Method of producing not-hardened waxy rice cake and waxy rice cake produced by using the same

A technology of glutinous rice cake and glutinous rice, which is applied in the field of processed food to achieve the effect of promoting development and realizing globalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

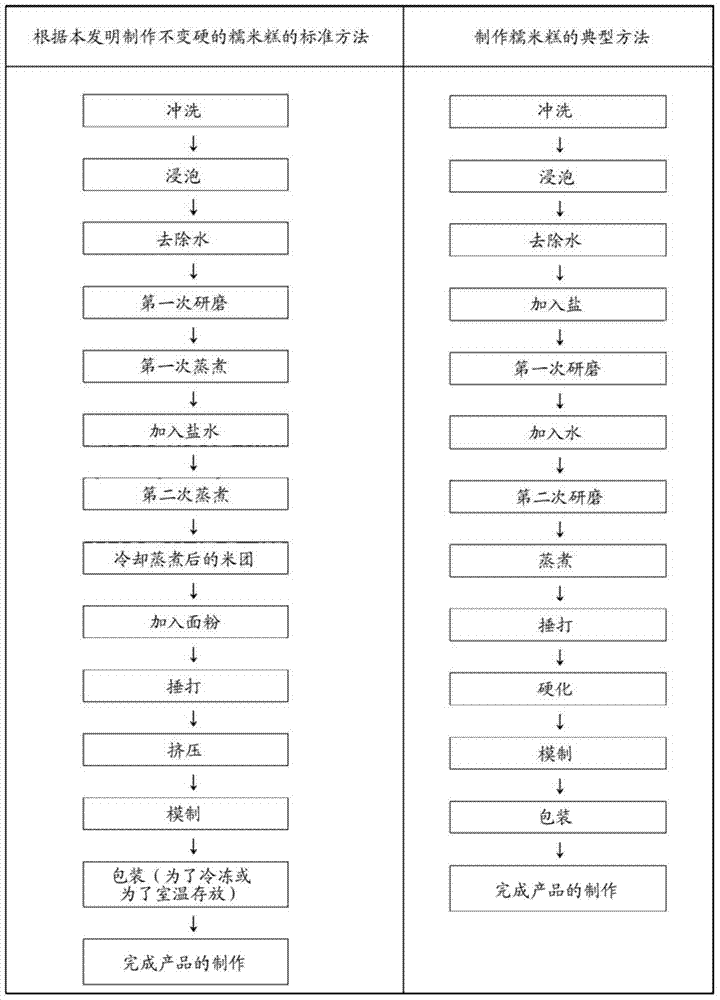

Method used

Image

Examples

Embodiment 1

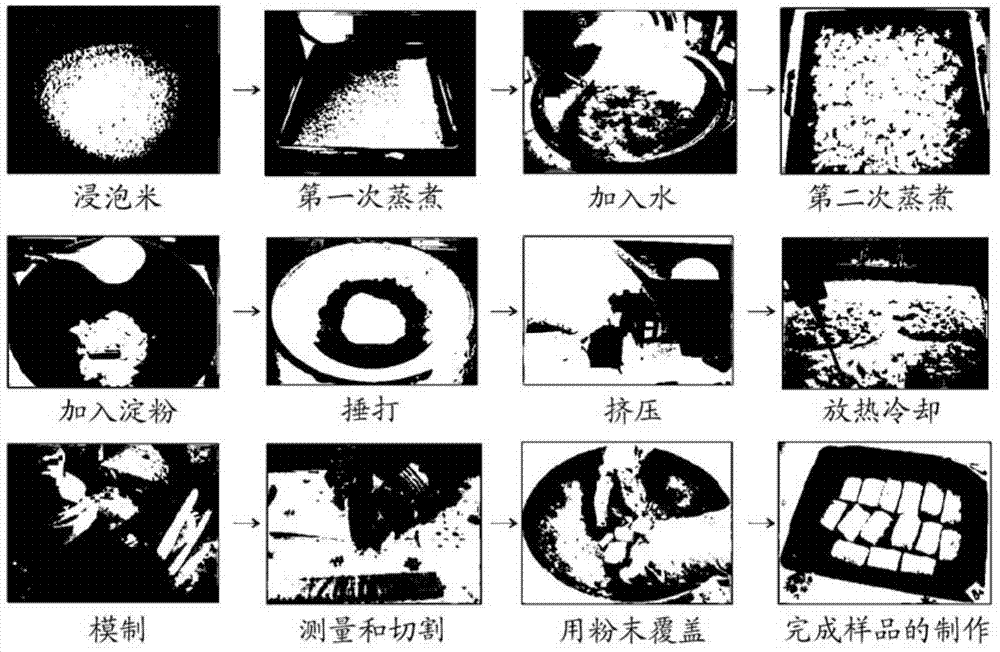

[0036] Production Example 1: Making Ingami with Different Water Contents

[0037] Ingami was made using the mixing ratios and methods shown in Table 1, but based on the weight of the water-soaked glutinous rice, the water content, which was a key factor in making Ingami, was varied to 0%, 5%, 10%, 15 % and 20%. Namely, the glutinous rice was soaked in water for 4 hours to 8 hours, then the water was removed from the glutinous rice, the weight of the glutinous rice soaked in water was measured, and it was steamed for the first time in an earthenware steamer-type steam pot (Kyungchang machine, Kyunggi Kwangjoo, Korea) Glutinous rice 20 minutes to 40 minutes. In each case, based on the weight of the soaked glutinous rice, 0.8wt% to 1.5wt% of salt was added to the corresponding amount of water shown in Table 1 to prepare brine, and then, the brine was added to the first cooking After the glutinous rice, then steamed for the second time for 10 minutes to 30 minutes. Cool the sec...

