Spiral feeder used for fluidized-bed-type fast biomass pyrolysis

A screw feeder, biomass technology, applied in the direction of biofuels, feeding devices, chemical instruments and methods, etc., can solve the problems of reactor hot air flow escaping, stop feeding, hanging on the wall, etc., to achieve the amount of feed Consistent, continuous feeding, good mechanical sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

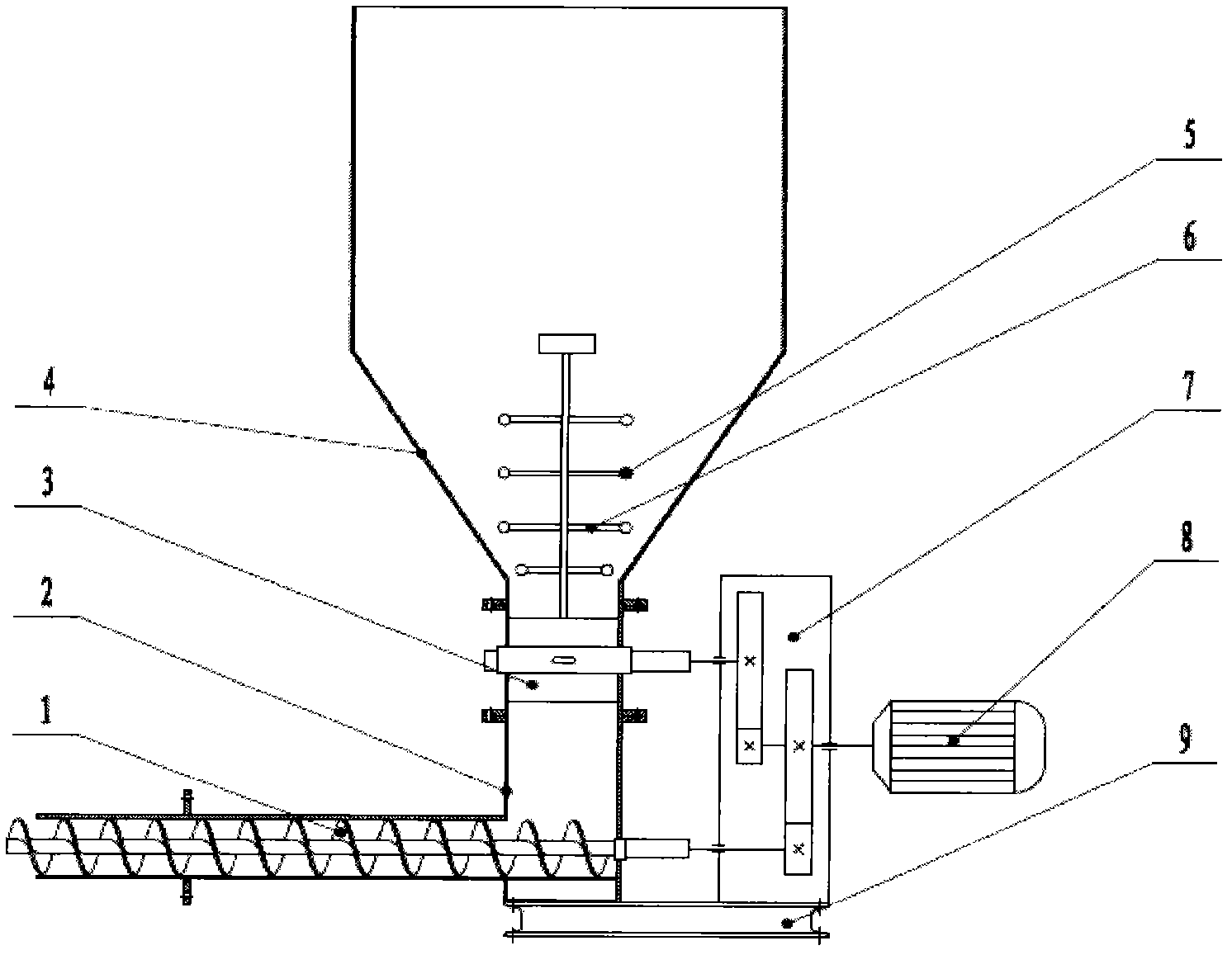

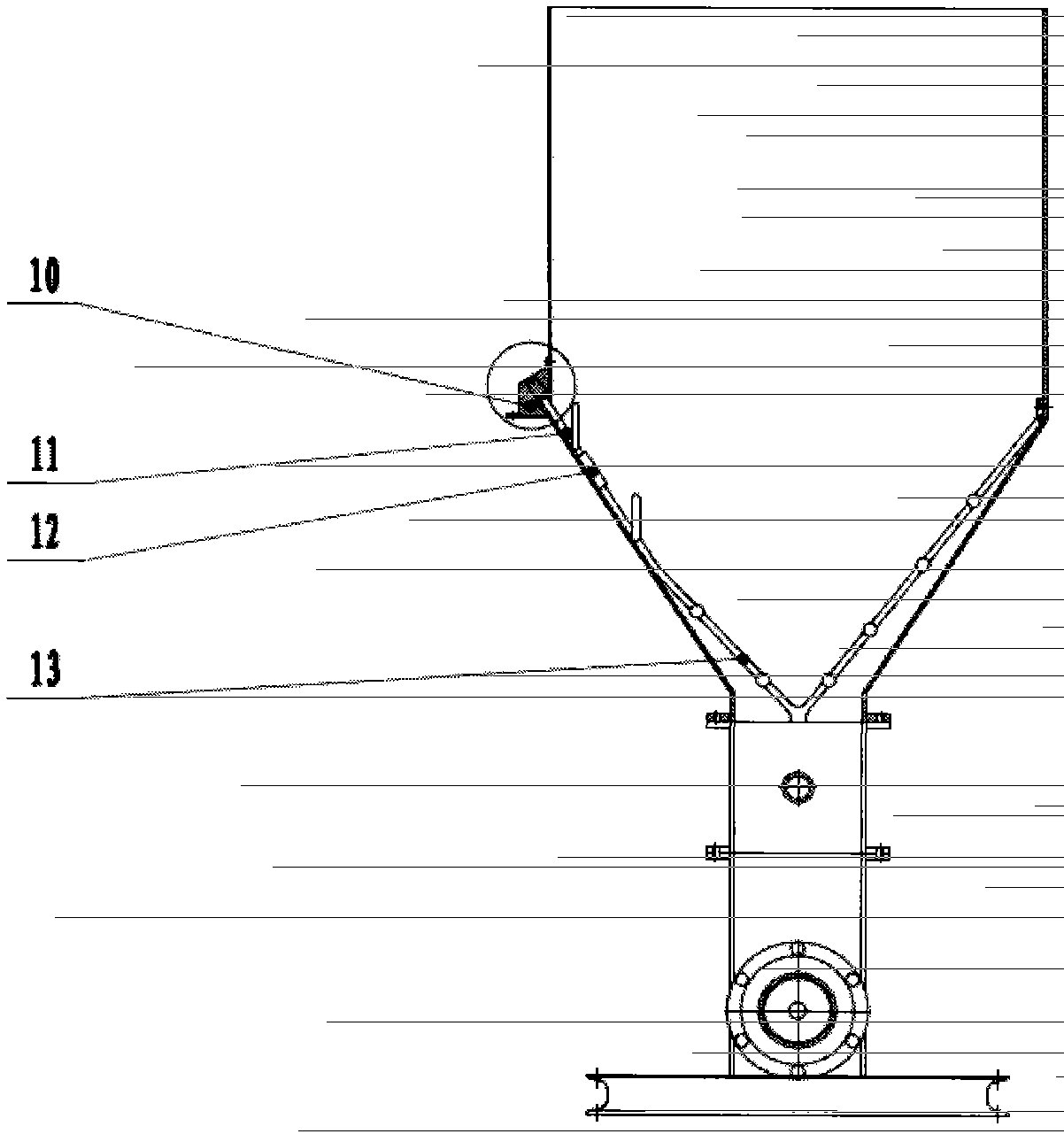

[0016] The present invention provides a screw feeder for rapid pyrolysis of fluidized bed biomass, and the present invention will be further described below with reference to the accompanying drawings and specific embodiments.

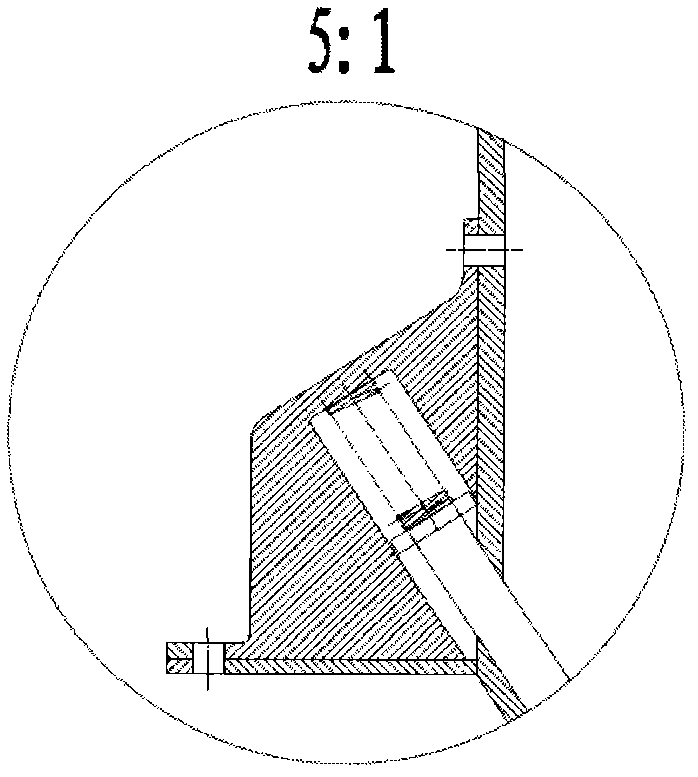

[0017] like figure 1 and figure 2 As shown, the structure of the biomass screw feeder is as follows: the feeder housing 2, the air shutoff device 3, and the silo 4 are vertically connected through flanges, and the feeding auger 1 is located in the feeder housing 2. Biomass enters the feeder shell 2 through the air shutoff device 3, and then is pushed into the fluidized bed reactor by the auger 1, which ensures continuous and uniform feeding. Simultaneously, the pressure-isolated air lock of the air shutoff device 3 and the material seal of the material in the feeder housing 2 have played the role of anti-spray; , connecting rod 6, and contact 5, one end is connected to the silo wall by bolts, the other end is connected to the spring member 10, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com