Calibration plate unloading and transferring device for large ring polishing machine

A ring polishing machine, a large-scale technology, used in grinding/polishing equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of external impurities, unfavorable workpiece surface finish indicators, etc., to avoid damage, pollution-free load, improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the embodiments, but the scope of the invention should not be limited by this.

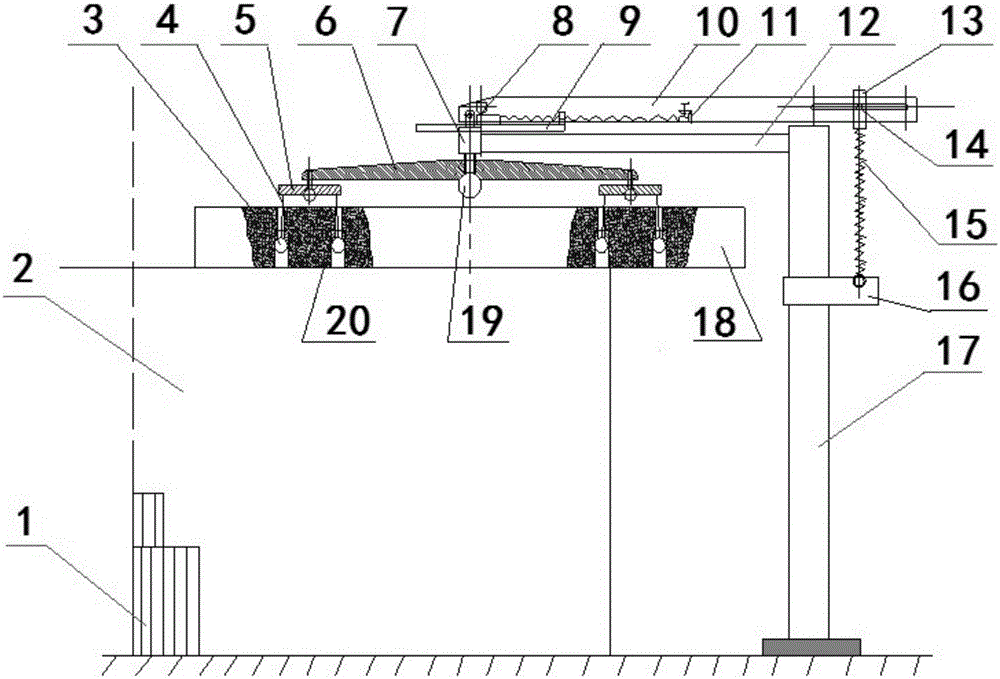

[0015] See first figure 1 , The schematic diagram of the structure of the best embodiment of the workpiece transfer device of the large ring polisher. The correction disk unloading and transfer device of the large ring polisher of the present invention includes a cantilever beam 12 supported by a column 17, on which the cantilever beam 12 is provided There is a lever 10, a fastening hoop 16 is fixed on the column 17, a pin guide 13 and a pin 14 are provided at the end of the lever 10 close to the column 17, and a power-supply tension adjusting spring 15 is connected Between the pin 14 and the fastening hoop 16, the position of the pin 14 is controlled by the pin guide 13; the free end of the lever 10 is provided with a fulcrum 8 and a cross knife edge is sequentially arranged below the fulcrum 7. The hanger 6 and the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com