Cross mechanical anti-theft lock with fixed lock cylinder

A mechanical anti-theft lock, fixed technology, applied in construction locks, cylinder pin locks, locks with turning keys, etc., can solve problems such as reducing damage, achieve increased manufacturing costs, simple structure, and prevent destructive opening of locks. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

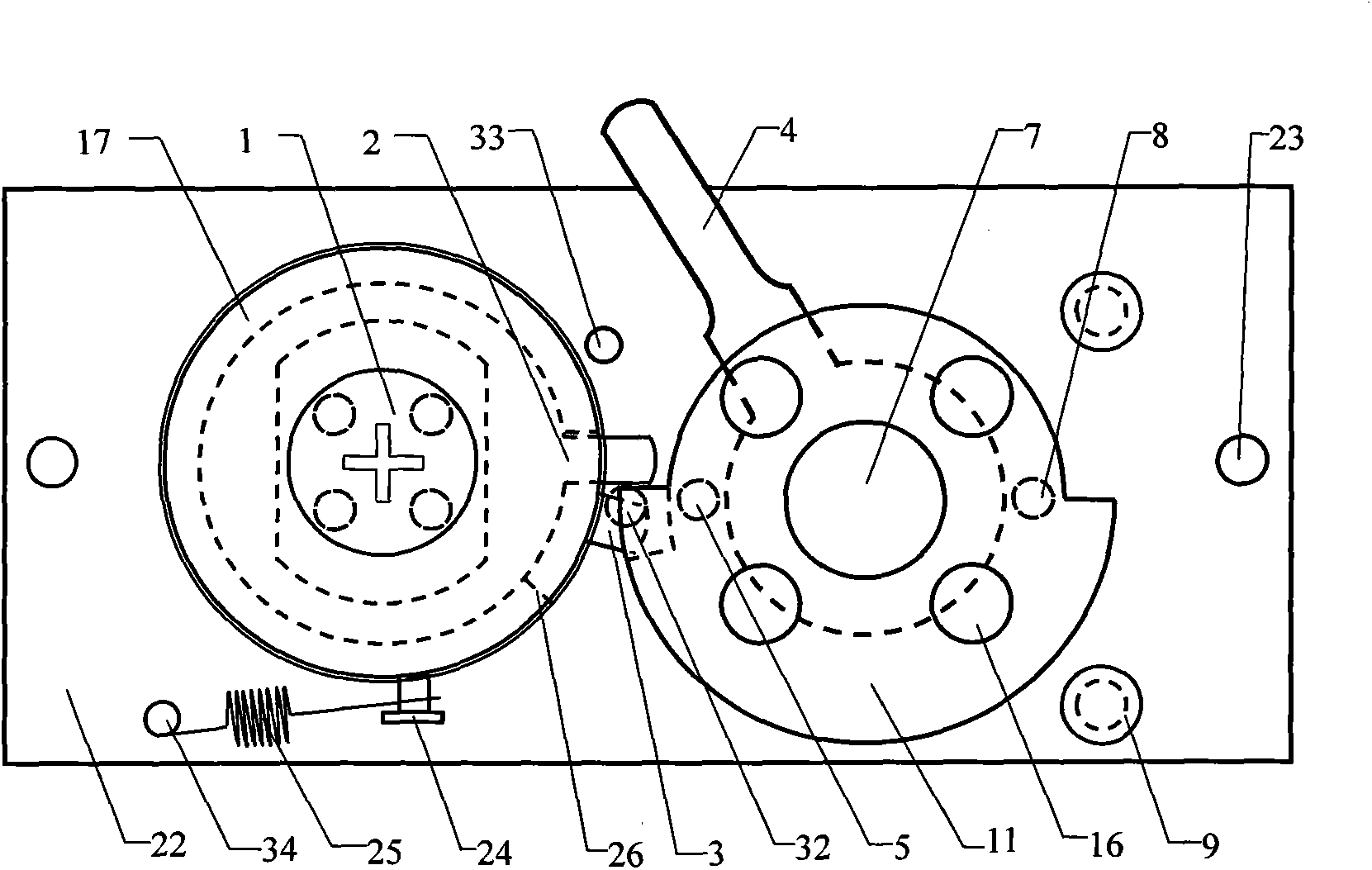

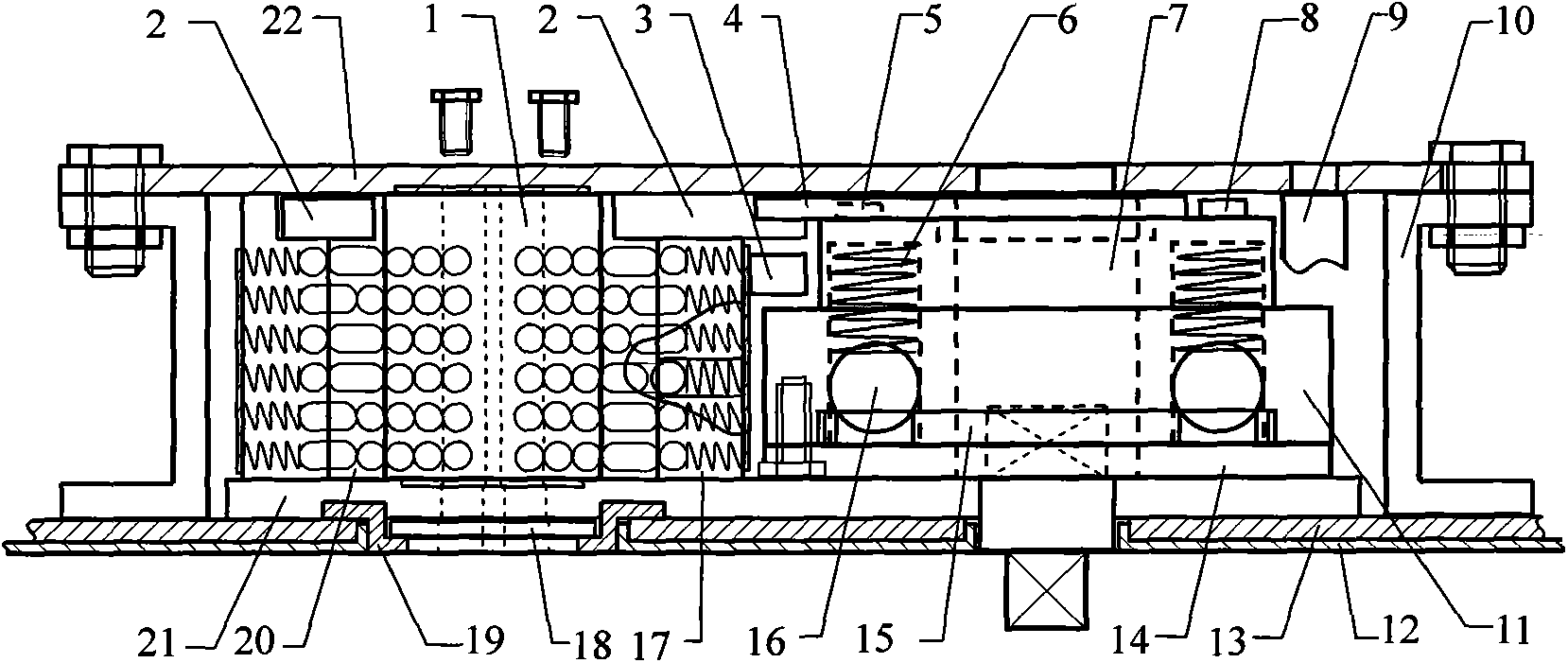

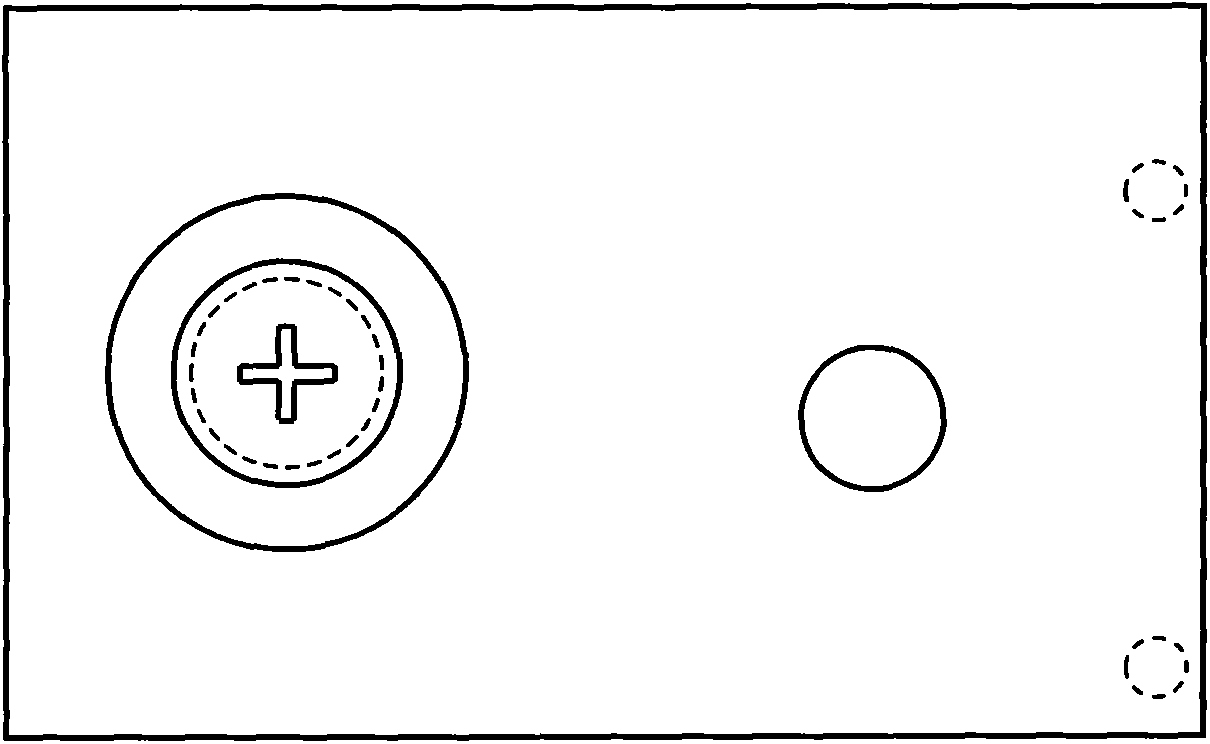

[0047] figure 1 , figure 2 It is an assembly schematic diagram of the present invention, wherein, the lock core 1 (such as Figure 13 , 14 Shown) the diameter 19mm of the middle journal, the length 25.5mm, the diameter 17mm of the inner side journal, long 0.5mm, and the backboard shallow hole 31 of the backboard 22 (such as Figure 7 , 8 shown) is fixed by 4 screws, and the position of each screw hole is as follows figure 1 shown. The diameter 16mm of the axle journal of the outside end of lock core 1, long 0.5mm, and with the anti-skid plate shallow hole 29 of anti-skid plate 21 (as image 3 , 4 Shown) assembly, the depth of above-mentioned two shallow holes should be greater than 0.5mm, make the spacing after anti-skid plate 21, backboard 22 assemble equal to the length 25.5mm of the middle part journal of lock cylinder 1. A limit pin 32 and a stop pin 33 are fixed on the back plate 22 . The central position of the anti-skid plate shallow hole 29 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com