Roller alignment device and roller alignment method

A roller and stacking technology, which is applied in the field of roller stacking devices, can solve the problems such as the inclination and falling off of the roller R, and achieve the effect of realizing the stacking time and shortening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] [First example of embodiment]

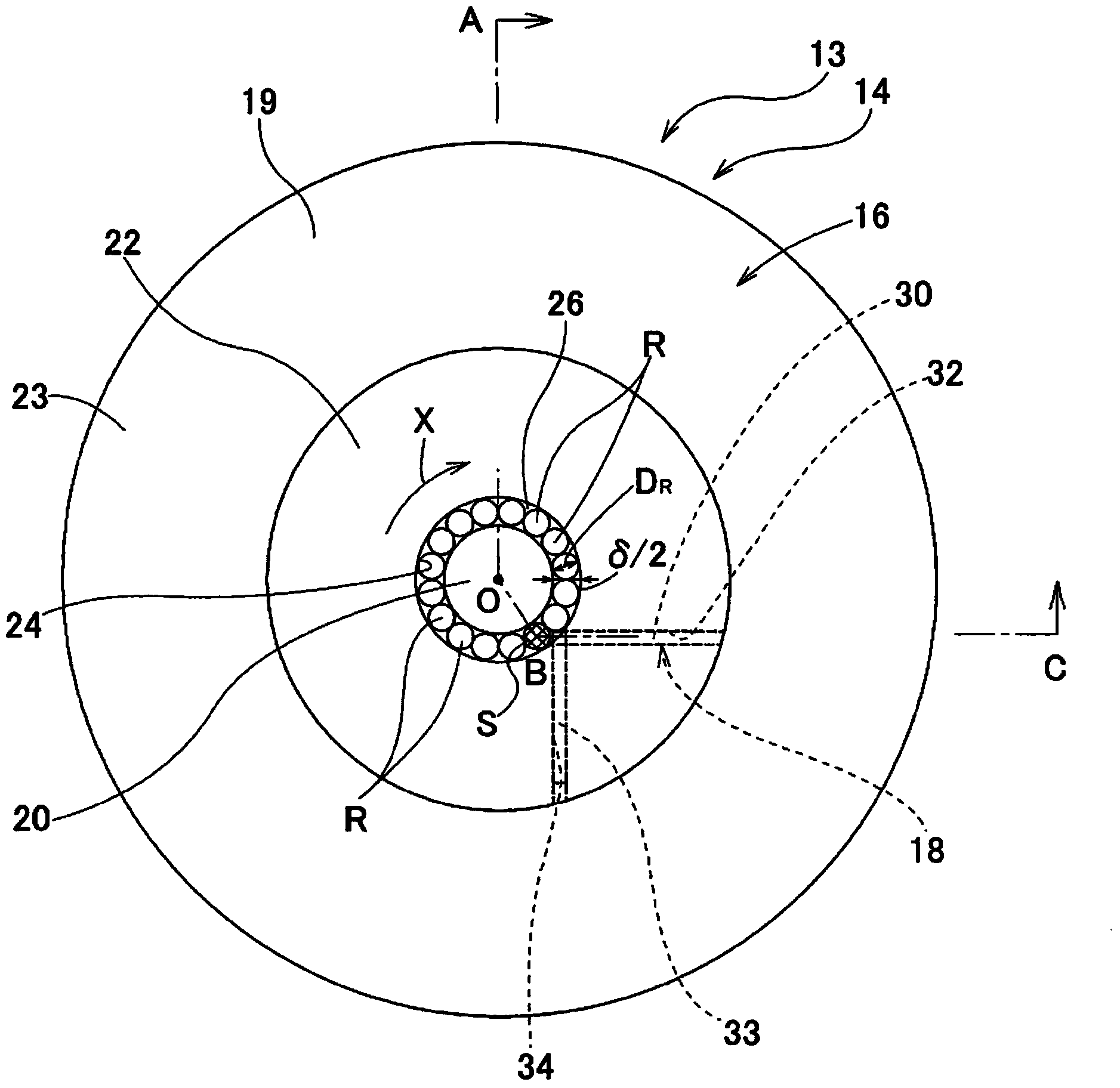

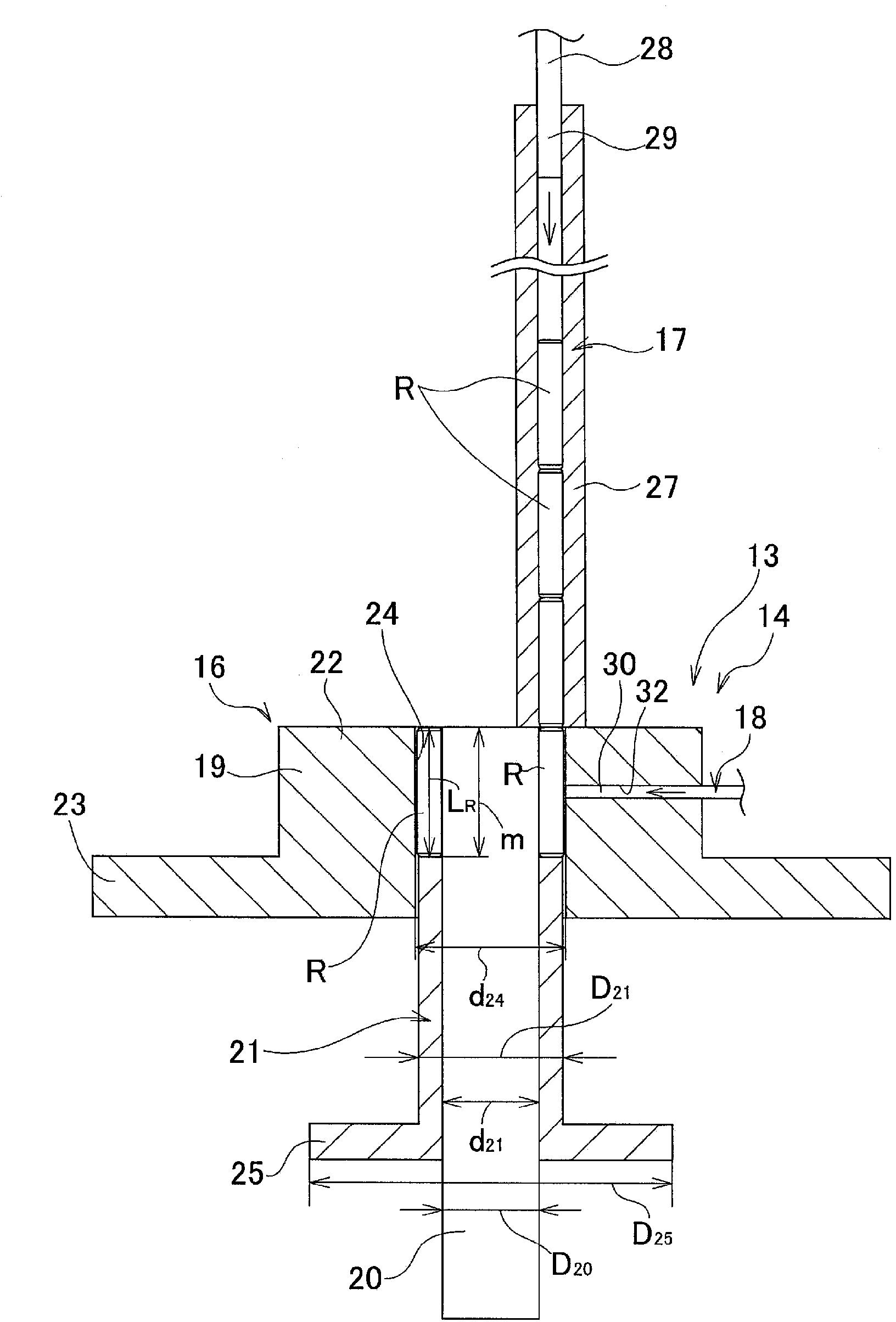

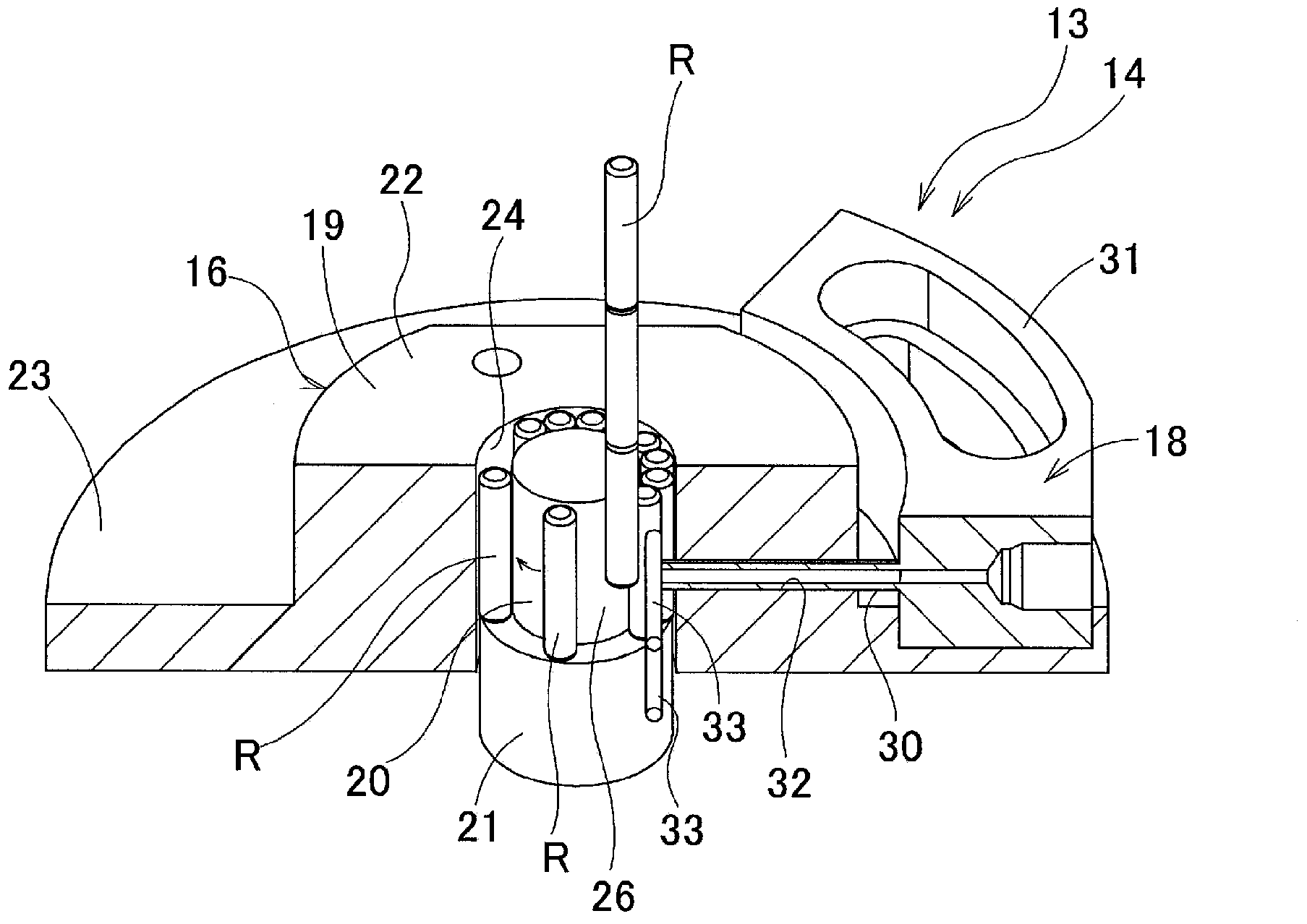

[0046] Figure 1 to Figure 8 The first example of the embodiment of the present invention is shown. The assembly device 13 is composed of a stacking device 14 and an insertion tool 15 for assembling a plurality of rollers R inside the outer ring W constituting the full complement radial roller bearing.

[0047] The stacking device 14 of the present invention has a tool body 16 , a roller supply part 17 and a stacking fluid supply part 18 . The tool body 16 is composed of a guide cylinder 19, a guide shaft 20, an extruding tool 21, and a cover (not shown). The part surrounded by these members forms a space with a predetermined space for stacking a plurality of rollers side by side. Shaped stacking space 26.

[0048] The guide cylinder 19 has a stepped cylindrical shape, and is composed of a thick portion 22 on the inner diameter side half and a thinner portion 23 on the outer diameter side half. A through hole 24 penetrating in the axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com