Ring-pull can cover production device capable of online adjusting machining specification and use method of ring-pull can cover production device

A technology for cans and production equipment, which is applied to metal processing equipment, shearing machine equipment, manufacturing tools, etc., can solve problems such as inconvenience, and achieve the effect of convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

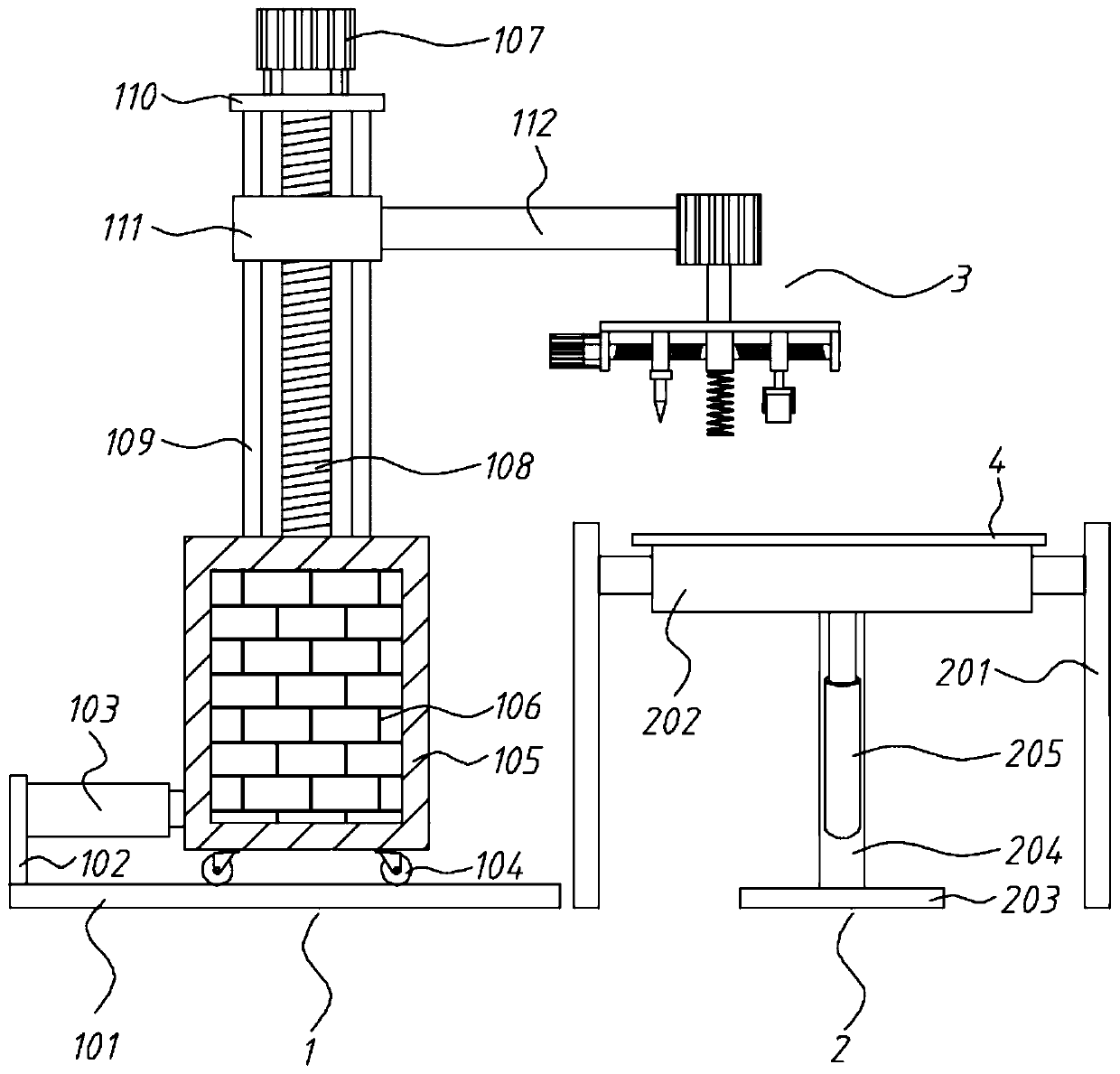

[0044] Can lid production equipment that can adjust processing specifications online, including adjustment component 1, transmission component 2, shear component 3 and aluminum plate to be processed 4;

[0045] Transmission assembly 2 comprises roller shaft support 201 and roller shaft 202, and roller shaft support 201 is arranged symmetrically left and right. The roller shaft 202 is conveyed to move along the front and back direction;

[0046] The adjustment assembly 1 is arranged on the left side of the transmission assembly 2, including a box body 105, No. 1 servo motor 107, screw mandrel 108, guide rod 109, top plate 110 and No. 1 moving nut 111; the bottom of the box body 105 is equipped with a roller 104, and the box body 105 is provided with a power supply 106 for power supply; the top plate 110 is arranged on the top of the box body 105, and is fixedly connected to the box body 105 by a vertical guide rod 109; the top plate 110 is equipped with a No. 1 servo motor 107,...

