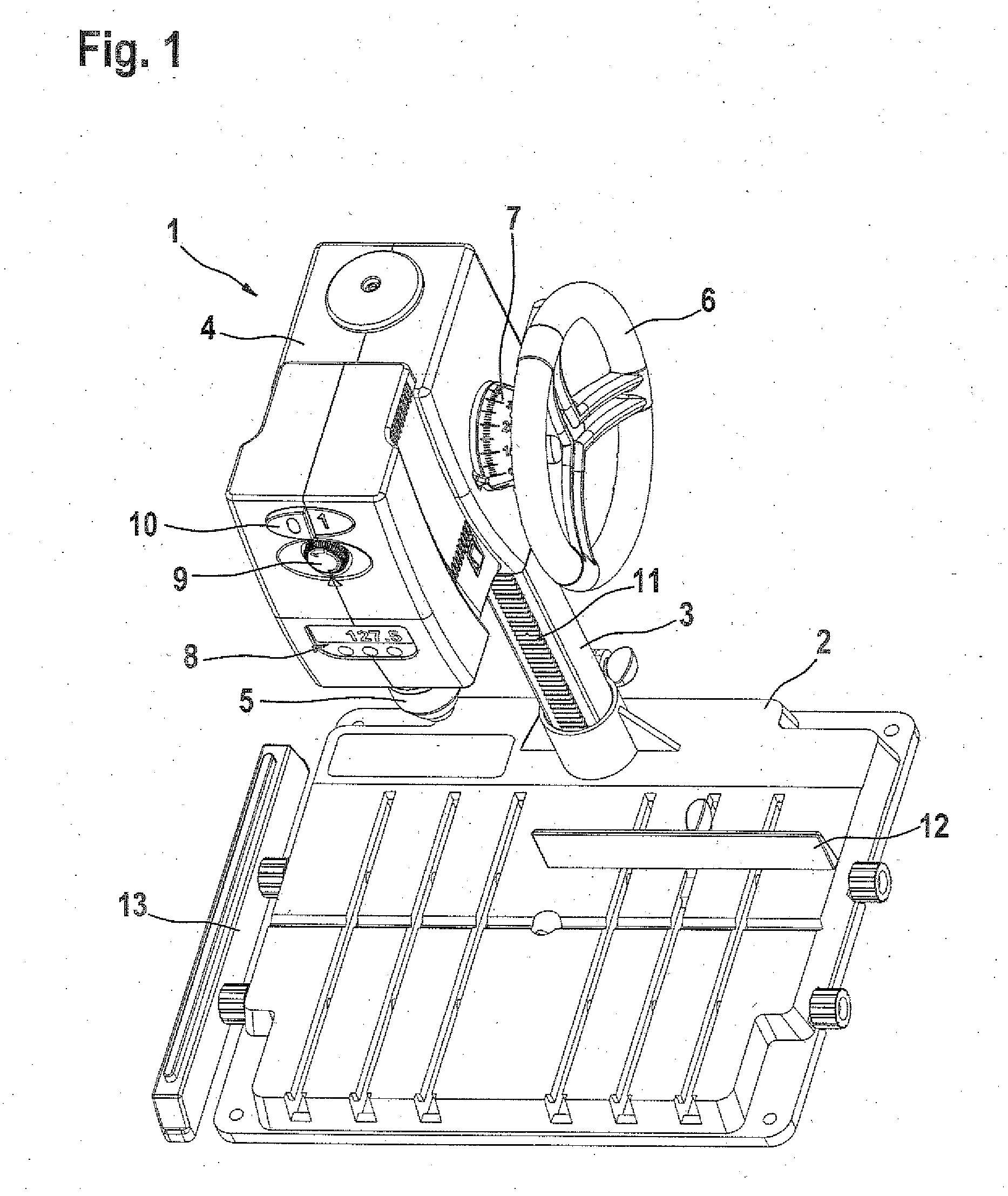

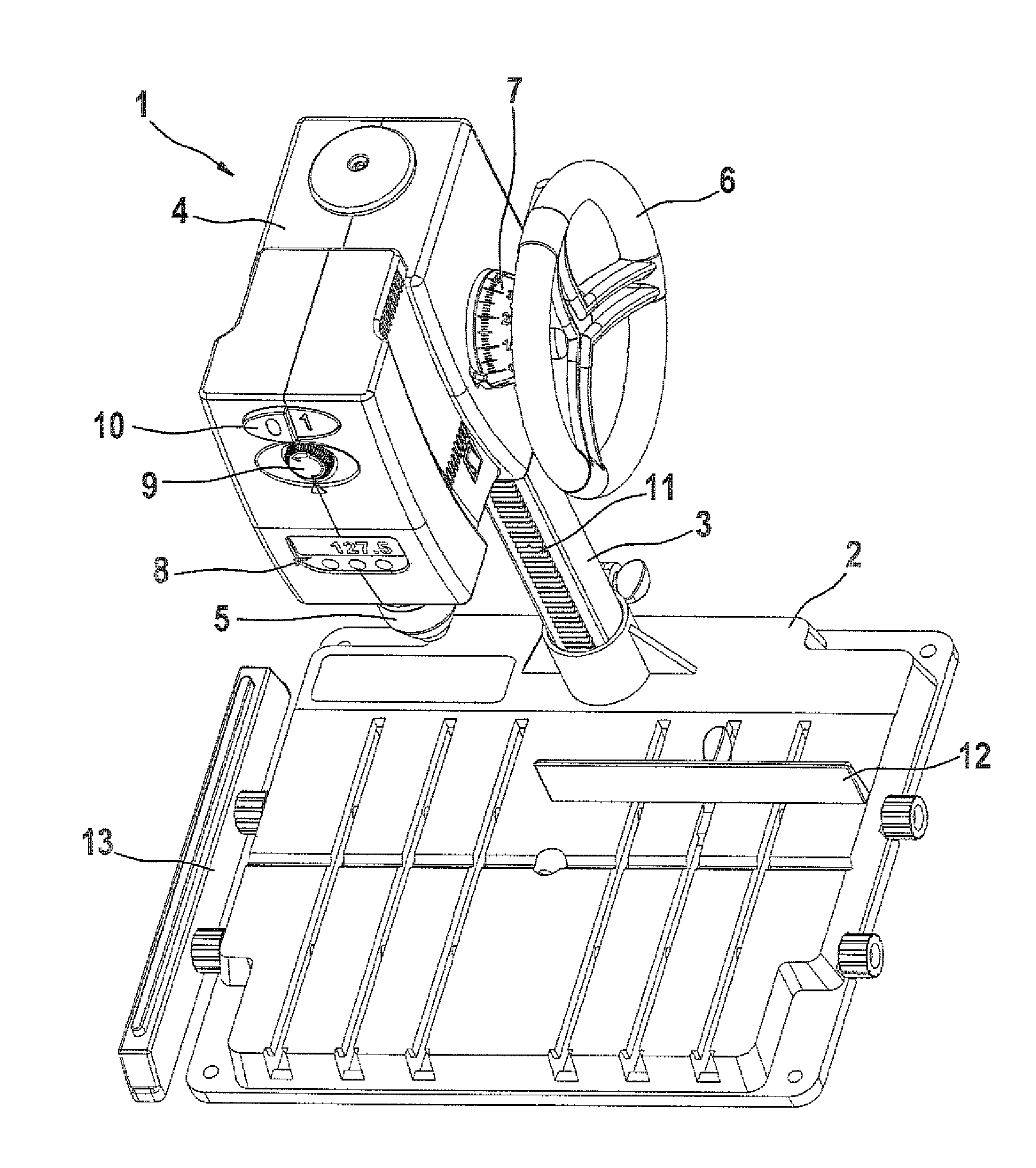

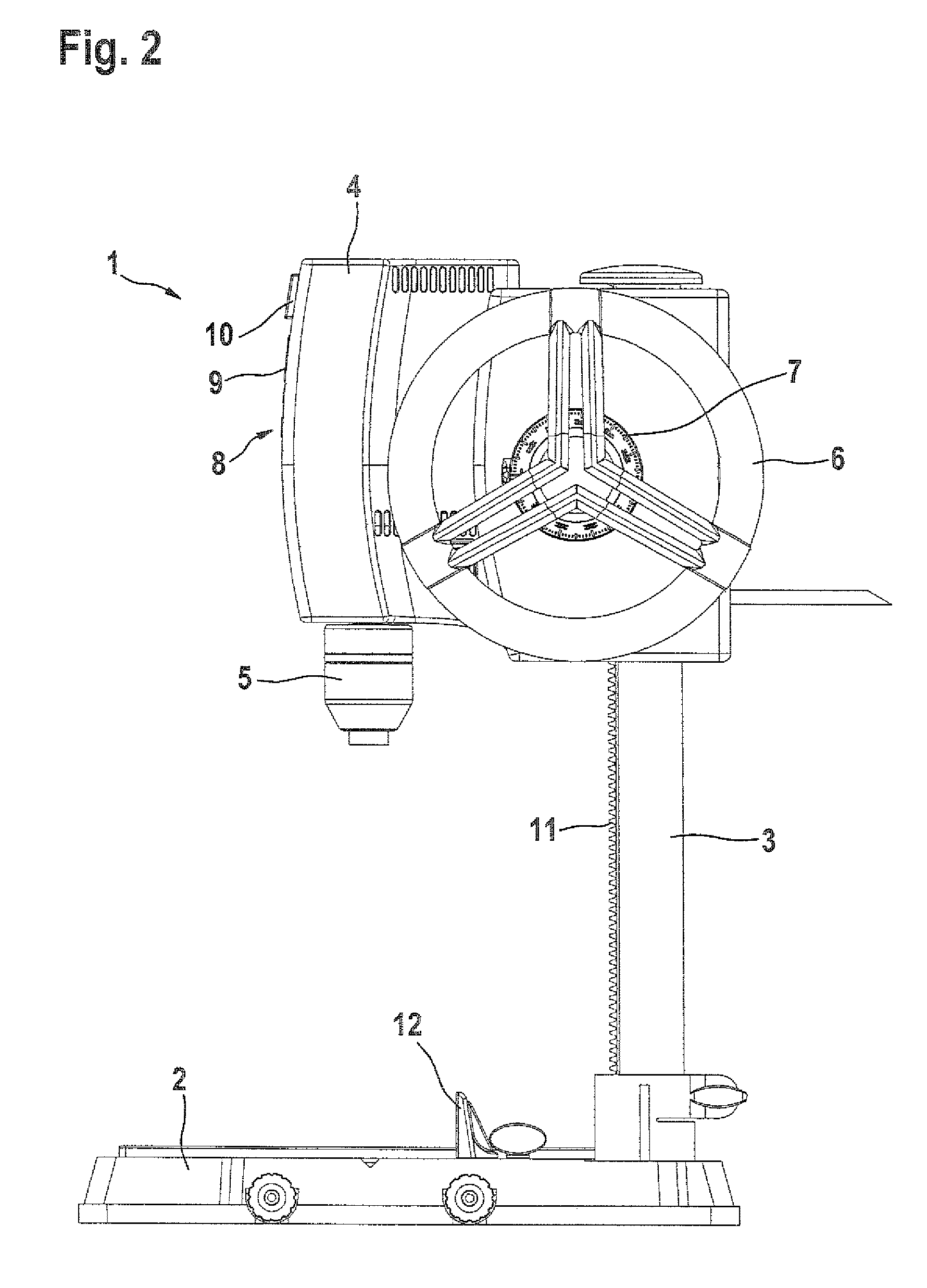

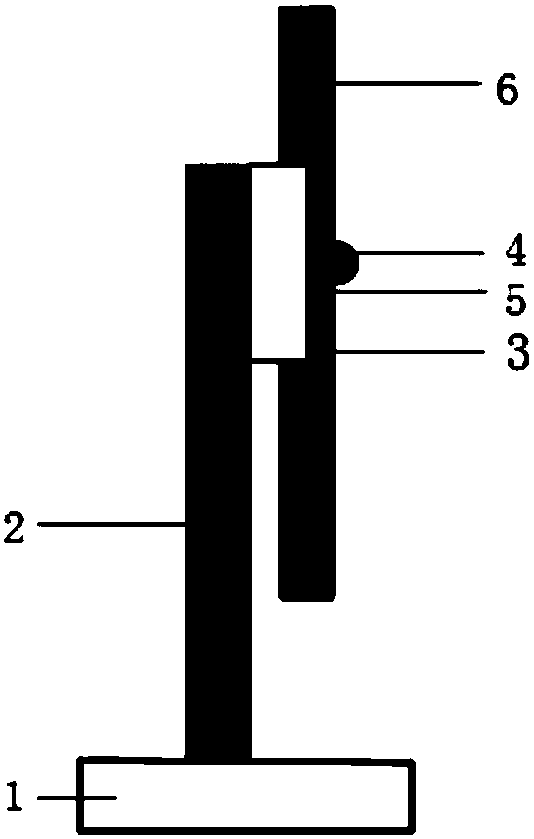

Stationary power drill

ActiveUS20080166193A1High elongationHigh spring forceDrilling/boring measurement devicesThread cutting machinesDrive shaftEngineering

A stationary power drill has a drill unit disposed in a tool housing is connected to a base vertically adjustably via a guide column and is vertically adjustable along the guide column by means of a drive unit. The drive unit includes a rotating drive shaft, and a compensation spring element engaging the drive shaft and braced on the other end on the tool housing.

Owner:ROBERT BOSCH GMBH

Yarn false twist texturing apparatus

A texturing apparatus for draw texturing a synthetic yarn. To this end, the texturing machine comprises a first feed system, a heating device, a cooling device, a texturing unit, a second feed system, and a takeup device for winding the textured yarn. Between the heating device and the cooling device, a wetting device is provided for wetting the heated yarn with a cooling fluid for purposes of precooling. The wetting device consists of a rotatable cooling cylinder which includes on its circumference a yarn track that contains a cooling fluid. The yarn can be wetted by contacting the yarn track. At the point of contact, the yarn friction is advantageously dependent on the relative speed between the yarn and the yarn track on the circumference of the cooling cylinder.

