Unloading and transferring device for correcting plate of large ring throwing machine

A ring polishing machine, a large-scale technology, used in grinding/polishing equipment, parts of grinding machine tools, metal processing equipment, etc., can solve problems such as unfavorable workpiece surface finish indicators, external impurities, etc., to achieve simple structure and avoid damage. , high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with embodiment, but should not limit the transformation range of the present invention with this.

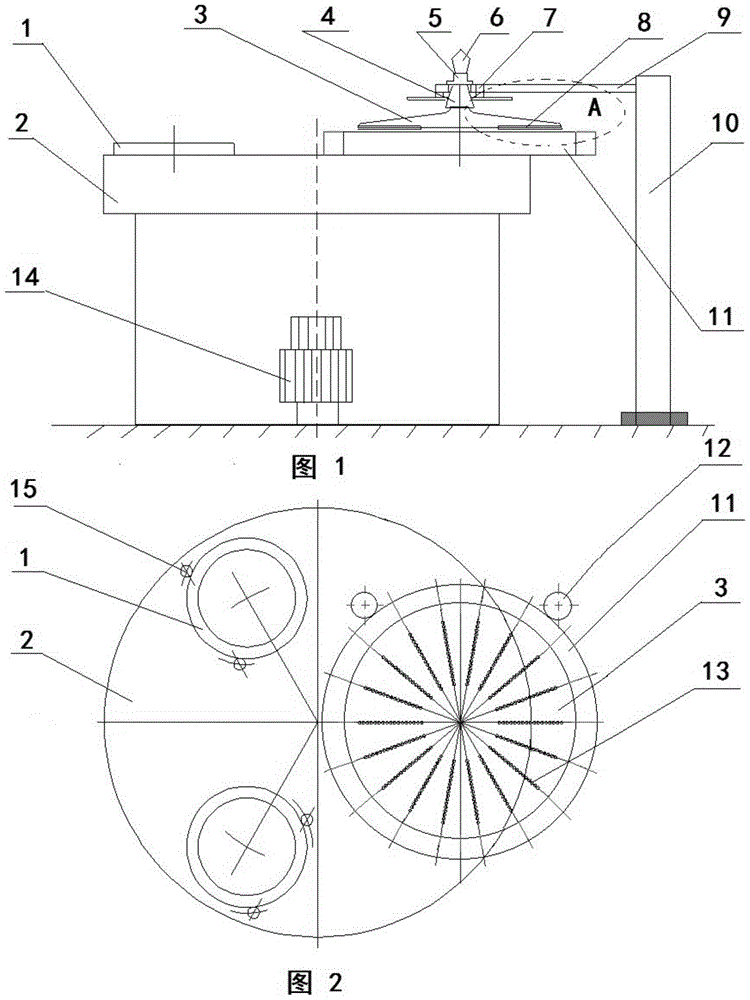

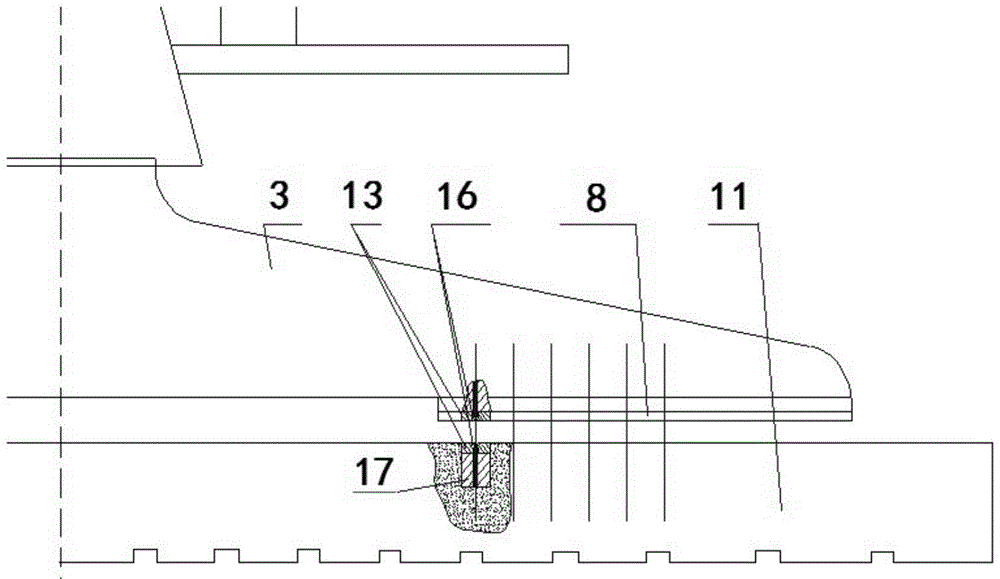

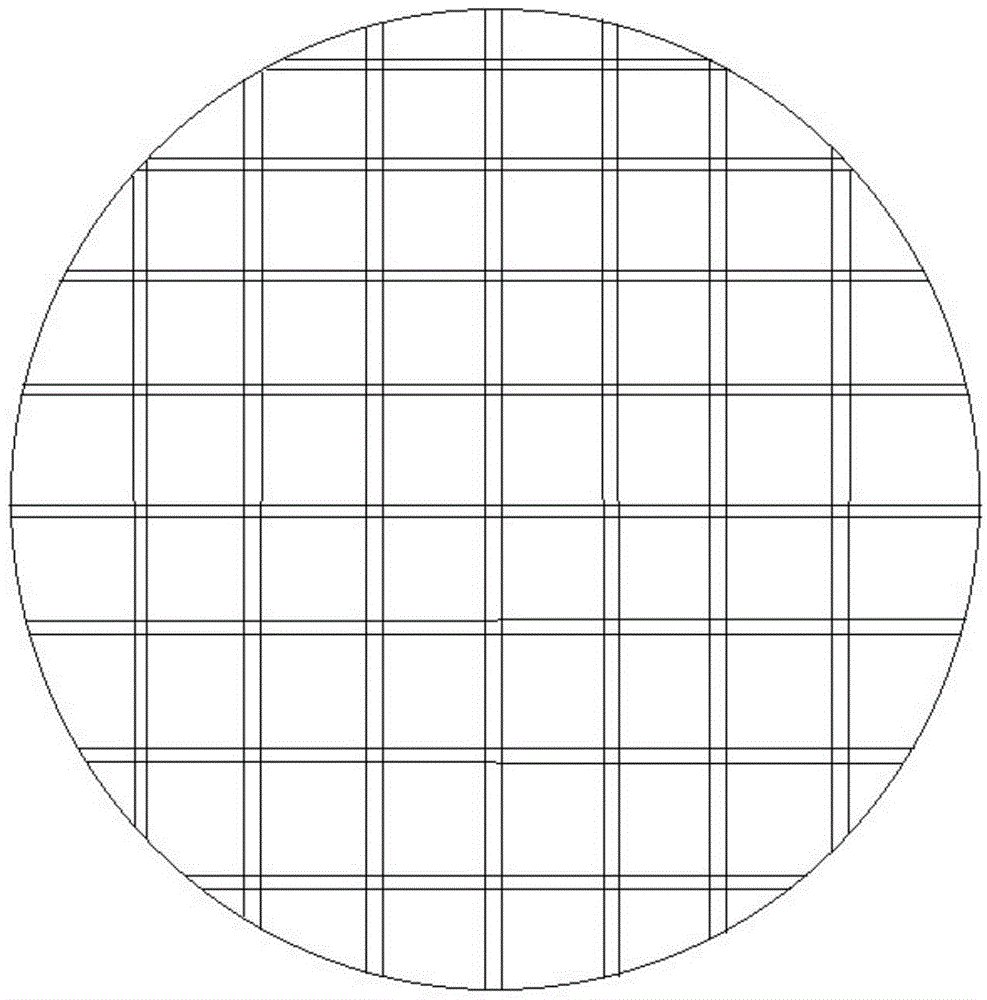

[0024] See Figure 1, Figure 2, image 3 and Figure 4 , Fig. 1 is a schematic structural view of the preferred embodiment of the present invention, as can be seen from the figure, the unloading and transferring device of the large-scale ring throwing machine correction plate of the present invention comprises a cantilever beam 9 supported by a column 10, and the free end of the cantilever beam 9 is set There is a moving slide 7, the center of the moving slide 7 is an automatic tracking pedestal 5, the bottom of the automatic tracking pedestal 5 is a slewing support 4, a support plate 3 is fixed below the slewing support 4, and the support plate 3 is evenly distributed There are several grooves, and several permanent magnetic steels 13 are fixed by fixing screws 16 in each groove, and each groove can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com