Combined bearing used for vertical epicyclic gearbox of nuclear power circulating water pump

A planetary gearbox, circulating water pump technology, applied in the direction of bearings, flexible bearings, bearing components, etc., can solve the problems of inconvenient disassembly and maintenance, affecting the correct meshing of gears, uneven load on thrust bearings, etc., to achieve the effect of lubrication and heat dissipation Good, to ensure convenience, to avoid the effect of dry friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

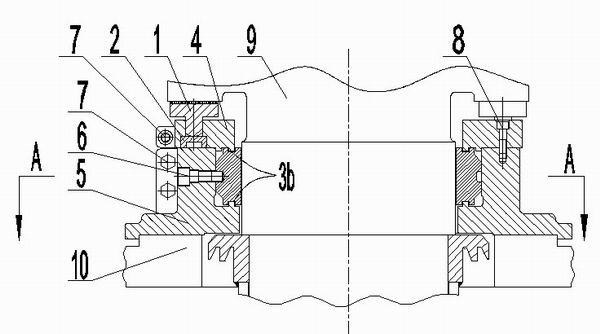

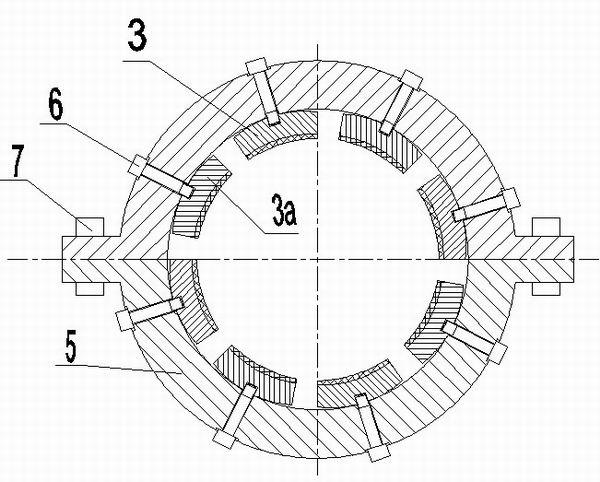

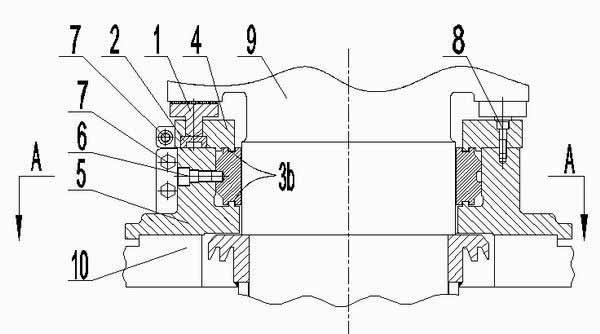

[0019] figure 1 , figure 2 The combined bearing for the vertical planetary gearbox of nuclear power circulating water pump shown is composed of thrust bearing 1, flexible support block 2, radial bearing 3, thrust bearing seat 4, radial bearing seat 5, adjusting bolt 6, coupling bolt 7, screw 8 composition. The thrust bearing seat 4 and the radial bearing seat 5 overlap up and down and are coaxially installed, the lower end surface of the thrust bearing seat 4 and the upper end surface of the radial bearing seat 5 are attached together, and the two are fixedly connected by axially evenly distributed screws 8 . The flexible support block 2 is a rectangular block with a hole at the bottom. The flexible support block 2 is arranged between the thrust bearing seat 4 and the radial bearing seat 5 and is distributed in a circle. The thrust bearing 1 axially passe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com