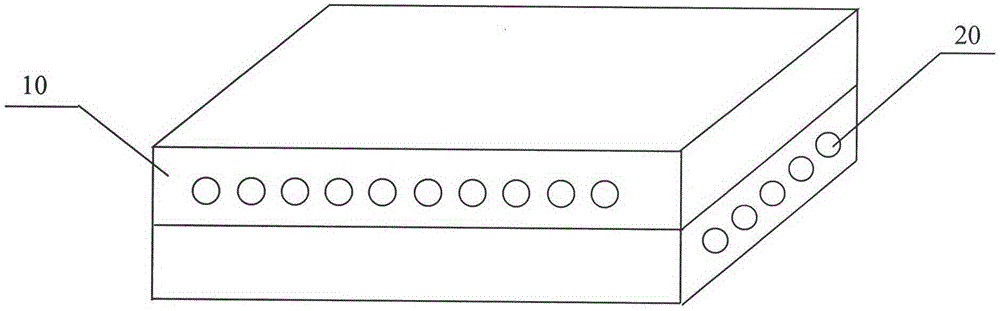

Sound-absorption structured composite material and preparation method thereof

A composite material and microporous channel technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of sound-absorbing layer peeling failure, low-frequency sound absorption coefficient, and increased process links, etc. Achieve the effect of high product dimensional stability, high hole dimensional accuracy, and no need for auxiliary processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Clean and preheat the mold, and apply a release agent;

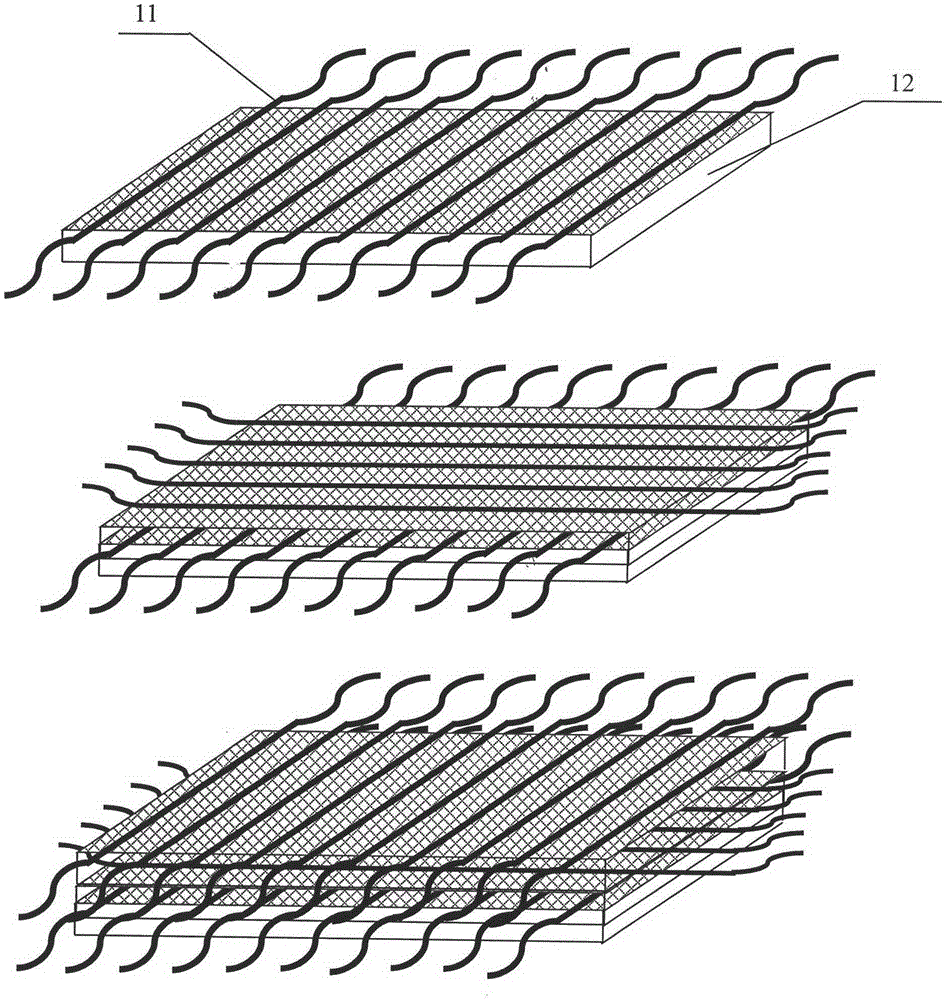

[0030] (2) impregnating pre-woven glass fibers with a content of 46% to form a prepreg with epoxy resin;