Embodiment 2

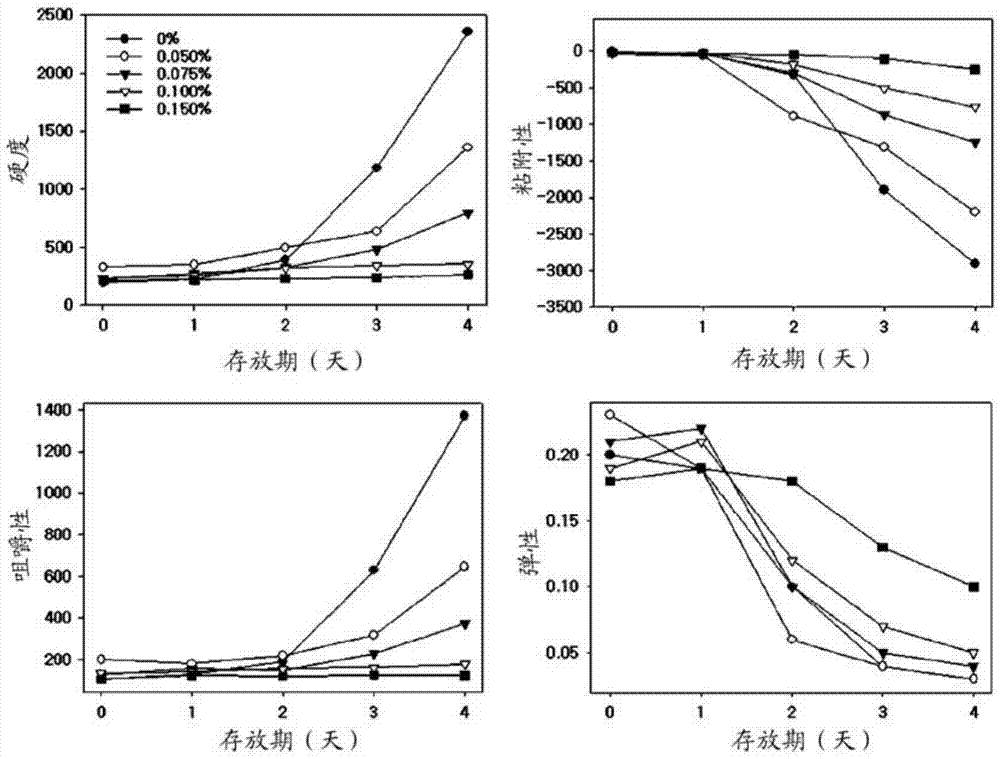

[0042] Production Example 2: Making Ingami with Different Flour Contents

[0043] Table 2 below shows the mixing ratio and method of Ingami prepared with different flour contents. In the process of making Ingami, the flour content is a key factor during the beating. Except that the water content is 5% or 10% by weight of the water-soaked glutinous rice and the flour content is 0%, 0.05%, 0.1%, 0.15% and 0.2% by weight of the water-soaked glutinous rice. Ingami is made in the same way as Example 1.

[0044] [Table 2]

[0045] Mixing Ratio and Method of Ingami at Different Flour Contents

[0046]

Embodiment 3

[0047] Production Example 3: Production of Ingami when further extruded

[0048] The method of making Ingami also includes squeezing after beating. Specifically, except that the water content is 5% of the weight of the glutinous rice soaked in water and the flour content is 0%, 0.05%, 0.075%, 0.1% and 0.15% of the weight of the glutinous rice soaked in water, in the same way as the preparation Ingami is made in the same way as Example 1. Extrusion is performed by squeezing the beaten mochi with a bar-shaped rice cake forming machine. Extrusion minimizes unflattened grains of glutinous rice in the mochi and smoothes the mochi.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com