Light harvesting tube insertion base of micro-balance

A micro-balance and light-collecting technology, used in weighing, measuring devices, detailed information of weighing equipment, etc., can solve the problems of unstable work, affecting the quality of main products, inaccurate measurement, etc., and achieve reasonable structure and precision. High, properly designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing:

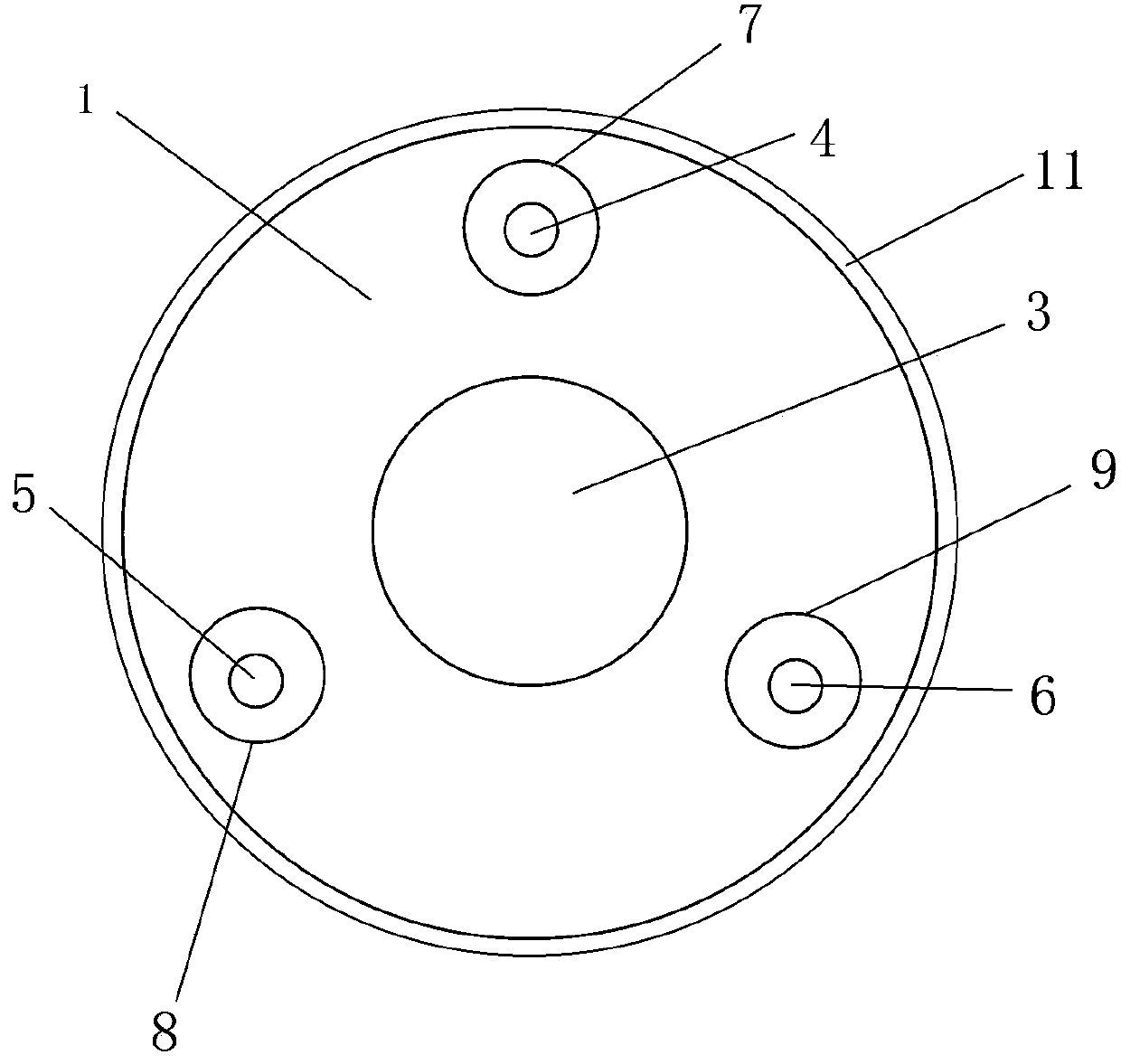

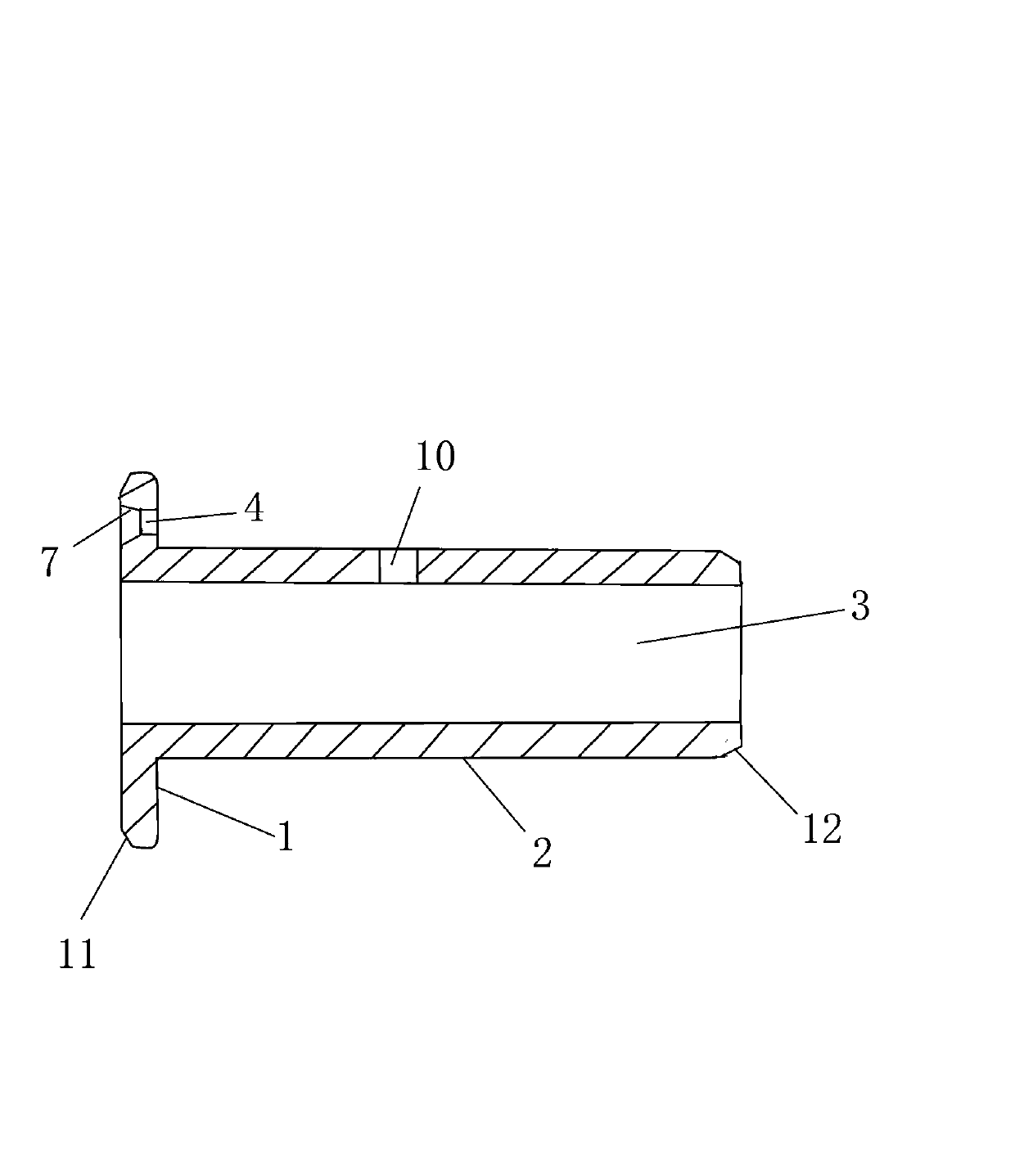

[0012] A light collecting tube socket for a micro balance, comprising a first metal round seat, a second metal round seat and a socket hole, characterized in that the light collecting tube socket is connected by mixing the first metal round seat 1 and the second metal round seat 2 The first metal round seat 1 and the second metal round seat 2 are all cylinders; the diameter of the outer circumference of the first metal round seat 1 is 390mm, and the front and rear lengths of the first metal round seat 1 are 20mm; The diameter of the outer circle of the second metal circle seat 2 is 210mm, and the front and rear lengths of the second metal circle seat 2 are 430mm; the back circle of the first metal circle seat 1 and the front circle of the second metal circle seat 2 Hybrid connection, the center of the first metal round seat 1 and the center of the second metal round seat 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com