[0031] (3) Three layers of the above-mentioned prepreg layers are stacked in the mold, and 20 prefabricated long straight copper pipes are placed in parallel between the layers. The diameter of the pipes is 1 mm, and the length is sufficient to protrude from both ends of the formed resin-based composite material;

[0032] (4) Mold clamping and fixing, injection of epoxy resin, molding by molding process;

[0033] (5) curing demoulding, trimming the glass fiber reinforced epoxy resin matrix composite material that makes;

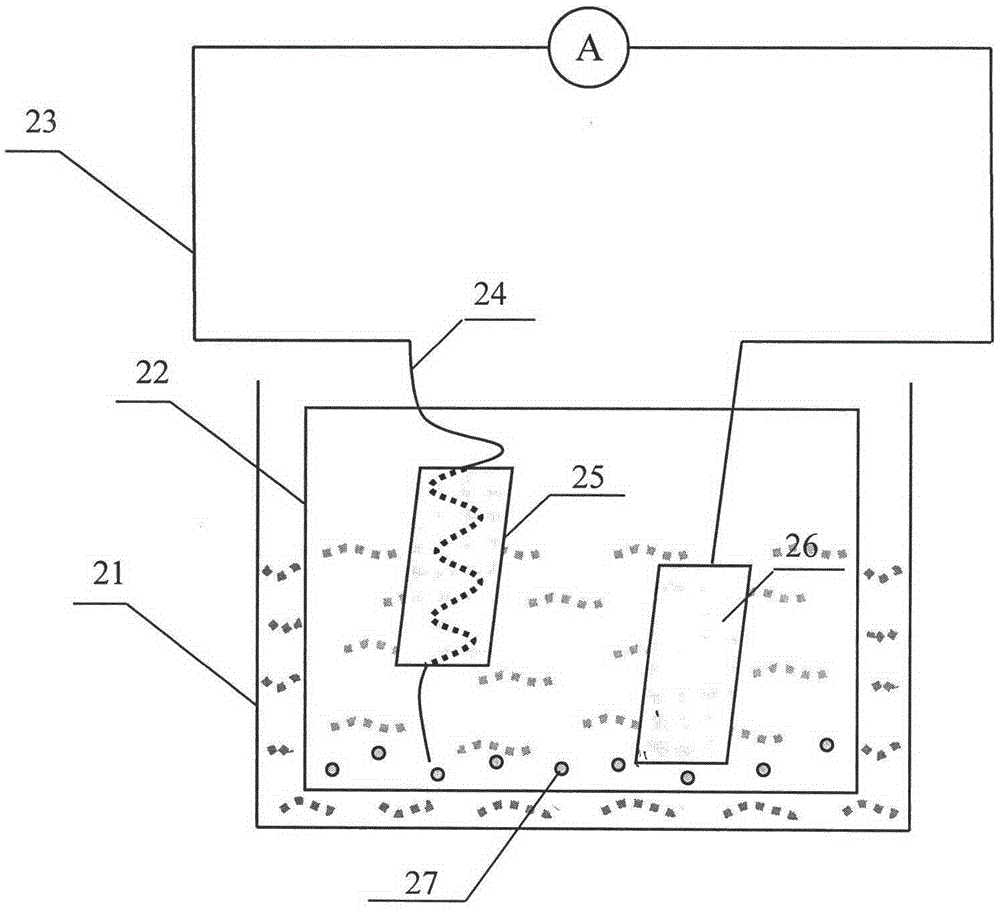

[0034] (6) Prepare the power supply, wires, etc., use dilute hydrochloric acid with coupling agent as the corrosion solution, use the carbon material as the cathode, and the resin-based composite material as the anode to lap the corrosion circuit. The lower half of the resin-based compo...

Embodiment 2

[0037] (1) Clean and preheat the mold, and apply a release agent;

[0038] (2) pre-weaving carbon fiber with a content of 22% and glass fiber with a content of 38% and impregnated with epoxy resin to form a prepreg;

[0039] (3) Place 6 layers of the above-mentioned prepreg layers in the mold, place 40 prefabricated long straight aluminum pipes in parallel between the layers, the diameter of the pipes is 100 μm, and the length is sufficient to protrude from both ends of the formed resin-based composite material;

[0040] (4) Mold clamping and fixing, injection of epoxy resin, molding by molding process;

[0041] (5) curing and demoulding, trimming the obtained high-performance fiber reinforced epoxy resin-based composite material;

[0042] (6) Prepare power supply, wires, etc., use ammonia water with coupling agent as corrosive solution, carbon material as cathode, and resin-based composite material as anode to lap the corrosion circuit, and the lower half of the resin-based ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com