Machining clamp for automobile steering knuckle flange end face holes

A technology for automobile steering knuckle and end face, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of low production efficiency, high labor intensity and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

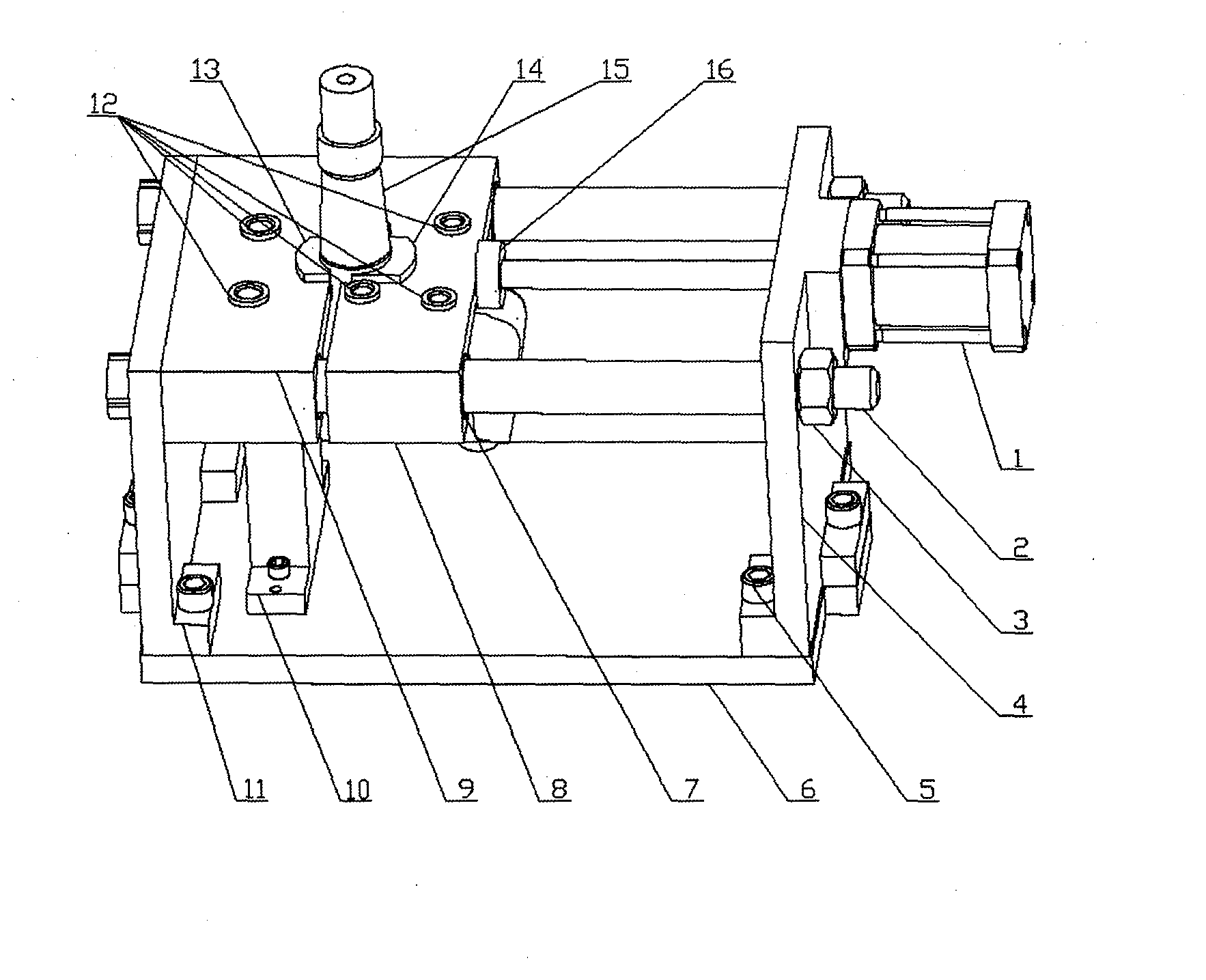

[0009] combined with figure 1 As shown, the fixture design adopts the face-up flip-up automatic compression method of the workpiece flange. When the hydraulic cylinder (piece 1) shrinks, the coupling nut (piece 16) at the end of the hydraulic rod drives the movable drilling template (piece 8) to slide and separate along the two guide rods (piece 2), and the shaft of the workpiece goes upward, and the movable template (piece 8) is put into the moving template (piece 2). 8) Between the fixed template (piece 9), the ear of the workpiece is placed on the V-shape of the orientation seat (piece 10). The hydraulic device pushes the movable drilling template and the half ring connected to the drilling template to automatically correct the workpiece shaft and hold it tightly on the half ring of the fixed drilling template to complete the clamping work. Start the main shaft of the machine tool, and the drill bit drills the workpiece along the drill cover (piece 12).

[0010] This new ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com