Panel Mount Connector

A connector and panel technology, applied in the direction of connection, connection component installation, two-component connection device, etc., can solve problems such as reduction of tensile force resistance, falling off, etc., to achieve enhanced tensile resistance, deformation prevention, efficient and easy fixing operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

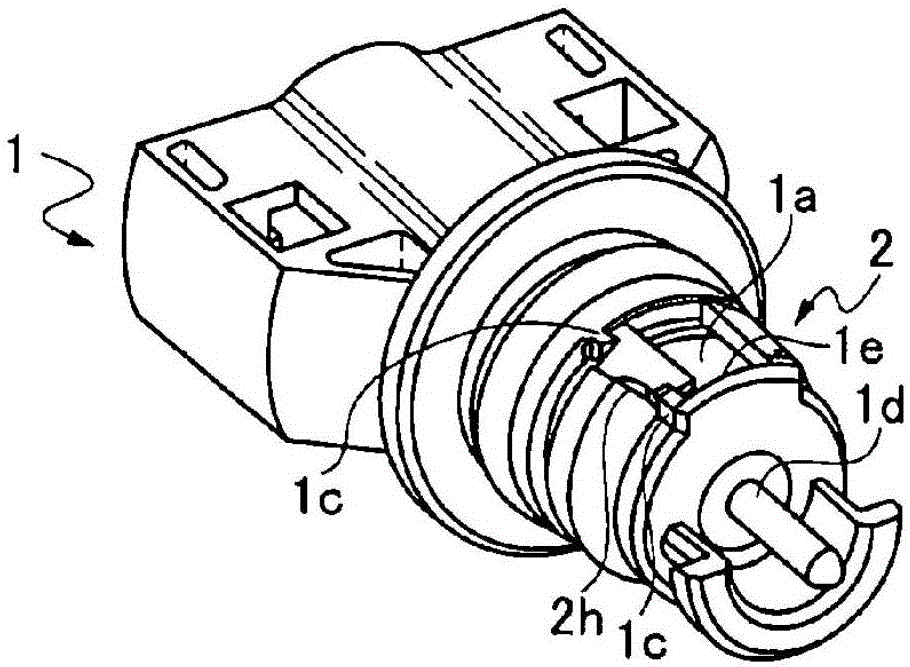

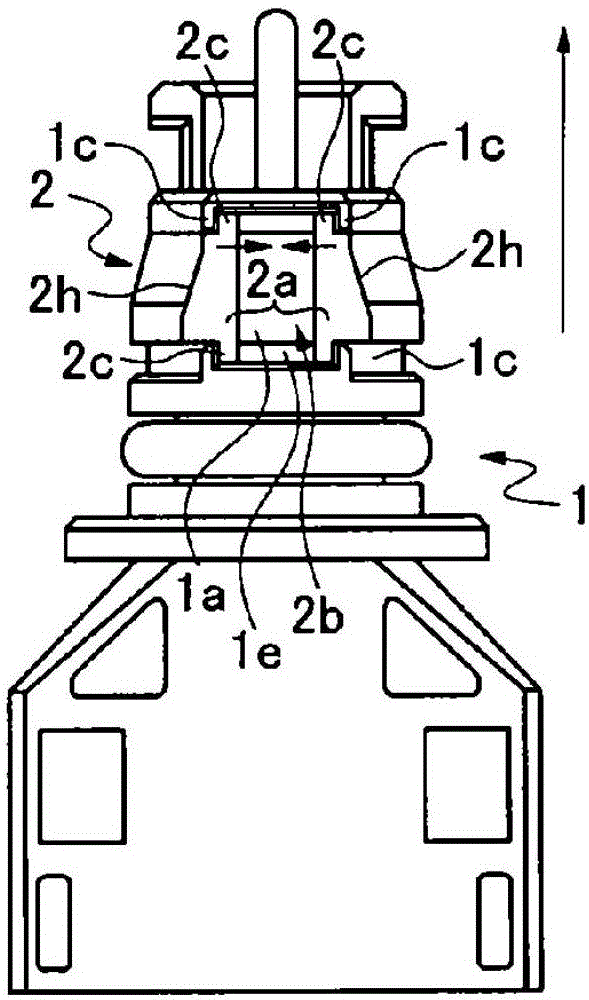

[0039] Figure 1A˜2C show the panel mount connector 1 in Embodiment 1 of the present invention, and the connector 1 has a groove 1 a formed over the entire circumference of the cylindrical portion on the front end side. An annular locking piece 2 formed of an elastic member is fitted and fitted into this groove 1a.

