Full-falling-film evaporator with double refrigerant distribution devices

一种降膜式蒸发器、冷媒分配的技术,应用在蒸发器/冷凝器、水淋冷却器、直接接触式换热器等方向,能够解决下部换热管群换热系数低、增加冷媒充注量、蒸发器冷媒含油量高等问题,达到减少充注量和换热面积、提高换热系数、防止飞溅的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings to facilitate a clearer understanding of the present invention, but they do not limit the present invention.

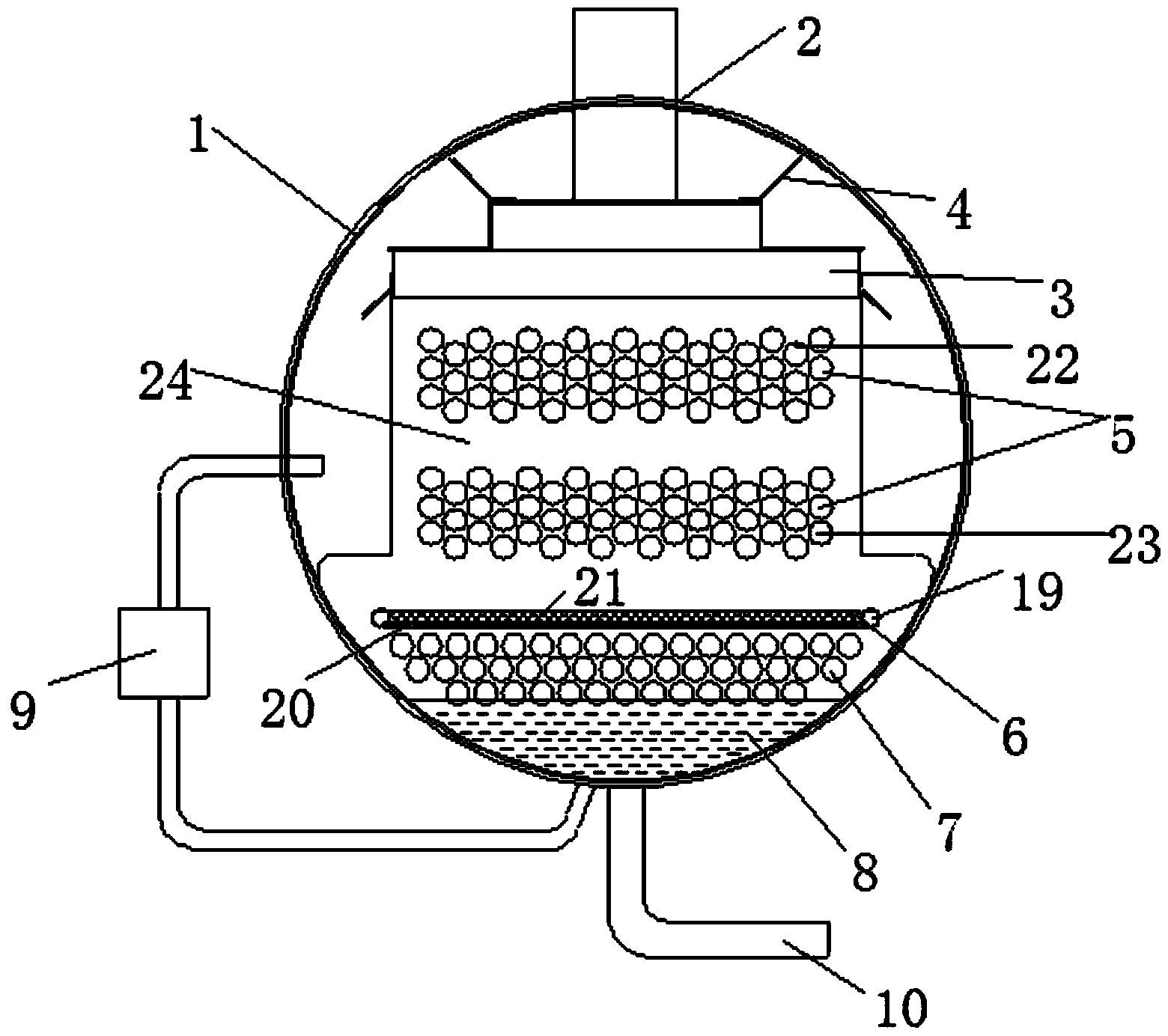

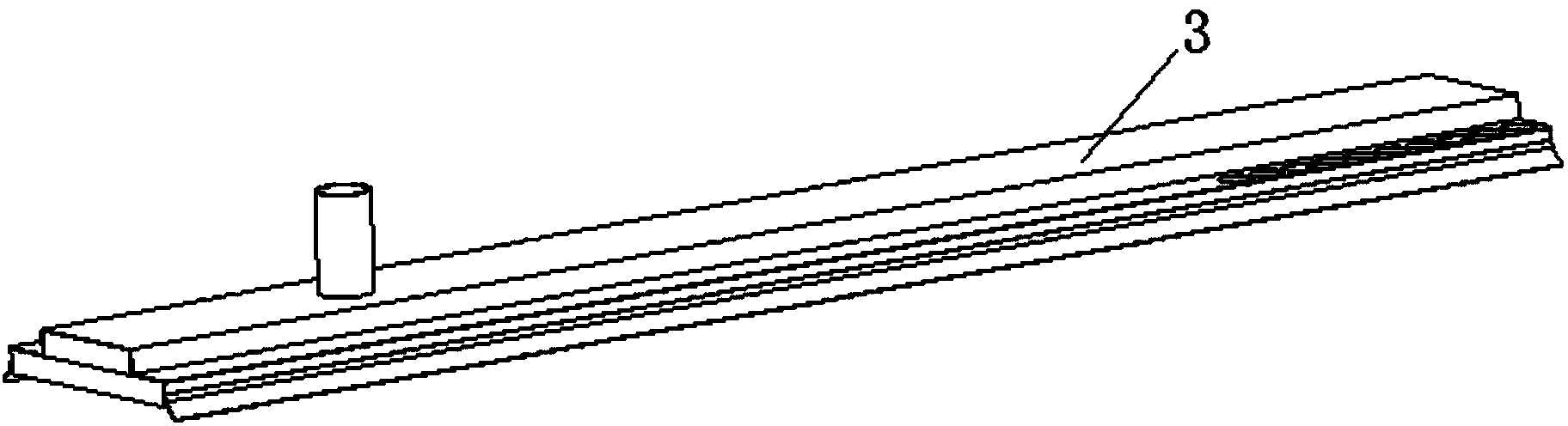

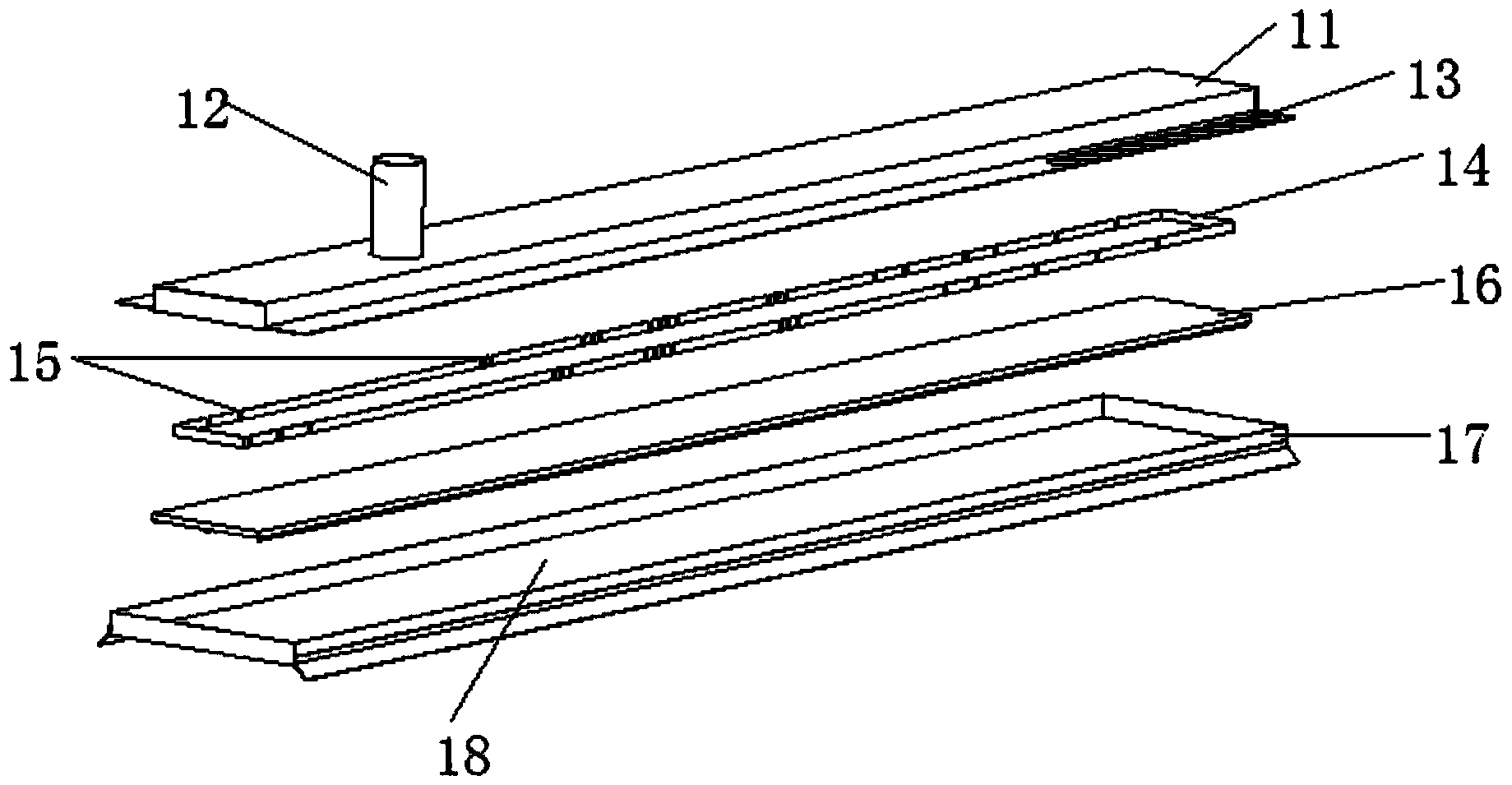

[0015] Such as figure 1 As shown, a full falling film evaporator with double refrigerant distribution device includes a cylinder body 1, a refrigerant inlet 2 and a refrigerant outlet are arranged on the top of the cylinder body 1, and an upper distributor is arranged on the top of the cylinder body 1 3. There are gas baffles 4 on both sides of the top of the upper distributor 3 respectively. The gas baffles 4 are provided with a number of holes communicating with the refrigerant outlet. The lower part of the upper distributor 3 is provided with The upper heat exchange tube group 5, the upper heat exchange tube group 5 includes a top heat exchange tube group 22 and a bottom heat exchange tube group 23, leaving a space between the top heat exchange tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com