Owner:SAURER GMBH & CO KG

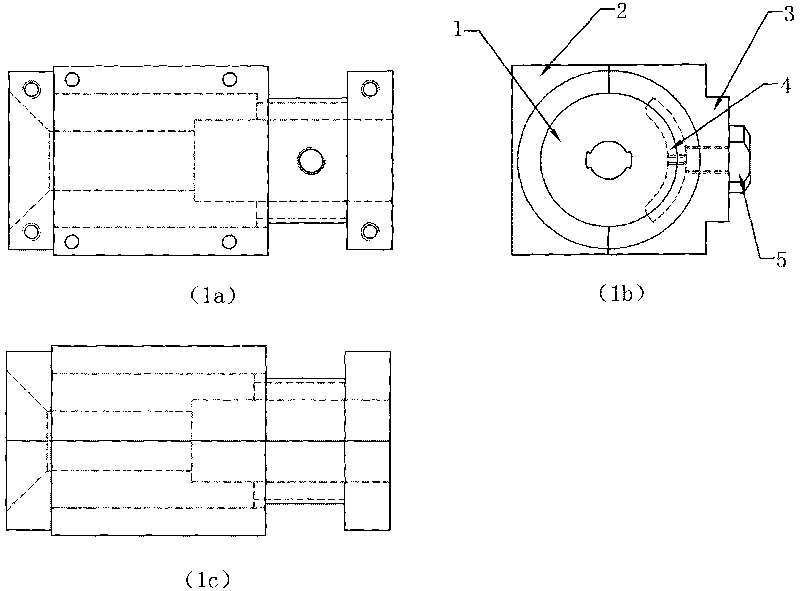

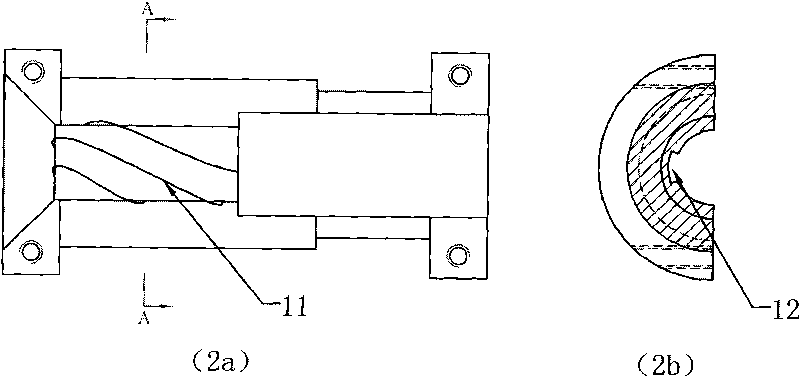

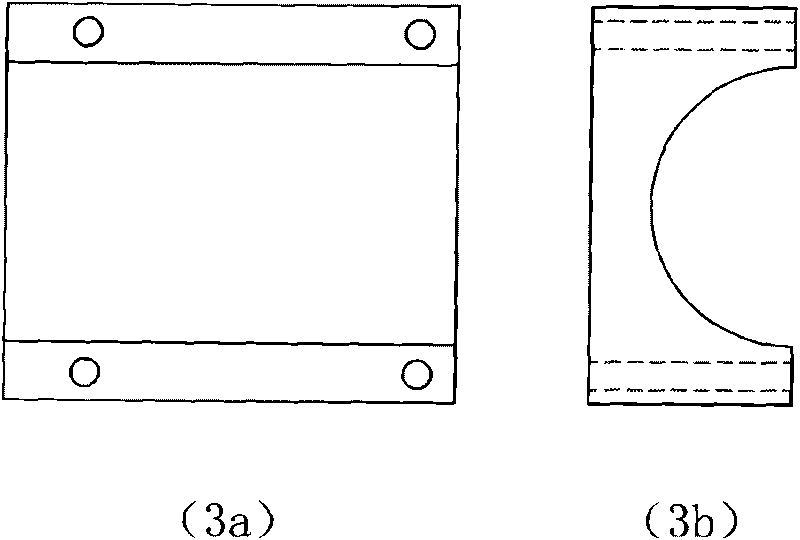

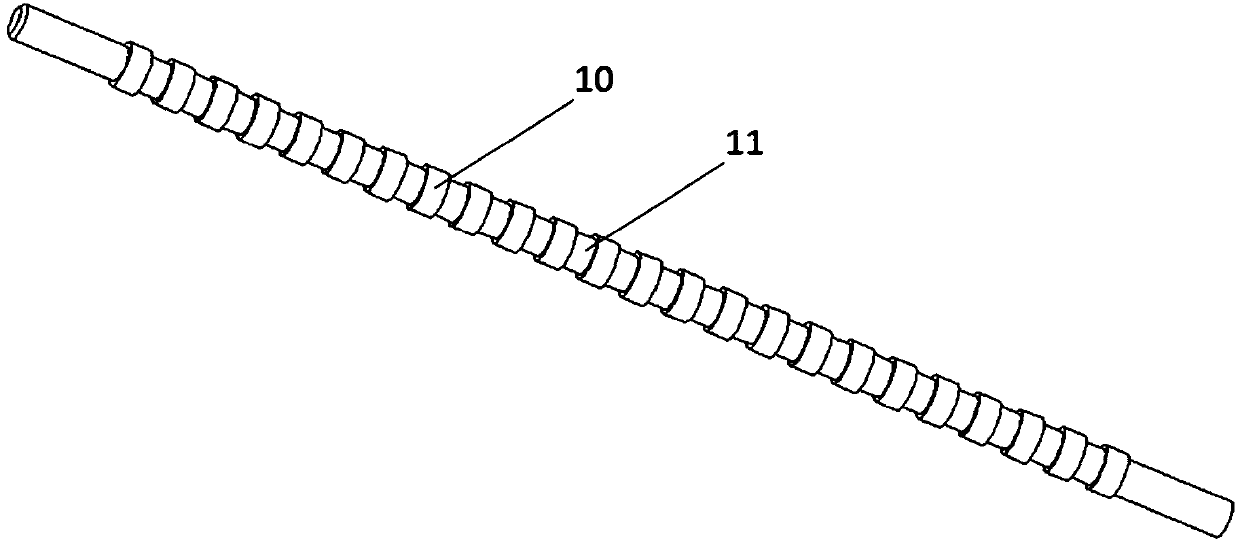

Lead stranding die mold device with low wind noise

ActiveCN101707091AFlexible rotationAdjustable frictionCable/conductor manufactureLow noiseFree rotation

The invention relates to a passive lead stranding die mold device with low wind noise, consisting of a rotatable inner die mold, a fixed outer die mold , a torsional moment adjustable friction plate and a torsional moment adjustable bolt, wherein the fixed outer die mold comprises a first fixed outer die mold and a second outer die mold, the rotatable inner die mold realizes free rotation by taking the center of the fixed outer die mold as an axle, and the thread pitch of screw thread and the groove depth of the rotatable inner die mold can be set according to the pitch value of an outer layer and the protruded height of the stranding lead with low wind noise; and the passive lead stranding die mold device has the advantages of flexible rotation, adjustable friction force, favorable rotating symmetry and the like. The passive lead stranding die mold device with low wind noise is used as a lead outlet die mold of a stranding machine and can be used for producing leads with low noise.

Owner:CHINA ELECTRIC POWER RES INST +1

Novel multifunctional descent control device with cyclic lifting function

The invention discloses a novel multifunctional descent control device with the cyclic lifting function. The novel multifunctional descent control device comprises a shell with a descent control rope outlet, a friction piece and a descent control rope. The shell is provided with shoulder straps. A rotary shaft and a transmission shaft are arranged in the shell, wherein the rotary shaft is used for mounting the friction piece, the descent control rope is wound around the rotary shaft, and the transmission shaft is used for driving the rotary shaft to rotate and winding the descent control rope. The transmission shaft is driven through a drive device. The friction piece comprises a main friction piece body and an auxiliary friction piece body which is arranged opposite to the main friction piece body and used for reducing the descent speed of the descent control device. A friction box is connected to the shell. The main friction piece body is arranged in a cavity of the friction box and fixedly connected with the rotary shaft. A control device used for adjusting the friction force of the auxiliary friction piece body and the main friction piece body is connected with the friction box in a sliding manner. The novel multifunctional descent control device further comprises a spring which is arranged between the auxiliary friction piece body and the friction box and used for increasing thrust for assisting the control device in moving the auxiliary friction piece body. The novel multifunctional descent control device is small in size, light, simple in structure, convenient to operate, safe and reliable, and time and labor are saved.

Owner:张文革

Anti-capsizing support of bridge

InactiveCN106087717AHigh sensitivityStrong blessingBridge structural detailsScrew threadFriction force

The invention discloses an anti-capsizing support of a bridge. The anti-capsizing support of the bridge comprises a first plate, a second plate and a third plate, wherein the first plate, the second plate and the third plate are arranged in parallel from top to bottom. Clamping grooves are formed in the two sides of a second insertion plate vertically. Each clamping groove communicates with a channel through a square hole between the clamping groove and the channel. A movable brake pad is placed in each clamping groove. A tie piece is arranged in the channel. Wedges are arranged on the two sides of the tie piece at intervals and face the same direction, and each wedge makes contact with the movable brake pad in the corresponding position. A threaded hole is formed in the end of the tie piece, and a tension bolt is installed in the threaded hole for tensioning connection. The anti-capsizing support of a bridge is of a pure mechanical structure, and long-term maintenance-free operation can be achieved; and in addition, main friction force happens to friction plates between the insertion plates, the automobile brake pads are used as the friction plates and are free of maintenance in the whole life, and the friction force of the brake pads can be adjusted conveniently through the tension bolt.

Owner:孙新迪 +11

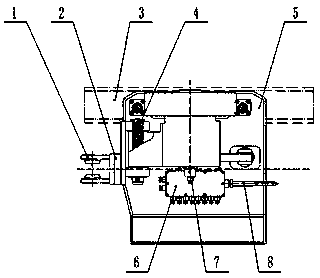

Automatic travelling system of mining intrinsically safe rail inspection robot

The invention provides an automatic travelling system of a mining intrinsically safe rail inspection robot. The system comprises a bearing bridge, wherein a load bearing is fixedly installed on the bearing bridge, and is in contact with the inner side of the lower edge of a C-shaped guide rail, the two ends of the bearing bridge are connected to the two sides of a bearing support through connecting pieces, a speed sensor, a friction wheel, a driving motor and a brake device are arranged inside the bearing support, the driving motor drives the friction wheel to rotate through a gear, the driving motor, the speed sensor and the brake device are connected to a controller in a signal mode, the controller controls the brake device to move in the bearing support, so that the friction wheel is braked, the friction wheel and the load bearing are both in contact with the lower edge of the C-shaped guide rail, and the lever effect is formed between the load bearing and the friction wheel of thebearing bridge. The automatic travelling system of the mining intrinsically safe rail inspection robot is safe, reliable, simple to install, convenient to use, small in occupied space and low in cost.

Owner:TIANJIN HUANING ELECTRONICS

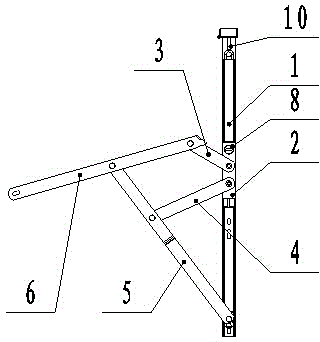

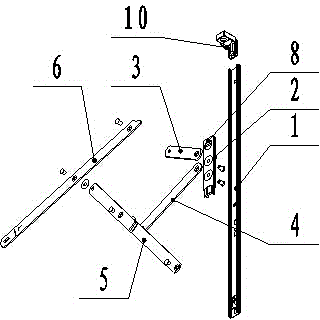

Hinge

The invention discloses a hinge. The hinge comprises a sliding rail, a sliding block and a connecting rod mechanism. The hinge is characterized in that the sliding block is connected with the sliding rail in a sliding way; the connecting rod mechanism is formed by a cantilever I, a cantilever II, a supporting arm I and a swinging arm; one end of the cantilever I and one end of the cantilever II are hinged to the sliding block; the other end of the cantilever I is hinged to one end of the swinging arm; the other end of the cantilever II is hinged to the supporting arm I; one end of the supporting arm I is hinged to the sliding rail, and the other end of the supporting arm I is hinged to the middle part of the swinging arm; in a polygon formed by the sliding block, the cantilever I, the cantilever II, the supporting arm I and the swinging arm, the total sum of the effective length of the supporting arm I and the effective length of the swinging arm is slightly greater than the total sum of the length between two joint points of the sliding block, the effective length of the cantilever I and the effective length of the cantilever II. The hinge disclosed by the invention has very remarkable beneficial effects that the structure is simple and stable, the cost is low, the use is convenient, the safety performance is good, and a stiffness force and a friction force can be regulated.

