Transverse shearing production line

A production line and cross-cutting technology, which is applied in the direction of shearing devices, shearing machine equipment, shearing machine accessories, etc., to achieve the effect of enriching shearing functions and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

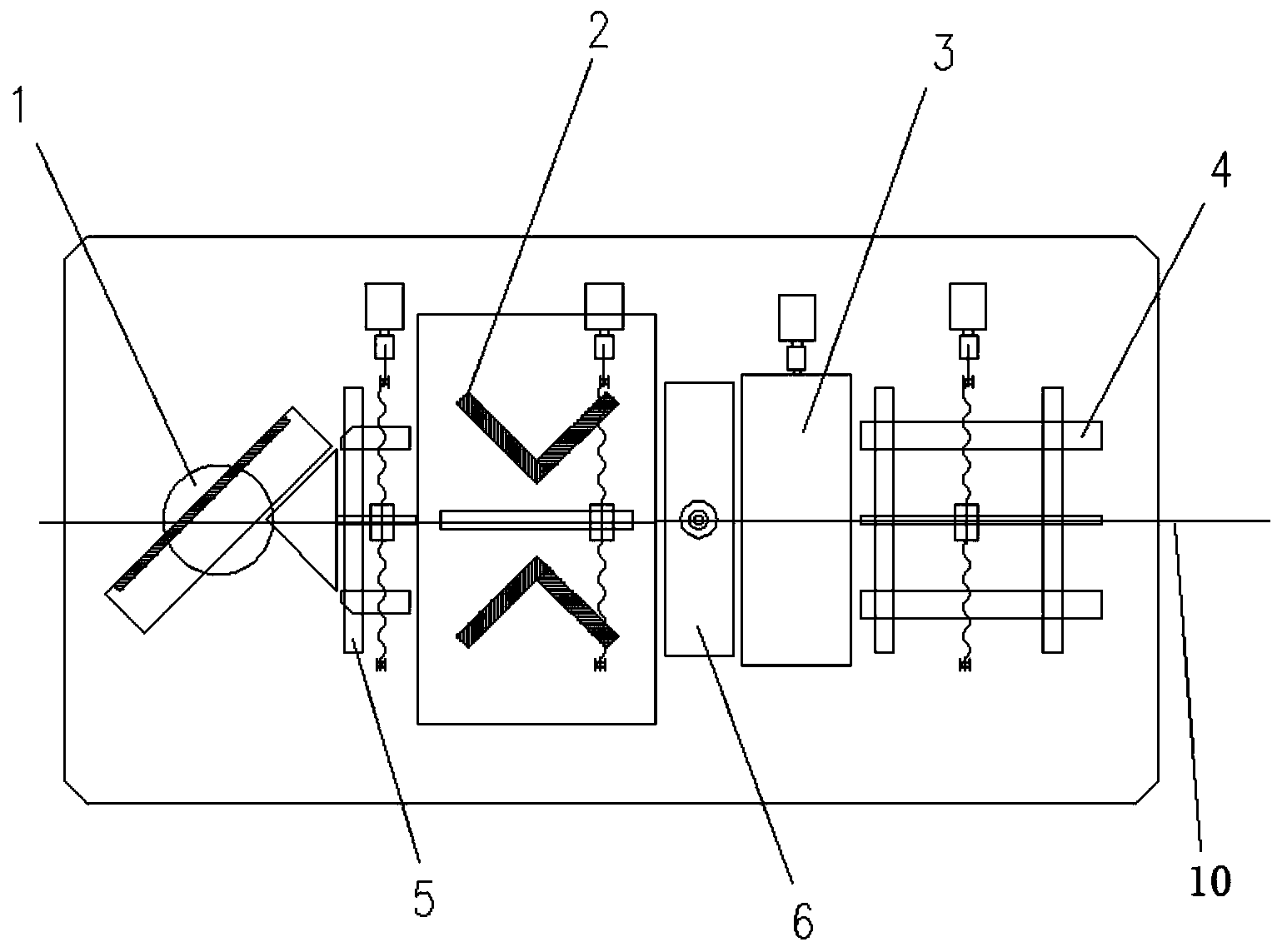

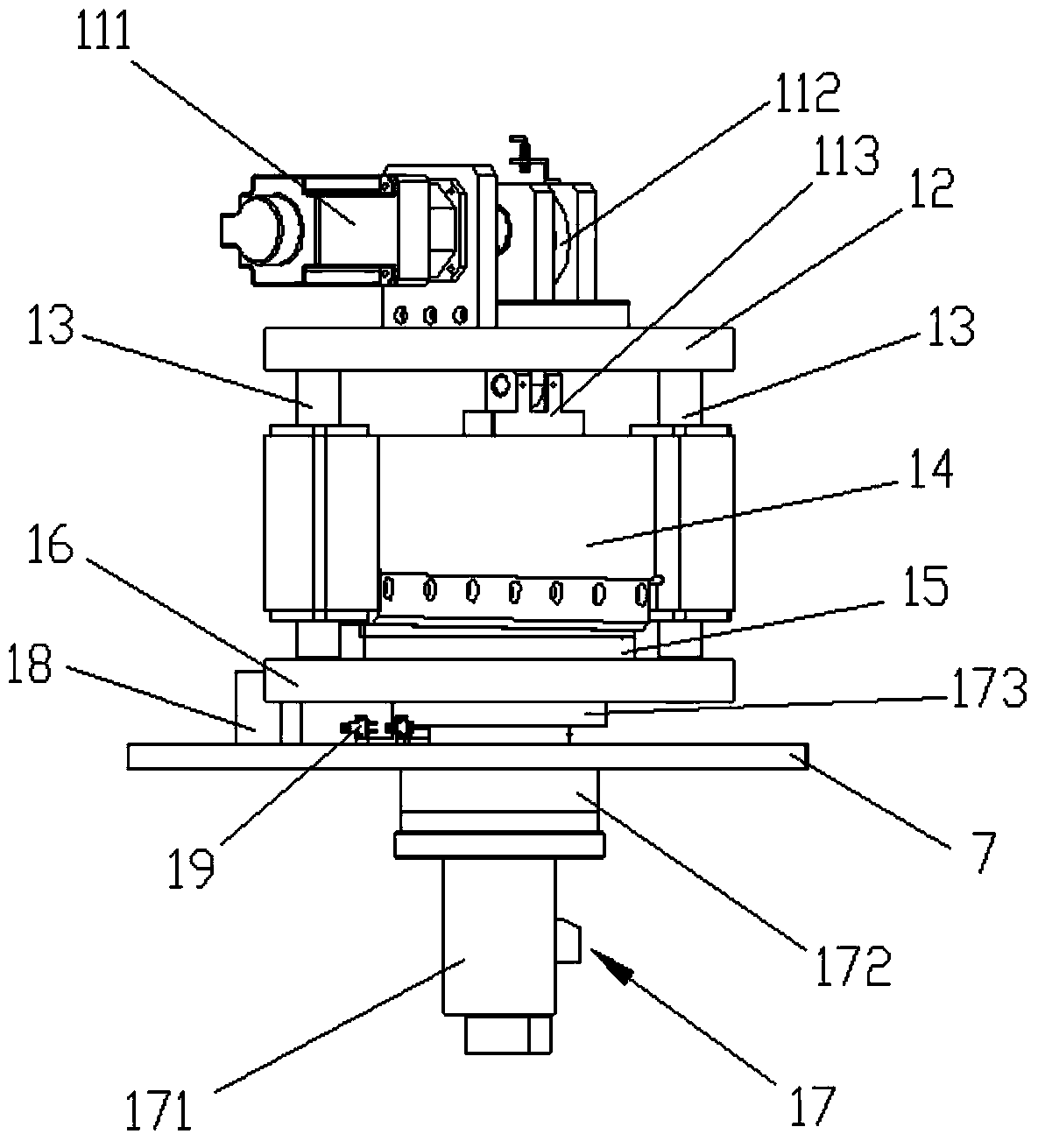

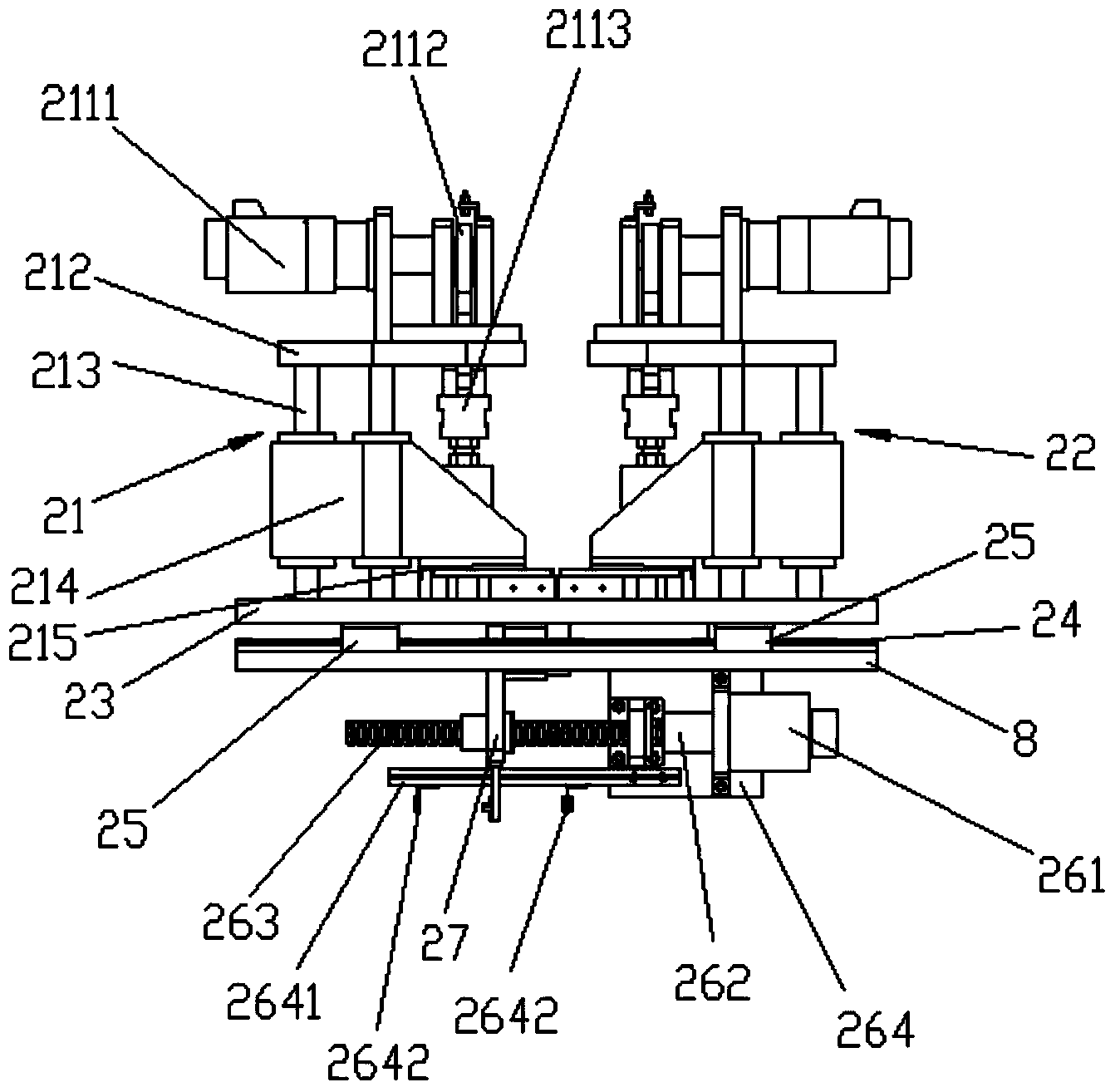

[0027] Embodiment one, such as figure 1 As shown, the cross-cutting production line includes a swinging scissors mechanism 1, a side scissors mechanism 2, a feeding mechanism 3, a front center positioning mechanism 4, a rear center positioning mechanism 5, a punching mechanism 6, a first machine platen 8 and a second machine platen 7. The side scissor mechanism 2 is set on the first