Strip Width and Center Measurement System and Method Based on Parallel Laser Lines

A measurement method and measurement system technology, applied in the direction of measurement devices, optical devices, instruments, etc., can solve the problems of vibration interference, poor real-time performance, etc., and achieve the effect of strong anti-vibration interference, low cost, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

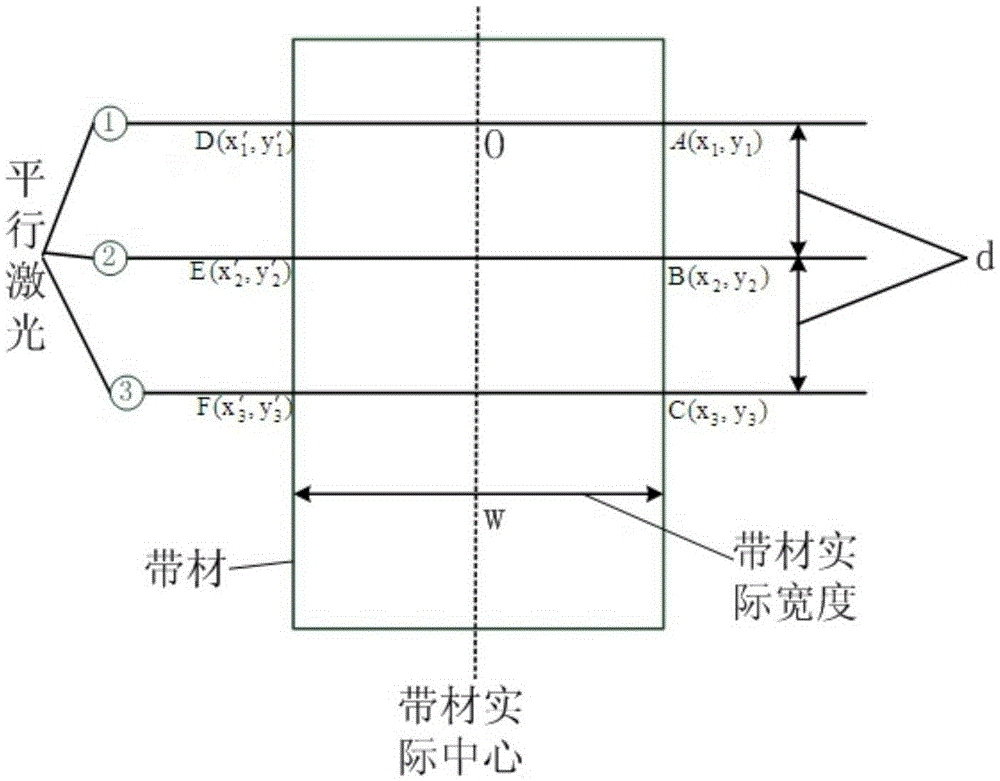

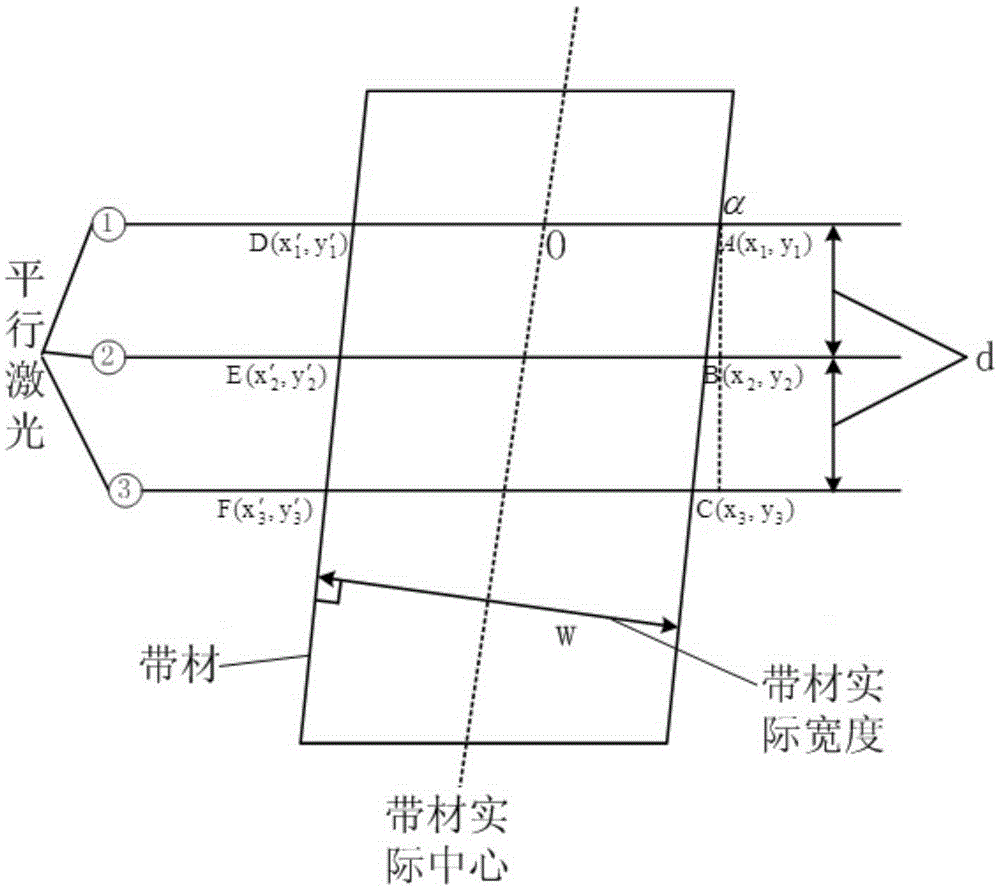

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

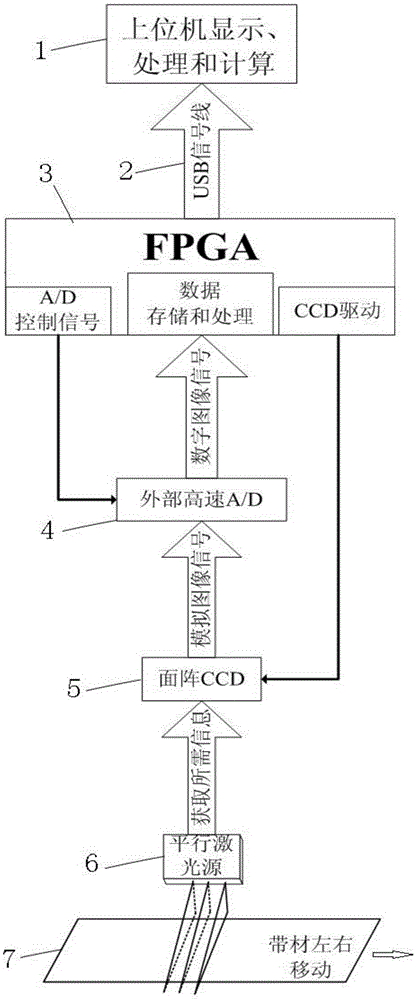

[0014] refer to figure 1 , the measuring system structure of the present invention is, comprises the parallel laser source 6 that is arranged on conveying line directly above and detection sensor, and detection sensor is connected with FPGA processor 3 in addition,

[0015] The parallel laser source 6 adopts a parallel laser with a wavelength of 635nm to 650nm, which can emit parallel laser lines to the strip on the conveying line, with high power, long service life, easy installation and use, and the parallel laser source 6 irradiates vertically downward The parallel laser line should be perpendicular to the plane of the strip, and the parallel laser line illuminated on the strip must be perpendicular to the forward direction of the strip;

[0016] The FPGA processor 3 has a high-speed digital signal processing function, and the FPGA proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com