Wear-resistant high-tenacity polyester-butadiene acrylonitrile rubber composite powder coating and preparation method thereof

A technology of nitrile rubber and composite powder, applied in powder coatings, polyester coatings, coatings, etc., can solve the problems of low friction coefficient, unsatisfactory adhesion, and potential safety hazards on the coating surface, and achieve the best user experience And the effect of improving service life, improving shrinkage cavity and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

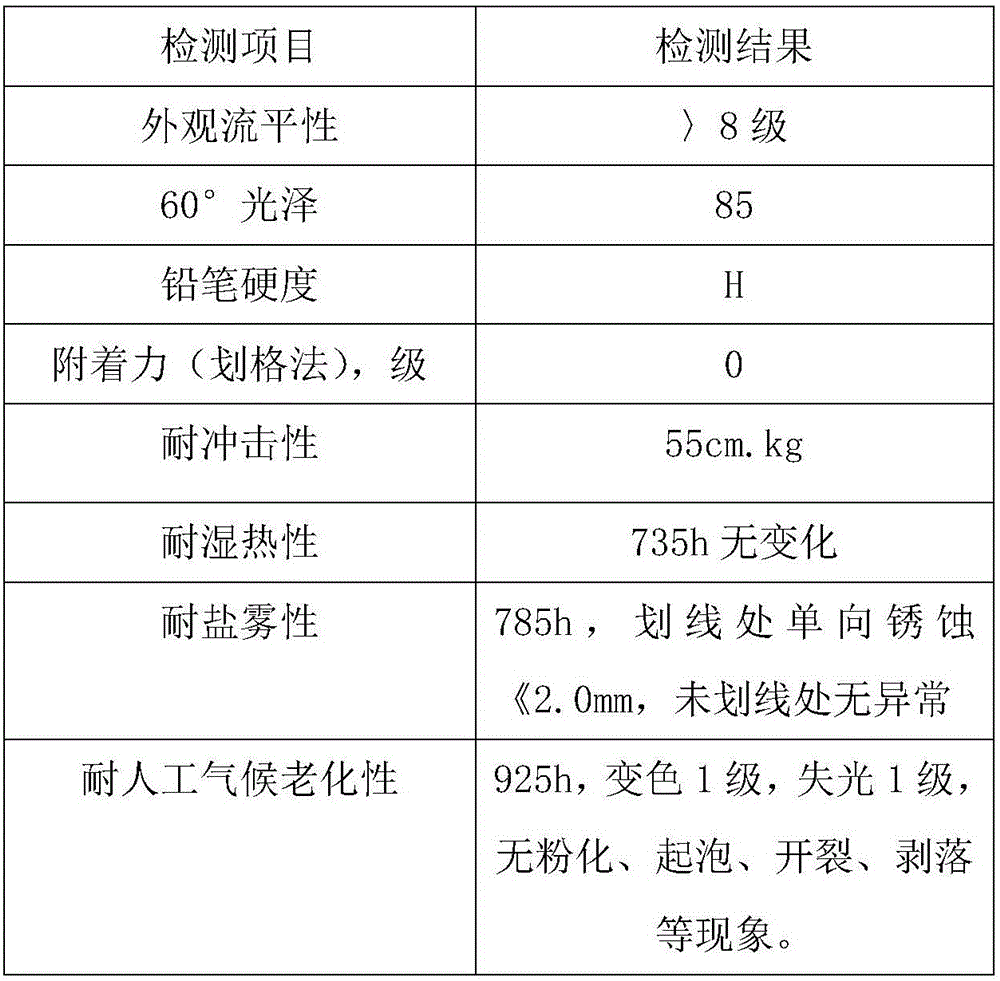

Examples

Embodiment Construction

[0011] A wear-resistant high-toughness polyester nitrile rubber composite powder coating, the powder coating is made of the following raw materials in parts by weight: polyester resin chip 50, liquid nitrile rubber 10, hyperbranched polyester 8, cashew nut shell oil friction Powder 4, polyether modified silicone oil 3, hydroxyalkylamide 3, pigment 5, zinc stearate 1, silane coupling agent kh560 0.4, vulcanizing agent PDM 0.1.

[0012] The preparation method of described a kind of wear-resistant high-toughness polyester nitrile rubber composite powder coating, described preparation method comprises the following steps:

[0013] (1) Mix, grind and disperse the cashew nut shell oil friction powder and silane coupling agent kh560 for 20 minutes, and then set aside;

[0014] (2) Put the material obtained in step (1) into a high-speed mixer together with other remaining raw materials to stir and mix evenly, then send the material into a twin-screw extruder, extrude and granulate at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com