Plasma display panel and phosphor

A display panel and plasma technology, applied in the field of phosphors, can solve the problems of prolonged afterglow time, animation intermodulation distortion, and reduced animation display characteristics of PDP, etc., and achieve the effect of short afterglow time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

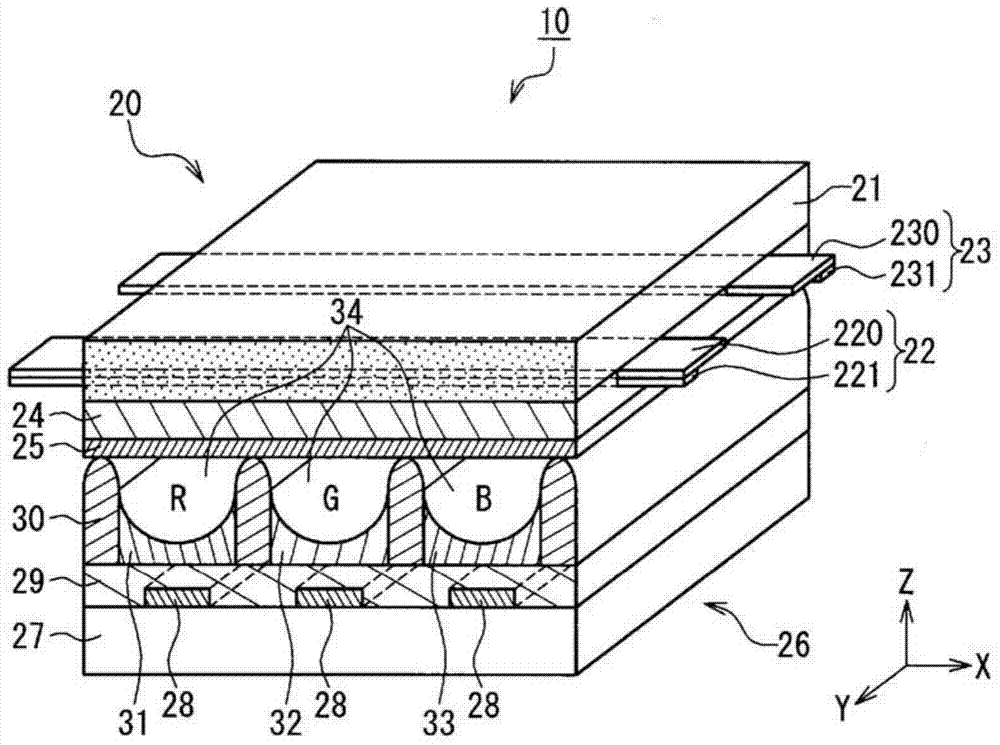

Image

Examples

Embodiment

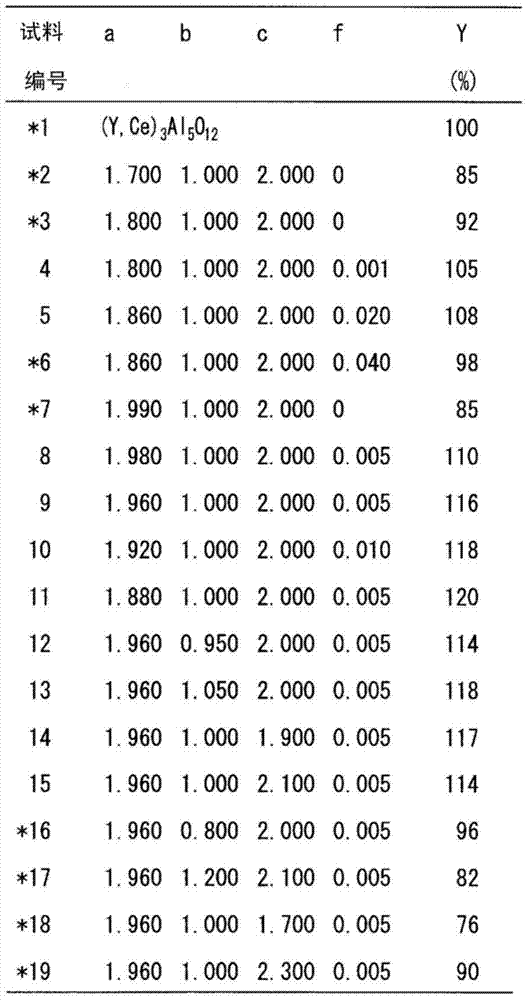

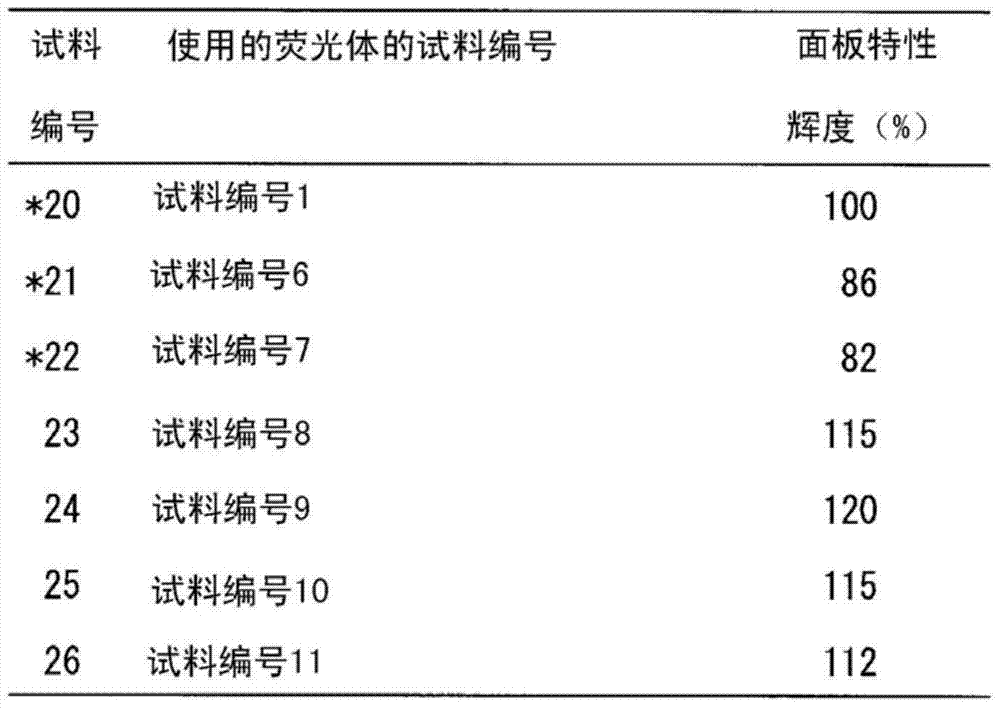

[0047] Specific examples and comparative examples are given below to describe the phosphor in the present invention in detail, but the phosphor in the present invention is not limited to these examples.

[0048]

[0049] As a starting material, BaCO was used 3 、Eu 2 o 3 , MgO, SiO 2 , CaCl 2 , weighed to make it a prescribed composition, and wet-mixed in pure water using a ball mill. After drying the mixture, first, it is fired in the air at a temperature range of 800 to 1000° C. for 4 hours, and secondly, it is fired at a temperature range of 1000 to 1200° C. in nitrogen containing 1 to 5 volume % hydrogen for 4 hours. Hours to obtain phosphor powder.

[0050] Furthermore, the obtained phosphor powder was pulverized again using a ball mill to adjust the particle size distribution.

[0051]

[0052] Phosphor samples corresponding to Examples and Comparative Examples were irradiated with vacuum ultraviolet light having a wavelength of 146 nm in vacuum to measure lumin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com