Dairy product rich in cellulose and preparation method thereof

A technology for dairy products and cellulose, applied in the field of cellulose-rich dairy products and their preparation, can solve the problems of poor taste of insoluble dietary fiber, hinder mineral absorption, and have a mushy taste, achieve moderate taste, and promote intestinal tract Peristaltic, frankincense effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

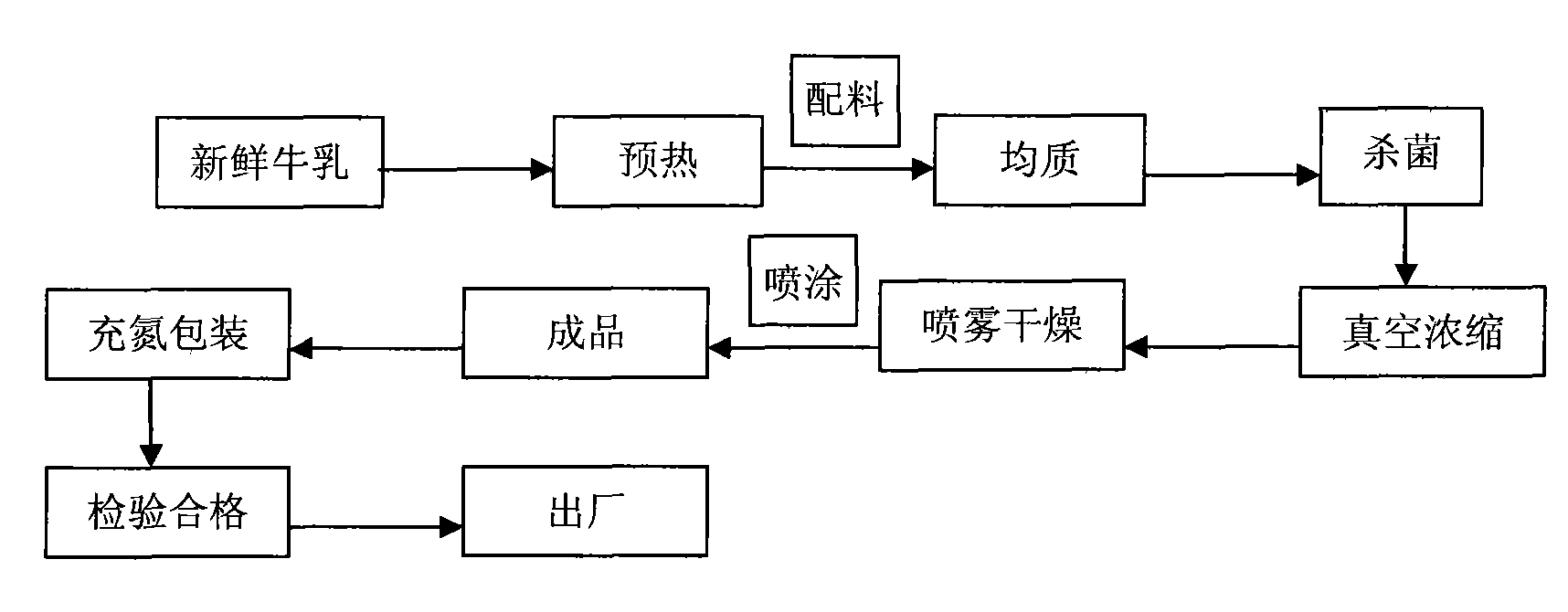

Method used

Image

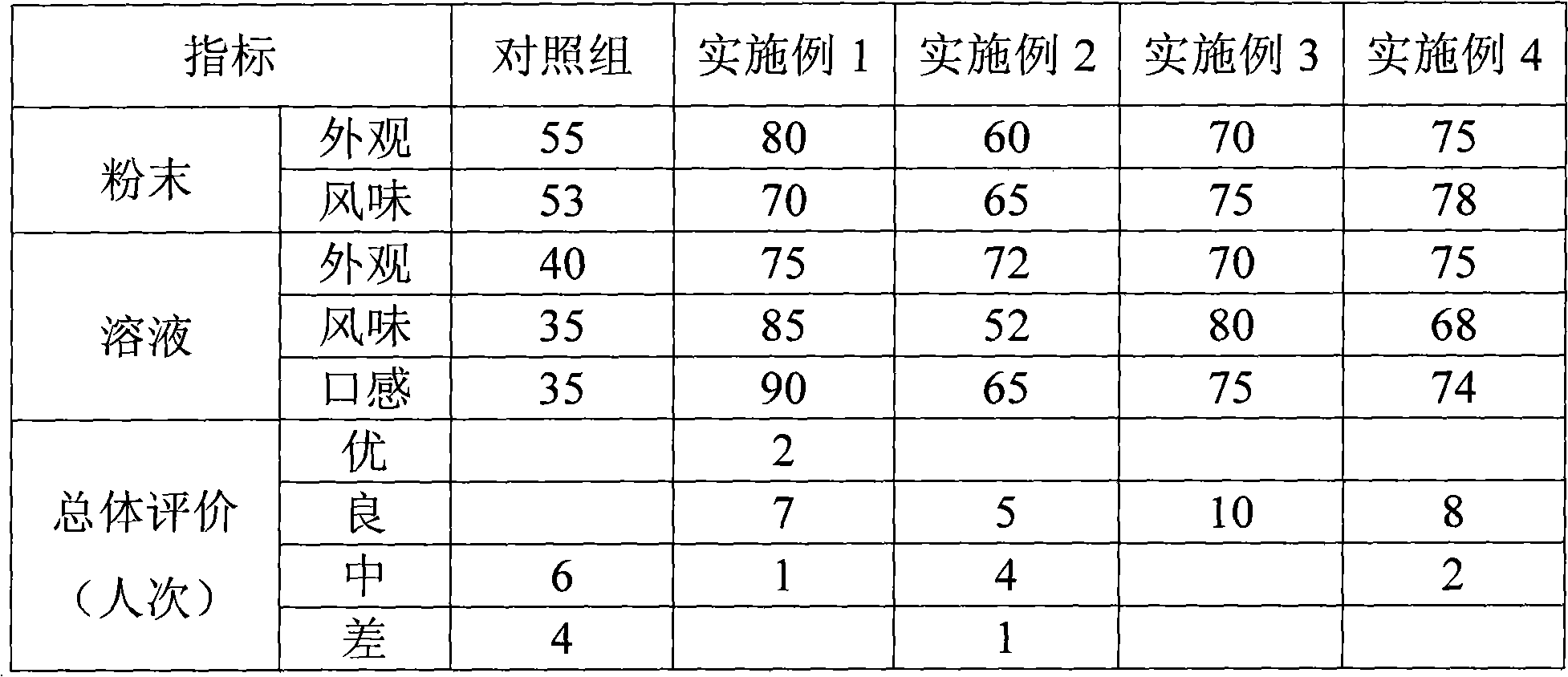

Examples

Embodiment 1

[0033] formula:

[0034] Raw material name

Dosage(kg)

skim milk

4330

620

multi-vitamins

2

complex minerals

3

coffee powder

4

Powdered Coffee Flavor

2

[0035] Preparation Process:

[0036] ①Standardized skim milk, milk solids 8.4%, protein ≥ 2.9%, fat ≤ 0.1%, lactose ≥ 4.8%.

[0037] ②Preheat skim milk to 55°C, add soluble dietary cellulose, multivitamins, multiminerals, and coffee powder one by one, and stir evenly.

[0038] ③ Homogenize the batched emulsion (homogeneous pressure 16nPa), sterilize (70°C, 30S steam direct injection sterilization), vacuum concentrate (four-effect vacuum concentration, 50°C, 15 minutes), spray dry (inlet air temperature 160 ℃, the air outlet temperature is 80 ℃), and a brown powdery product is obtained.

[0039] ④ The product is dry-mixed with the powder essence and then packaged and molded.

