A Diagonally Compressed Bistable Plate Piezoelectric Energy Harvesting Device

A piezoelectric energy collection device technology, applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, generators/motors, etc. Bistable structure, low energy collection efficiency and other issues, to achieve the effect of improving energy collection efficiency, simple structure, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

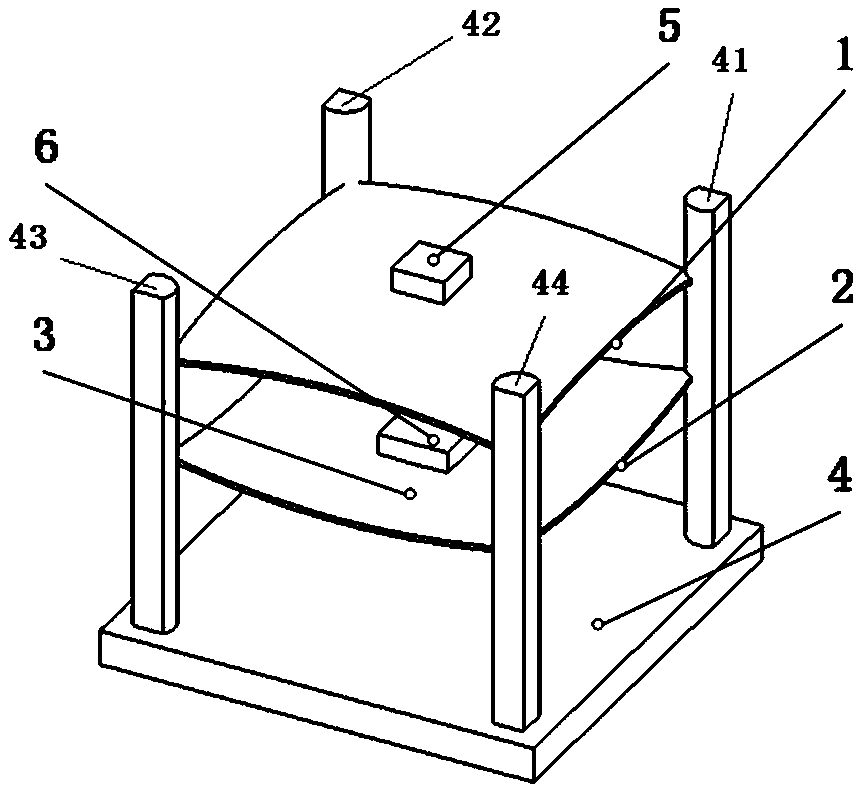

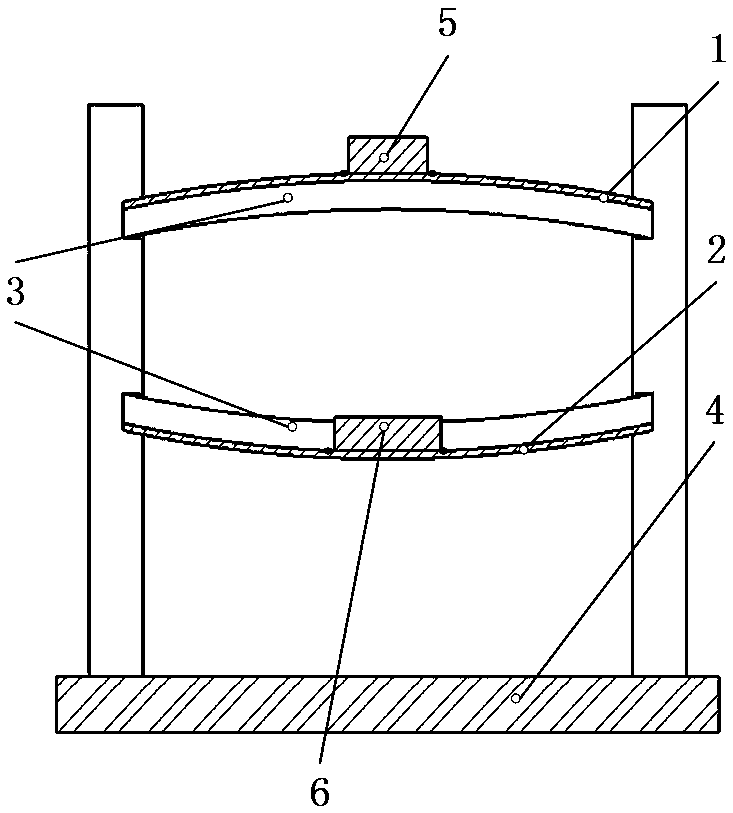

[0023] This embodiment provides an example of a diagonally compressed bistable plate piezoelectric energy harvesting device, and its structural schematic diagram is as follows figure 1 shown in .

