Modularized ultrasonic clutch and brake apparatus

A clutch device, ultrasonic technology, applied in the direction of clutch, brake actuator, brake type, etc., can solve the problem that the clutch device has not been engaged or disengaged, and achieve the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

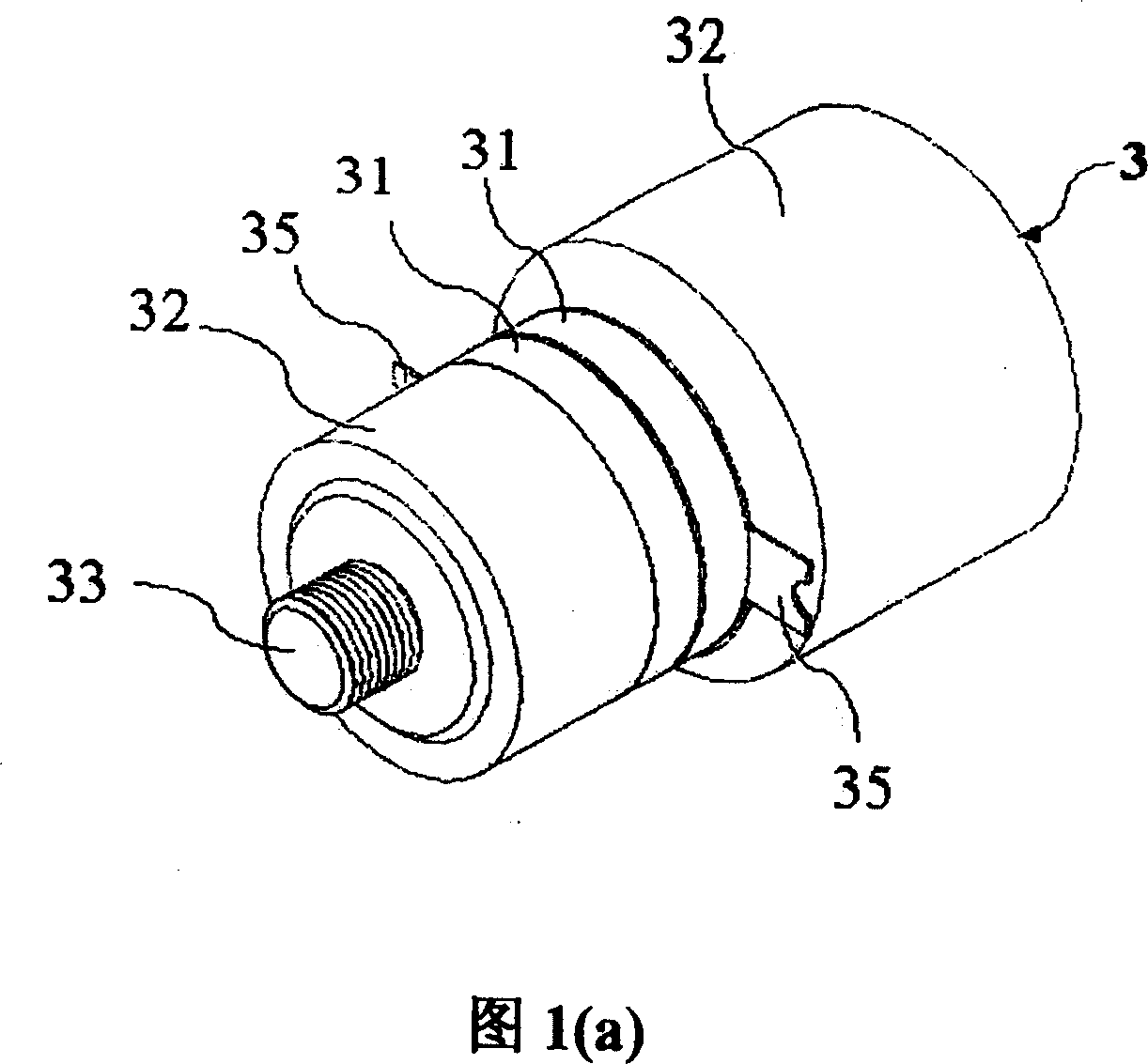

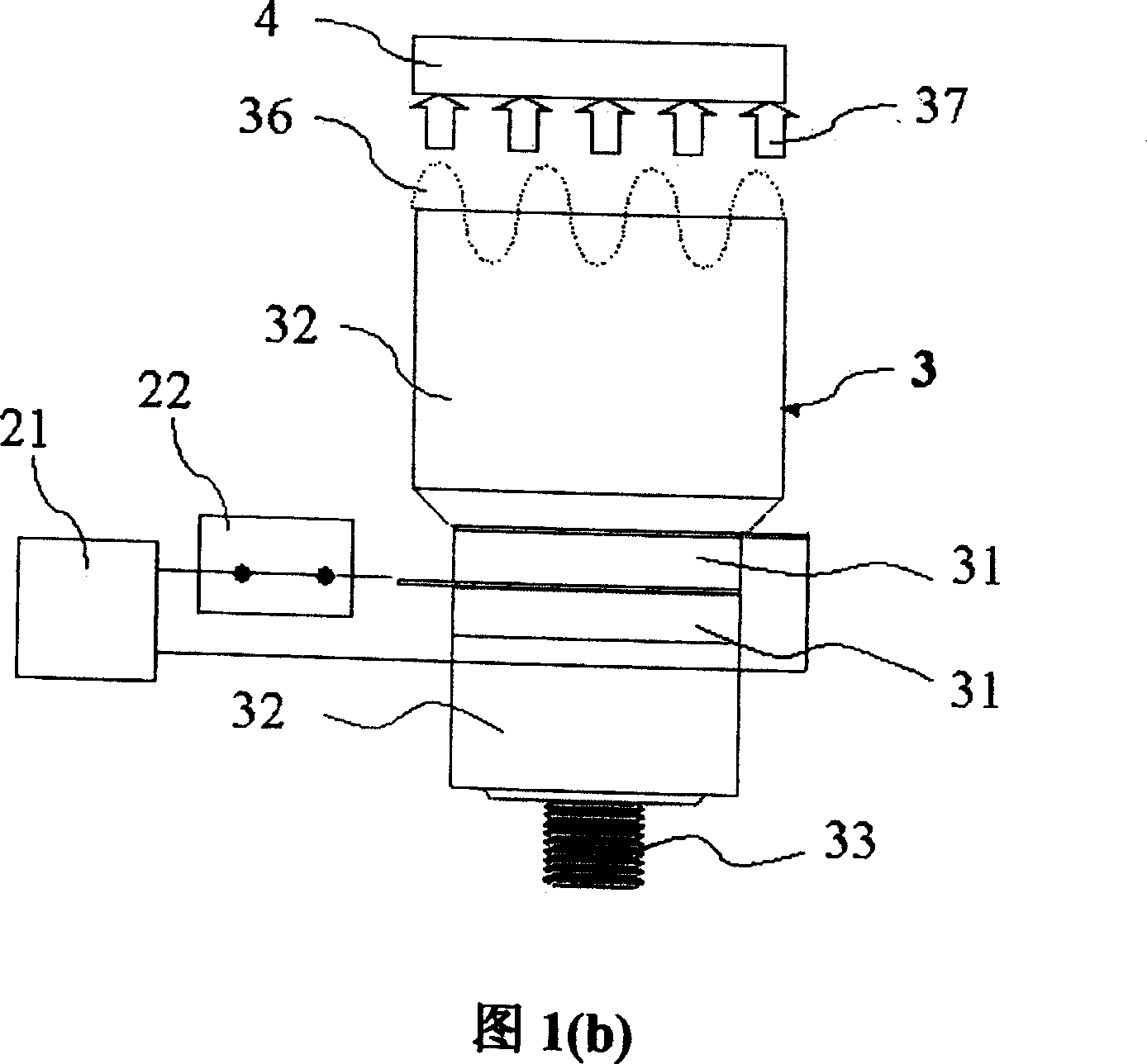

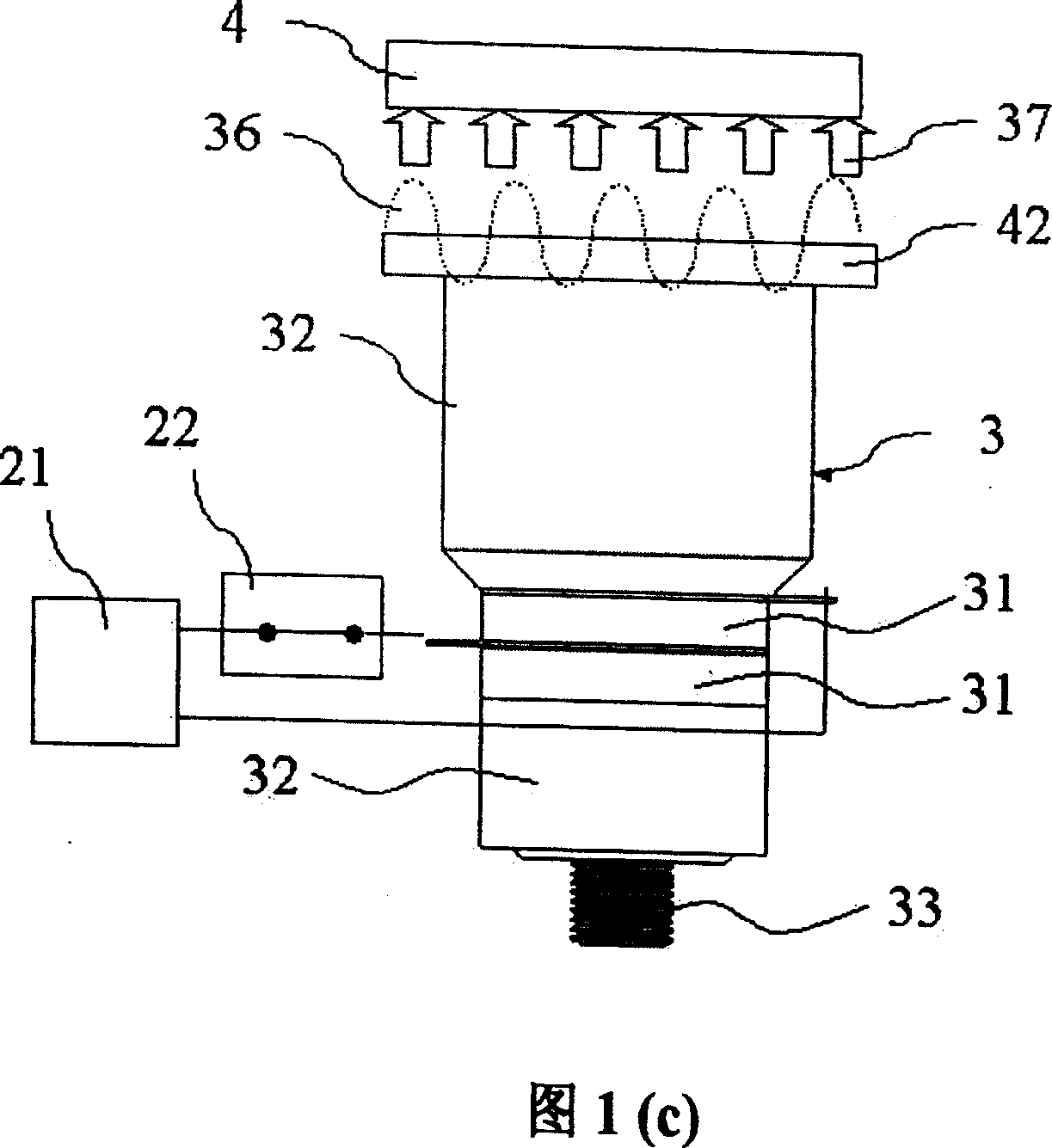

[0050] Please refer to Fig. 3 (a) ~ (c), which is a preferred embodiment of the modular ultrasonic clutch device provided by the present invention. The present invention adopts a symmetrical structural design, mainly including a control power supply group, a drive Component 3 , a driven component 4 , two support frames 51 a , 51 b , a preload adjusting device 6 , two fixing seats 11 a , 11 b and a base 12 .

[0051] Please refer to Fig. 2(a)-(d) and Fig. 3(a)-(c), the modular ultrasonic clutch device uses screws to fix the two supporting frames 51a, 51b on the base 12; secondly, A driving element 3 will be inserted into the inner hole of the bearing on the left side support frame 51a, and a driven element 4 will be inserted into the inner hole of the bearing fixed on the right side of the base 12 support frame 51b; then, drive The end points of the threaded brackets of the element 3 and the driven element 4 can be placed into the fixing seats 11a, 11b, wherein the fixing seats...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com