Valve system

A proportional valve and distribution valve technology, applied in the field of valve systems, can solve the problems of long load adjustment time and inability to accurately locate the load, and achieve the effect of low cost and short adjustment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

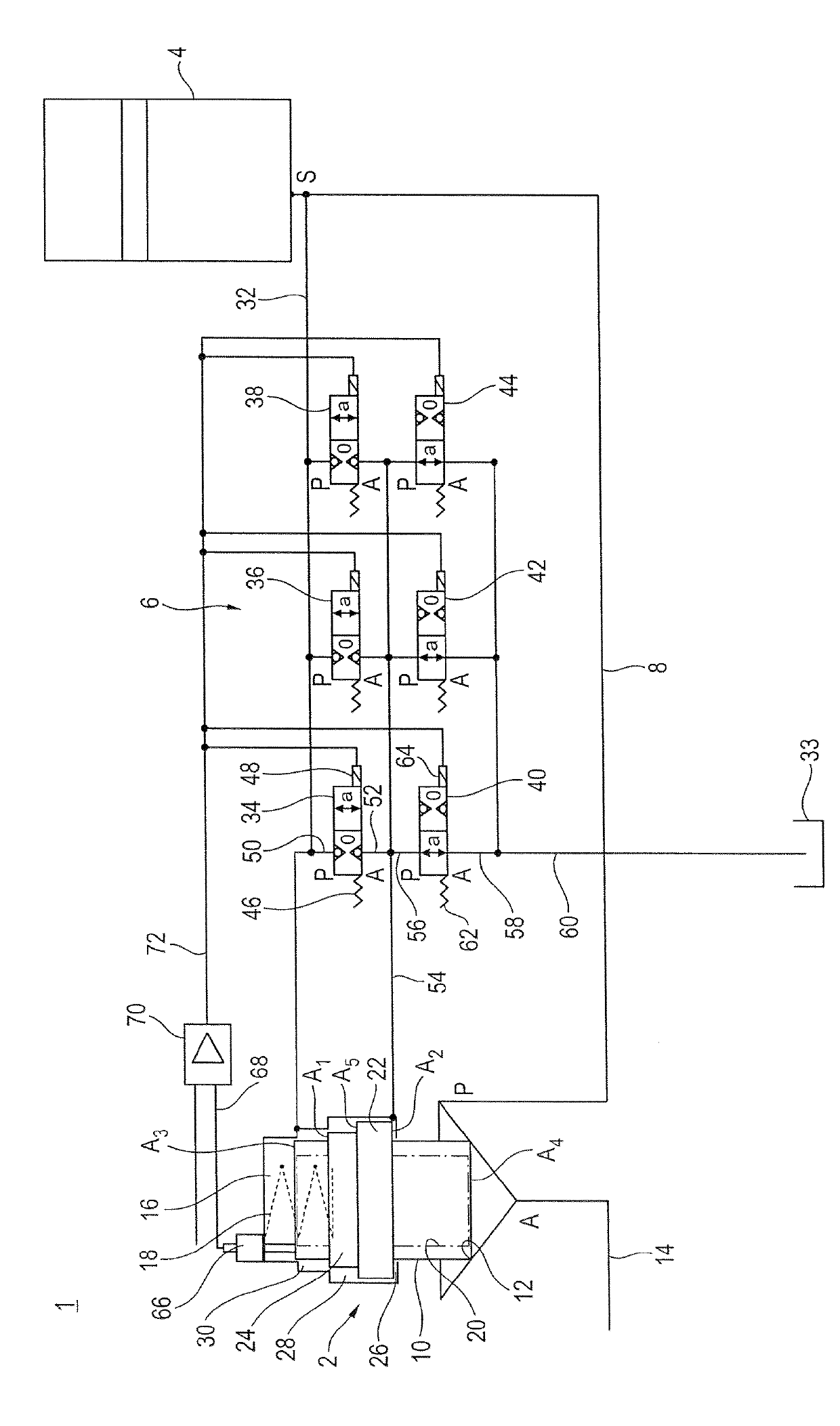

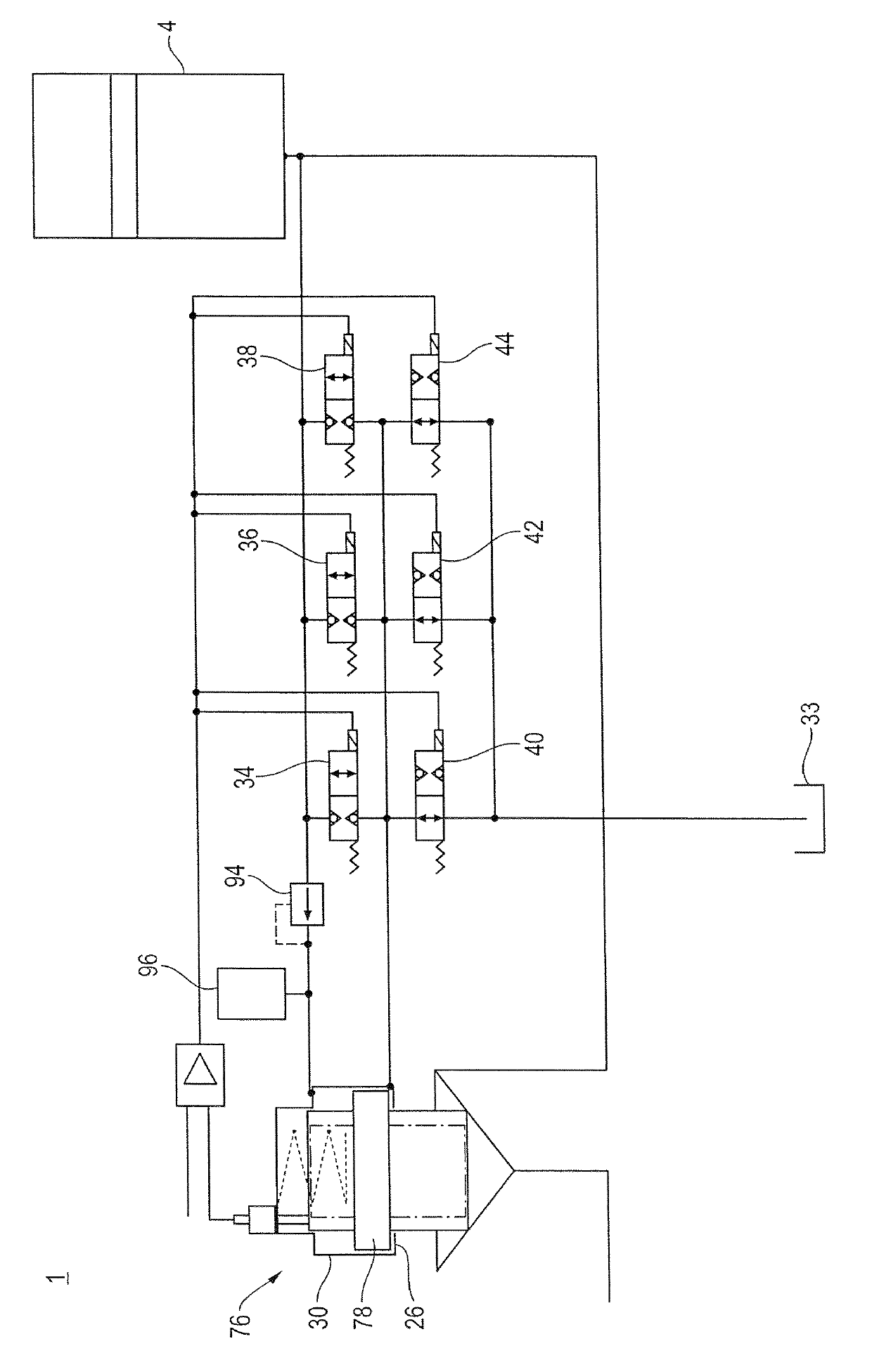

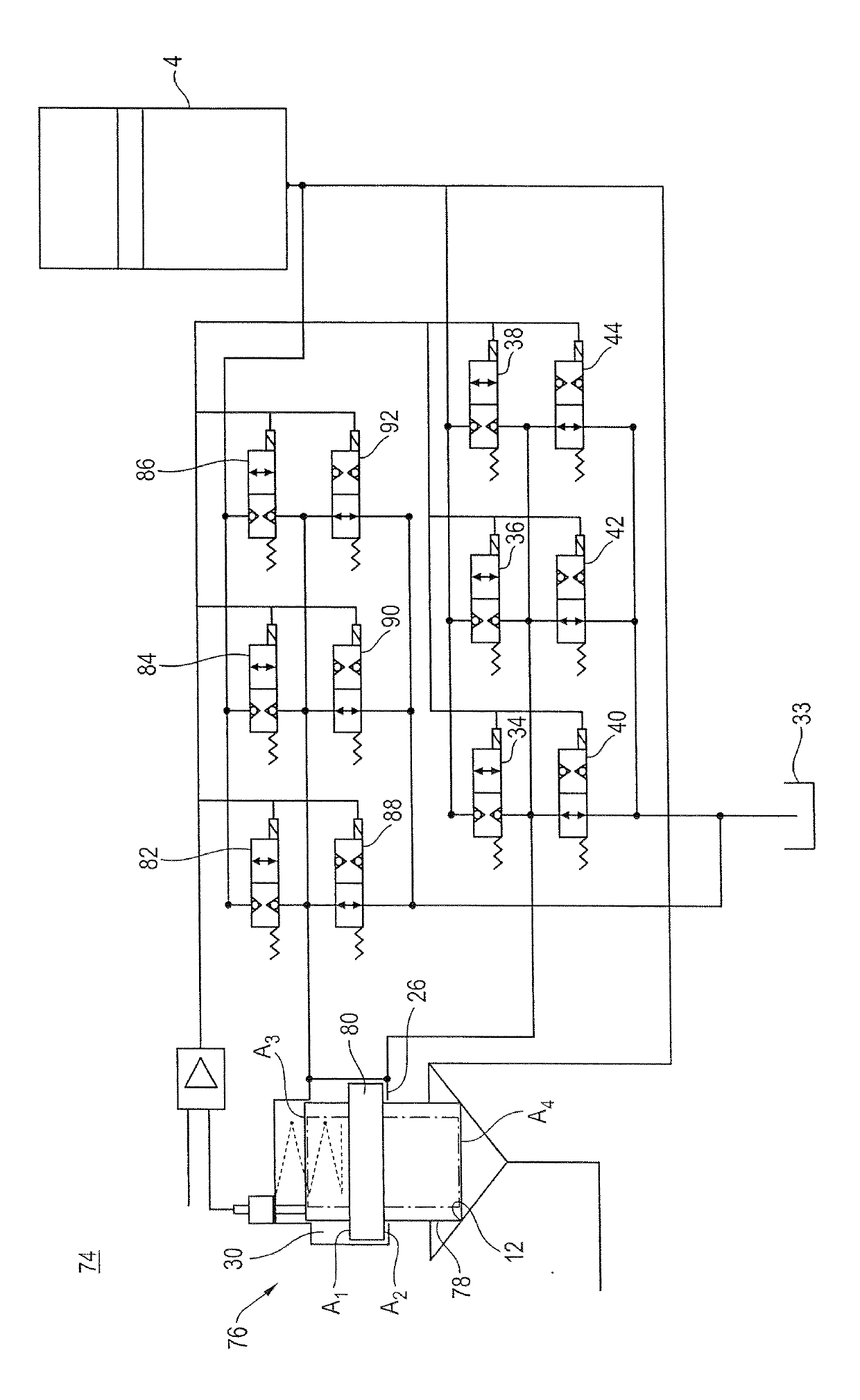

[0088] according to figure 1 A valve system 1 according to the invention is shown. The valve system has a proportional valve 2 for opening and closing a control (zusteuern) pressure medium connection between a hydraulic accumulator 4 and a consumer (not shown). The proportional valve 2 can be controlled here by a pilot control valve line 6 . Such a valve system 1 is used in particular for applications in printing machines, injection molding machines, molding machines or casting machines, since a proportional valve 2 with high dynamics and a high flow rate is required for hydraulic loads.

[0089] The proportional valve 2 basically corresponds to the installation of a continuous valve or an active logic valve, as is shown, for example, in applicant's data sheet RD 21040 / 11.10. However, the proportional valve 2 according to the first embodiment has an additional control surface A 1 and A 2 , which is explained in detail below.

[0090] The proportional valve 2 has a pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com