[0040] Index: (g / 100g produc...

Embodiment 2

[0043] formula:

[0044] Raw material name

Dosage(kg)

Whey Protein Concentrate 80

585

400

Silica (anticaking agent)

10

[0045] Preparation Process:

[0046] ① Concentrated whey protein 80, soluble dietary fiber and silicon dioxide are mixed evenly by dry method after ultraviolet sterilization.

[0047] ② Packaging molding.

[0048] Index: (g / 100g product)

[0049] Test items

Embodiment 3

[0051] formula:

[0052] Raw material name

Dosage(kg)

fresh whole milk

3630

Whey Protein Concentrate 34

300

280

Anhydrous Cream

4

2

[0053] Preparation Process:

[0054] ① Standardized fresh whole milk, milk solids 11.5%, protein ≥ 2.9%, fat ≥ 3.1%, lactose ≥ 4.8%, non-fat milk solids ≥ 8.5%.

[0055] ②Preheat milk to 50°C, add concentrated whey protein 34 and soluble dietary cellulose, and stir well.

[0056] ③ Homogenize the batched emulsion (homogeneous pressure 18nPa), sterilize (70°C, 30S steam direct injection sterilization), vacuum concentrate (four-effect vacuum concentration, 45°C, 20 minutes), spray dry (inlet air temperature 180 ℃, air outlet temperature 80 ℃), spray the mixture of anhydrous cream and lecithin to obtain a milky white powder product.

[0057] ④ Packaging molding.

[0058] Index: (g / 100g product)

[0059] Test items

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com