Embodiment 2

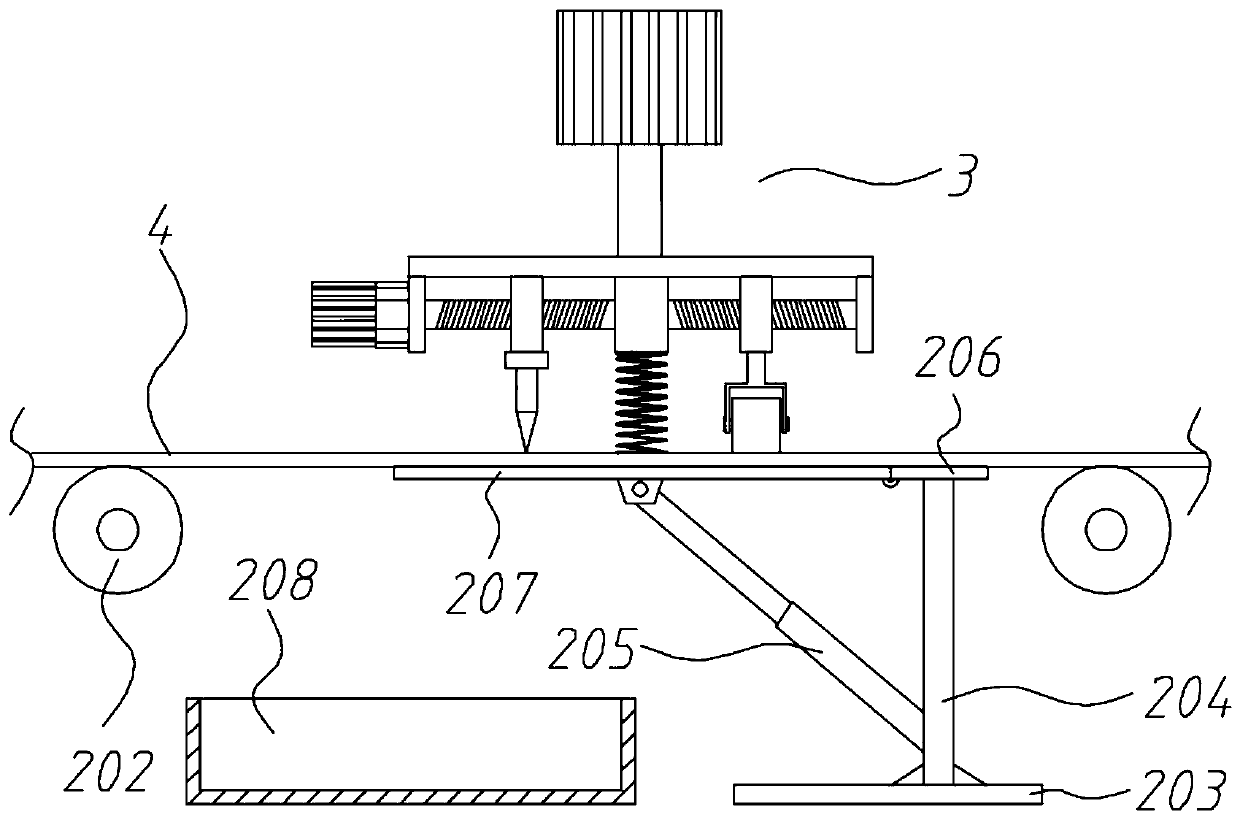

[0050] Can lid production equipment that can adjust processing specifications online, including adjustment component 1, transmission component 2, shear component 3 and aluminum plate to be processed 4;

[0051] Transmission assembly 2 comprises roller shaft support 201 and roller shaft 202, and roller shaft support 201 is arranged symmetrically left and right. The roller shaft 202 is conveyed to move along the front and back direction;

[0052] The adjustment assembly 1 is arranged on the left side of the transmission assembly 2, including a box body 105, No. 1 servo motor 107, screw mandrel 108, guide rod 109, top plate 110 and No. 1 moving nut 111; the bottom of the box body 105 is equipped with a roller 104, and the box body 105 is provided with a power supply 106 for power supply; the top plate 110 is arranged on the top of the box body 105, and is fixedly connected to the box body 105 by a vertical guide rod 109; the top plate 110 is equipped with a No. 1 servo motor 107,...