Owner:泰斯安建筑五金(宁波)有限公司

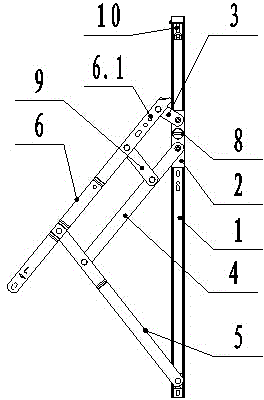

Linear stepping motor used for dot matrix image forming and tactile feedback

The invention discloses a linear stepping motor used for dot matrix image forming and tactile feedback. The linear stepping motor comprises a rotor, a stator component and a shell, wherein the rotor is mounted in the shell through a guiding piece; the stator component sleeves the exterior of the rotor and is mounted in the shell; the shell comprises a sleeve-shaped outer shell and a contact pin seat; the rotor is of a stepped shaft structure in which a plurality of annular grooves are uniformly formed along the axial direction at intervals; the rotor is accurately mounted on the central axis of the shell through the guiding piece; the guiding piece comprises a first sliding bearing, a second sliding bearing, a gasket, a rubber sleeve and a rotor; the stator component sleeves the exterior of the rotor between the first sliding bearing and the second sliding bearing, and comprises a stator iron core, two coil windings and three permanent magnet rings; each coil winding is formed by serially and electrically connecting two non-skeleton self-adhesion coils in opposite directions mainly. The linear stepping motor is high in kinematics precision and small in volume, linear movement of the rotor is directly realized, and the motor can be used for 3D dot matrix image forming, tactile feedback and precision linear transmission.

Owner:ZHEJIANG SCI-TECH UNIV

Electric steering device transmission for rear-view mirror of car

An electric driver for controlling the back-view mirror is aimed at reducing idle running and noise and benefiting manual regulation, and has a rack bar which is fixed to spherical sleeve and engaged with the top gear of output axle assemblage. It features that the output axle assemblage behind the speed variator of electric motor has a friction sliding mechanism. Its advantages are short idle running, low noise, smooth rotation and not jamming easily.

Owner:王振惠

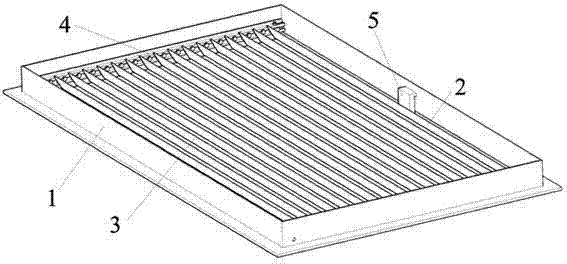

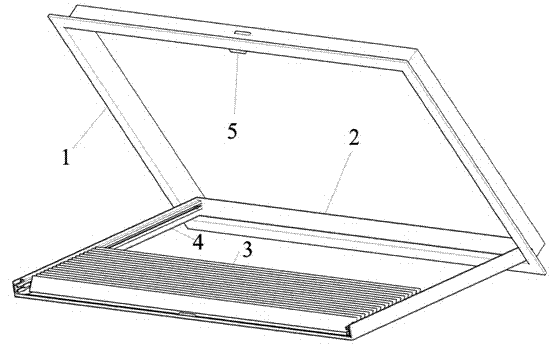

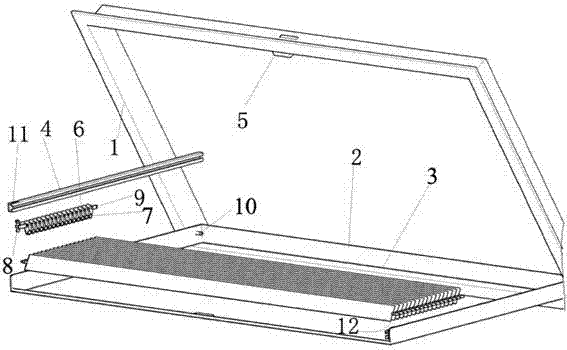

Building air conditioner outlet

InactiveCN104729048AIncrease frictionAdjustable frictionAir-flow control membersFixed bearingEngineering

The invention relates to a building air conditioner outlet. The two sides of one end of an outlet main frame are connected with outlet auxiliary frames through fixing bearings so that the outlet auxiliary frames can rotate around one side of the outlet main frame. The two sides of the inner walls of the outlet auxiliary frames are provided with concave slide way grooves. A plurality of small wheels sliding in the grooves are matched and connected with the interiors of the concave slide way grooves. Every two adjacent small wheels are connected into a whole contraction support through a foldable contraction small support 7. Each pair of foldable contraction small supports on the left side and the right side are connected with an outlet shutter blade to form an adjustable outlet shutter. Compared with the prior art, the building air conditioner outlet has the advantages of being low in manufacturing and producing difficulty, low in cost, capable of replacing the rusted shutters in time and saving materials, easy and reliable to operate, firm and convenient in connection and high in manufacturing efficiency.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Stationary power drill

ActiveUS8142114B2Easy to operateSimple configurationDrilling/boring measurement devicesThread cutting machinesDrive shaftEngineering

A stationary power drill has a drill unit disposed in a tool housing is connected to a base vertically adjustably via a guide column and is vertically adjustable along the guide column by means of a drive unit. The drive unit includes a rotating drive shaft, and a compensation spring element engaging the drive shaft and braced on the other end on the tool housing.

