The clamping method when processing the upper and outer parts of the metal shell

A technology of metal shell and outer parts, applied in metal processing machinery parts, metal processing equipment, clamping and other directions, can solve the problems of low processing rigidity and precision, low production efficiency, shorten the service life of fixtures, etc., to improve cutting parameters , Improve production efficiency and increase damping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

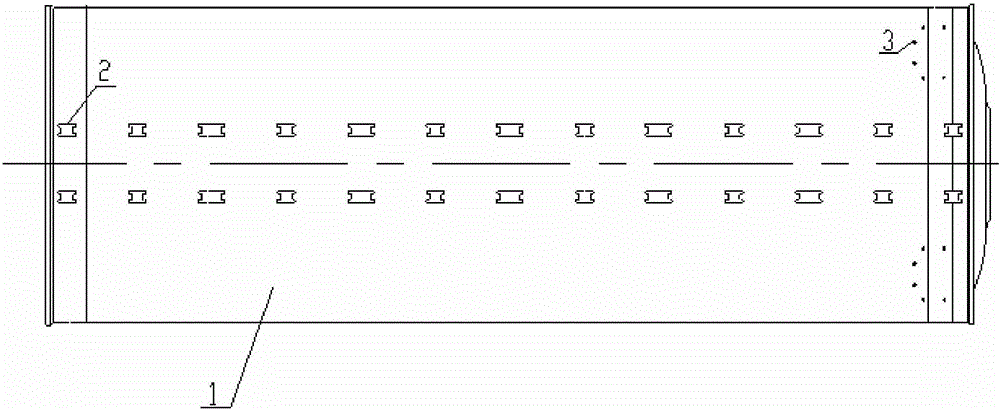

[0036] This embodiment is a processing method for the upper and outer parts of a certain type of metal shell. The upper and outer parts of the metal shell include a cable support and a rudder base support.

[0037] The material of the metal shell is 30CrMnSiA, the total length is 3813mm, the wall thickness is 4mm, and the outer diameter of the cylinder section is Ф750mm.

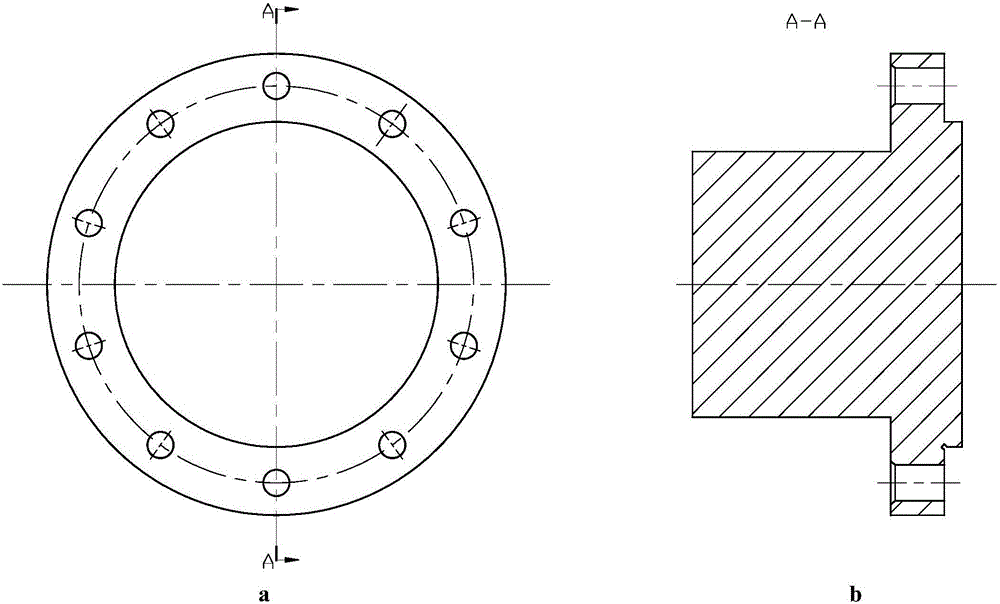

[0038] There are 52 cable supports, distributed along the axial direction of the metal shell 1 on both sides of quadrant II and quadrant IV on the outer surface of the metal shell. The distance l between the two cable supports 2 located at both ends of the metal shell is 3500 mm. The upper surface of each cable support shall have a machine allowance of 5mm.

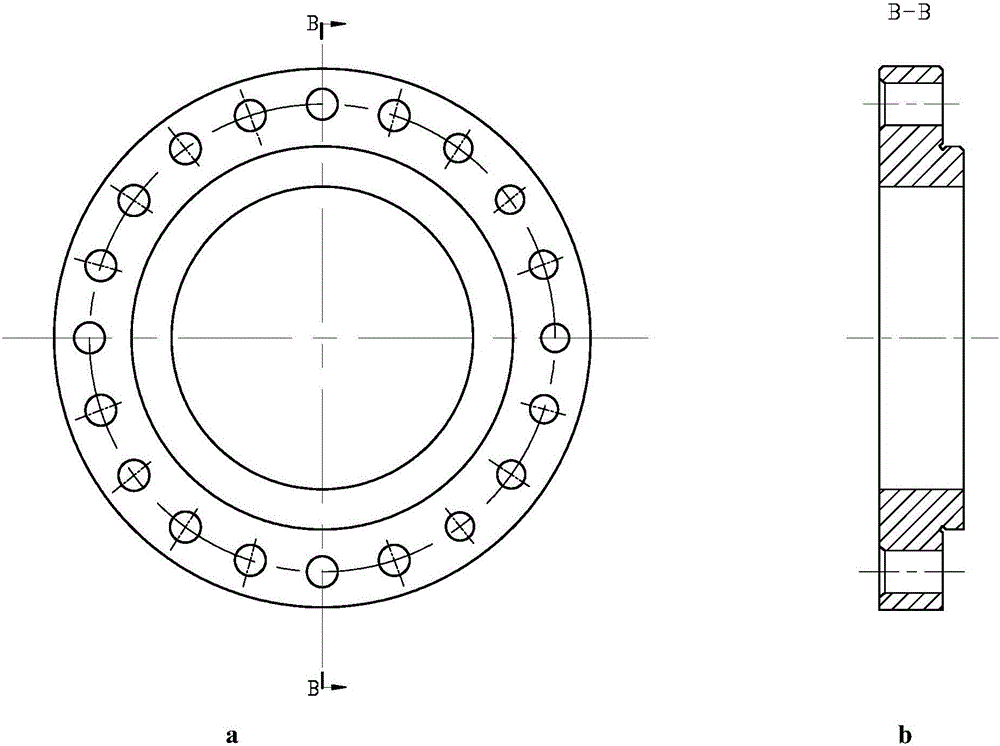

[0039] There are 24 rudder base plate supports 3, which are distributed along the circumferential direction of the metal shell on both sides of the angle bisector of quadrant I to quadrant IV on the outer surface of one end of the metal shell. The uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com