Multi-scale precision micro deep drawing die allowing real-time forming detection of ultrathin plates

A real-time detection, ultra-thin plate technology, applied in forming tools, manufacturing tools, metal processing, etc., can solve the problem of inability to guarantee the matching precision of micro-forming molds, sheet metal forming accuracy, inability to compare the forming characteristics of macro parts, and inability to respond to micro-forming forming Features and other issues, to achieve the effect of precise centering, high forming precision and precise guidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

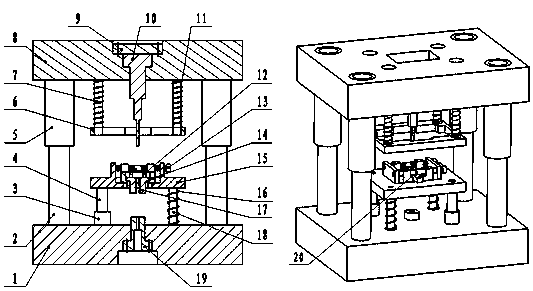

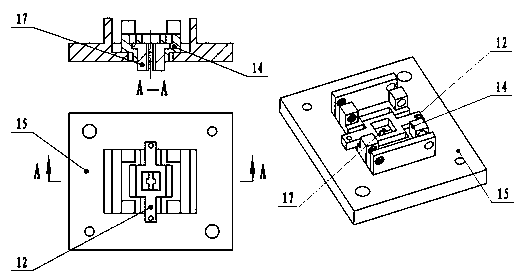

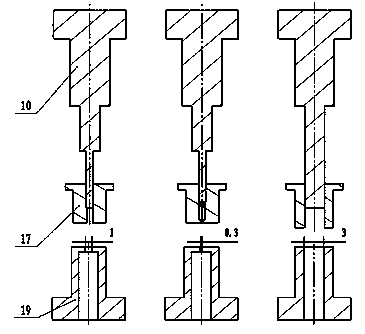

[0019] The present invention is realized through the following technical solutions, and the present invention includes: an upper mold assembly, a segmented blank holder device, a lower mold assembly, a guiding mechanism and a real-time detection system.

[0020] The upper mold assembly includes a punch fixing plate 8, a punch 10, a blank holder push plate 6, a hexagon head limit bolt 7, a punch baffle plate 9, and a spring 11. The upper mold assembly is installed as follows: The mold 10 is placed in the middle inner hole of the punch fixing plate 8, and the punch 10 is pressed against the punch fixing plate 8 by the punch baffle 9, and the punch baffle 9 is fixed in the punch fixing plate 8, and the punch There are 4 stepped through holes on the mold fixing plate 8, and the 4 stepped through holes are symmetrically arranged, and correspond to the threaded holes in the blank holder push plate 6 one by one, and the hexagon head limit bolt 7 is installed on the punch fixing plate....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com