Owner:ROBERT BOSCH GMBH

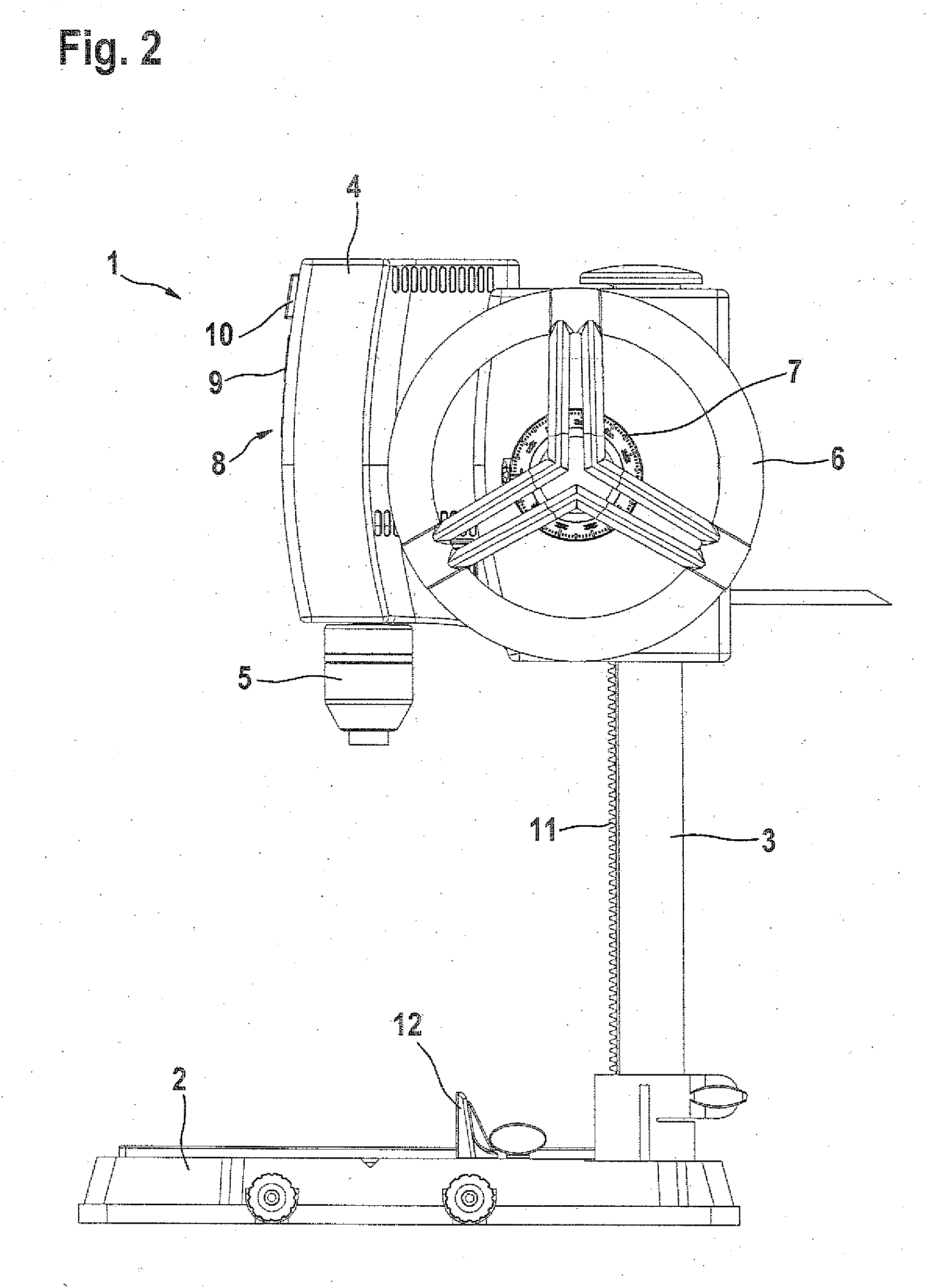

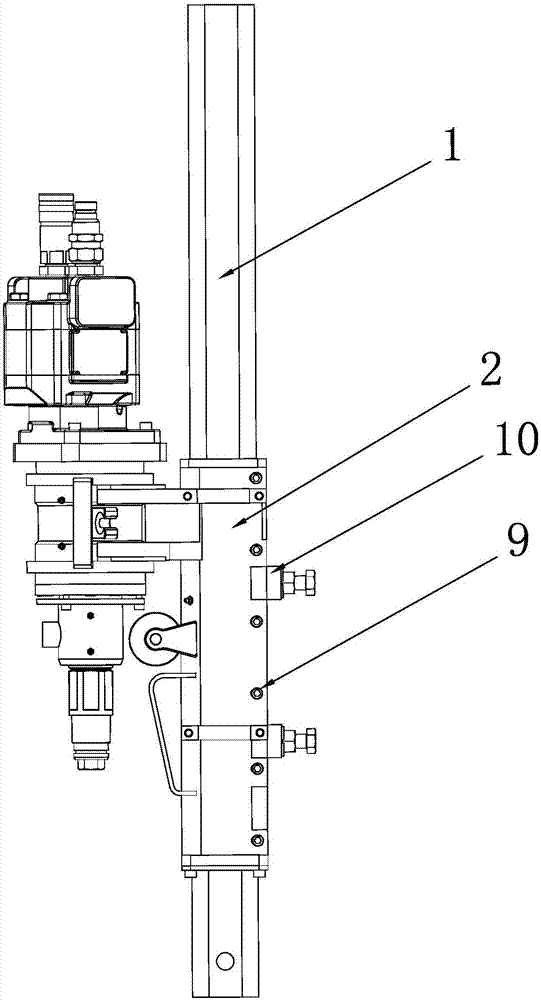

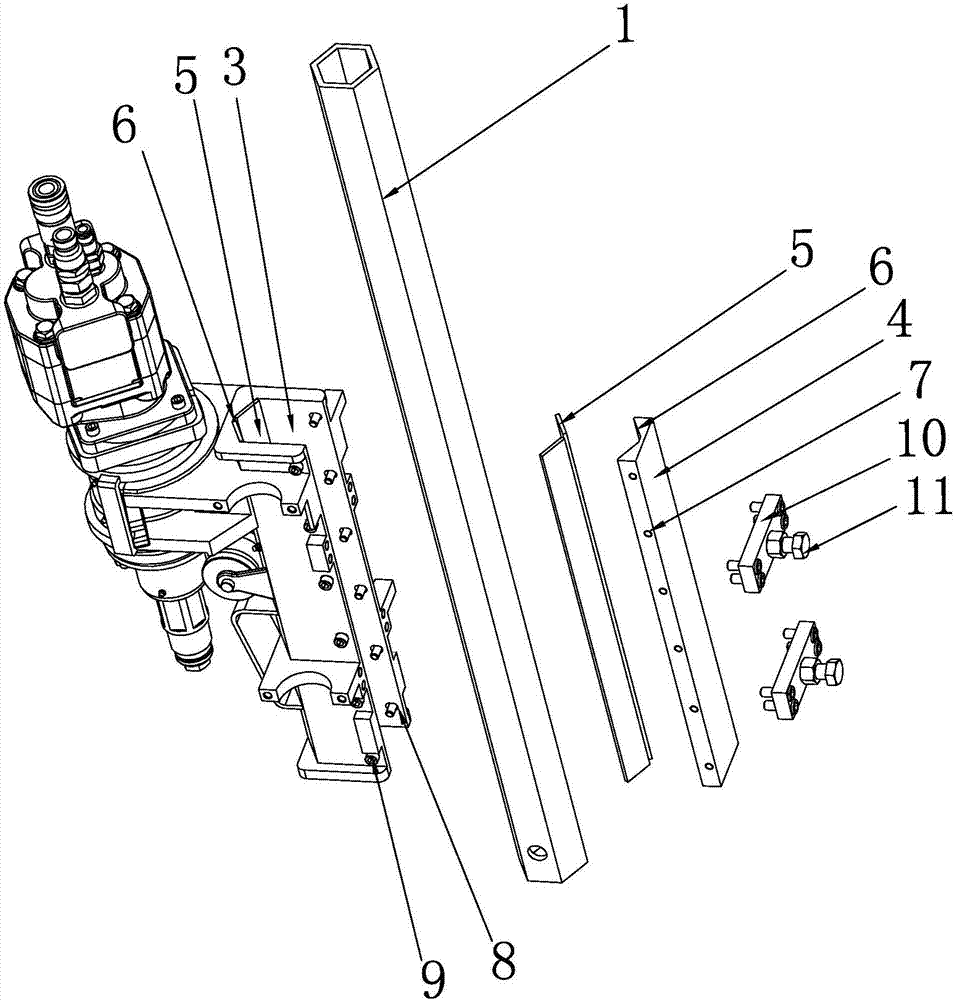

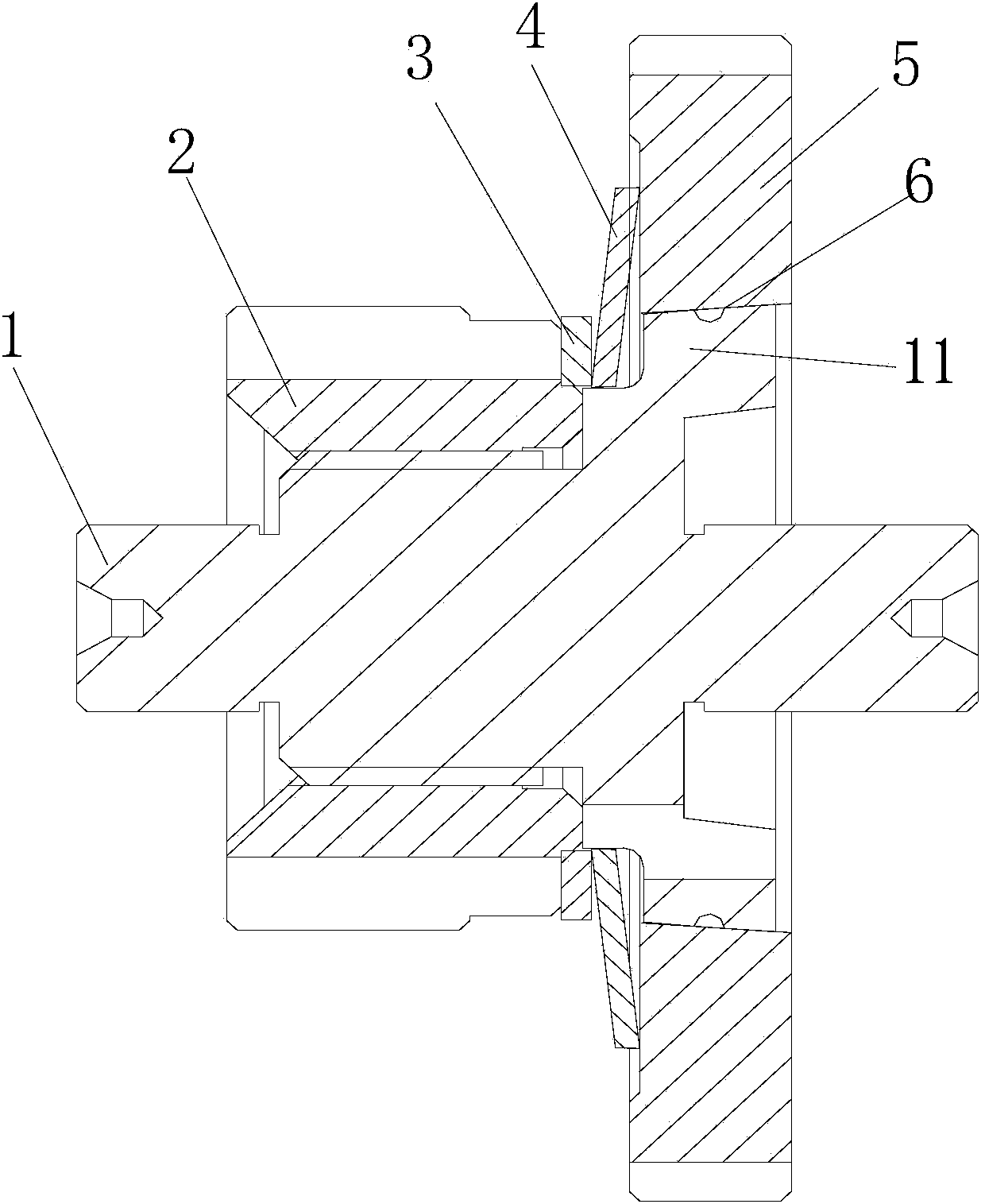

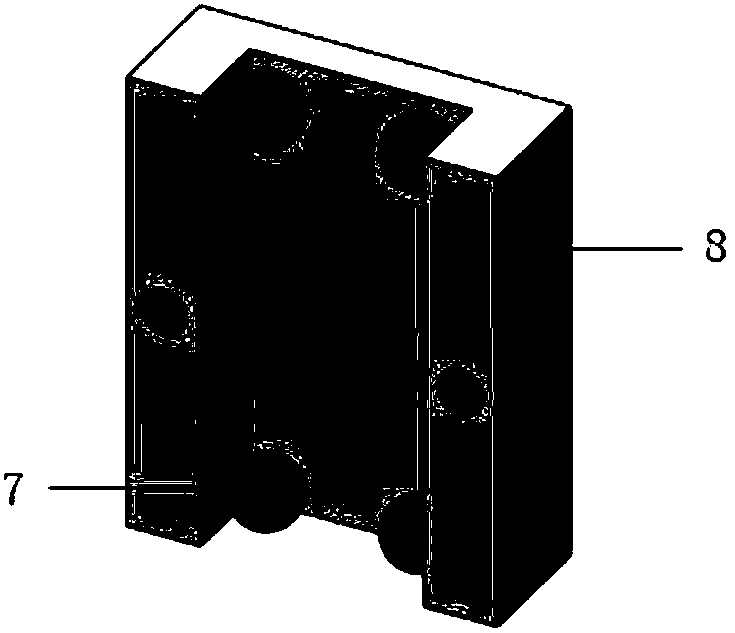

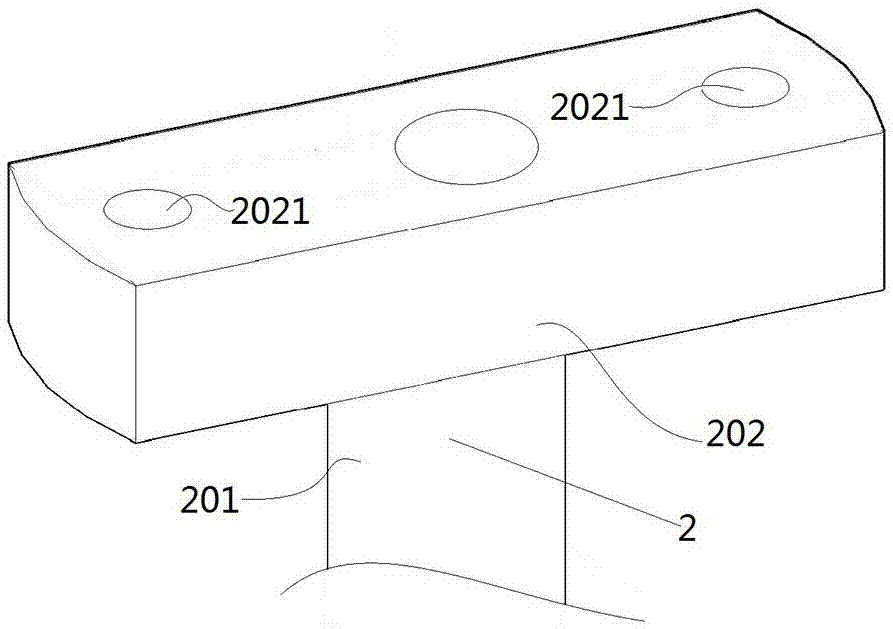

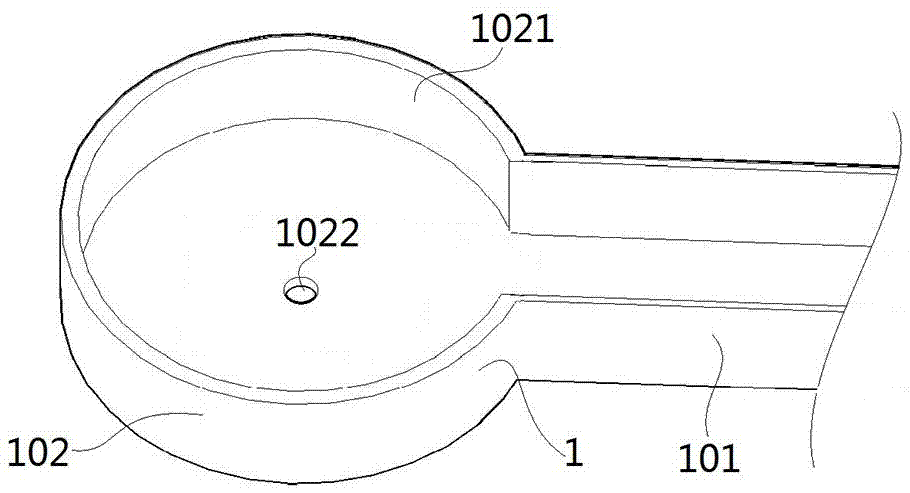

Power head guiding rail structure of drilling machine

The invention discloses a power head guiding rail structure of a drilling machine. The power head guiding rail structure comprises a guiding rail installed on a drilling machine support and a power head support installed on the guiding rail and capable of moving along the guiding rail. A vertically-through guiding groove with an opening in the right side is formed in the power head support, an adjusting block is detachably installed on the right side in the guiding groove, and the position, relative to the guiding groove, of the adjusting block can be adjusted. The adjusting block is matched with the guiding groove to clamp the guiding rail, and wear-resisting pieces are arranged between the left side of the guiding groove and the guiding rail as well as between the left side of the adjusting block and the guiding rail correspondingly. According to the power head guiding rail structure of the drilling machine, the guiding groove with the opening in one side is adopted for matching installation; the power head guiding rail structure is different from a traditional closed type guiding rail structure, components at the two ends of the guiding rail do not need to be specially detached and installed during assembly, assembly is easy, and the requirements for assembly places and equipment are reduced; and the wear-resisting pieces are convenient to adjust through the adjusting block, and friction force between the power head support and guiding rail can be adjusted after the wear-resisting pieces are worn, so that drilling accuracy of the drilling machine is kept for a long term, and a power head is prevented from wobbling.