[0024] The diagonally compressed bistable plate piezoelectric energy harvesting device includes one or more rectangular plate-shaped piezoelectric energy harvesting units, and clamps the edge of the piezoelectric energy harvesting unit and provides centripetal force to the piezoelectric energy harvesting unit. Clamp 4 for compressive force;

[0025] The piezoelectric energy harvesting unit includes a rectangular plate-shaped flexible rectangular plate, and a flexible piezoelectric element 3 attached to the surface of the flexible rectangular plate;

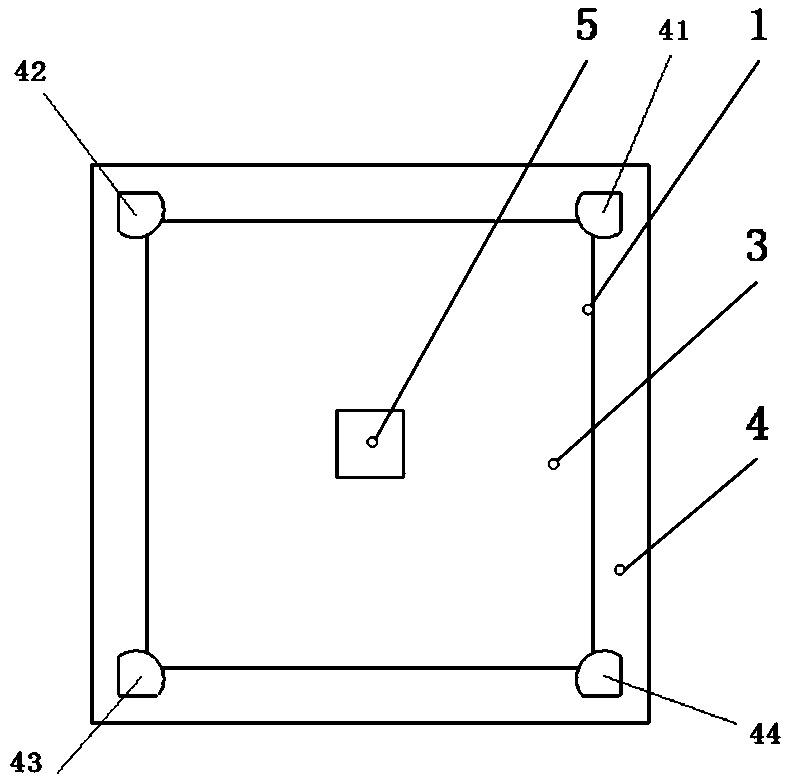

[0026] The fixture 4 is provided with one or more clamping device groups, and the number of the clamping device groups is the same as the number of the piezoelectric energy harvesting units and corresponds to each other; the clamping d...

Embodiment 2

[0038] This embodiment provides an example of specific parameters of a diagonally compressed bistable plate piezoelectric energy harvesting device, the structure of which is the same as that of Embodiment 1.

[0039] In this embodiment, the thickness of the flexible rectangular plate is 1 cm, and the length and width are both 11 cm. The height of clamp arm one 41, clamp arm two 42, clamp arm three 43 and clamp arm four 44 is 40 centimeters; the length and width corresponding to the bottom surface of clamp 4 are 10 centimeters. The distance between the grooves on the first clamp arm 41 , the second clamp arm 42 , the third clamp arm 43 and the fourth clamp arm 44 from the bottom of the clamp is 15 centimeters and 30 centimeters. Since the distance from clamp arm one 41 to clamp arm three 43 and the distance from clamp arm two 42 to clamp arm four 44 are 10 centimeters, they are all less than the diagonal length 11 of piezoelectric energy harvesting unit one 1 and piezoelectric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com