Adjusting mechanism of bagged chewing tobacco former

A technology of adjusting mechanism and forming device, applied in the direction of packaging machine, packaging, transportation and packaging, etc., can solve the problems of high cost, complex structure, unsuitable for heat-sealing packaging equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific drawings and embodiments.

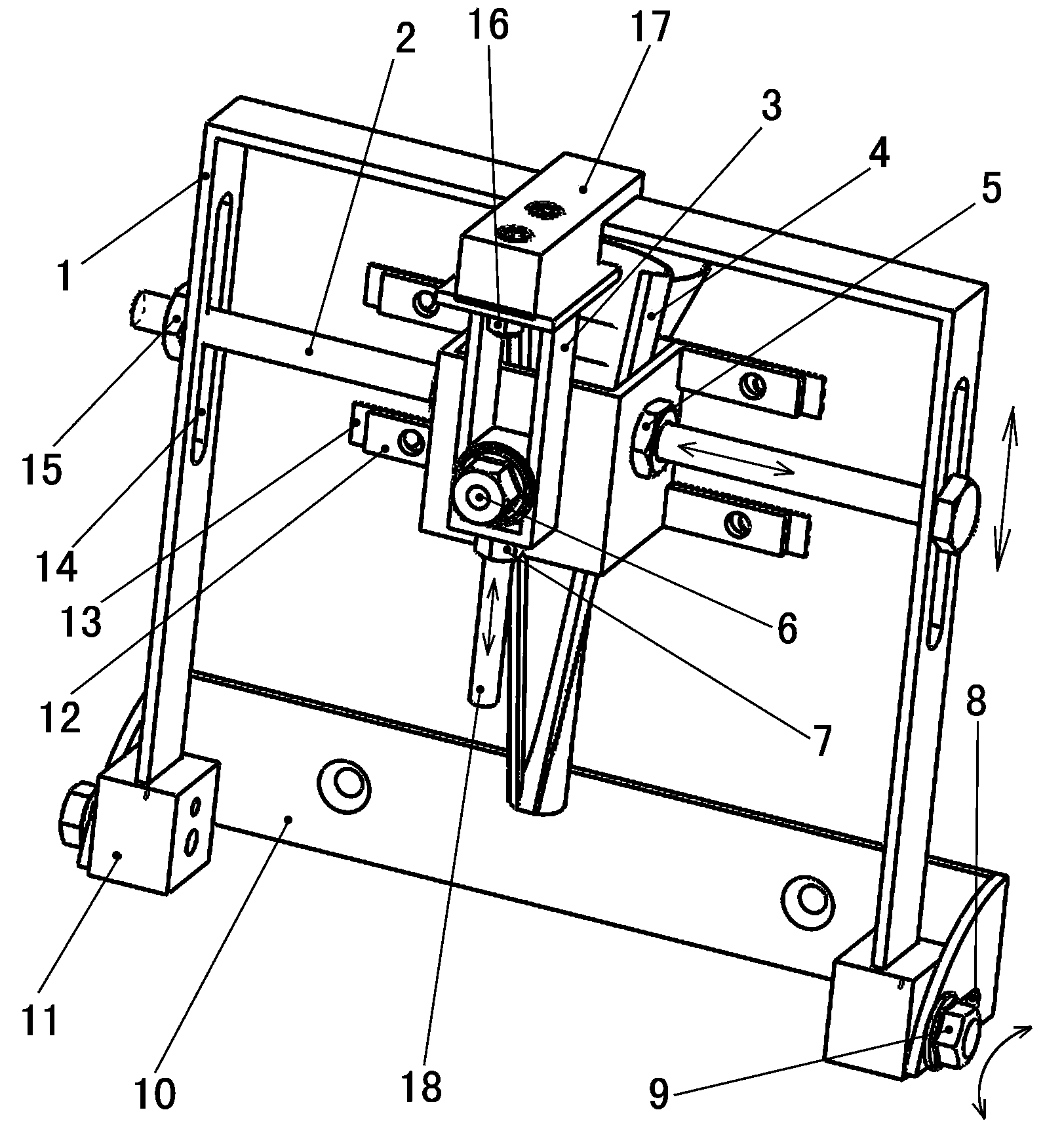

[0015] Such as figure 1 As shown, the lower end of the U-shaped bracket 1 is fixed on the rectangular connecting block 11 through a slot and screws, and the rectangular connecting block 11 is fixed on the longitudinal horizontal waist groove 8 provided on the bracket fixing base 10 through a lock nut 9 and screws. The U-shaped bracket 1 can realize the adjustment of the vertical and horizontal direction and the angle adjustment relative to the bracket fixing base 10 through the longitudinal horizontal waist groove 8; the U-shaped bracket 1 has vertical waist grooves 14 on both sides, and the vertical waist groove 14 penetrates A horizontal level adjustment bolt 2, the level adjustment block 12 is contained on the horizontal level adjustment bolt 2, a screw rod in the horizontal direction integrated with it is arranged on the level adjustment block 12, through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com