Power head guiding rail structure of drilling machine

A power head and guide rail technology, which is applied in earthwork drilling, drilling equipment, support devices, etc., can solve the problems of drill pipe and drilling rig centering mechanism wear, drilling rig power head guidance and orientation deterioration, low efficiency, etc., to achieve Maintain drilling accuracy, high coaxiality, and prevent shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

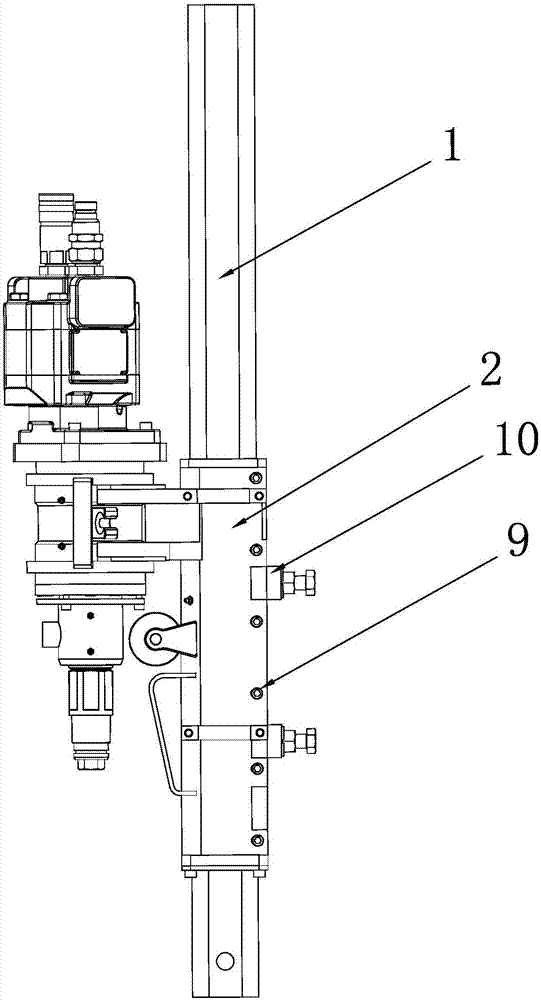

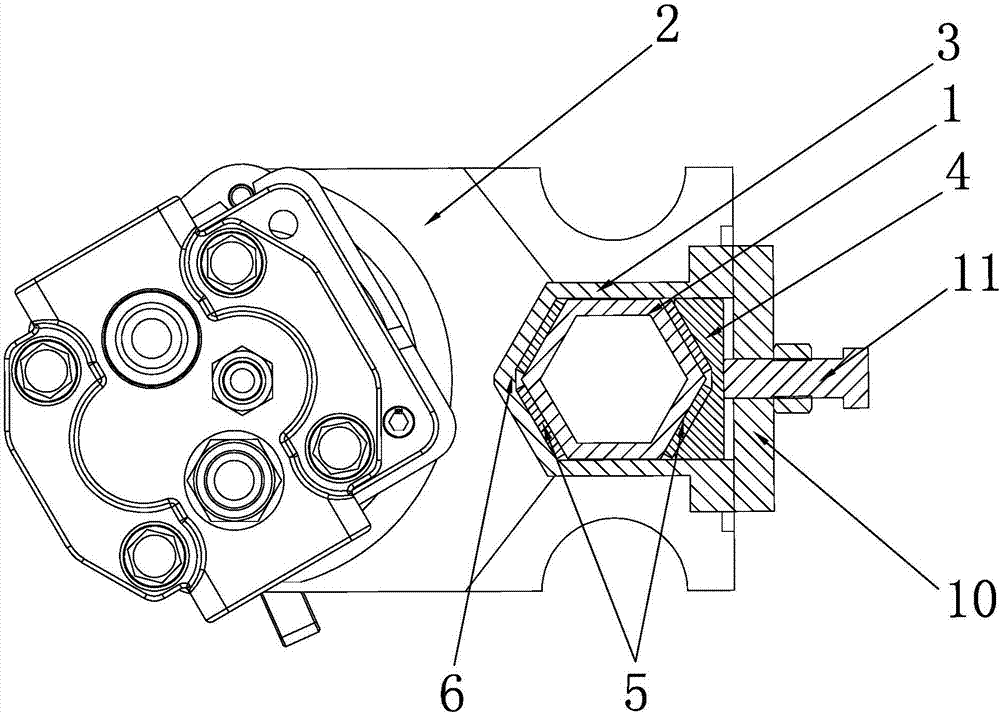

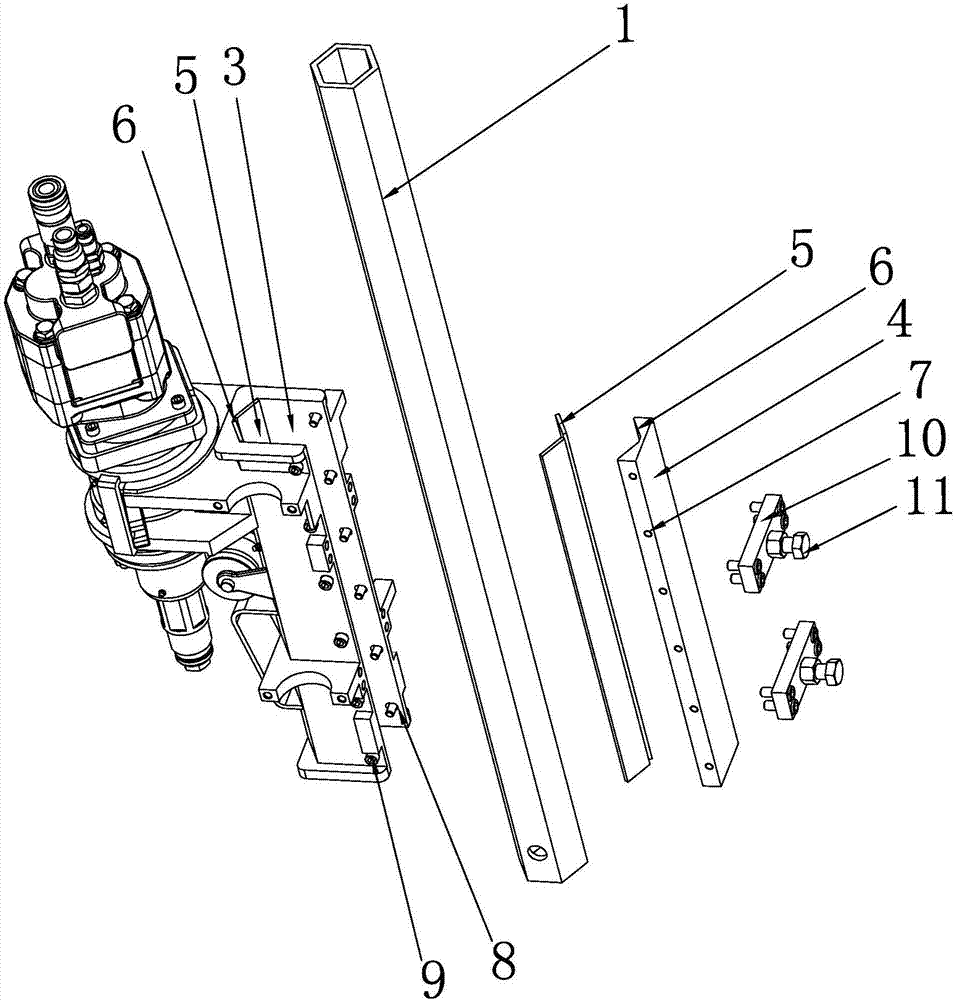

[0023] see figure 1 and figure 2 , a power head guide rail structure of a drilling rig according to the present invention, comprising a guide rail 1 installed on the drill bracket and a power head support 2 mounted on the guide rail 1 and movable along the guide rail 1, the power head support 2 is provided with upper and lower Through the guide groove 3 with opening on the right side, an adjustment block 4 is detachably installed on the right side of the guide groove 3 , and the position of the adjustment block 4 relative to the guide groove 3 is adjustable.

[0024] Specifically, as image 3 As shown, the front and rear sides of the adjustment block 4 are provided with threaded holes 7, and the front and rear side walls of the guide groove 3 are provided with strip holes 8, and the length direction of the strip holes 8 is in line with that of the guide rail 1. The axial direction is vertical, and the adjustment block 4 is installed in the guide groove 3 through the locking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com