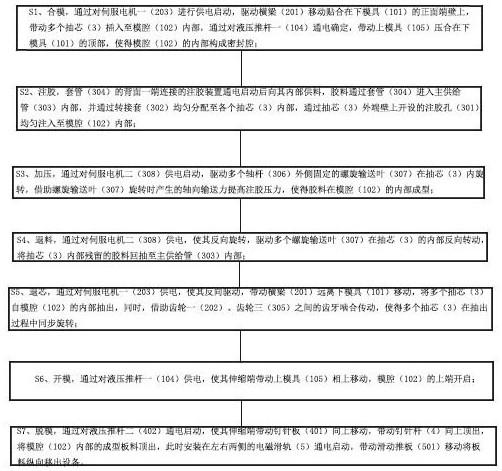

PVC material processing technology

A PVC material and processing technology, applied in the field of PVC plastic processing, can solve the problems of large and irregular hollow areas in the sheet, affecting the structural strength of the sheet, and reducing the quality of the sheet, so as to improve the convenience of use, The effect of reducing the probability of defective products and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

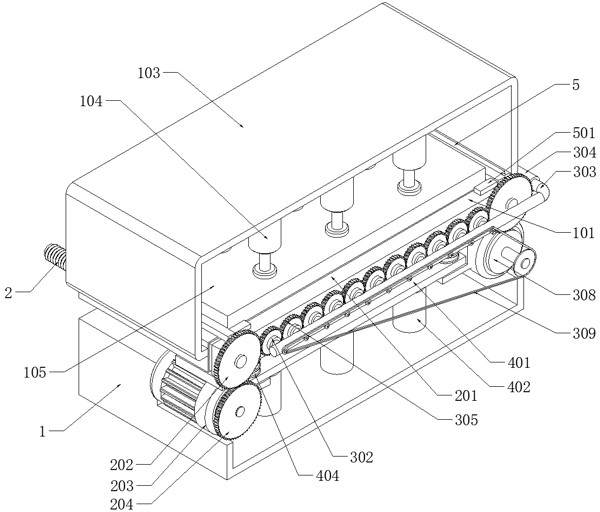

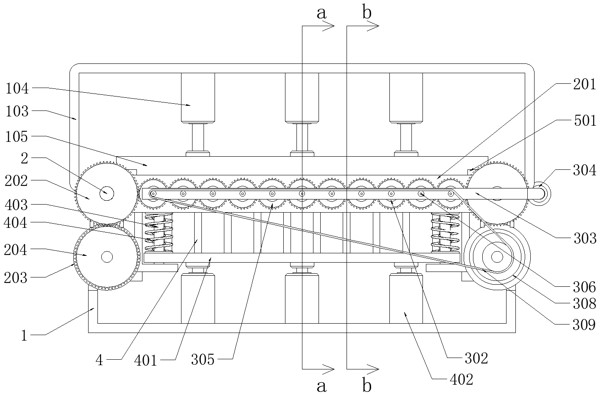

[0055] see Figure 2-11 , including a base 1, a lower mold 101 is fixedly installed on the top of the base 1, and a mold cavity 102 is provided inside the lower mold 101, and a bracket 103 sleeved above it is fixedly installed on the outer end wall of the lower mold 101, and the bracket The interior of 103 is fixedly installed with a plurality of vertically downward hydraulic push rods-104, and the telescopic ends of multiple hydraulic push rods-104 are fixedly connected with an upper mold 105 covering the top of the lower mold 101;

[0056] The left and right sides of the lower mold 101 are internally threaded with longitudinally symmetrically arranged screw rods 2, and the front ends of the two screw rods 2 are rotatably connected to a crossbeam 201, and the outer side of the front end of the crossbeam 201 is fixedly sleeved with a gear one 202, and the bottom of the crossbeam 201 is fixed A servo motor 1 203 is installed, and a gear 2 204 meshing with the servo motor 1 203 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com