Gradual drive type hub electricity generation bicycle

A bicycle and hub technology, applied to bicycle accessories, vehicle parts, wheel hubs, etc., can solve the problems of photoelectric conversion rate and weather factors, riding difficulties, etc., so as to improve user experience, reduce user burden, and prevent device failure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

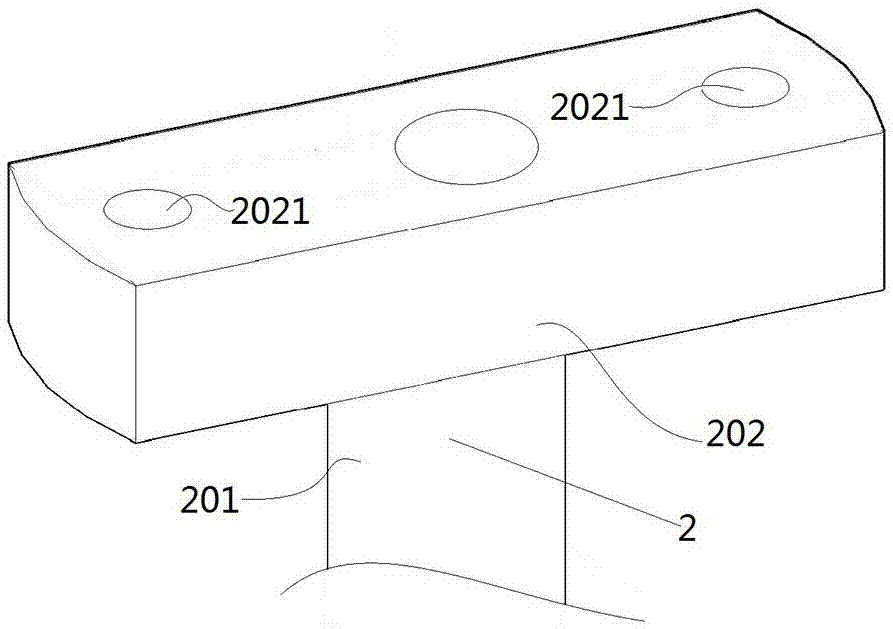

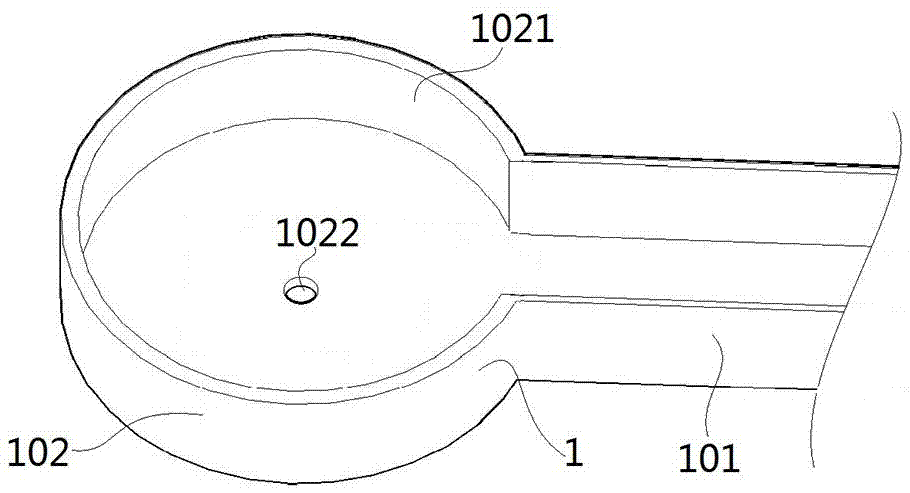

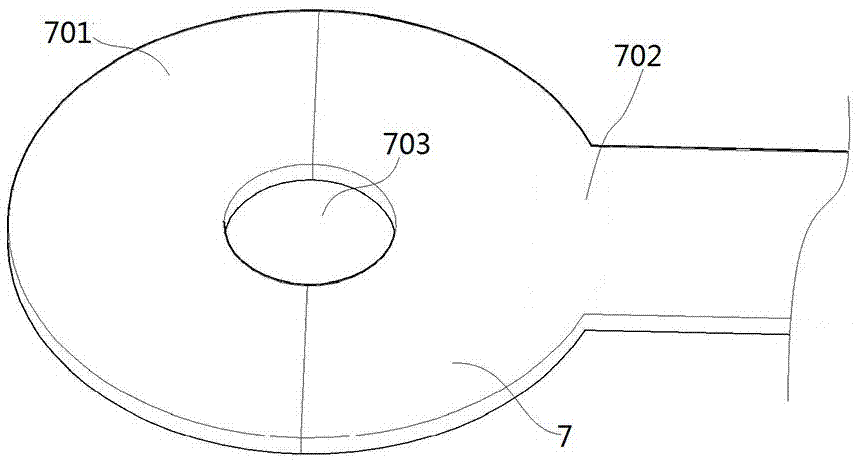

[0035]A kind of gradually driving type hub power generation bicycle of the present embodiment comprises a front fork (1), a wheel shaft (3), a driving device (2), a driven wheel (4), a bearing, a generator (5), a friction transmission device ( 6) and a cover plate (7), the front fork (1) includes a fork arm (101) and a fork head (102); Drive-type hub power generation device; the fork (102) has a cylindrical cavity (1021) structure corresponding to the center axis of the wheel; the fork (102) is located at the center of the far side of the wheel to make the wheel shaft (3) the hole (1022) that passes through, the opening (1023) that is adapted to the inner diameter of the cylindrical cavity on the side near the fork (102) and the wheel; one end of the wheel shaft (3) passes through the fork (102) hole (1022) and is fixed to the fork (102) by screws; the driven wheel (4) is a disk suitable for the inner diameter of the cylindrical cavity (1021); the middle part of the driven whe...

Embodiment 2

[0037] A progressively driven hub generator bicycle of this embodiment is basically the same as that of Embodiment 1, except that it also includes a screw; the hole (2021) is a through hole, and the through hole is far away from the end of the driven wheel (4) It is a threaded structure; the friction transmission device (6) is installed in the through hole, and the screw rod is installed in the threaded section of the through hole, and the friction transmission device (6) is squeezed by changing the length of the screw rod screwed into the through hole to change Friction force; a spring can be installed between the screw rod and the bottom end of the friction transmission device (6).

Embodiment 3

[0039] A kind of gradual drive type hub power generation bicycle of this embodiment is basically the same structure as any one of Embodiment 1 or 2, the difference is that: the friction transmission device (6) is a magnet or a magnetic buckle, and its magnetic attraction Facing towards the side of the driven wheel (4); correspondingly, the position corresponding to the movement track of the driven wheel (4) and the friction transmission device (6) is a magnetically permeable material; and the surface of the magnetically permeable material on the driven wheel (4) is covered with Non-magnetic material, to avoid debris generated by friction from entering the magnetic buckle and affecting the attractive force; the magnetic buckle can be an adjustable magnetic buckle; the magnetic adjustable magnetic buckle includes a ring magnet, a shell and a screw; the shell It is a cavity structure made of magnetically permeable materials. The cavity is a cylindrical cavity that is compatible wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com