Sewn product and method for sewing material

A technology for sewing products and fabrics, which is applied in the field of sewing products and fabrics, and can solve the problems of conspicuous seams, increased thickness of seams, and wide width of seams, so as to ensure strength and reduce unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

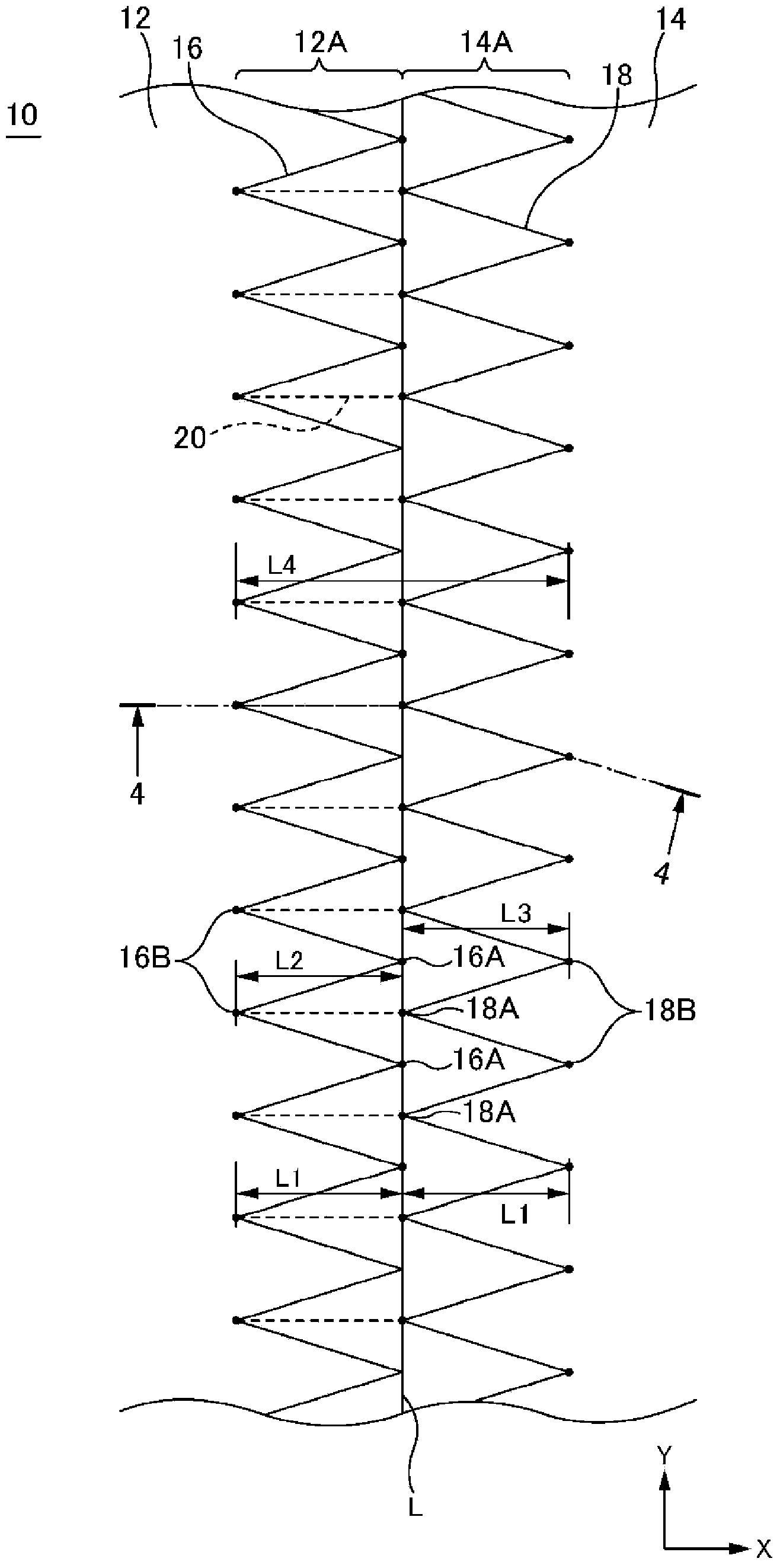

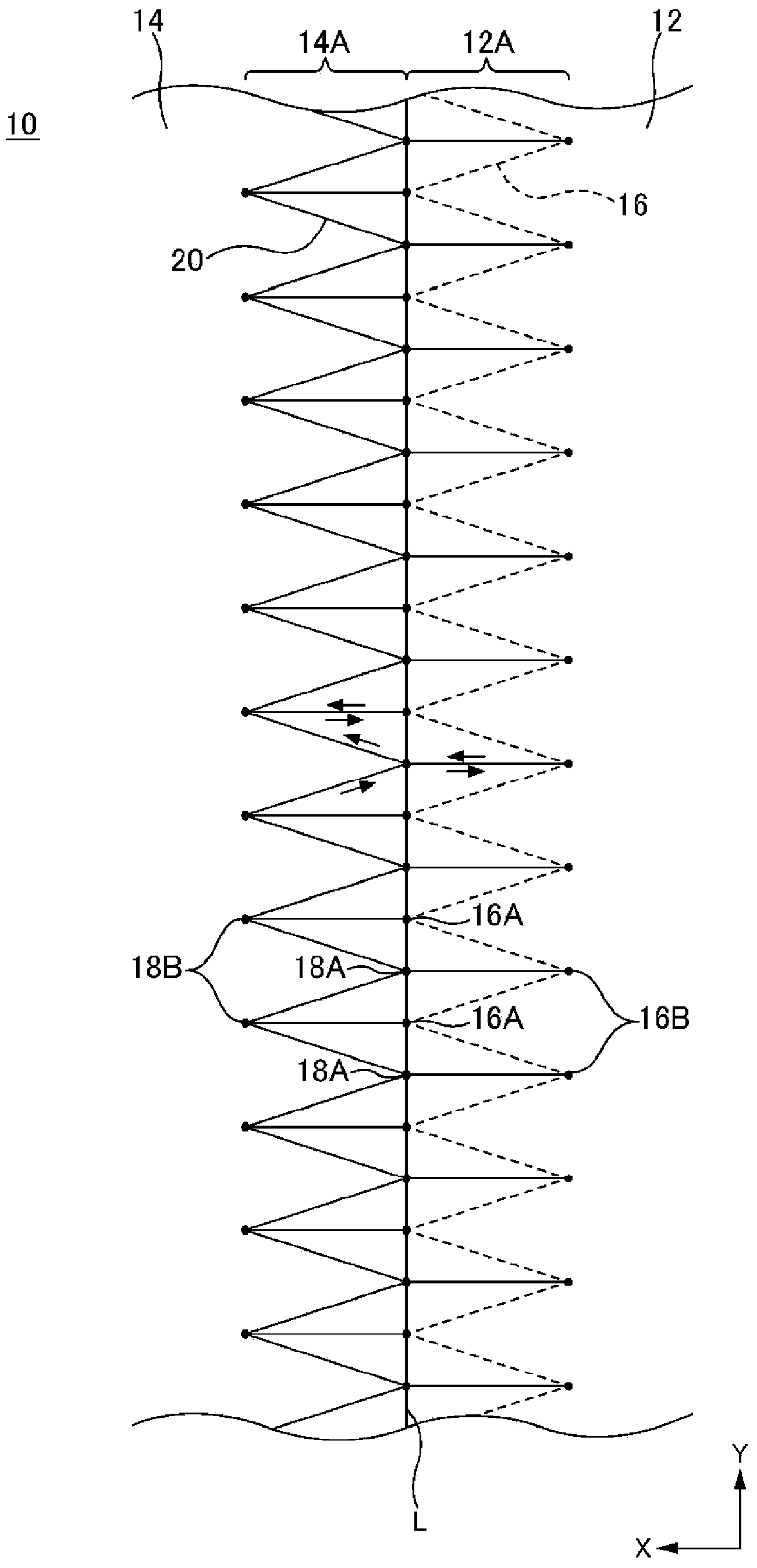

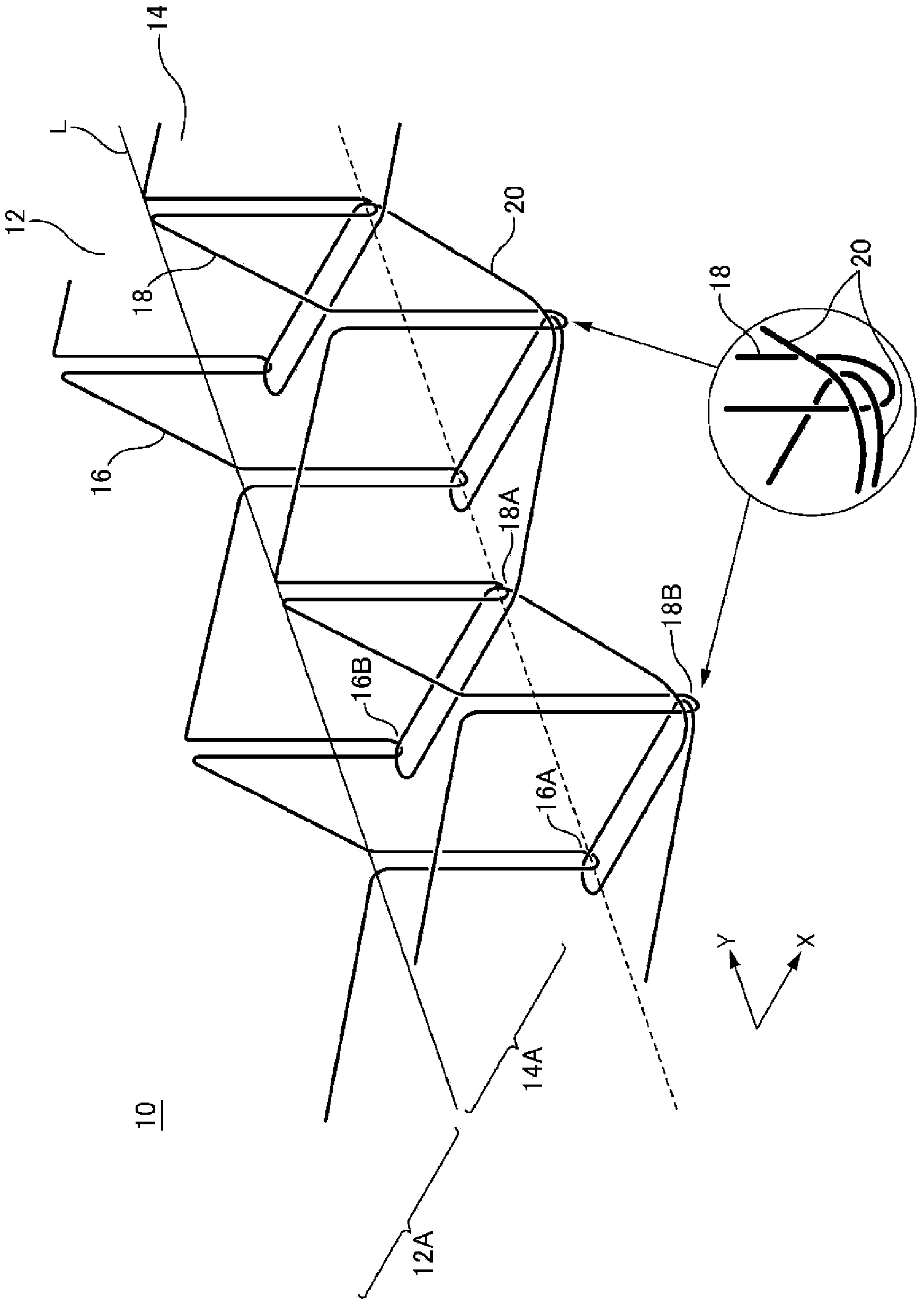

[0028] Hereinafter, an embodiment of the present invention will be described with reference to the drawings. figure 1 It is a plan view showing one surface of a sewn product 10 according to one embodiment, figure 2 It is a plan view showing the other surface of the sewn product 10 . As shown in these two figures, the sewn product 10 is sewn in a flat state by butting an end portion (hereinafter referred to as a cloth edge) 12A of a cloth 12 and an end portion (hereinafter referred to as a cloth edge) 14A of a cloth 14 . And sewn into sewing products. The fabrics 12 and 14 are felt fabrics, knitted fabrics, knitted compressed wool, jersey, etc., and the sewn product 10 is clothes such as underwear and outerwear.

[0029] The sewing of the fabric ends 12A, 14A uses two upper threads 16 , 18 and one lower thread 20 . In addition, in the following description, the side where the upper threads 16 and 18 of the sewn product 10 are exposed as stitches is called the front side, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com