machine plate 8, the swing scissor mechanism 1 is set on the second machine plate 7, and the side scissor mechanism 2 is set on the feeding mechanism 3 and the swing scissor mechanism 1 Between, the rear center positioning mechanism 5 is arranged between the side scissors mechanism 2 and the swinging scissors mechanism 1, and the punching mechanism 6 is arranged between the feeding mechanism 3 and the side scissors mechanism 2, and the feeding mechanism 3 is arranged on Between the front center positioning mechanism 4 and the feeding mechanism 3, the punching mechanism 6 is used to punch holes in t...

Embodiment 2

[0034] Embodiment 2, the difference between embodiment 2 and embodiment 1 is that the sliding drive assembly is set as the first air cylinder or the first hydraulic cylinder, and one end of the connecting piece is arranged on the output end of the first air cylinder or the first hydraulic cylinder, The first air cylinder or the first hydraulic cylinder drives the bottom plate to slide through the connecting piece.

[0035] The shear driving assembly is set as a second air cylinder or a second hydraulic cylinder, the output end of the second air cylinder or the second hydraulic cylinder is connected with the swing upper scissors seat, and the second air cylinder or the second hydraulic cylinder drives the swing upper scissors seat to move up and down .

[0036] The left drive component is a left drive cylinder or a left drive hydraulic cylinder, the output end of the left drive cylinder or left drive hydraulic cylinder is connected with the left upper tool seat, and the left dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com