MEMS and detection circuit

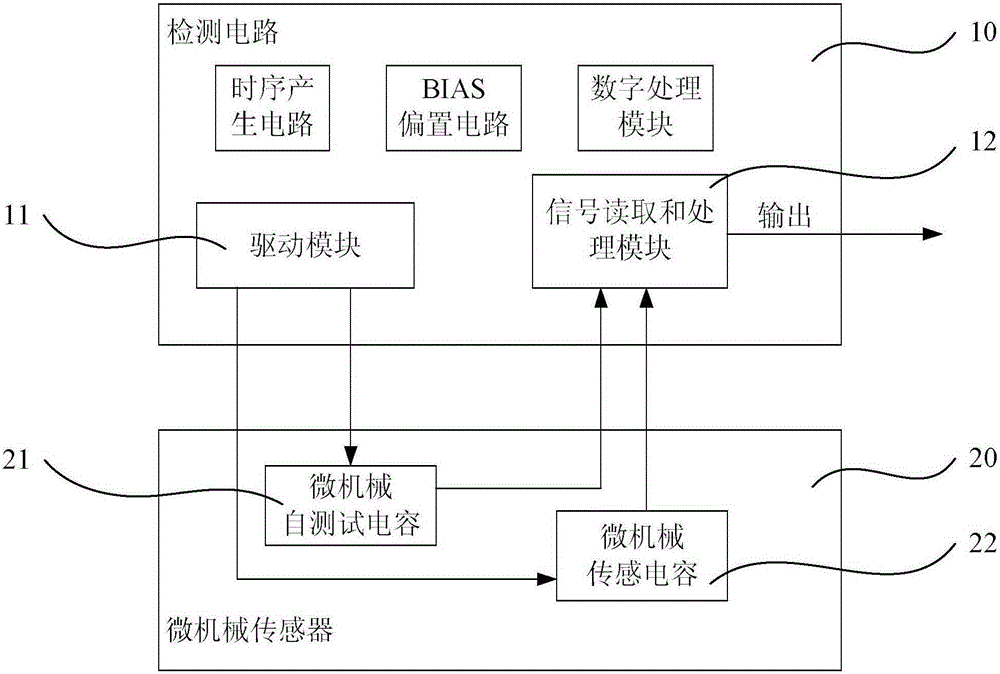

A technology of micro-electromechanical systems and detection circuits, which is applied to components of TV systems, generators/motors, televisions, etc., can solve problems such as inconvenient self-test process, low reliability, and increased difficulty in the design of detection circuit drive modules.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