Owner:ZHUHAI EAGLER SPECIALTY DRILLING EQUIP CO LTD

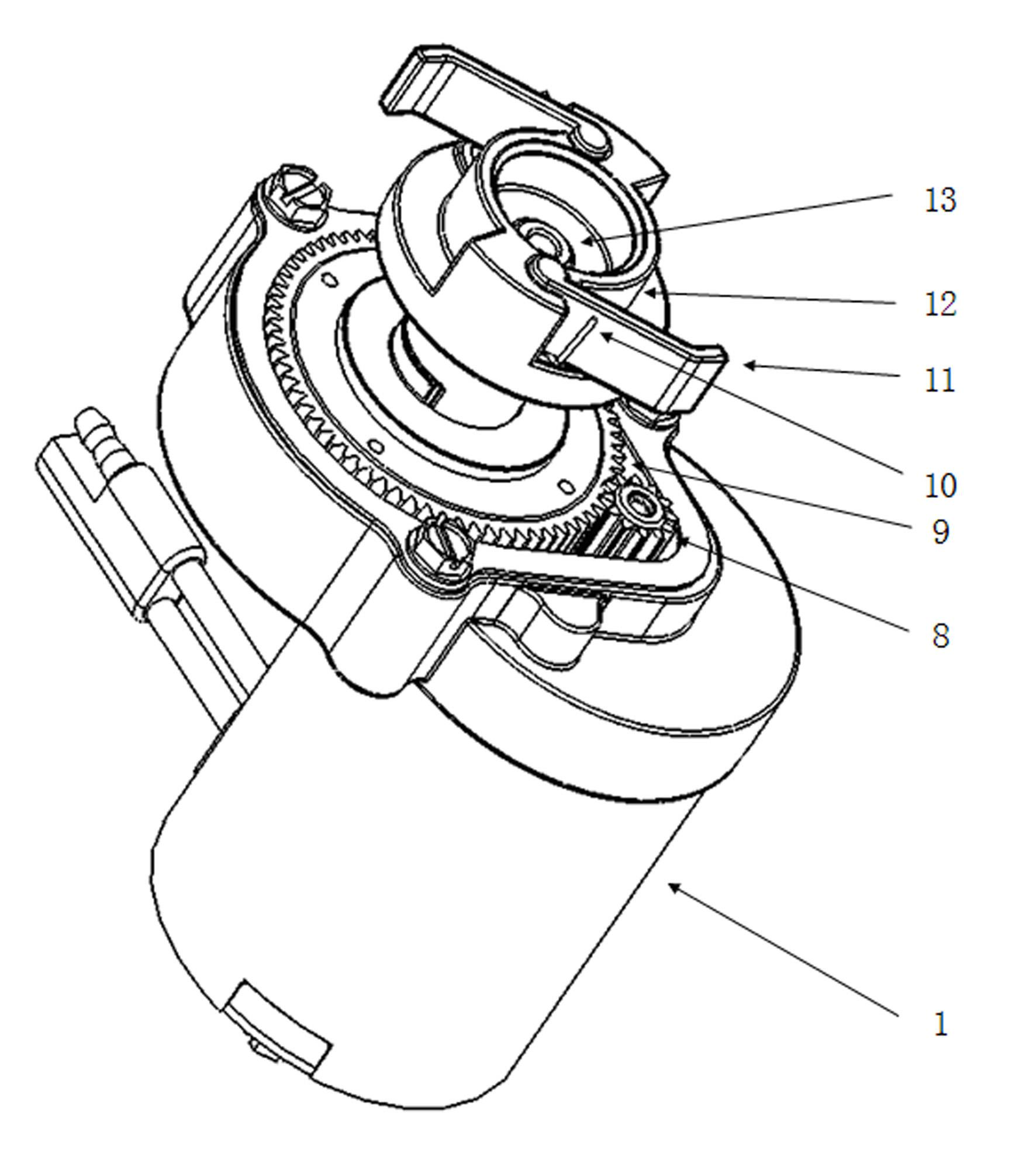

Overload protection type electrical starting duplicate gear and starting system

InactiveCN103726968AGood transmission effectFrequent replacementPortable liftingElectric motor startersElectricityStatic friction

The invention discloses an overload protection type electrical starting duplicate gear and a starting system. The overload protection type electrical starting duplicate gear comprises a duplicate gear shaft, a gear body I and a gear body II, wherein the gear body I and the gear body II are arranged on the duplicate gear shaft in a drive matching mode. The duplicate gear shaft is sleeved with the gear body II so that an inner conical surface of the gear body II and an outer conical surface of the duplicate gear shaft can form a conical surface pair. The gear body II has axial force for locking the conical surface pair and enabling the sliding torsion value of the conical surface pair to be larger than or equal to the electrical starting torsion value. When the reverse dragging phenomenon occurs and the torsion value exceeds the largest static friction force between the conical surfaces due to the fact that an engine suddenly slows down or stops under heavy loads and great inertia in the high-speed running process, the inner conical surface and the outer conical surface can slide, in other words, the gear body II and the duplicate gear shaft can slide relative to each other, and therefore the gear and a starting clutch of the whole electrical starting system can not be damaged, and the overload protection function is achieved. In the use process, the taper angle, the roughness of the conical surfaces and the axial force can be set according to the actual requirements, and therefore the required largest static friction force can be set.

Owner:CHONGQING LONCIN ENGINE

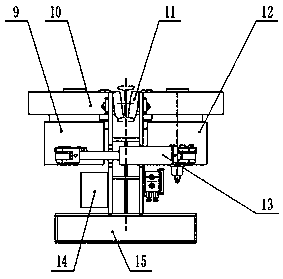

Movement detection device and detection method for monorail crane

PendingCN111458067AQuick disassemblyIncrease output hydraulic dampingServomotor componentsServomotorsPull forceControl engineering

A movement detection device and a detection method for a monorail crane belong to the electrical field, the detection device comprises a hydraulic valve group and a tension sensor, a pull rod seat isconnected with one end of the tension sensor, and the other end of the tension sensor is connected with a frame body; four bearing wheels are arranged on the frame body and slide back and forth alonga monorail track; a hydraulic oil pump and a generator are arranged on the two sides of the frame body respectively and connected with the frame body and a clamping oil cylinder. Driven rubber wheelsare installed at the input wheel ends of the hydraulic oil pump and the generator and can clamp the monorail track through contraction of the clamping oil cylinders. A hydraulic valve group and an electric control box are arranged on the lower sides of the hydraulic oil pump and the generator, and are respectively fixed on two sides of the frame body; and a generator shaft is connected with a rotary encoder, and a hydraulic oil tank is integrated below the frame body. According to the invention, the relation between the speed and the tension of the locomotive in the moving process is analyzed,and the traction force of the locomotive is detected more accurately.

Owner:TAIYUAN KUANGJI ELECTRIC

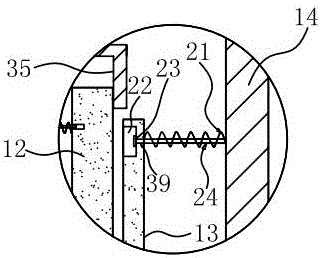

Readable compound damper and using method thereof

ActiveCN104878851AAdjustable frictionImprove vibration damping effectShock proofingEngineeringFriction force

The invention relates to a readable compound damper and the using method thereof. The readable compound damper comprises a rectangular box, wherein a movable plate is transversely arranged in the box, the two ends of the movable plate stretch out of the box, a connecting hole used for being connected with an external supporting component is formed in one of the two ends stretching out of the box, a longitudinal rectangular protruding part is arranged on the front side face, located in the box, of the movable plate, at least two longitudinal arc-shaped protruding parts are arranged on the rear side face, located in the box, of the movable plate, a friction plate which is used for being matched with the rectangular protruding part is arranged in the box and is located in front of the rectangular protruding part, a plurality of push plates which are connected with the friction plate through a plurality of compression springs are arranged on the front side of the friction plate, a plurality of adjustment bolts which penetrate into the box, abut against the push plates and are provided with readable scales are arranged on a front side plate of the box, a chamber, where the longitudinal arc-shaped protruding parts are located, in the box is filled with a lead body, and a longitudinal bolt which is connected with a structural main body is further arranged on a base plate of the box. The compound damper is simple and compact in structure, the friction force can be adjusted, and the operation method is simple.

Owner:FUZHOU UNIV

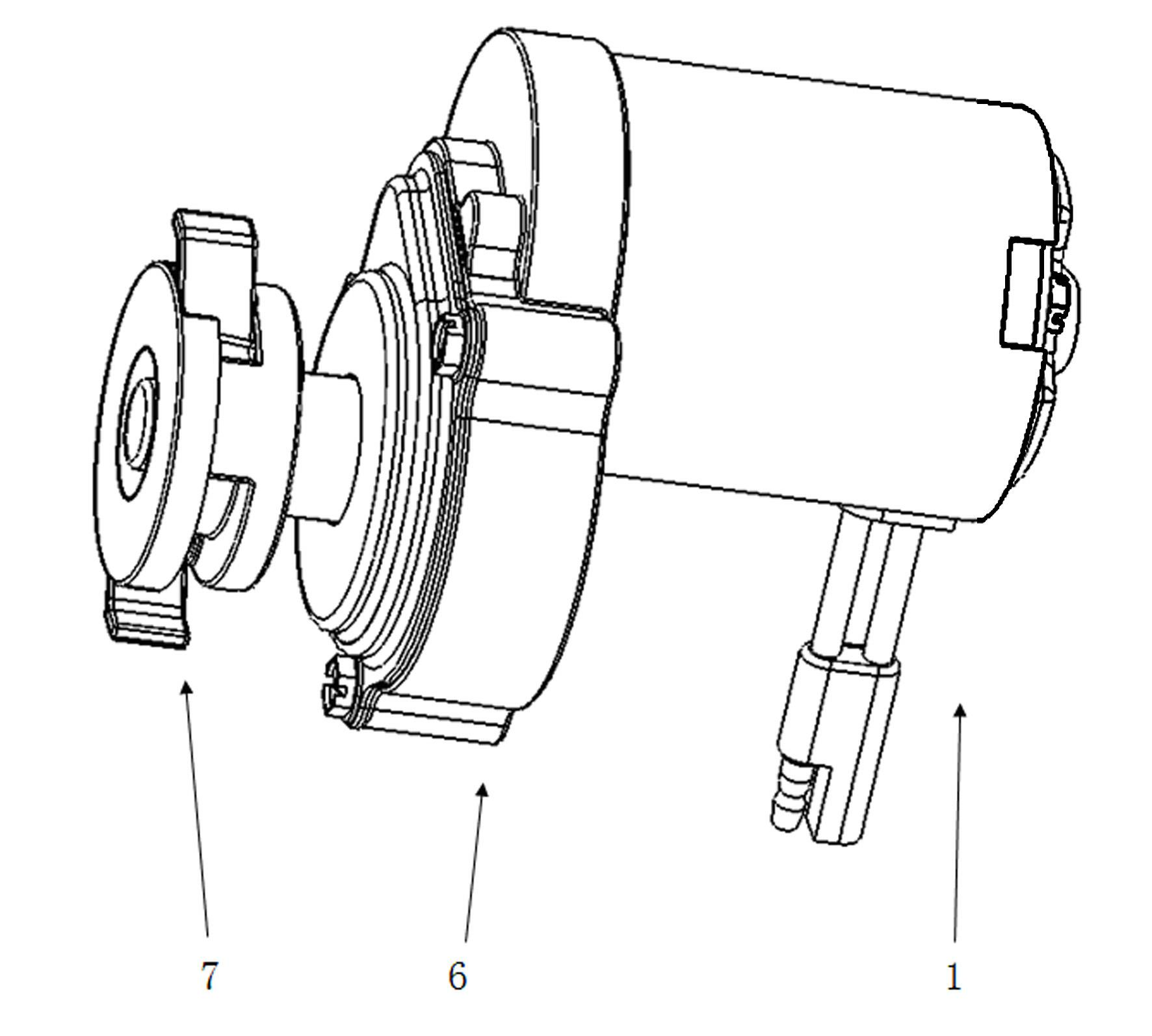

Starting motor

InactiveCN102386716AMesh precisionReliable engagementElectric motor startersMachines/enginesFreewheelEngineering

