Device and method for forming gear through rotary swaging in radial direction

A gear and forging die technology, which is applied in the field of gear radial swaging forming devices, can solve the problems of low forming precision and large load, and achieve the effects of improving forming precision and tooth strength, improving material utilization, and strong reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

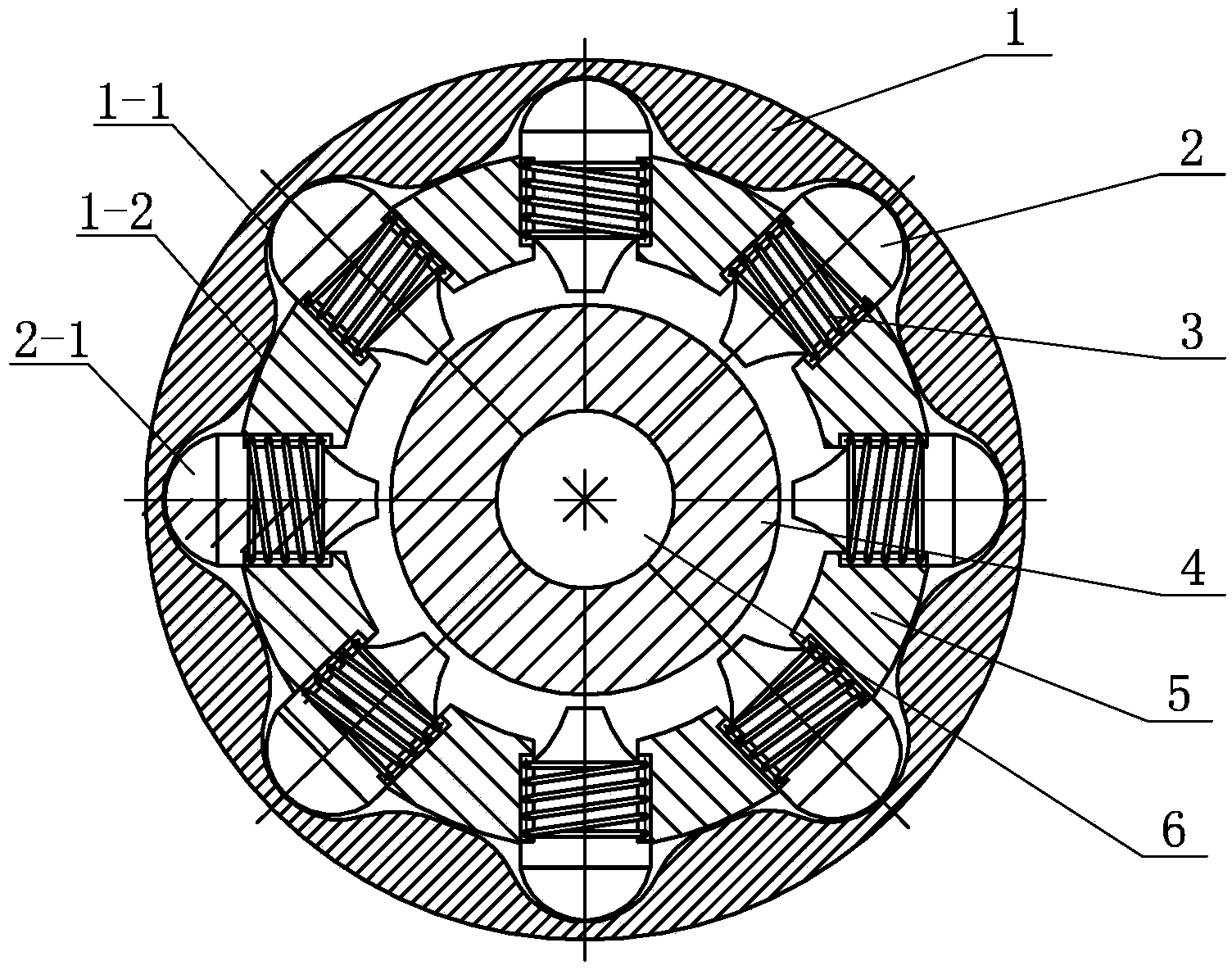

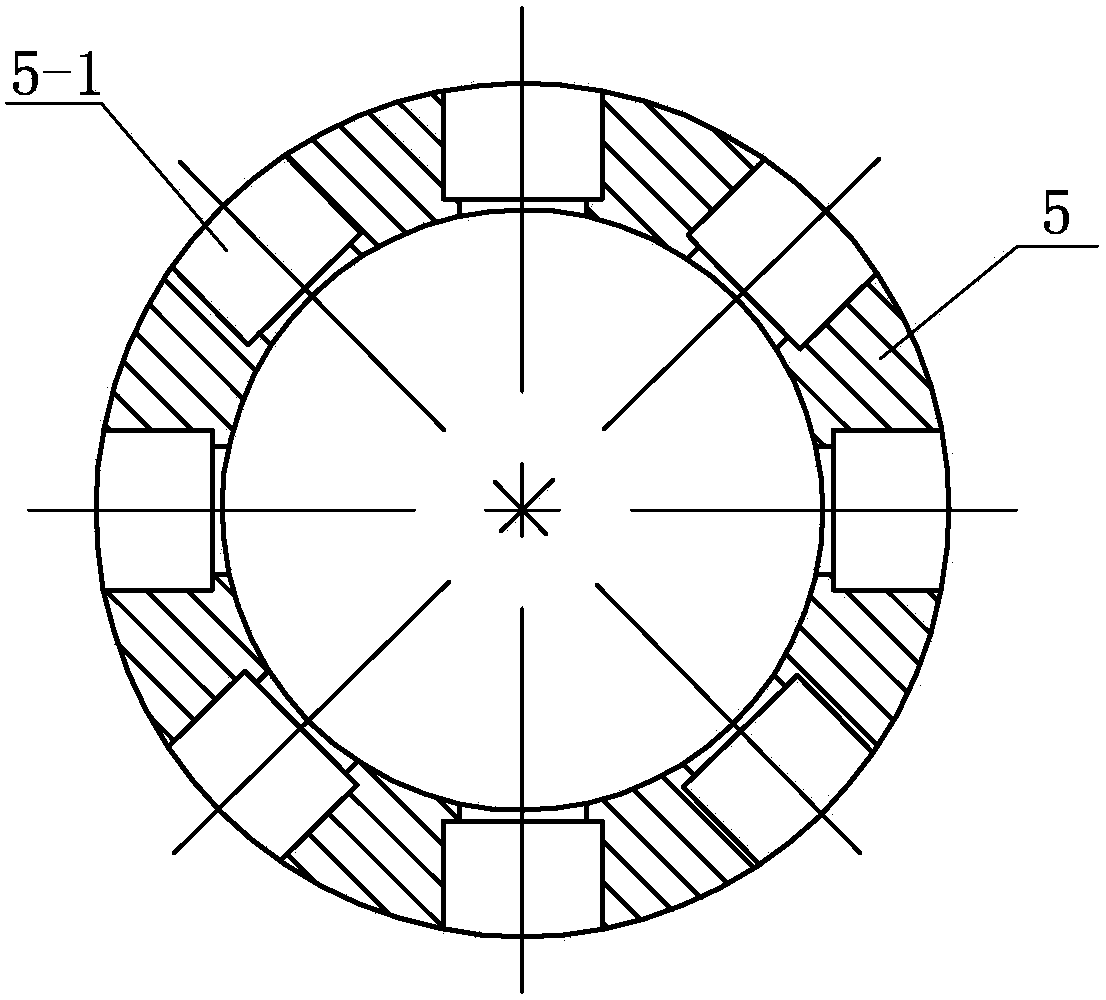

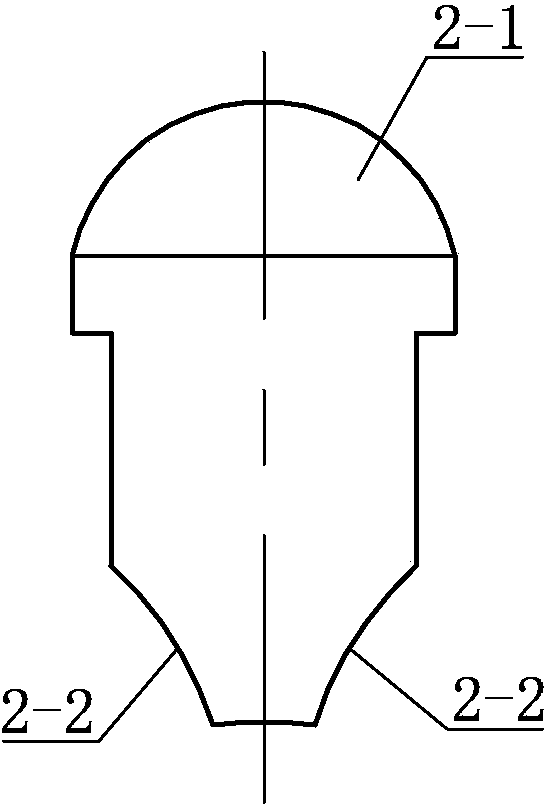

[0027] Specific implementation mode one: combine Figure 1 ~ Figure 4 Describe this embodiment. This embodiment includes a swaging die 1, a spring 3, a guide die 5, a mandrel 6 and several radial punches 2. The inner wall of the swaging die 1 is evenly arranged with several arc grooves 1 along the circumference. -1 and several protrusions 1-2, several arc grooves 1-1 and several protrusions 1-2 are arranged alternately, the number of arc grooves 1-1 is the same as the number of radial punches 2, One end of the radial punch 2 is an arc head 2-1, and the other end of the radial punch 2 is symmetrically provided with an inward concave arc 2-2 based on the axis line of the radial punch 2, so The guide die 5 is evenly distributed along the circumference with stepped holes 5-1 equal to the number of radial punches 2, and the radial punches 2 with springs 3 on the bottom are respectively put into each stepped hole 5-1, and the springs 3, The assembly of the radial punch 2 and the gu...

specific Embodiment approach 2

[0028] Specific implementation mode two: combination image 3 and Figure 5 To describe this embodiment, the radian of the concave arc 2-2 in this embodiment is the same as the radian of the tooth profile of the gear to be machined. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0029] Specific implementation mode three: combination figure 1 , Figure 5 and Figure 6 Describe this implementation mode, this implementation mode is realized through the following steps:

[0030] Step 1. Set the to-be-processed circular blank 4 on the mandrel 6;

[0031] Step 2. Rotate the swaging die 1 clockwise or counterclockwise for 1 / 2N (one part of 2N) circle, N is the number of punches;

[0032] Step 3. During the rotation process, the protrusion 1-2 on the swaging die 1 exerts pressure on the arc head 2-1, and the radial punch 2 gradually moves toward the center of the mandrel 6 along the stepped hole 5-1 of the guide die 5. The axis moves, and while the spring 3 is compressed, the radial punch 2 exerts radial pressure on the blank 4;

[0033] Step 4. When the swaging die 1 rotates until the center of the protrusion 1-2 coincides with the axial center of the radial punch 2 (see Figure 5 ), that is, the end of the forming of a blank;

[0034] Step 5. Continue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com