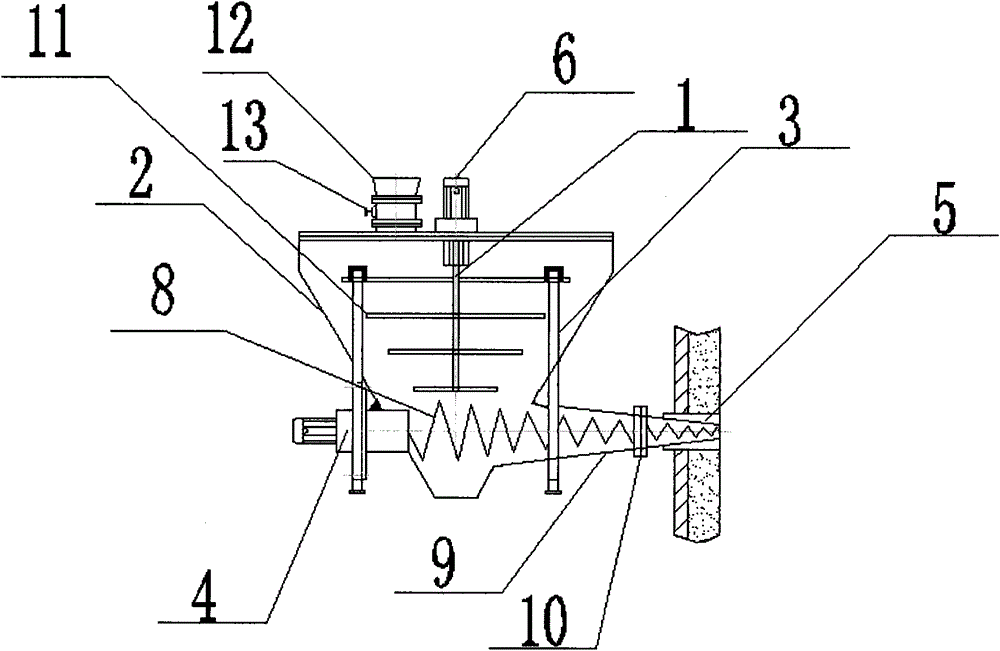

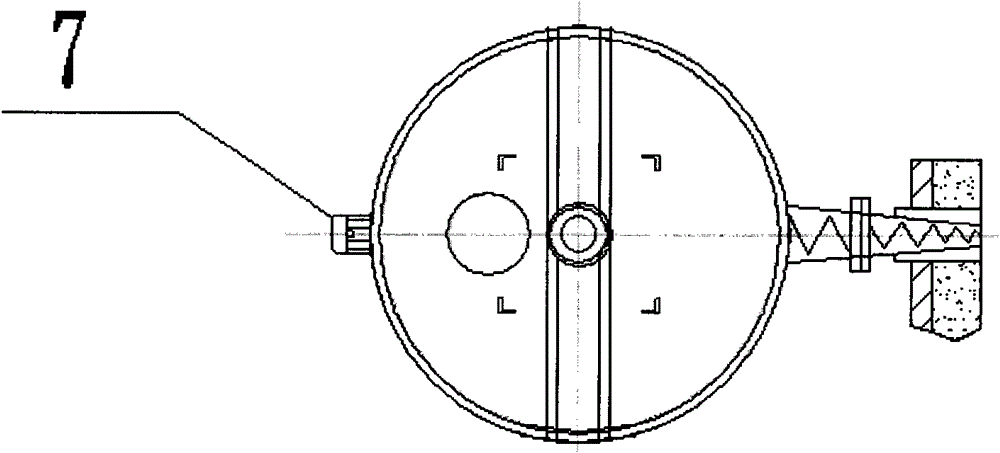

Built-in biomass screw feeder

A screw feeder and biomass technology, which is applied in educts, fuel supply, granular/powdered fuel gasification, etc., can solve the problems of ignition materials, shed materials, fires, etc., and achieve the reduction of feeding distance and The effect of increasing space and packing density and avoiding winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Taking the processing capacity of the feeder as 100kg / h as an example,

[0024] The taper of the conical feeder is 20° from the horizontal. The screw pitch of the variable-diameter twisted cage is gradually reduced from P=160mm to P=120mm, ΔP=20mm, and the biomass accumulation density is increased by about 20%. When the motor speed is 5rpm, the feeding amount of the feeder can be realized to be 100kg / h.

Embodiment 2

[0026] Taking the processing capacity of the feeder as 1000kg / h as an example,

[0027] The taper of the conical feeder is 15° from the horizontal. The screw pitch of the variable-diameter twisting cage is gradually reduced from P=400mm to P=180mm, ΔP=40mm, and the biomass accumulation density is increased by about 25%. When the motor speed is 8rpm, the feeding amount of the feeder can be realized to be 1000kg / h.

Embodiment 3

[0029] Taking the processing capacity of the feeder as 10t / h as an example,

[0030] The taper of the conical feeder is 25° from the horizontal. The screw pitch of the variable-diameter twisting cage is gradually reduced from P=800mm to P=200mm, ΔP=150mm, and the biomass accumulation density is increased by about 40%. When the motor speed is 15rpm, the feeding amount of the feeder can be realized to be 10t / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com