The invention provides a starting motor and relates to a motor. At present, an industry typical starting motor is worn quickly, has low reliability, is easy to be out of operation and can produce a big noise. The starting motor provided by the invention comprises a motor and is characterized by also comprising a driving assembly axially connected with the motor, a torque converter which is connected with the driving assembly to rotate along with the driving assembly, a torque output piece one end of which is connected to the torque converter, an unfolding assembly used for unfolding the torque output piece, a return spring which is arranged between the torque converter and the torque output piece and causes the torque output piece to reset and an engine flywheel which can collide with the torque output piece to cause the torque output piece to drive the engine flywheel to rotate, wherein the engine flywheel is provided with a pushed part, and the torque output piece changes a rotating angle and increases length extending outside the torque converter by virtue of the unfolding assembly, so that the torque output piece collides with the pushed part of the engine flywheel to drive the engine flywheel to rotate. According to the technical scheme adopted by, the structure is simple, the torque output piece can be meshed with the engine flywheel accurately and reliably, and noise during operation can be effectively reduced.

Owner:WOLONG ELECTRIC GRP CO LTD

Single piezoelectric stack-based inertial nanometer stepping motor

PendingCN107681917AImprove rigidityHigh precisionPiezoelectric/electrostriction/magnetostriction machinesEngineeringBeryllium copper

The invention discloses a single piezoelectric stack-based inertial nanometer stepping motor. The single piezoelectric stack-based inertial nanometer stepping motor comprises a base, a piezoelectric stack, a rigid force transmission block, a flexible force transmission block (comprising a beryllium copper spring sheet and two screws) and a sliding rod; the piezoelectric stack is perpendicularly fixed on the base based on mutual short circuiting between a positive electrode and a negative electrode, and a path of sawtooth wave voltage driving signal is applied on the piezoelectric stack; the rigid force transmission block is glued and fixed at the free end of the piezoelectric stack, and the sliding rod is fixed by the rigid force transmission block and the flexible force transmission blockin an extrusion manner; and the extrusion pressure satisfies a condition that the maximum static friction force of the rigid force transmission block and the flexible force transmission block on thesliding rod is slightly greater than the self gravity of the sliding rod. The single piezoelectric stack-based inertial nanometer stepping motor is simple in structure, easy to manufacture, and capable of controlling stepping movement of the sliding rod by only needing one piezoelectric stack and one path of sawtooth wave voltage driving signal; and meanwhile, the single piezoelectric stack-basedinertial nanometer stepping motor is adjustable in friction force, controllable in driving force, high in rigidity, has the nano-scale stepping precision, and is suitable for being used as a fine tuning positioning apparatus of a micro scanning probe microscope in an extreme condition.

Owner:NANJING UNIV OF POSTS & TELECOMM

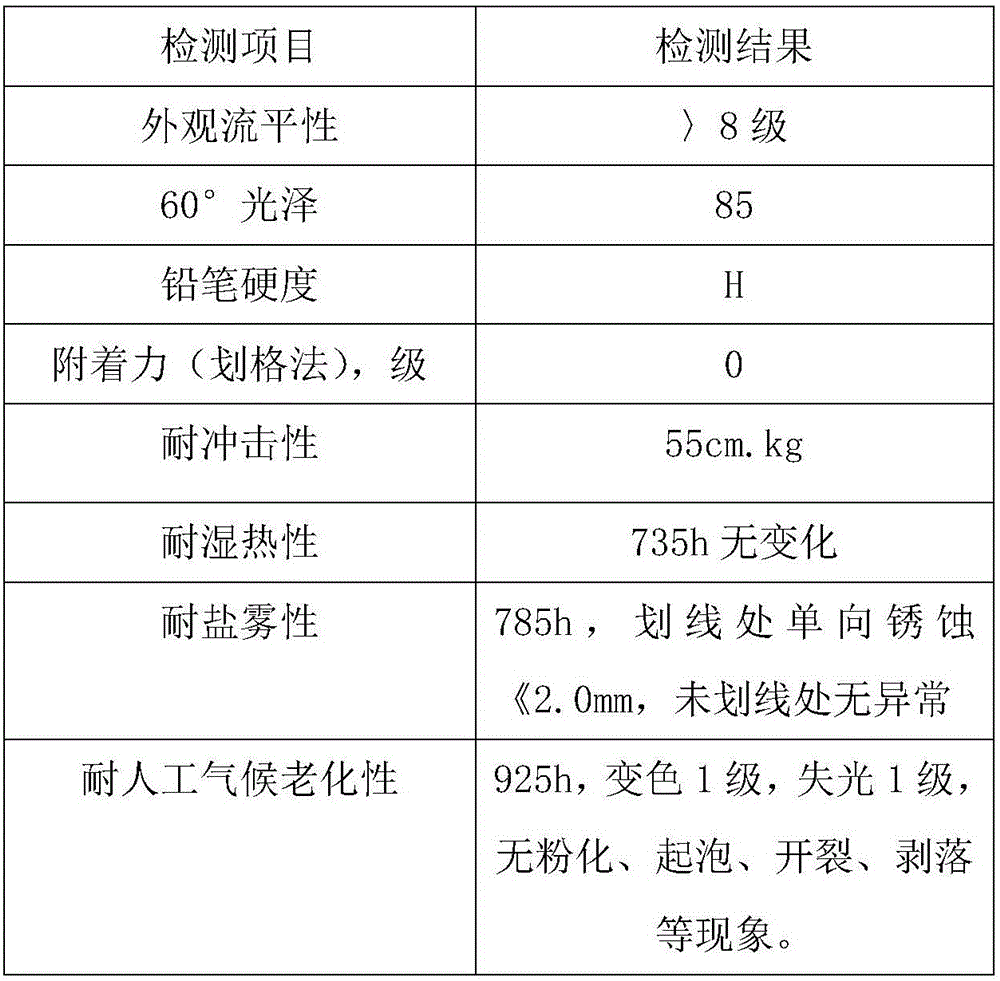

Wear-resistant high-tenacity polyester-butadiene acrylonitrile rubber composite powder coating and preparation method thereof

InactiveCN106280919AImprove shrinkageImprove adhesionConjugated diene hydrocarbon coatingsPowdery paintsCashew nutPolymeric Macromolecules

The invention discloses a wear-resistant high-tenacity polyester-butadiene acrylonitrile rubber composite powder coating. Polyester resin and liquid butadiene acrylonitrile rubber are compounded, so that hole shrinking and cracking of a coating when hydroxyalkyl amide is used as a curing agent are improved effectively, and adhesive power between the coating and metal materials is improved; by adding hyperbranched polyester, compatibility among macromolecules is effectively improved, and tenacity of a composite material is improved; cashew nut shell oil friction powder after being modified by a silane coupling agent kh560 is higher in dispersibility, friction performance of the coating can be adjusted, and retentivity can be improved; other raw materials are combined, and the composite powder coating having good film forming performance and using performance is prepared finally. The composite powder coating is nontoxic, odorless, skid-resistant, wear-resistant, high in tenacity, cracking-resistant, high in adhesive power with a metal substrate and less prone to scaling and shedding, and using experience in outdoor environment is improved effectively while service life is prolonged effectively.

Owner:FUYANG WEIYE FURNITURE

Gradual drive type hub electricity generation bicycle

PendingCN107284573AReduce user burdenImprove user experienceHubsCycle equipmentsElectric generatorElectricity

The invention discloses a gradual drive type hub electricity generation bicycle which comprises a hub, an axle, a front fork, an electricity generator and a gradual drive type driving device. On the basis of drive force generated when the hub rotates, the electricity generator is driven by the gradual drive type structure to rotate so as to replace a gear drive mode in the prior art. According to the gradual drive type hub electricity generation structure, the phenomenon that a user needs great effort during riding due to the fact that electricity generation can be enabled when static friction force of the components and mass inertia of the electricity generator need to be overcome at the same time in the existing drive process is avoided in the riding process, by adopting the gradual drive scheme, a user can slowly start the electricity generator just by overcoming static friction force of the components in the riding process, and therefore the better riding experience is obtained.

Owner:马鞍山虹迈专业化设计有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com