Embodiment 3

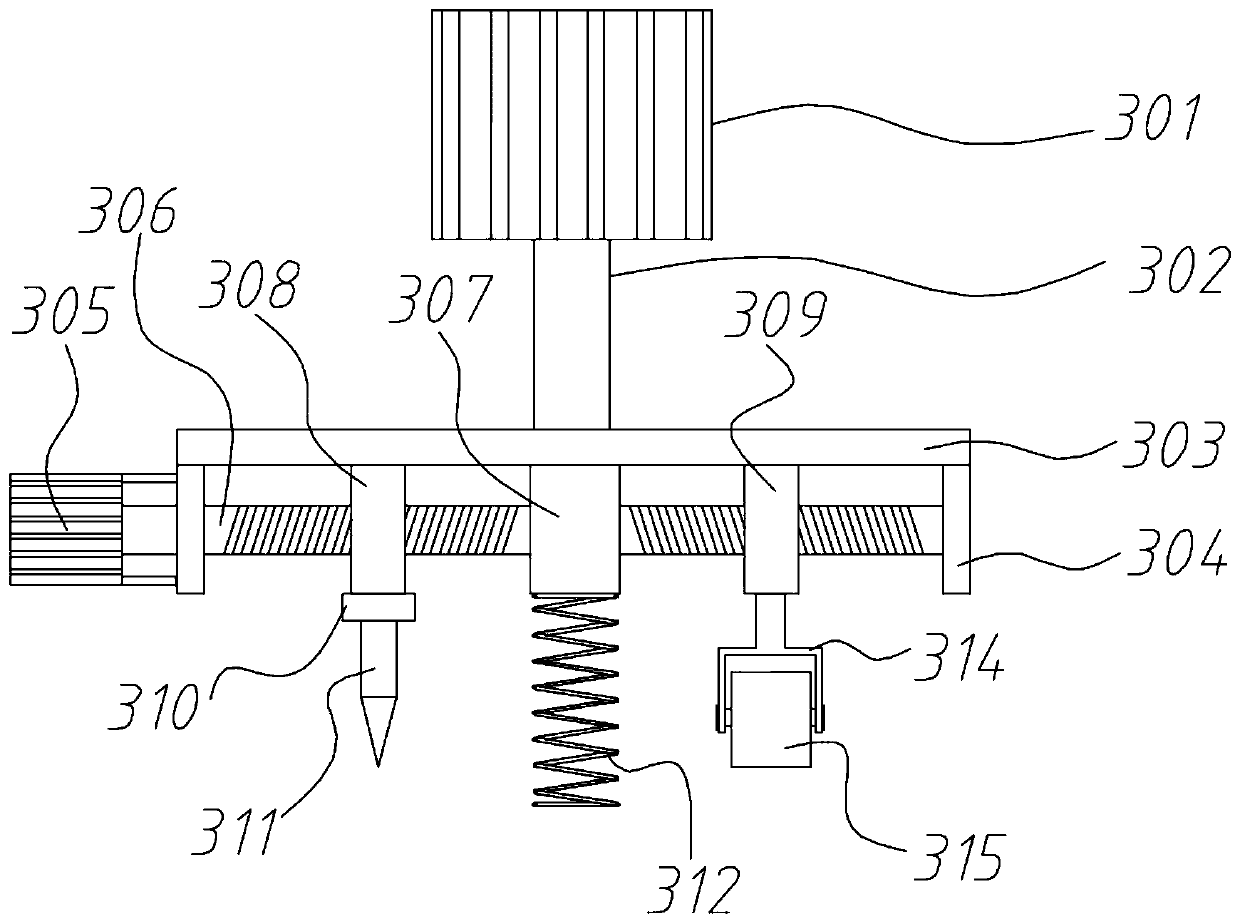

[0057] Can lid production equipment that can adjust processing specifications online, including adjustment component 1, transmission component 2, shear component 3 and aluminum plate to be processed 4;

[0058] Transmission assembly 2 comprises roller shaft support 201 and roller shaft 202, and roller shaft support 201 is arranged symmetrically left and right. The roller shaft 202 is conveyed to move along the front and back direction;

[0059] The adjustment assembly 1 is arranged on the left side of the transmission assembly 2, including a box body 105, No. 1 servo motor 107, screw mandrel 108, guide rod 109, top plate 110 and No. 1 moving nut 111; the bottom of the box body 105 is equipped with a roller 104, and the box body 105 is provided with a power supply 106 for power supply; the top plate 110 is arranged on the top of the box body 105, and is fixedly connected to the box body 105 by a vertical guide rod 109; the top plate 110 is equipped with a No. 1 servo motor 107,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com