Stretch film dispenser

a technology of stretch film and dispenser, which is applied in the direction of packaging, etc., can solve the problem that the stretch film dispenser cannot provide the stretch with enough tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

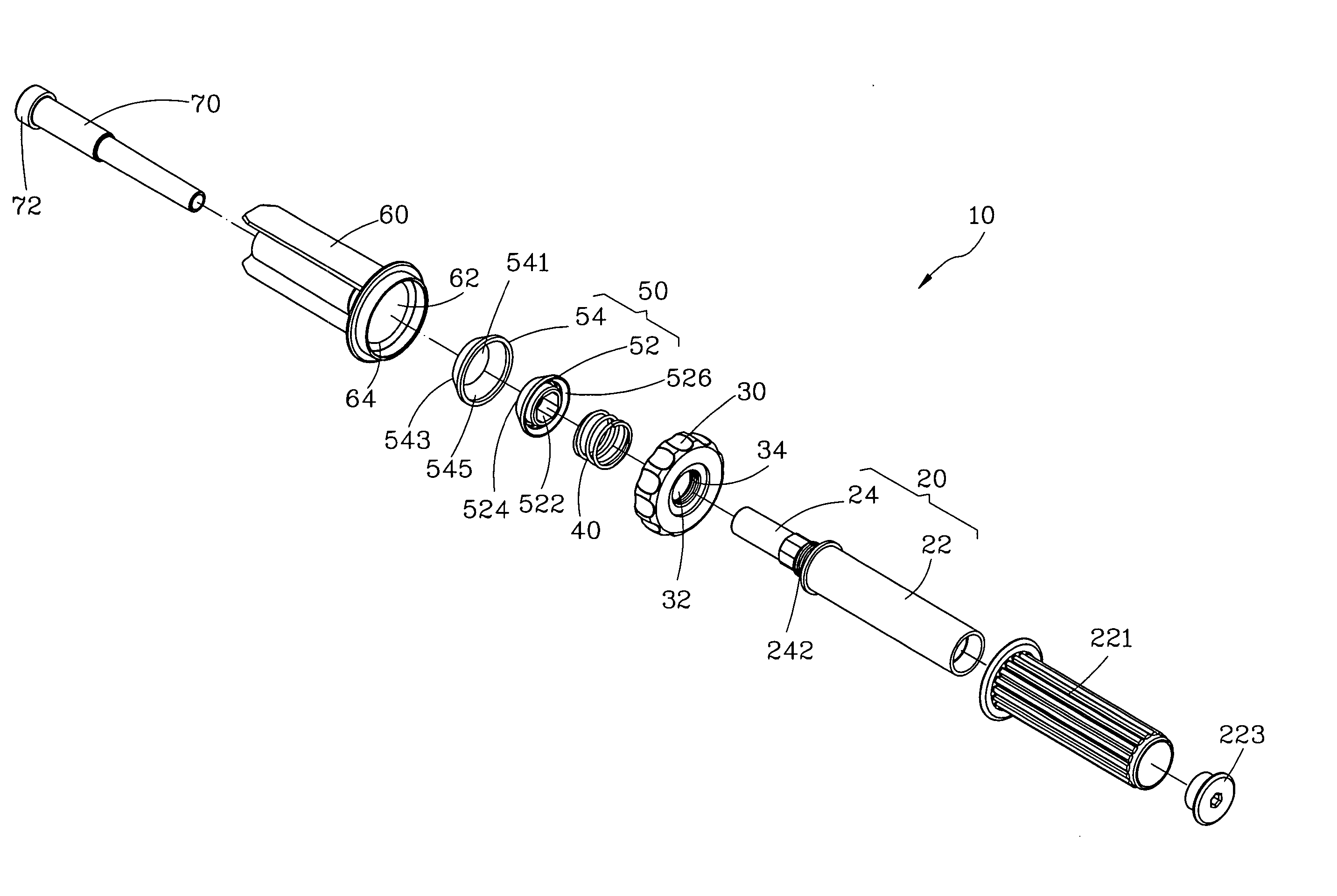

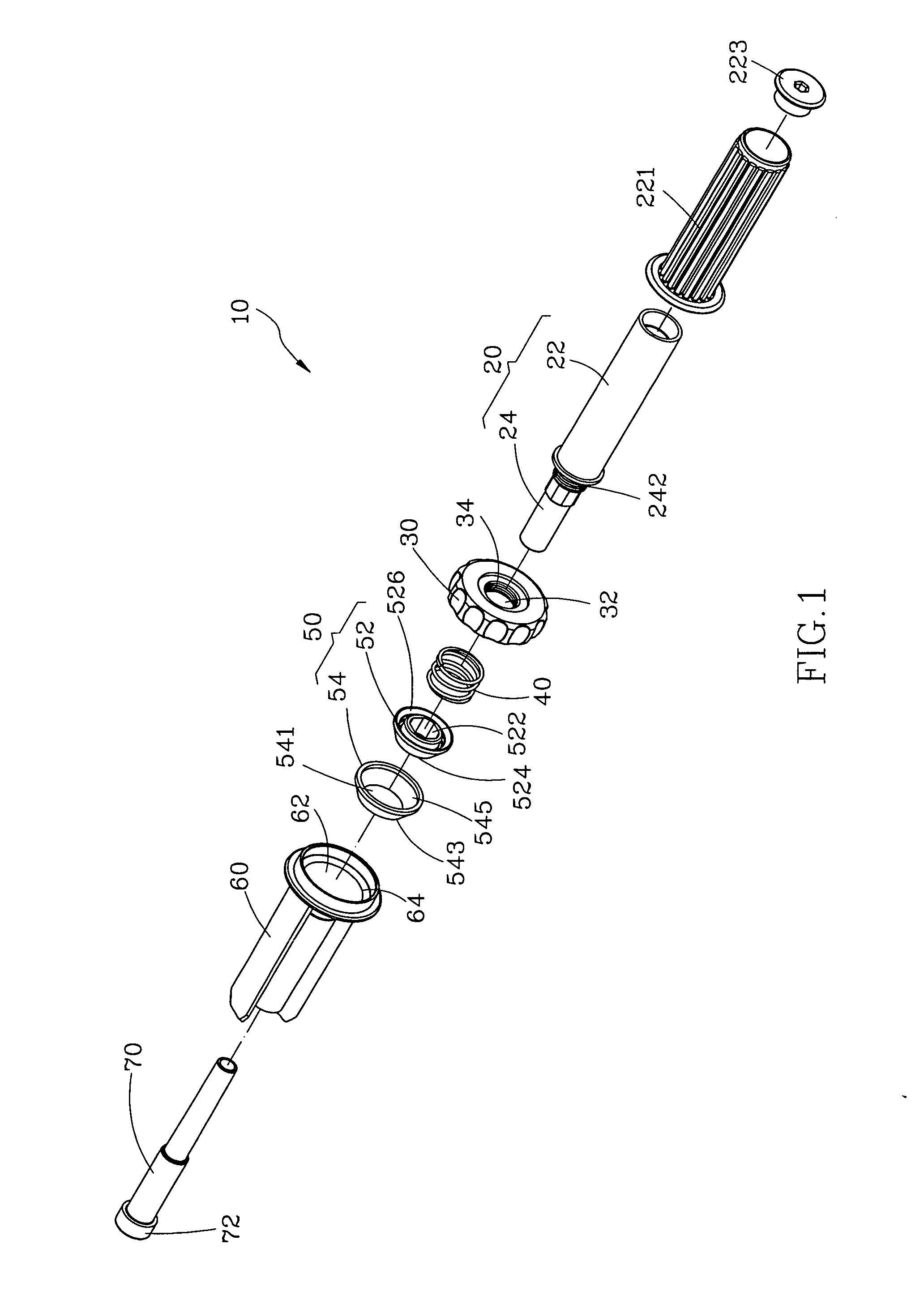

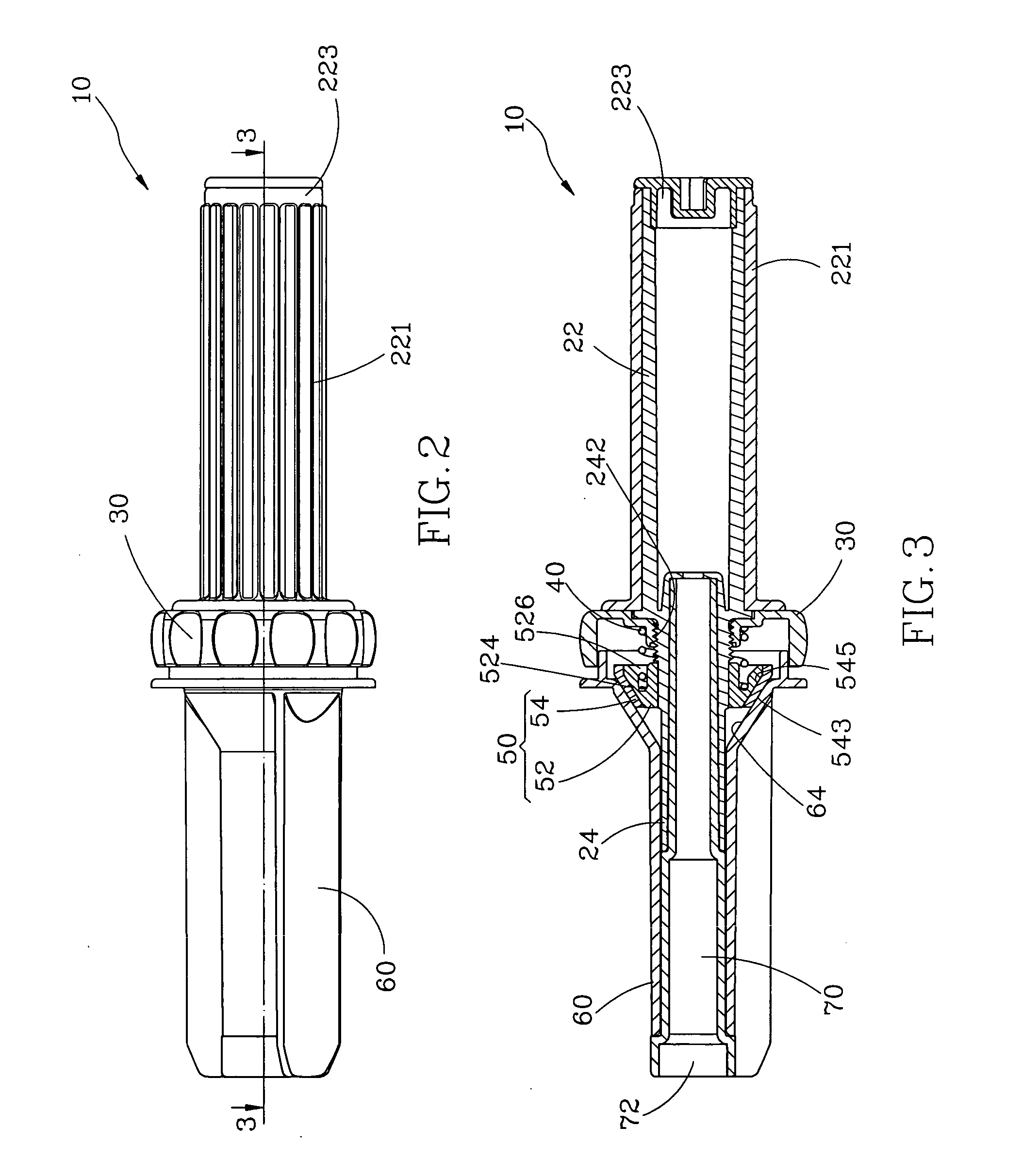

[0014] As shown in FIG. 1 to FIG. 3, a stretch film dispenser 10 of the preferred embodiment of the present invention comprises a core member 20, an adjusting device 30, an elastic member 40, a brake device 50, a roller 60 and a stop member 70.

[0015] The core member 20, which is a tubular member, has a handle portion 22 and a coupling portion 24. A handle tube 221 is fitted to the handle portion 22 of the core member 20, and a plug 223 is inserted into an end of the handle portion 22. The coupling portion 24 has a threaded section 242 adjacent to the handle portion 22.

[0016] The adjusting device 30 has a hole 32 at a center and a threaded section 34 on a sidewall of the hole 32. The adjusting device 30 is screwed onto the coupling portion 24 of the core member 20 with the threaded section 34 meshed with the threaded section 242 of the coupling portion 24.

[0017] The elastic member 40, which is a spring in the present embodiment, is fitted to the coupling portion 24 of the core mem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com