Yarn false twist texturing apparatus

A texturing machine and crimping technology, applied in textiles and papermaking, liquid/gas/steam yarn/filament processing, etc., can solve the problem of insufficient twisting of filaments, and achieve the effect of avoiding filament friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

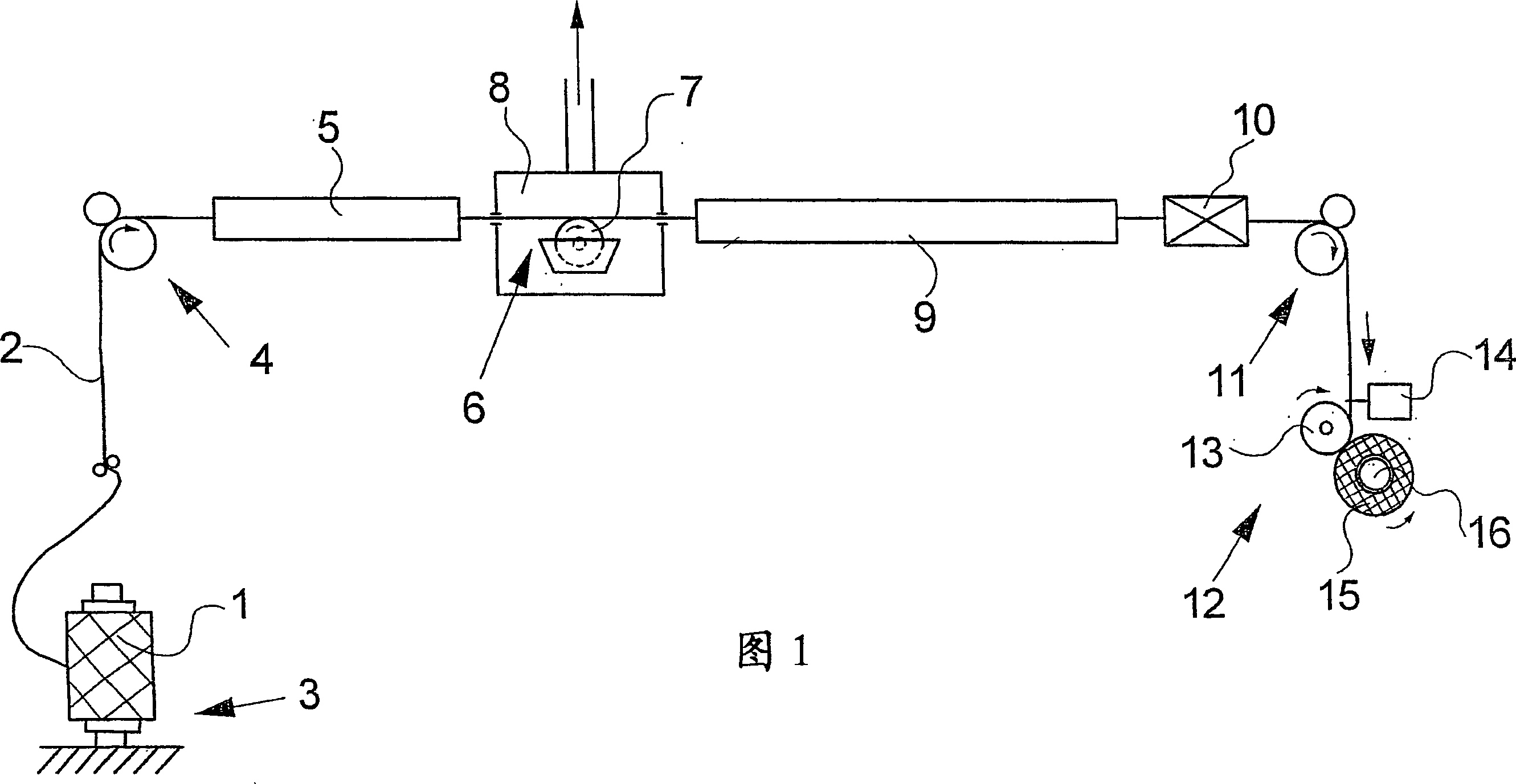

[0023] FIG. 1 schematically shows the stations of a first embodiment of a texturing machine according to the invention. The frame for fixing the machine base of each processing device is not shown in the figure here.

