Biomass feeding device

A feeding device and biomass technology, applied in the direction of packaging, fuel supply, conveyor objects, etc., can solve the problems of poor sealing, entering the combustion device or gasification device, and high fiber content, so as to avoid winding and bulk density increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. The following is only exemplary and does not limit the protection scope of the present invention.

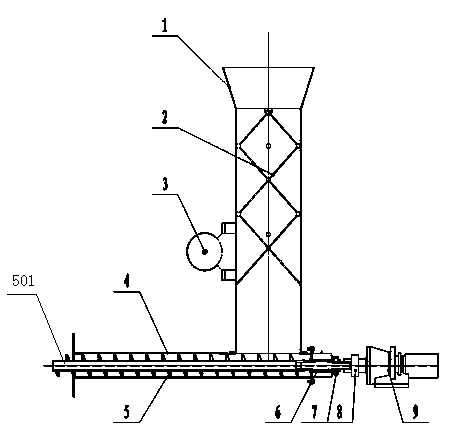

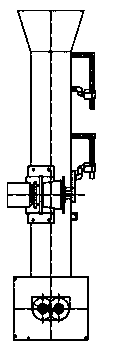

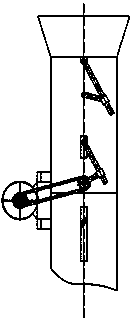

[0027] Reference attached figure 1 , 2 , 3, 4, a kind of biomass feeding device, comprises material cylinder 1, distributor and feeder; Distributor comprises distributing motor 3 and connecting rod mechanism 2, the output shaft of distributing motor 3 is connected transmission mechanism, and transmission mechanism is connected The linkage mechanism 2, the linkage mechanism is set in the barrel 1, the material distribution motor 3 drives the linkage mechanism 2 through the transmission mechanism to realize the material shifting and continuous feeding, and pushes the biomass into the feeder; the feeder includes a shell 4. The auger body 5 and the feed motor 9, the casing 4 and the barrel 1 are combined at right angles, and the casing 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com