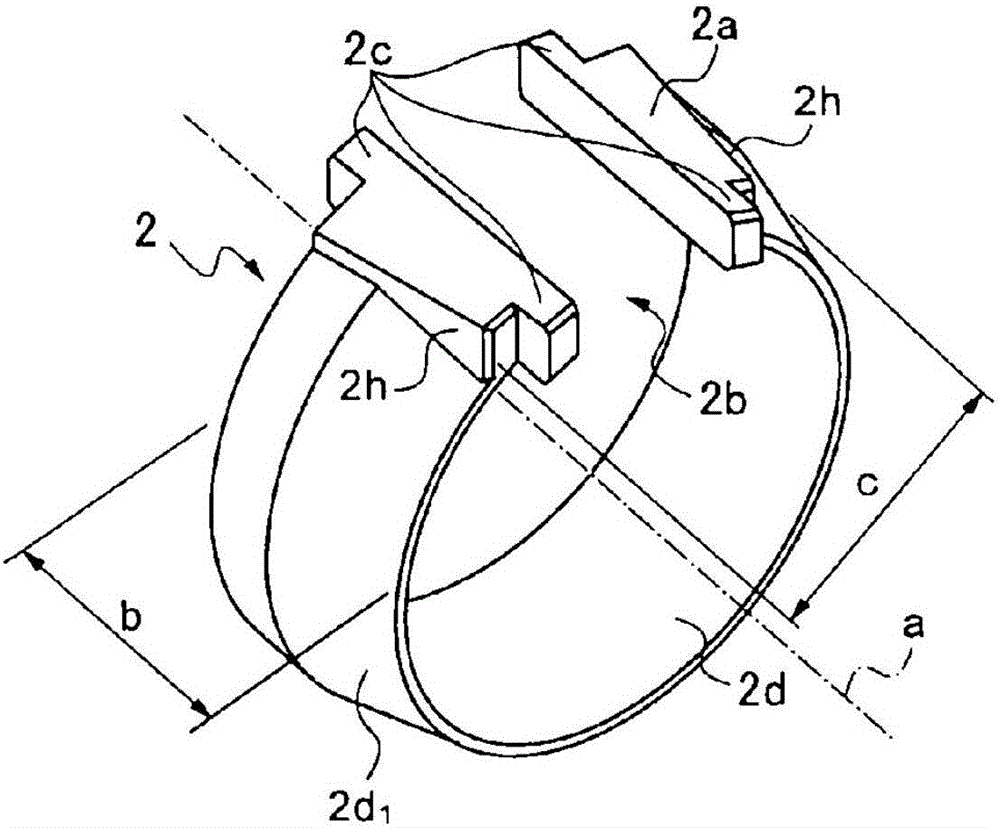

[0040] The locking piece 2, such as Figure 1C As shown, there is an annular body part 2d formed by cutting off a part of the circumference. The outer peripheral surface of the main body portion 2d has an inclined surface 2d whose diameter becomes smaller toward the front end side. 1 . Protrusions 2a protruding upward are respectively formed at both end edges of the body portion 2d facing across the notch portion 2b formed by cutting out a part of the circumference. Protruding portions 2c protruding in the direction of the axis a of the main body portion 2d are respectively provided at both ends of the protruding portion 2a.

[0041] In addition, a total of f...

Embodiment 2

[0048] Figure 3A-3D This panel mounting connector 1 in Embodiment 2 of the present invention is shown. This connector 1 is the same as the first embodiment except that the locking piece 2e to be mounted in the groove 1a formed in the cylindrical portion on the front end side is different, so repeated description of the same parts will be omitted.

[0049] On the locking piece 2e, such as Figure 3C As shown, the protruding portion 2a is formed through the extending portion 2f extending upward with the width b of the main body portion 2d. Furthermore, protruding portions 2c protruding from a part of both ends of the protruding portion 2a in the axial direction of the locking piece 2e are formed. In the locking piece 2e, the width c between the circumferential outer wall surfaces of the extending portions 2f and 2f facing each other in the enlarged diameter state is the same as Figure 3B The width D between the pair of partition walls 1c, 1c formed in the circumferential di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com