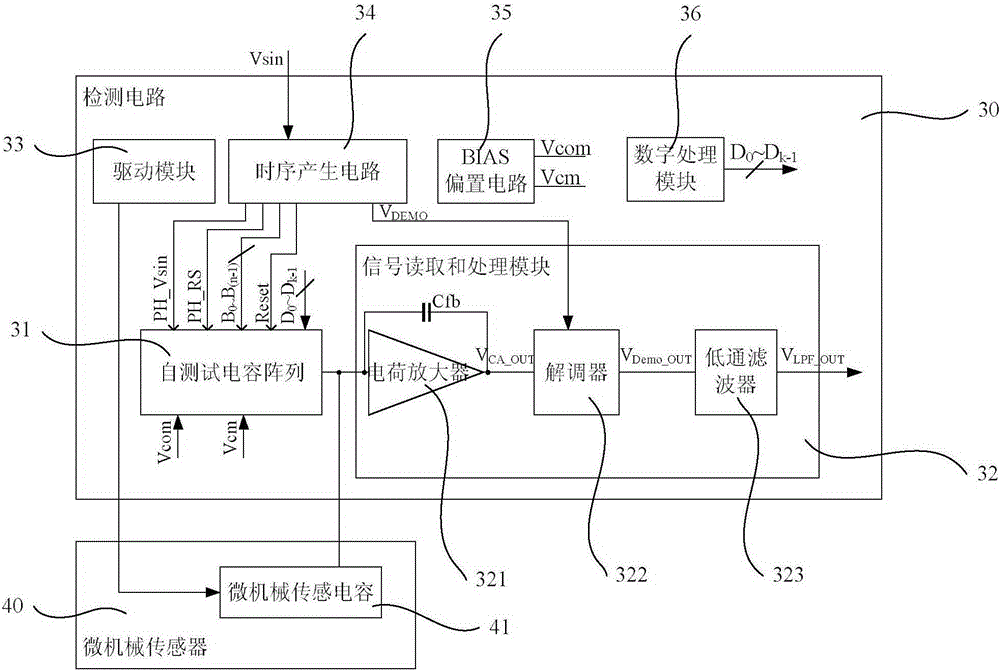

[0075] The micro-electro-mechanical system and detection circuit proposed by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. Advantages and features of the present invention will be apparent from the following description and claims. It should be noted that all the drawings are in a very simplified form and use imprecise scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

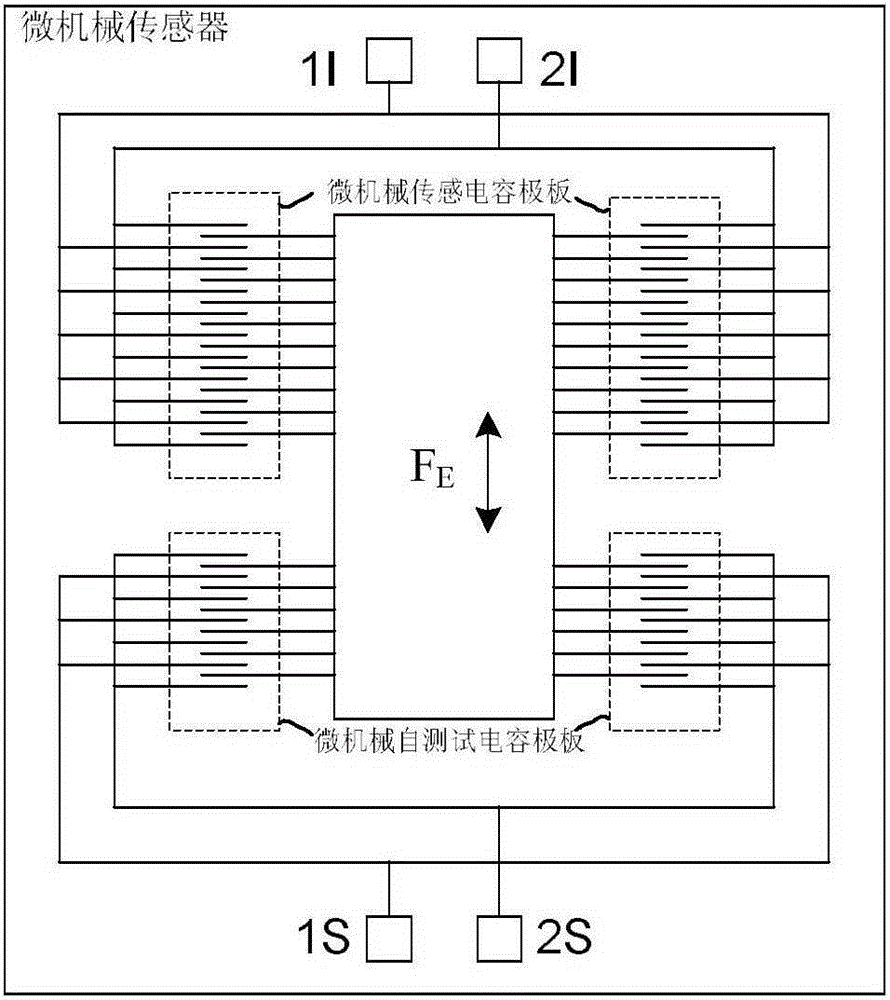

[0076] Please refer to image 3 , which is a schematic structural diagram of a MEMS according to an embodiment of the present invention. Such as image 3 As shown, the micro-electro-mechanical system includes: a micro-mechanical sensor 40 and a detection circuit 30 connected to the micro-mechanical sensor 40; wherein,

[0077]The micro-mechanical sensor 40 includes a micro-mechanical sensing capacitor 41; that is, in this embodiment, the micr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com