[0024] On creel 3, fix one and feed bobbin 1. The feed bobbin 1 contains a filament 2 which is drawn off from the feed bobbin 1 by means of a first conveying device 4 . A heating device 5 , a wetting device 6 , a cooling device 9 , a crimping device 10 and a second conveying device 11 are arranged downstream of the first conveying device 4 in the thread path. The filament 2 is fed by a second feed mechanism 11 to a winding device 12 . The filament 2 is wound into a package 15 in the winding device 12 . The winding device 12 is composed of a driving roller 13 , a reciprocating mechanism 14 and a bobbin holder 16 . The mandrel 15 is here driven at a substantially constant speed by means of a drive roller 13 .

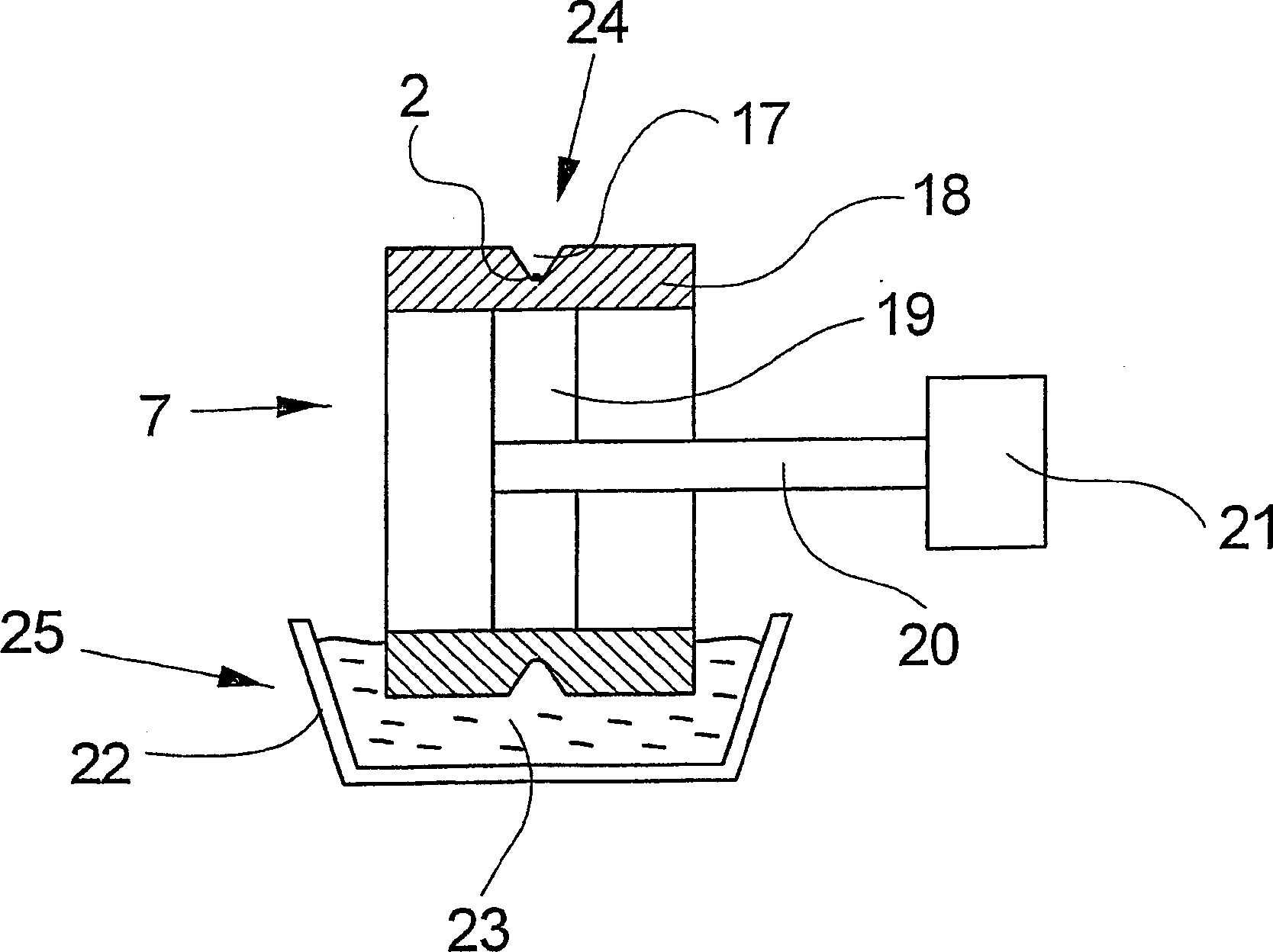

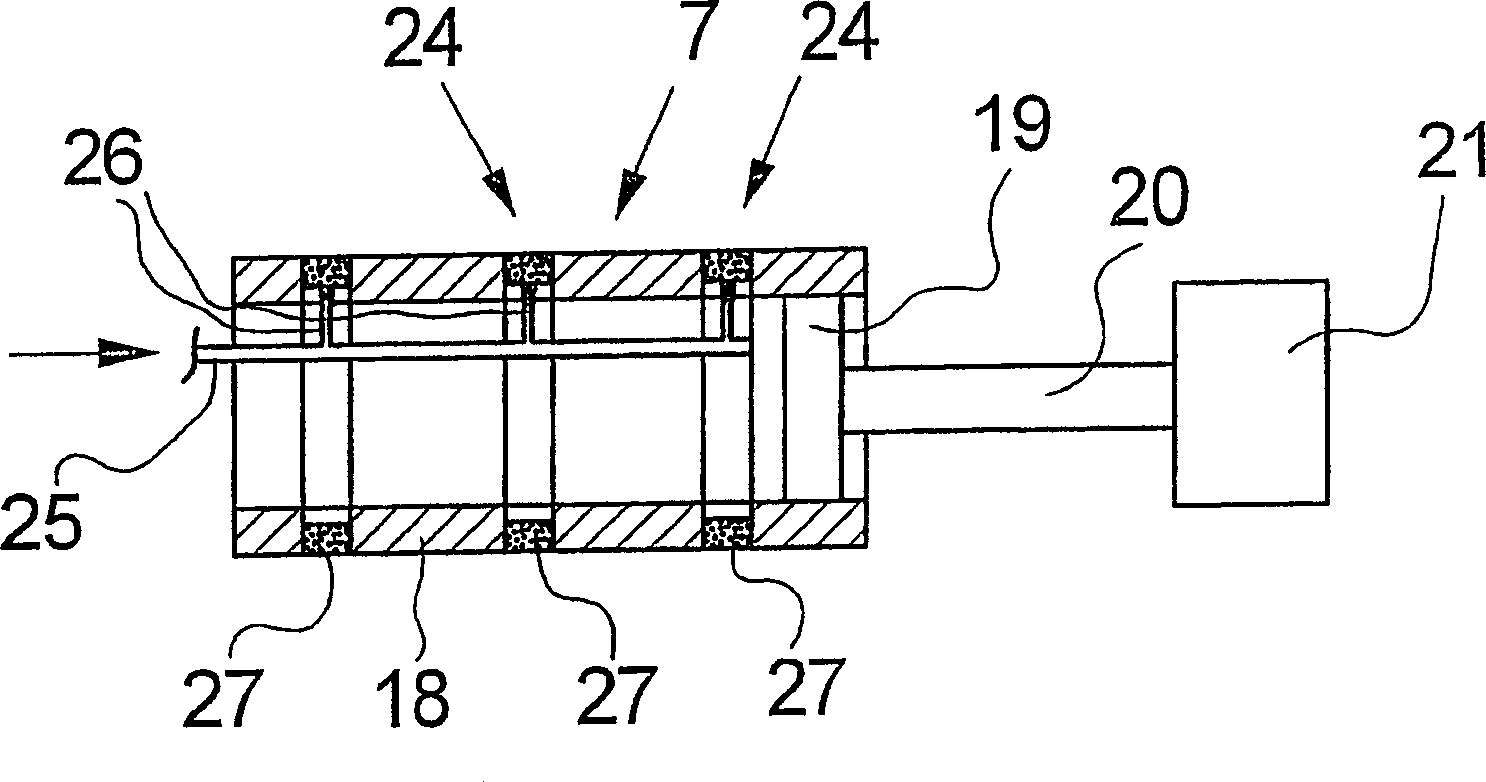

[0025] In the crimping zone formed between the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com