Starting motor

A technology for starting motors and engines, which is applied in the direction of starting electric motors for engines, engine components, machines/engines, etc. It can solve problems such as low reliability, easy grease or dust, fast wear of motor gears and engine flywheels, and improve work efficiency. The effect of flexibility, convenient adjustment and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

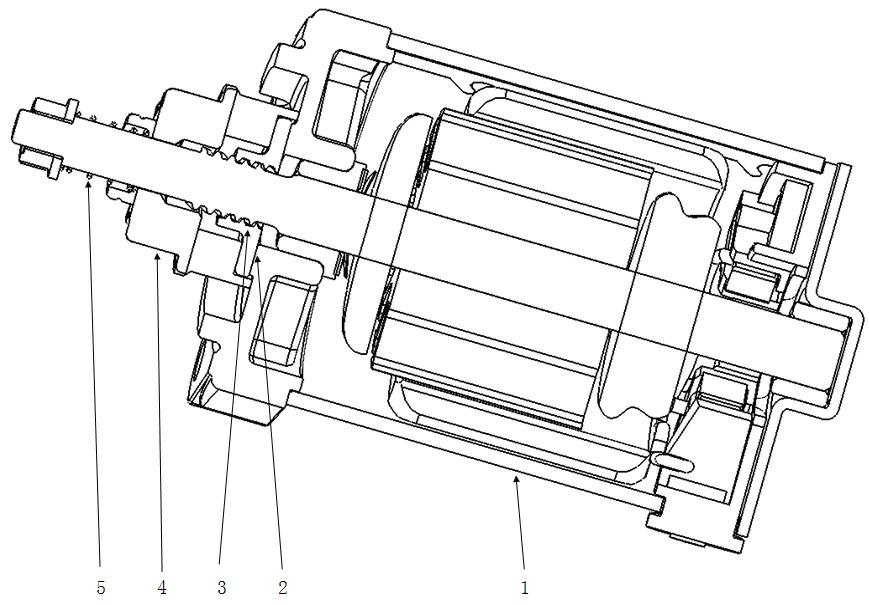

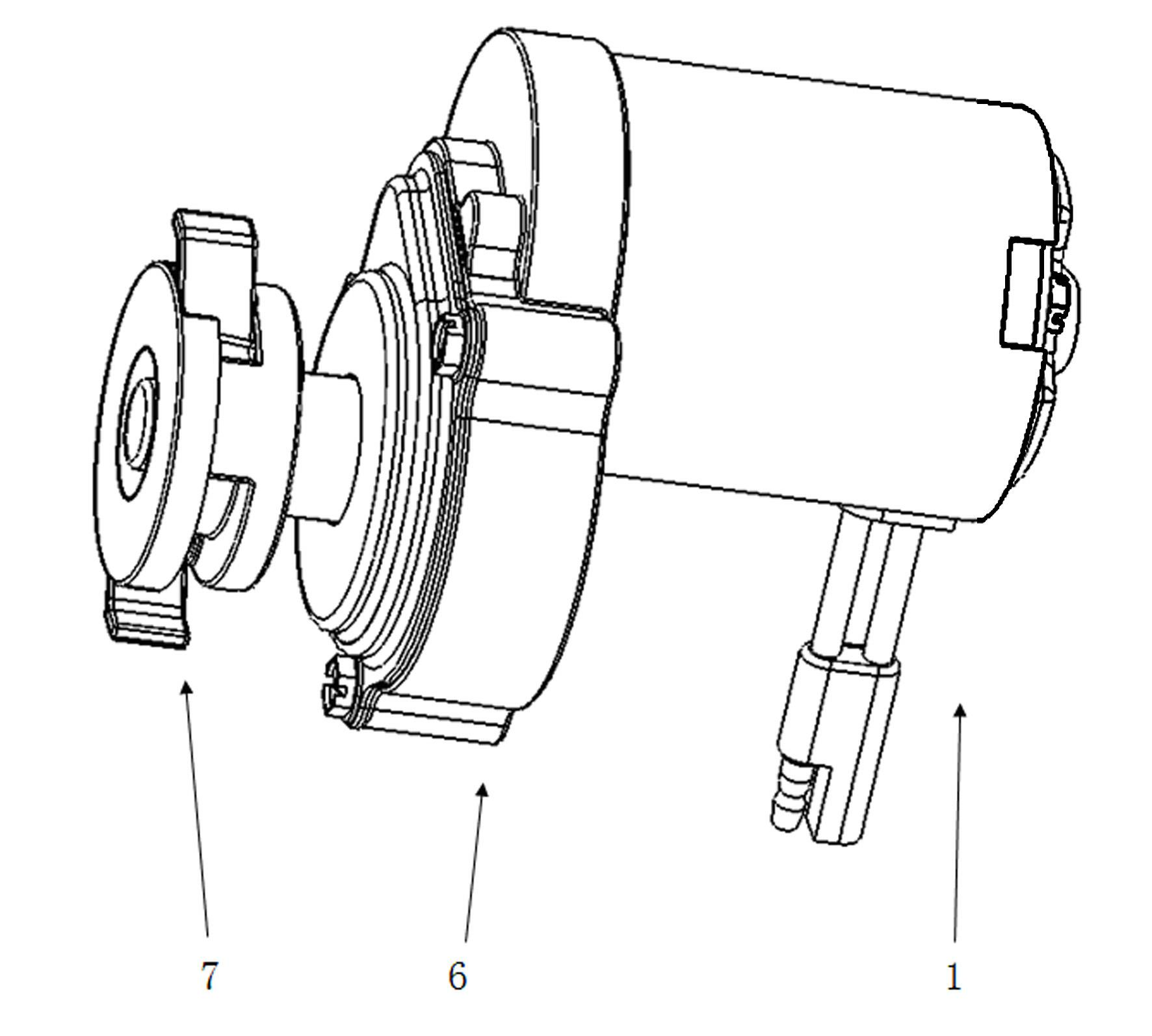

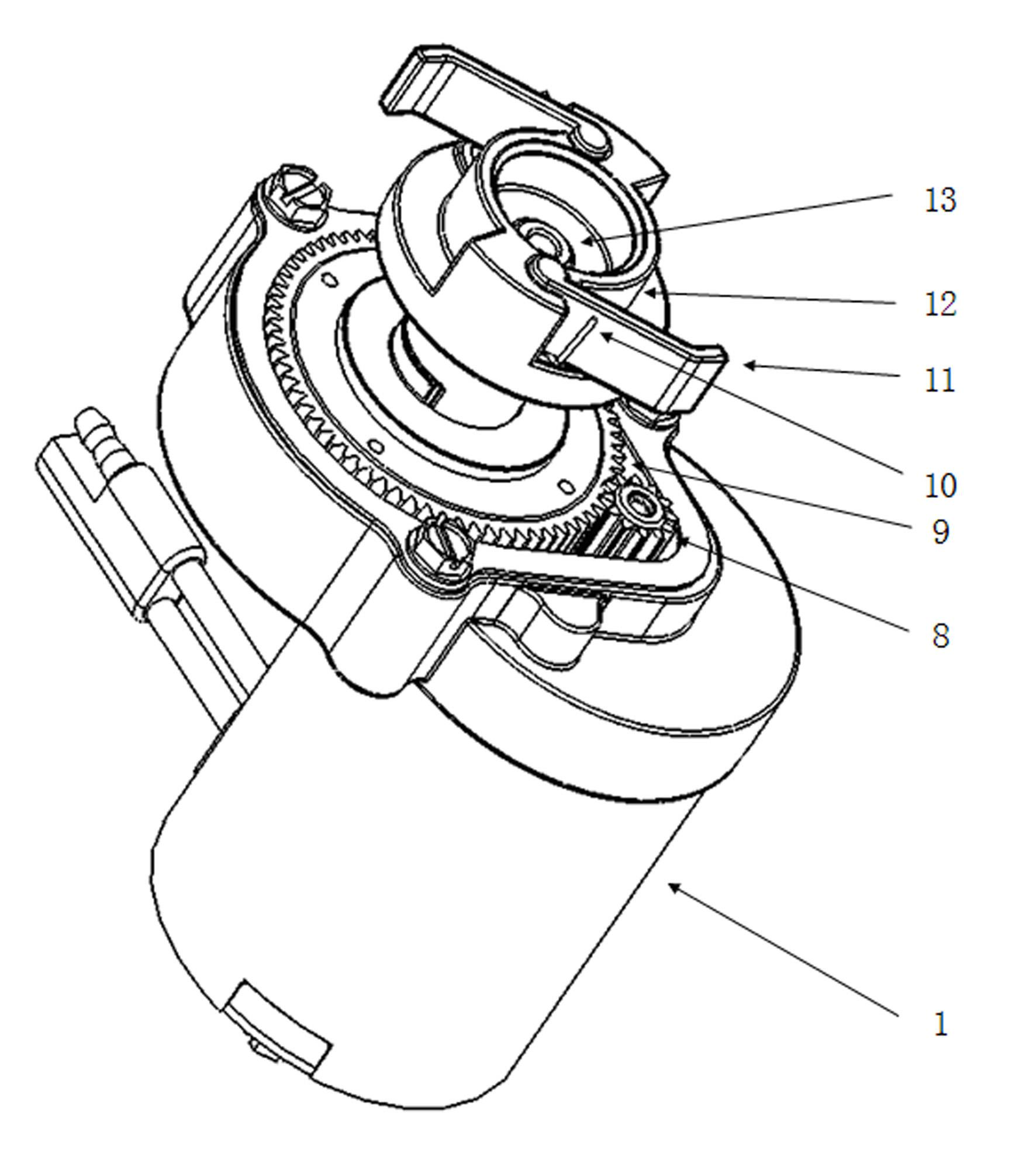

[0024] Embodiment one: if figure 2 , 3 , 5, the present invention includes a motor 1, a drive assembly 6 connected to the shaft of the motor 1, a torque converter 12 connected to the drive assembly 6 to follow its rotation, and at least one torque output piece connected to the torque converter 12 at one end 11. The expansion assembly 7 for opening the torque output sheet 11, the return spring 10 that is located between the torque converter 12 and the torque output sheet 11 to return the torque output sheet 11 and can collide with the torque output sheet 11 to The engine flywheel 17 that makes the torque output plate 11 drive its rotation, the engine flywheel 17 is provided with a thrust portion, and the torque output plate 11 changes the angle of rotation by opening the assembly 7 to increase the length of the overhanging torque converter 12 so that it is in contact with the engine flywheel 17. The pushing parts collide to drive the engine flywheel 17 to rotate. The drive a...

Embodiment 2

[0027] Embodiment 2: The difference from Embodiment 1 is that the bull gear 9 and the torque converter 12 are of an integrated structure, which is convenient for assembly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com