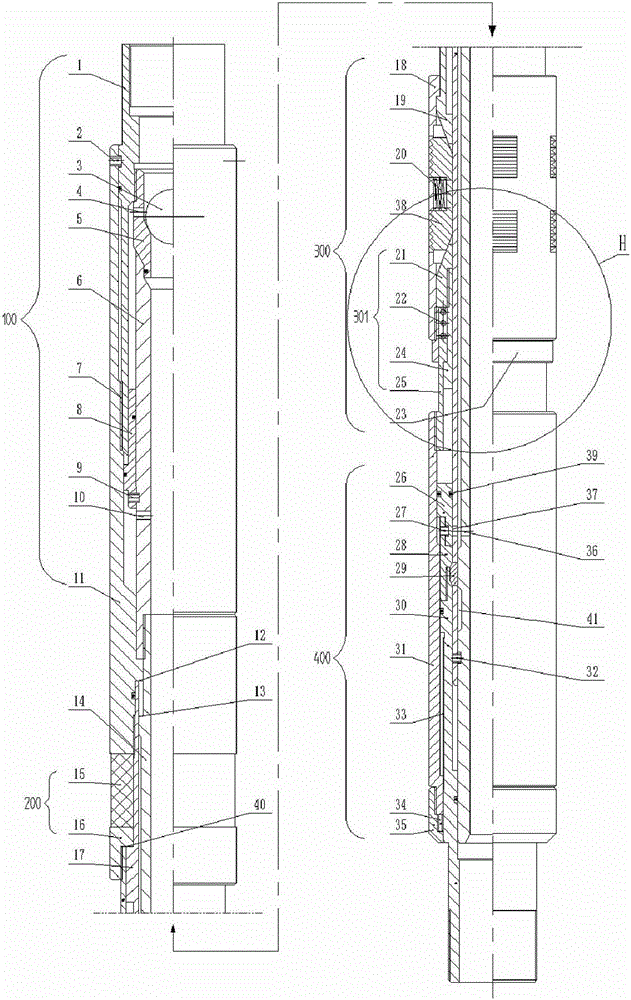

Hydraulic packer and installation method thereof

A packer and hydraulic technology, applied in the direction of sealing/isolation, earthwork drilling, wellbore/well parts, etc., can solve problems such as moving up, automatic unsealing, and weak anchoring of packers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

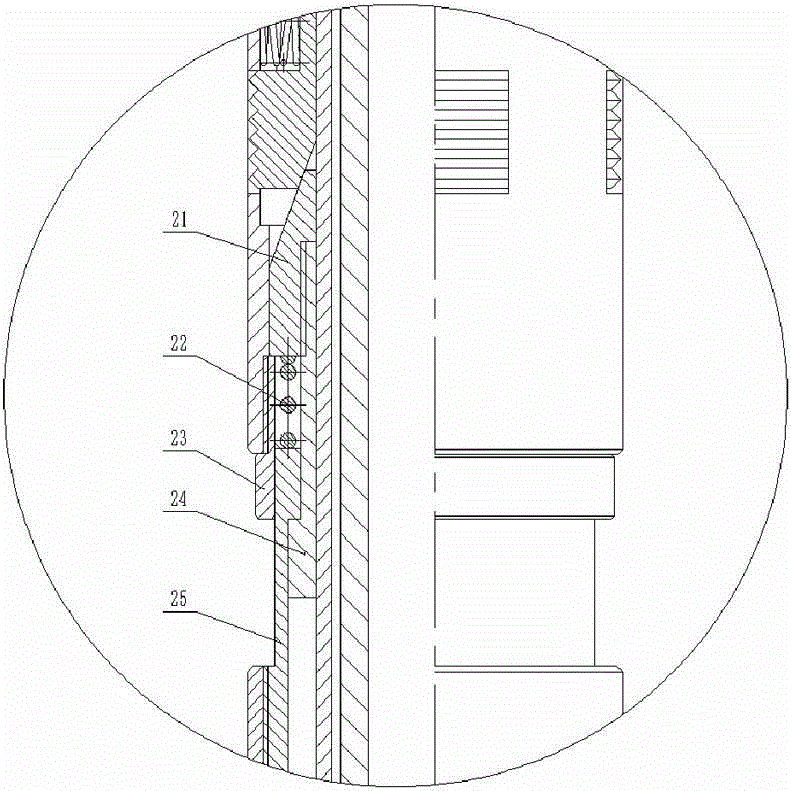

Embodiment 1

[0051] The installation steps of the preferred embodiment of the present invention-hydraulic packer are:

[0052] a. Use tubing or drill pipe to send the hydraulic packer to the downhole design position. The necessary string combination is: tubing or drill pipe + hydraulic packer [without ball (3)] + pressure controller;

[0053] b. Increase the hydraulic pressure in the string to reach the design value of the setting force of the hydraulic packer;

[0054] c. Maintain or reduce the hydraulic pressure in the pipe string, but ensure that the hydraulic pressure in the pipe string is greater than the hydraulic pressure in the oil jacket annulus;

[0055] d. Lower the pipe string from the wellhead to load the hydraulic packer with a mechanical force of 50kN-250kN;

[0056] e. Remove the hydraulic pressure in the string.

[0057] f. Throw the ball (3) from the tubing or drill pipe, and make the ball (3) fall on the ball seat (5);

[0058] g. Increase the hydraulic pressure in th...

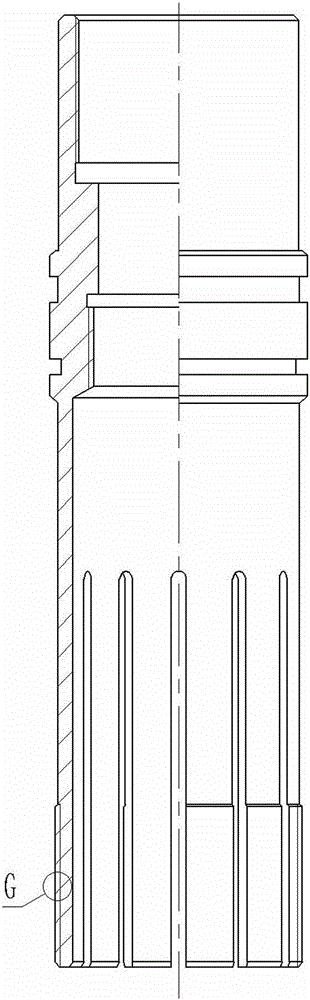

Embodiment 2

[0064] The installation method of preferred embodiment 2 hydraulic packer comprises the following steps:

[0065] a. Use tubing or drill pipe to send the hydraulic packer to the downhole design position. The necessary string combination is: tubing or drill pipe + hydraulic packer;

[0066] b. Increase the hydraulic pressure in the string to reach the design value of the setting force of the hydraulic packer;

[0067] c. Maintain or reduce the hydraulic pressure in the pipe string, but ensure that the hydraulic pressure in the pipe string is greater than the hydraulic pressure in the oil jacket annulus;

[0068] d. Lower the pipe string from the wellhead to load the hydraulic packer with a mechanical force of 50kN-250kN;

[0069] e. Remove the hydraulic pressure in the string.

[0070] f. Lift the oil pipe or drill pipe to the original suspension, turn the pipe string to the right to unscrew the hand thread (7);

[0071] g. Lift the tubing or drill pipe out of the upper join...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com